Enabling Serial Production with Metal 3D Printing

How additive manufacturing can improve efficiency in leading manufacturing companies like INDEX group.

Serial production of the slider trolley for INDEX-Werke

This article was first published on

webforms.pipedrive.comThe potential of metal 3D printing has long extended beyond prototyping, moving into the realm of serial production. In a compelling case study, INDEX-Werke demonstrates how this innovative technology can optimize production efficiency, reduce costs, and improve overall quality. By shifting key components of its multi-spindle automatic machines from conventional manufacturing to metal additive manufacturing, INDEX proves that metal 3D printing is not only feasible for serial production but also highly advantageous.

The Challenge: Complex Assembly and High Costs

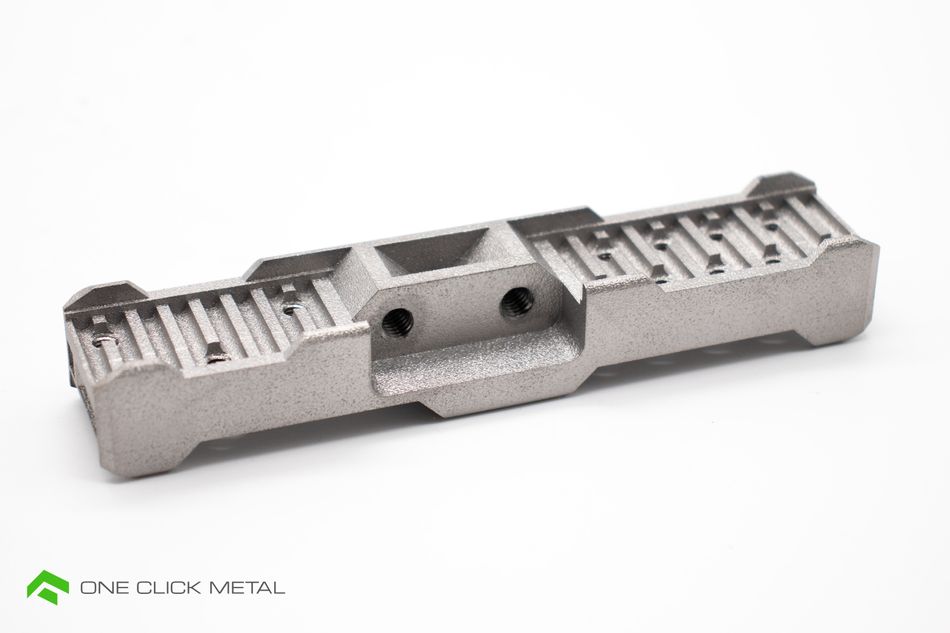

INDEX's multi-spindle automatic machines require a bar feeder to guide raw material into the processing chamber. This process involves a slider, composed of a slider trolley and a clamping piece. Traditionally, the production of these components was complex, involving numerous steps such as welding and assembly, which led to higher costs and increased lead times.

For example, the slider trolley was produced by welding a turned part to a base plate, a process prone to errors, especially with the weld seams. The clamping piece, on the other hand, required multiple parts to be assembled from different suppliers, further complicating the supply chain and leading to significant assembly times.

The Solution: Transition to Metal 3D Printing

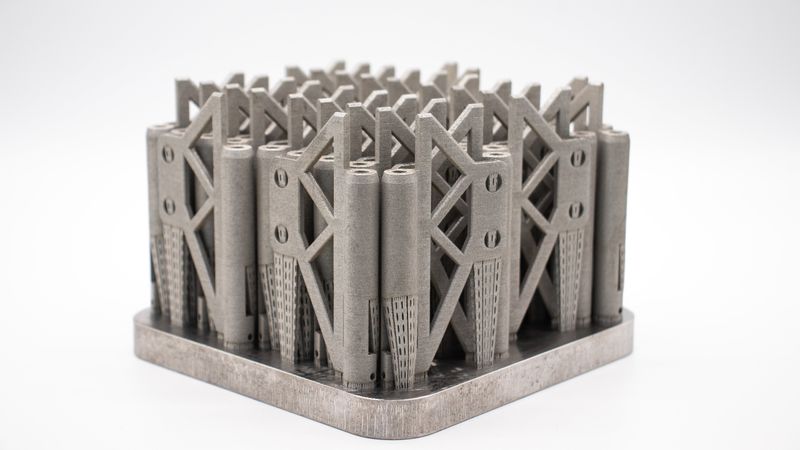

INDEX leveraged Laser Powder Bed Fusion (LPBF) technology for the additive manufacturing of these components. By redesigning the slider trolley and clamping piece for 3D printing, the company eliminated the need for multiple parts and welding, allowing each component to be manufactured in one piece.

Key Benefits of Metal 3D Printing for Serial Production

Reduced Lead Times: One of the most significant advantages of metal AM for serial production is the dramatic reduction in lead times. For example, the printing time for 42 slider trolleys was reduced from 74.5 hours to 50.5 hours due to design optimization. Similarly, the clamping piece, which used to require extensive assembly, could now be produced in a single piece, cutting total lead time from 42 days (traditional method) to just 10 days with 3D printing.

Cost Savings: The shift to metal 3D printing resulted in a substantial reduction in costs. The manufacturing cost per slider trolley dropped from €127 to €29, while the cost per clamping piece was reduced from €205to €97. These cost savings stem from eliminating welding and assembly steps, reducing material waste, and optimizing the design for additive manufacturing.

Optimized Material Use: By further adapting the design to fit the capabilities of 3D printing, INDEX was able to reduce material consumption. For example, material usage for a build plate full of slider trolley was reduced from 457 cm³ to 381 cm³, minimizing waste and further decreasing production time.

Enhanced Design Flexibility: Metal 3D printing offers unprecedented design freedom, allowing INDEX to create components that would have been impossible or highly inefficient to manufacture using conventional methods. The clamping piece, for instance, no longer required multiple parts and could be produced with pre-printed threads, further simplifying the manufacturing process.

Reduced Scrap and Improved Quality: The elimination of welding not only reduced potential points of failure but also led to a 10% reduction in scrap rates. Moreover, with fewer assembly steps, the overall quality and consistency of the components improved, ensuring better long-term reliability.

Streamlined Supply Chain and Reduced Storage Requirements: Since 3D printing enables the on-demand production of parts, INDEX was able to reduce its storage needs by 66%, further optimizing its production environment.

Conclusion: Metal 3D Printing for Serial Production

The case study from INDEX-Werke underlines the impact of metal 3D printing in serial production. Through the application of LPBF technology, INDEX was able to reduce costs, shorten lead times, and improve the overall efficiency of its manufacturing processes.