Engineering Thermoplastics Guide. Chapter 3. Performance Enhancement Strategies for Engineering Plastics Products

To enhance the applicability of thermoplastics across various industries, reinforcing additives are added to improve properties such as mechanical strength, UV resistance, and conductivity, contributing to the material's overall performance.

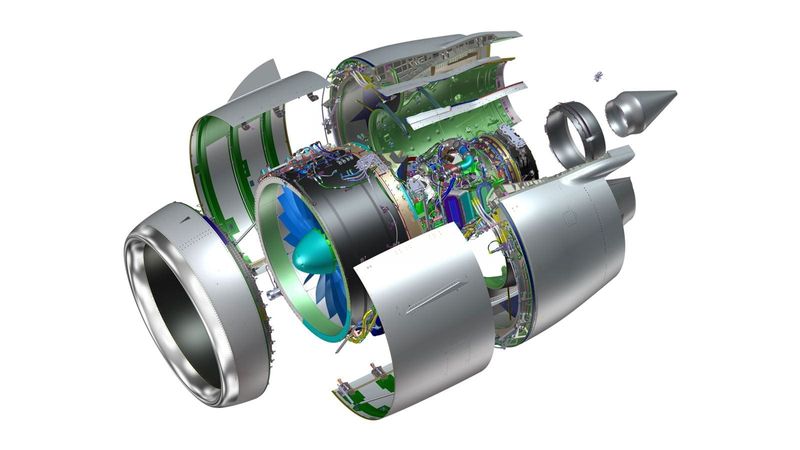

Image credit: CollinsAerospace

This is an excerpt from Chapter 3 of The Engineering Thermoplastics Guide. Download the full guide below for the full text, including technical diagrams and application notes.

Introduction

While thermoplastics possess several attractive properties, such as low weight, low cost, ease of processability, and design freedom, the applications of unmodified plastics are limited. For example, most thermoplastics possess lower mechanical strength, lower resistance to UV radiation, and lower conductivity compared to metals. In order to increase the applicability of thermoplastics across various industries, these properties must be enhanced.

Reinforcing additives, like chemical substances, can be added to thermoplastics to improve the behavior of the product throughout its lifespan. They are mechanically dispersed within the polymer matrix, contributing significantly to the overall performance of the material. The addition of additives can improve many properties of thermoplastic products, including mechanical behavior, tribological properties, thermal and UV resistance, chemical stability, fire retardancy, resistance to electromagnetic interference, and electrostatic dissipation.[9]

This chapter excerpt offers an overview of common additives for thermoplastics and illustrates their applications.

Understanding the Need for Enhancement

Despite their versatility, the applicability of thermoplastics is limited in many contexts due to the intrinsic challenges of these materials. Although the mechanical and tribological properties of thermoplastics vary widely depending on the type of material, with advanced thermoplastics exhibiting much higher strength and toughness, standard unmodified thermoplastics can be unsuitable for many demanding applications.

UV resistance is another issue with thermoplastics. Due to their organic nature, polymers can be prone to chemical degradation as a result of long exposure to light and atmospheric conditions. This can lead to loss of aesthetic appeal, such as discoloration, as well as a reduction of functional properties. Similarly, the organic composition of thermoplastics, which are mostly composed of carbon, hydrogen, and oxygen, often makes them susceptible to combustion.

Lastly, most thermoplastics are not suitable for applications where electrostatic discharges (ESD) can be an issue. This is because these materials are insulators and are unable to dissipate electric charge. In the electronics and semiconductor industries, ESD phenomena can lead to serious damage to expensive components. Many unmodified thermoplastics are also transparent to electromagnetic radiation, resulting in interference issues when these materials are used in electronic devices.

For these reasons, thermoplastics are often enhanced with fillers and additives to improve their mechanical, chemical, thermal, and electrical properties. With new enhancement strategies, these versatile materials are adapting to an increasing number of unprecedented applications.

Performance Enhancement Strategies

Mechanical Reinforcement (Fillers)

Fillers play a crucial role in enhancing the mechanical and functional properties of commodity, engineering, and advanced thermoplastics. Typically, fillers are inorganic solid materials of small size (<100 microns) added in a relatively large volume fraction to the matrix. They are incorporated into thermoplastic products to improve their stiffness, impact strength, appearance, conductivity, and flammability, making them highly versatile in adjusting material properties for specific applications.

While initially used as extenders to reduce the cost of plastic products, modern fillers, known as “functional fillers”, are primarily focused on enhancing functionality, with a specific effect on mechanical properties. Stiffness, toughness, strength, and modulus can all be improved thanks to the addition of specific fillers. Tribological features of plastics are also improved by the addition of inorganic fillers. This results in enhanced wear and friction resistance properties under dynamic conditions. [9]

Despite the advantages they offer, achieving effective filler dispersion in polymers can be challenging. A homogeneous distribution of the fillers is important to achieve the desired properties. While fillers are typically inorganic and hydrophilic, plastic matrices are organic and often hydrophobic. Because of this, compatibilization via specific additives is crucial.

The influence of fillers on the mechanical properties of thermoplastics depends on their nature, size, shape, and distribution, as well as their impact on the matrix's microstructure. Among the fillers used in thermoplastic products, glass fiber, carbon fiber, and graphite are some of the most widely used.

Glass fiber is the most commonly employed filler due to its cost-effectiveness and capacity to enhance strength and impact resistance while offering chemical resistance and low weight. The addition of glass fiber results in materials with high flexural and tensile strength. Carbon fiber, despite its higher cost compared to glass, has become a staple functional filler in high-performance thermoplastics, with continuously growing demand. In addition to improving mechanical properties, carbon fiber can also enhance thermal and electrical conductivity. Compared to glass fiber-filled thermoplastics, carbon fiber-filled materials are also suitable for dynamic applications, where they do not abradeact abrasive towards the mating counter part. Glass and carbon fiber can also be mixed resulting in hybrid reinforcement systems. [1]

Graphite, when added to thermoplastics, can significantly impact both mechanical and tribological features, making it a versatile choice for tailored applications. Due to its improved thermal conductivity and nonflammability, graphite is an ideal filler in industrial applications where high heat dissipation is needed.

Important parameters for the selection of fillers in thermoplastic materials.

UV Stabilizers

UV stabilizing additives are crucial for preserving the integrity and longevity of thermoplastic products exposed to sunlight. When polymers are subjected to light, they undergo photooxidative degradation in the presence of air. The absorbed light initiates photochemical reactions, particularly affecting specific chemical groups within the material known as chromophores. This can lead to loss of mechanical and functional properties.

The specific sensitivity of each thermoplastic to radiation depends on the material’s chemical structure. In particular, weaker chemical bonds undergo more pronounced degradation. Double bonds also tend to interact more strongly with light. In addition, photosensitive groups can be introduced as impurities during manufacturing. In general, due to their microstructure, semi-crystalline thermoplastics tend to exhibit increased sensitivity to light. [9]

UV stabilizers are essential in combating UV-induced degradation by absorbing and safely dissipating ultraviolet radiation, thus protecting the material. These stabilizers typically consist of organic molecules with tailored photochemical properties, although inorganic fillers such as carbon black can also improve UV resistance. UV stabilizers are particularly crucial for plastics exposed to outdoor conditions, as they prevent the aging process and protect against discoloration. Additionally, UV stabilizers play a vital role in safeguarding the contents of packaged goods from degradation due to UV light exposure. [10]

Antioxidants

During processing and use at high temperatures, thermoplastics are susceptible to a process known as auto-oxidation, caused by the spontaneous formation of free radicals. This can lead to a loss of mechanical and functional properties over time. For this reason, antioxidants play an important role in preserving the quality and extending the service life of thermoplastic materials by inhibiting their oxidative and thermal degradation processes.

These additives act as radical scavengers, retarding or preventing degradation during various stages, including processing, handling, and long-term use. They effectively interrupt the chain propagation steps in auto-oxidation reactions. Antioxidants must possess specific characteristics to effectively protect the material, such as resistance to degradation, easy incorporation into the polymer, and resistance to evaporation or leaching. These additives are typically categorized into primary and secondary antioxidants. [9]

Primary antioxidants, also known as chain breakers, are radical scavengers or hydrogen donors, and they include organic molecules such as hindered phenols and secondary amines. These molecules directly stop the free radical propagation. Secondary antioxidants, on the other hand, are peroxide decomposers. They turn these highly reactive molecules into less harmful compounds. Often, these two kinds of additives are combined to maximize their efficacy. [10]

Flame Retardants

Flame retardant additives play a crucial role in enhancing the fire resistance of thermoplastics, addressing their inherent flammability issues. In fact, most plastics are prone to easy ignition due to their chemical composition, primarily consisting of carbon and hydrogen.

A common measure for flammability is the limiting oxygen index (LOI), which quantifies the percentage of oxygen required in the atmosphere to sustain combustion under standardized conditions. While materials with an LOI below 21% burn easily, thermoplastics with an LOI between 21% and 28% are slow-burning, and those with an LOI above 28% are inherently fire extinguishing.

LOI of common thermoplastics

While most advanced thermoplastics exhibit inherent fire resistance, many plastics are known for their high flammability, often accompanied by the release of corrosive or toxic gases and smoke during combustion. Thus, improving the fire retardant behavior of thermoplastic products is essential for expanding their applicability across various industries.

Flame retardants can act through various mechanisms, such as inhibiting reactive radicals, reducing heat generation via endothermic reactions, or forming thermally insulating char layers on the plastic’s surface. The most widely used flame retardants are halogenated compounds.

While halogen-based flame retardants have historically dominated the market, the primary challenge today revolves around their substitution with more environmentally friendly options. Among these, phosphorous and metal hydroxide flame retardants are sustainable and effective halogen-free solutions. [11]

Electrical Properties Enhancers (Conductivity and ESD)

Electrostatic discharge (ESD) can be a significant issue with plastics due to their inherent electrical insulating properties. This can result in the accumulation of strong electrostatic charges that may disrupt or damage sensitive electronic components. To mitigate this issue, antistatic additives can be employed to enhance the electrical properties of thermoplastics.

ESD resistance enhancers can be classified into two main types: internal and external. Internal antistatic additives create a conductive path within the plastic, allowing for the rapid dissipation of electrostatic charges. On the other hand, external antistatic agents are applied to the surface of the material after processing and require minimal dosages. However, these external treatments may not be suitable for long-lasting applications due to potential issues with adhesion.

Internal antistatic additives are directly blended with the thermoplastic material during processing. Typically, these additives are inorganic fillers such as carbon black, carbon fiber, or metal powders. Thermoplastics with inherent conductivity, such as conducting polymers –-- also known as IDP (inherently dissipative polymers) –, may also be utilized to produce antistatic products. [9]

EMI Shielding Attributes

EMI (Electromagnetic interference) shielding is essential for preventing the passage of electromagnetic waves into or out of electronic devices. In many contexts, these interferences can cause serious issues with the correct functioning of electronic systems.

Most thermoplastics are naturally transparent to electromagnetic radiation. Because of this, metals have been traditionally employed as shielding materials. However, switching to plastics can lead to diminished costs, weight reduction, ease of production, and improved design freedom.

To address the inherent lack of EMI shielding in thermoplastics, various methods have been developed. These methods aim to enhance the electrical conductivity of plastics through approaches such as conductive coatings, compounding with conductive fillers, and using intrinsically conductive polymers (ICPs).

Conductive coatings, including metallic plating, are effective but require additional surface preparation and equipment. On the other hand, compounding with additives like carbon black, carbon fibers, stainless steel fibers, and aluminum can lead to optimal EMI shielding properties. The use of these fillers favors the increasing integration of thermoplastic materials into the electronics industry. [12]

Coloring agents

Coloring additives, including dyes and pigments, play a crucial role in enhancing the aesthetic appeal of thermoplastic products. Dyes are soluble organic compounds, while pigments can be either organic or inorganic but are typically insoluble. Certain pigments, such as carbon black, provide extra benefits beyond coloring, including UV protection, reinforcement, and improved electrostatic properties.

However, it's worth noting that some pigments and dyes can affect the photostability of thermoplastics by increasing their sensitivity to light. Pigments, especially in standard plastics such as polyethylene and polypropylene, may impact the molecular structure of the material, leading to a loss of dimensional stability. Therefore, pigments and dyes should be selected carefully depending on the material and the final application. [10]

Uses of Enhanced Thermoplastics

Enhanced thermoplastics can find applications in many demanding industrial sectors where other materials, such as metals, were previously used. Reinforcement of advanced thermoplastics with fillers such as carbon fiber, graphite, and glass fiber can lead to outstanding mechanical and tribological properties. These enhanced materials can be used in the most challenging applications such as the aerospace industry.

For example, MCG’s Duratron® T4301 PAI is an advanced thermoplastic with low-friction properties. It is enhanced with a graphite filler, providing exceptional reinforcement and wear resistance for labor-intensive components. This graphite-filled advanced material was employed in aircraft wing flaps, providing long-term endurance to wear, weight reduction, and optimal thermal and chemical resistance.

Improved electrostatic dissipation is crucial in the electronics and semiconductor industries. However, thermoplastics with enhanced ESD properties can also be employed in other industrial sectors to prevent the buildup of electrostatic charge and facilitate the flow of dusty materials. MCG’s TIVAR® 88-2 ESD is an electrostatic dissipative UHMW-PE material. Thanks to its optimal electrical and chemical properties, this material was used to substitute steel in silo liners for the bio-coal industry, leading to significant cost savings.

From aerospace to electronics and beyond, advanced thermoplastics offer effective solutions to common challenges associated with traditional thermoplastic materials across various industries.

You have just been reading an excerpt from Chapter 3 of The Engineering Thermoplastics Guide. Download the full guide below for the full text, including technical diagrams and application notes.

References

1. Gilbert M, editor. Brydson’s Plastics Materials. 8th ed. Oxford: Butterworth-Heinemann Elsevier; 2017.

9. Subramanian MN. Plastics Additives and Testing. Hoboken: Scrivener and John Wiley & Sons; 2013.

10. Fink JK. A Concise Introduction to Additives for Thermoplastic Polymers. Hoboken: Scrivener and John Wiley & Sons; 2010.