How Different Industries Benefit from BRIDGE Technology

Learn how different industries can benefit from Deep Trekker’s proprietary BRIDGE technology that enhances ROV functionality for underwater operations.

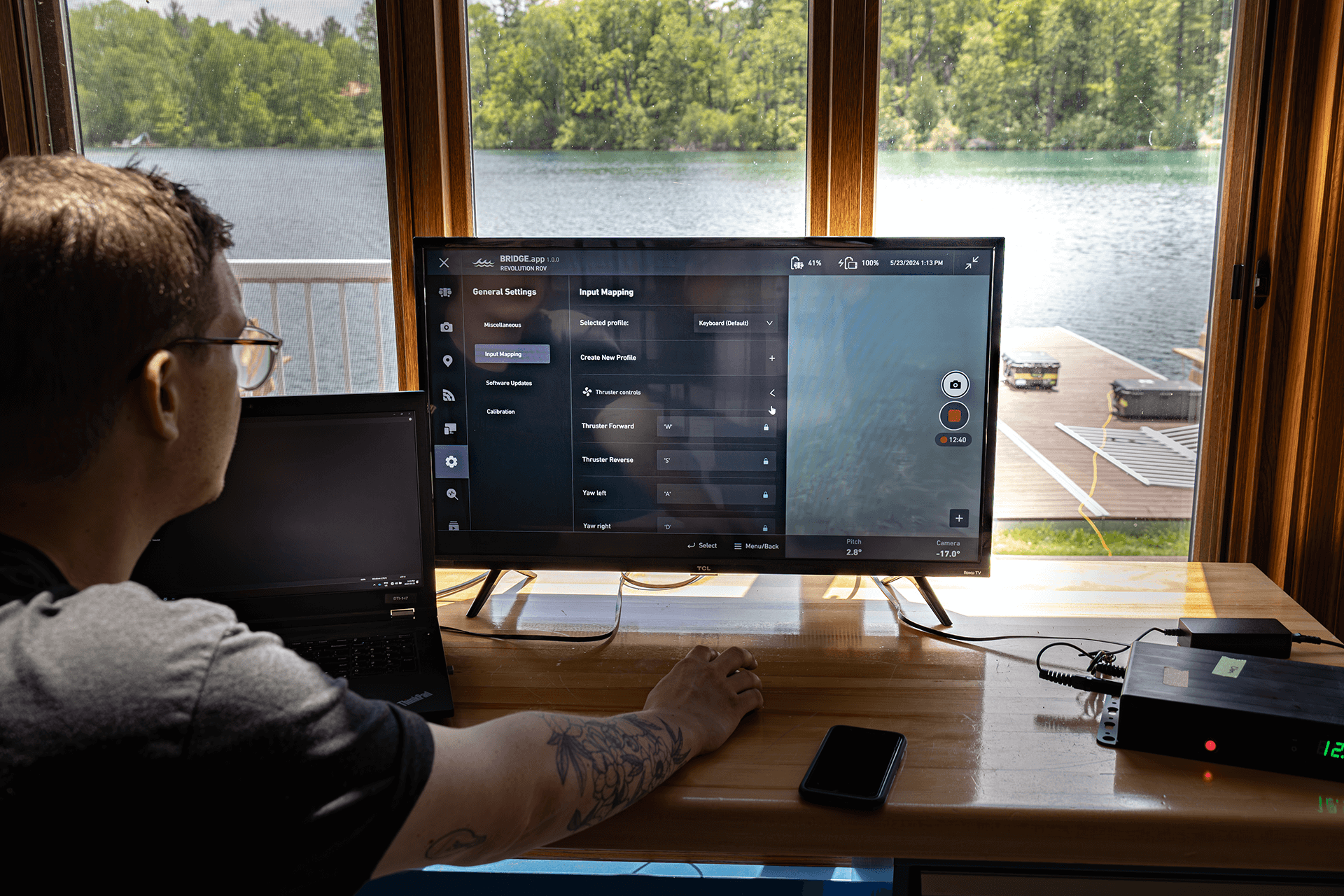

Operator using custom keyboard controls and laptop to pilot ROV remotely from control center.

This article was first published on

www.deeptrekker.com

Deep Trekker's proprietary BRIDGE technology transforms underwater operations across various industries by offering versatile and advanced solutions tailored to specific needs.

This architecture significantly improves ROV capabilities and data collection, making it a valuable asset for maritime inspections, offshore operations, defense missions, aquaculture management, marine science, nuclear facility inspections, and much more.

With features like data integration from multiple sources, remote ROV operation, and high-definition monitoring, BRIDGE technology allows operators to conduct thorough inspections and real-time monitoring from any location, improving operational capabilities and reducing downtime.

Maritime

Having a BRIDGE.box and connecting it to the BRIDGE.app supports real-time monitoring and control, enabling inspections from a centralized location. The system allows for multi-monitor support, offering a comprehensive view of high-definition video feeds, maps, data, and sonar imagery. This multi-faceted approach enables detailed analysis of ship hull conditions, allowing operators to identify and address potential issues such as corrosion or structural damage quickly.

This means increased topside flexibility and comfort due to BRIDGE technology's remote operation capabilities. Operators can manage inspections from their preferred office or control room setup with larger, high-resolution monitors to analyze real-time data effortlessly, minimizing exposure to hazardous conditions onboard. This remote accessibility improves operations by reducing downtime associated with manual inspections and ensuring continuous vessel readiness.

The integration of BRIDGE technology includes enhanced video quality and media playback capabilities, enhancing the clarity and reliability of inspection data. Picture-in-picture mode, which supports auxiliary cameras, further enhances the inspection process by providing additional perspectives and detailed views of critical areas.

Integration with permanent control centers or console installations also centralizes monitoring and enhances decision-making processes. Operators have access to a unified interface that streamlines data interpretation and enables proactive maintenance strategies. This centralized approach is not only a more efficient setup, but also supports compliance with maritime regulations, ensuring optimal vessel safety and performance.

Offshore

In offshore operations, the versatility of having a BRIDGE.box improves efficiency across different vessel sizes and operational requirements. Operators have the flexibility to run ROVs from smaller boats using the portable BRIDGE.box and handheld devices, while larger vessels can optimize operations with permanent console installations.

Topside footprint, or dive spread, is an important factor to consider in offshore operations. Skilled pilots can remotely operate ROVs during offshore inspections with minimal topside setup required, allowing them to monitor underwater assets without being physically present: from land, from a ship control room, or from anywhere in the world.

Multiple high-resolution screens enable monitoring of multiple streams, ensuring precise control and comprehensive situational awareness during complex offshore tasks. Optimized user interfaces also improve the piloting experience by simplifying operation, and API integration with existing systems streamlines the data collected without having to make complicated and potentially expensive changes to setups.

This setup not only improves safety by keeping operators out of dangerous environments and giving them access to more data sources simultaneously, but also supports proactive decision-making through detailed data insights gathered from the operations.

Search and Recovery

In search and recovery missions, the setup can vary depending on the size of the vessel employed. Smaller boats can utilize the portable BRIDGE.box in conjunction with a handheld device, providing nimble and rapid deployment capabilities. Conversely, larger vessels may opt for a more permanent console installation to support extended and complex operations.

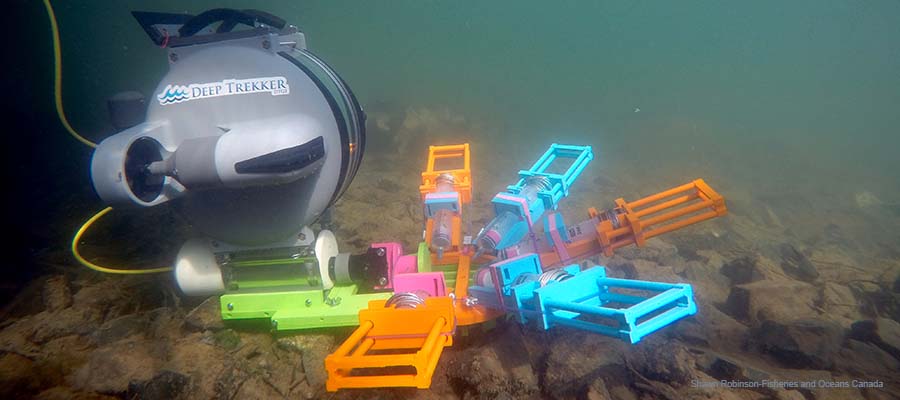

Maximize search and recovery operations further with precise planning using waypoint navigation, ensuring thorough coverage of target areas. Leverage advanced data capture to gather comprehensive information during operations with the integration of sonar, video, and maps.

Real-time and historical position tracking provides comprehensive documentation by tracking the ROV's movements in real time and storing historical data, improving mission effectiveness by providing detailed coverage of searched areas, and reducing redundant searches in locations that have already been inspected.

The adaptable nature of the BRIDGE framework enables easy integration with various operational requirements, supporting seamless control and monitoring during critical search and recovery efforts. This versatility improves operational flexibility and effectiveness, enabling fast response and careful execution in diverse maritime environments.

Defense

In defense applications, particularly in Explosive Ordnance Disposal (EOD) and expeditionary missions, BRIDGE provides invaluable advantages. The portability of BRIDGE.box and Deep Trekker ROVs is key in these scenarios. Their compact design enables quick deployment and operation in the field, ensuring rapid response capabilities and mission success.

This mobility is essential for navigating diverse and challenging environments encountered during critical operations, improving the effectiveness and safety of defense personnel engaged in these high-stakes missions. BRIDGE.box is designed with a focus on portability, remote operation, and intuitive usability, enabling EOD technicians to quickly deploy and execute precise disposal procedures.

The ability to remotely operate from a safe distance is a critical advantage offered by BRIDGE.box. EOD technicians can control the ROV integrated with the BRIDGE system from a secure location, minimizing the risk of direct exposure to potentially dangerous explosive devices. This capability not only elevates mission success rates but also significantly improves personnel safety by reducing the need for close physical proximity to hazardous materials.

The integration of BRIDGE technology also offers camera optimization that further improves surveillance and reconnaissance efforts. It provides high-quality imagery, real-time recording and playback for comprehensive mission analysis and review; integrated data capture for seamless information gathering, providing valuable insights for decision-making; and, real-time monitoring and control, providing continuous situational awareness during operations.

Aquaculture

In aquaculture farms, BRIDGE.box offers operators the convenience of running ROVs from an office setting. This setup provides significant advantages for operations in remote or challenging environments, including adverse weather conditions, by reducing the necessity for operators to remain on-site for extended periods.

By enabling remote operation, the BRIDGE framework supports efficient management of aquaculture farms, offering a cost-effective means to expand operational capabilities, quickly transfer information, and monitor cages remotely.

Monitoring cages remotely becomes more straightforward and efficient, as operators can utilize high-resolution video feeds and sensor data to ensure the well-being of aquatic livestock. This capability is important for maintaining optimal conditions within the cages, such as monitoring water quality, feeding schedules, and the structural integrity of the enclosures.

By conducting regular inspections and monitoring operations remotely, potential issues can be identified and addressed before they escalate, contributing to the longevity and reliability of farming assets. This improves productivity and sustainability in aquaculture practices, establishing effective resource management and proactive maintenance of aquatic environments.

Marine Science and Underwater Discovery

BRIDGE.box enables operators to control ROVs conveniently from a vehicle, such as a truck, which can be ideal for hydrographic surveys and environmental monitoring. This setup offers significant advantages for projects conducted in remote or harsh environments by reducing the necessity for operators to remain on-site for extended periods.

BRIDGE Technology also allows researchers to capture crystal-clear visuals and gain detailed insights from underwater environments; utilize live sharing capabilities to engage their team in real-time research, bringing the environment to them wherever they are; and, maximize their findings with multi-monitor display output, allowing them to view and analyze data on large, high-resolution screens.

By leveraging remote operation capabilities, live sharing, and multi-monitor displays, operators can increase safety while conducting detailed surveys and research activities, achieving accurate data collection and analysis without compromising personnel exposure to challenging conditions.

Nuclear

When operating in nuclear facilities, the capability to inspect hazardous environments such as nuclear reactors and confined spaces from a safe distance or offsite location is transformative. Remote operation keeps skilled operators out of the hot zone, significantly enhancing operator safety.

With BRIDGE.box, you can configure controls and display settings to your preference, enabling ROV operation from any location. Operate from control rooms or secure spots to minimize dose radiation exposure while streaming real-time footage from a convenient location.

Once connected to the network, BRIDGE can also share and record live footage for team collaboration, allowing for detailed and thorough inspections in demanding nuclear environments.

BRIDGE Technology refines nuclear operations and containment inspections with 4K camera optimization for clear visuals and real-time recording and playback for detailed monitoring. This system records live video and stores it for playback, allowing for review and analysis of captured footage.

Integrated data capture ensures comprehensive data collection by synchronizing data from various sensors and inputs into one system, enhancing accessibility and analysis, supporting safety and efficiency in nuclear facilities.![]()

Real-World Example

Examining a real-world use case provides a clear example of how BRIDGE technology delivers practical applications and benefits for underwater inspections that are much more efficient and cost-effective than traditional methods.

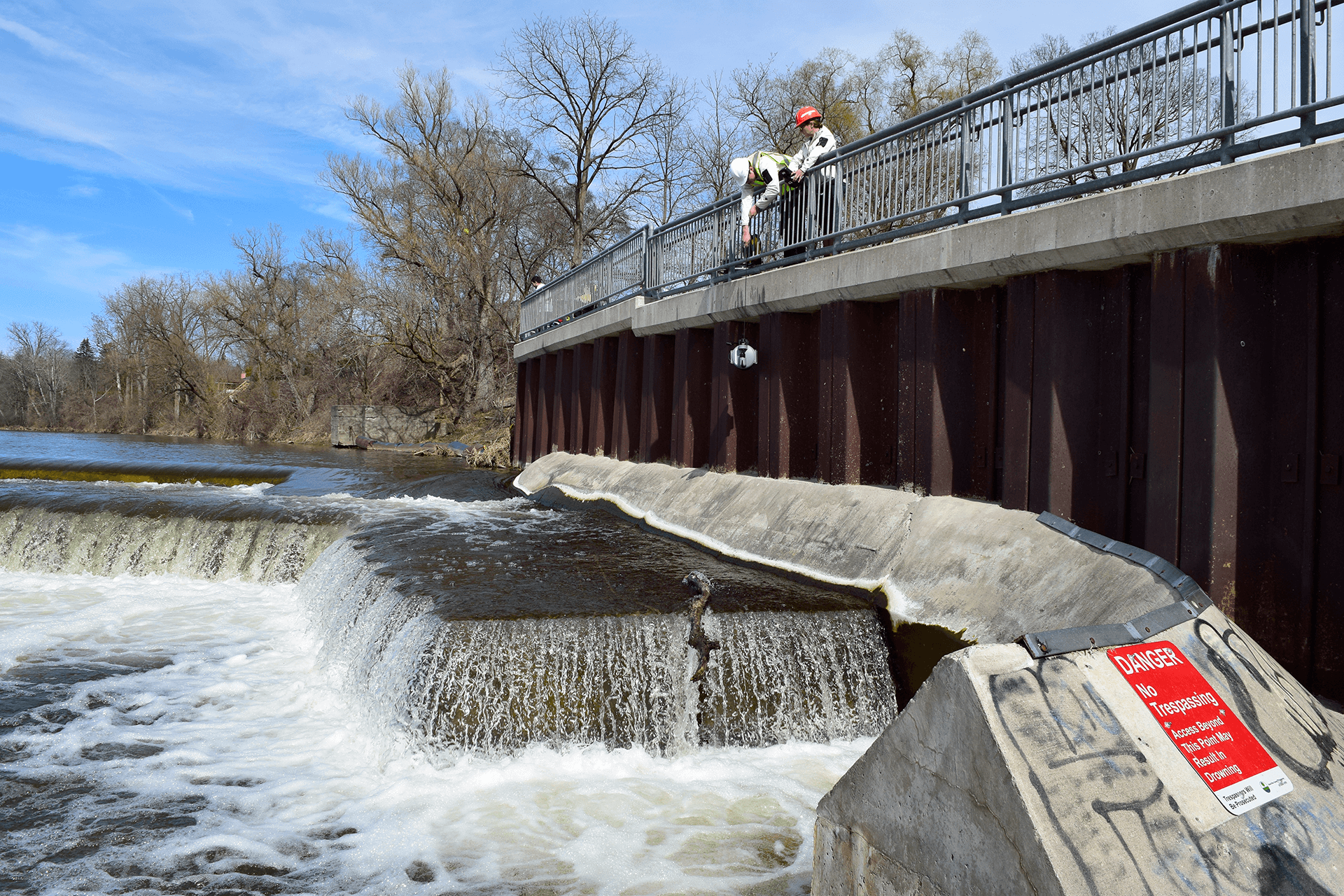

Hydro Quebec

At Hydro Quebec, BRIDGE.box modernized hydroelectric dam inspections by switching to operations from a truck-based command center. This setup reduced downtime significantly while improving operator comfort. Operators were able to remotely inspect critical components such as runners, penstocks, submerged pipes, and transmission lines.

BRIDGE technology also improved inspection planning by providing high-quality imaging and real-time monitoring capabilities. Operators could remotely control inspection ROVs integrated with BRIDGE systems, capturing detailed images and data without disrupting ongoing operations. This approach minimized downtime, risks, and allowed for continuous power generation by eliminating the need to shut down systems or dewater tanks.

The integration of BRIDGE technology not only provided better inspection results than with previous methods, but also enabled proactive maintenance strategies based on comprehensive inspection findings. Operators could assess infrastructure integrity with precision, identifying potential issues early and implementing necessary repairs promptly. This proactive approach not only enhanced safety protocols but also contributed to the reliability and longevity of hydroelectric assets.

Key Takeaways

Deep Trekker’s BRIDGE technology plays a pivotal role in advancing underwater operations across diverse industries. By integrating advanced capabilities into ROV operations, BRIDGE enhances efficiency, safety, and data collection capabilities across maritime inspections, offshore operations, defense missions, aquaculture management, marine science, and nuclear facility inspections.

Through features such as remote operation and real-time monitoring, alongside support for multi-monitor setups and seamless data integration, BRIDGE technology enables operators to conduct thorough inspections and make informed decisions from any location. This technology improves operational efficiency, enhances safety protocols, and supports proactive maintenance strategies, ensuring optimal performance and longevity of critical assets.

As industries continue to adopt and leverage the benefits of BRIDGE technology’s versatility and reliability, Deep Trekker remains dedicated to driving innovation in underwater exploration and promoting sustainable practices across global maritime environments.

Custom Solutions for Your Underwater Operations

Our experienced team is here to provide expert guidance for a diverse range of applications. Whether you need to inspect vessels, pipelines, underwater assets, or water tanks, or conduct underwater assessments across different industries, we are ready to assist you.

We ensure tailor-made solutions that precisely match your specific requirements. When you're prepared to acquire your Deep Trekker ROV, don't hesitate to get in touch with us for a personalized quote.