Expediting Infrastructure Development for Fuel Cells and Electrolysis to Enhance Hydrogen Energy Use.

Development of technology to enable use of hydrogen as a fuel to power turbines, engines, boilers, etc., safely and efficiently is already underway. This first approach is suitable for applications where comparatively large output is required.

This article was first published on

article.murata.comAlongside the utilization of renewable energy, the utilization of hydrogen energy plays an important role (Fig. 1).

Opportunities for consumers to encounter the utilization of hydrogen are pretty much limited to the occasional glimpse of a fuel cell vehicle (FCV) or fuel cell bus. Nevertheless, hydrogen has become an indispensable part of decarbonization efforts by industry as a high-output power source or heat source for turbines, engines, boilers, and the like. In the mobility area, decarbonization efforts have centered around the adoption of electric vehicles (EVs) as passenger cars, but the use of hydrogen has assumed a key role in studies of the future of large commercial vehicles such as buses or trucks that must operate over long distances; agricultural machinery, construction equipment, and aircraft (including drones); and ships.

For this reason, a variety of policies and projects intended to expand the scenarios in which hydrogen is utilized are proceeding in many countries and regions throughout the world.

Upgrading the Sophistication of the Electrical and Electronic Systems Tasked with Expanding, Managing, and Controlling Hydrogen Utilization is Key

Broadly speaking, hydrogen energy is expected to be utilized in two ways.

The first is the direct use of heat energy obtained by burning hydrogen. Development of technology to enable use of hydrogen as a fuel to power turbines, engines, boilers, etc., safely and efficiently is already underway. This first approach is suitable for applications where comparatively large output is required.

The second is the use of fuel cells to convert the chemical energy of hydrogen into electric power. The chemical reaction involved is the opposite of that underlying the electrolysis of water, familiar from demonstrations in science class at school. Hydrogen and oxygen from the atmosphere are converted into water and electricity.

This approach tends to be suitable for applications that use comparatively low output. The practical limits are such that the output of a single fuel cell can be used as the power source for a vehicle such as a bus. In addition, when hydrogen is converted to electric power for use, controlling the output is easier than when hydrogen is burned, so the second approach is also used for applications where precise drive control is required.

In order to utilize hydrogen in an effective, efficient, and stable manner, and to enable its adoption in a diverse range of usage scenarios, the electrical and electronic systems that manage and control the appropriate utilization of hydrogen must interoperate with each other. For example, ancillary to the equipment involved in the production, storage, distribution, and use of hydrogen are components such as stabilized power supplies, power converters, sensors, and noise suppression circuits. Also, these technologies need to become more sophisticated as the utilization of hydrogen expands.

Renewable Energy and Hydrogen Energy are Complementary

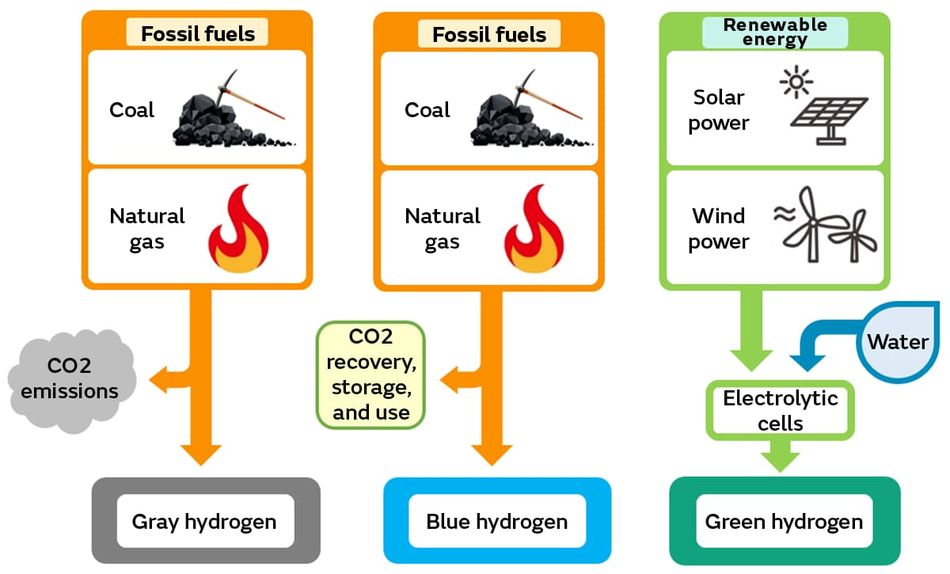

Hydrogen used as a source of energy is divided into three types based on how it is produced (Fig. 2), although the chemical composition of the different types is the same. These are "gray hydrogen," "blue hydrogen," and "green hydrogen." Each contributes to decarbonization to a different degree.

The raw materials for the production of gray hydrogen are fossil fuels such as coal and natural gas. Hydrogen can also be obtained as a byproduct of petroleum refining or the production of coke in a steelworks. It can also be produced through reforming by chemical or heat processing. A familiar example would be home fuel cells (ENE-FARM systems), which use gray hydrogen produced from city gas. However, since the production of gray hydrogen generates CO2, it cannot be said to contribute to decarbonization directly. By contrast, blue hydrogen is made in a way that ensures that the CO2 generated in its production is not released into the atmosphere. The systems used to produce it include mechanisms to recover, store, and use the CO2 generated. This reduces CO2 emissions, but the recovery, storage, and use of the CO2 bring with them corresponding costs.

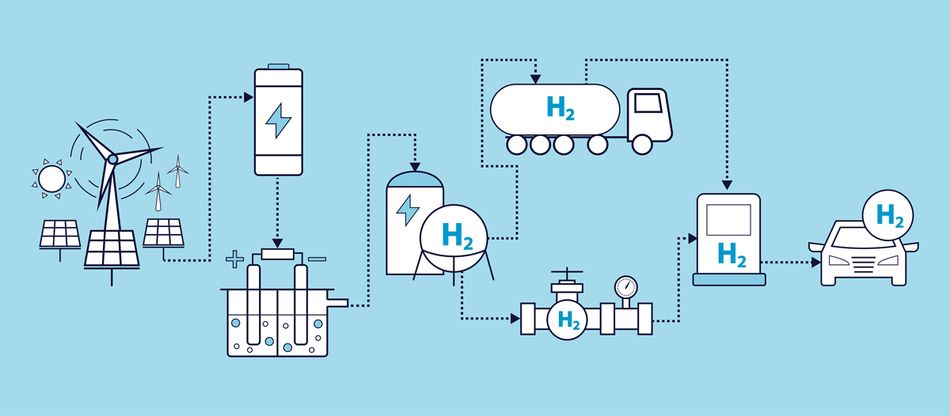

On the other hand, green hydrogen is produced from water by electrolysis, employing renewable energy such as sunlight or wind power as the source of the electricity used. With green hydrogen, CO2 emissions can be reduced to zero. In addition, since power generation methods such as solar are unstable means of generating electricity, they are suitable for applications that require storing surplus power for use later when it is needed. Large-capacity energy storage systems (ESS) employing batteries are also used for such applications, but green hydrogen is seen as suitable for use as an emergency power supply for cases requiring large storage capacity, factories, data centers, and the like.

It can be said that renewable energy and hydrogen energy are complementary. Against this background, the governments of many countries and regions are moving forward with policies and projects intended to promote the utilization of green hydrogen. For example, the European Commission and the European Clean Hydrogen Alliance, a group of hydrogen-related businesses within the EU, announced on May 5, 2022, a plan to increase the green hydrogen production capacity of electrolysis businesses to 10 times the current level by 2025.

How the Electronics Industry Can Contribute to Hydrogen Utilization

There are many ways in which electrical and electronic technology can help boost the utilization of hydrogen.

First, to increase efficiency when producing green hydrogen, DC power supplies are needed because of their high power efficiency. Only a low level of power, 1.23 V or more, is required to perform electrolysis of water. However, to produce green hydrogen in large volumes by making use of power from high-output renewable energy facilities such as Mega Solar power projects, DC power supplies capable of delivering high-voltage, high-amperage DC power consistently, without pulsations, to a large number of electrolysis electrodes connected in series and in parallel are necessary.

Such technology has been developed, using as a basis existing DC power technology from manufacturing and industrial fields including surface processing such as metal plating and the production of chemicals such as caustic soda. Most hydrogen production facilities currently use DC power supplies at voltages from several volts to several hundred volts and amperages from 10 amperes to several thousand amperes.

The scale of these facilities varies, but it ranges from low capacity for on-site compact hydrogen stations to large capacity for megawatt-grade hydrogen production plants. Demand is rising for DC power supplies at a range of capacity levels. Of these, many of the large-capacity systems connect to the AC power grid, and this necessitates measures to minimize the effects of harmonics on the power lines. In addition, to generate stabilized DC power more efficiently, power circuit configurations incorporating high-performance power semiconductor devices such as IGBTs or SiC-based MOSFETs are being considered.

Furthermore, after hydrogen energy is converted to electric power by a fuel cell, to use it requires a power converter to turn it into DC or AC power, to match the purpose for which the output will be used, and to supply it in a stable manner. In addition, management and control systems are needed to monitor the series of processes from power generation by the fuel cell to its consumption by motors, etc., and for safety control to prevent problems such as hydrogen gas leaks, short circuits, or thermal runaway. This requires a large number of sensors for detecting gas, pressure, flow, etc.

Downsizing Equipment Utilizing Hydrogen to Make It a More Familiar Energy Source

The utilization of hydrogen got its start from applications requiring relatively high output, and its adoption is now spreading. Nevertheless, once technology matures for generating green hydrogen, making fuel cells more efficient, and reducing cost, we can expect to see the downsizing of utilization systems, and it will become possible to use hydrogen as an energy source for devices requiring lower output.

Generally speaking, if hydrogen is produced in large quantities at power plants in regions outside of large cities and then shipped to where it will be consumed, a large amount of energy is lost during the transport process. This is because it is necessary to compress the generated hydrogen gas and then refrigerate it to liquid form. There are other shipping methods that involve converting hydrogen into chemicals that are easier to transport, but these applications also consume a commensurate amount of energy. For these reasons, enabling the local production for local consumption of hydrogen where possible is a better way to increase usage efficiency.

Already, hydrogen stations much like conventional gas stations have been set up here and there, and efforts are moving forward to realize the concept of local production of hydrogen and its supply as fuel for various types of mobility applications. One example of such an attempt is the commercialization of a portable fuel cell that can be used as a mobile battery to charge devices such as smartphones. The development and decentralized placement of compact hydrogen generation equipment based on photocatalyst technology that uses sunlight to perform photolysis of water is also being considered.

Hydrogen complements renewable energy as an energy source that is indispensable to achieving carbon neutrality. However, appropriate measures need to be taken to make it possible for consumers to utilize hydrogen gas safely in familiar settings. For safe and highly efficient utilization to become possible, safety standards and legislation must be put in place, while at the same time the utilization of electrical and electronic technology, including management and control systems making use of sensors of various types, high-efficiency DC power supplies, and power converter circuits, must become more sophisticated. Accordingly, there are high expectations for the development and proposal of new technologies by companies involved with electronics.