Human-robot collaboration: 3 Case Studies

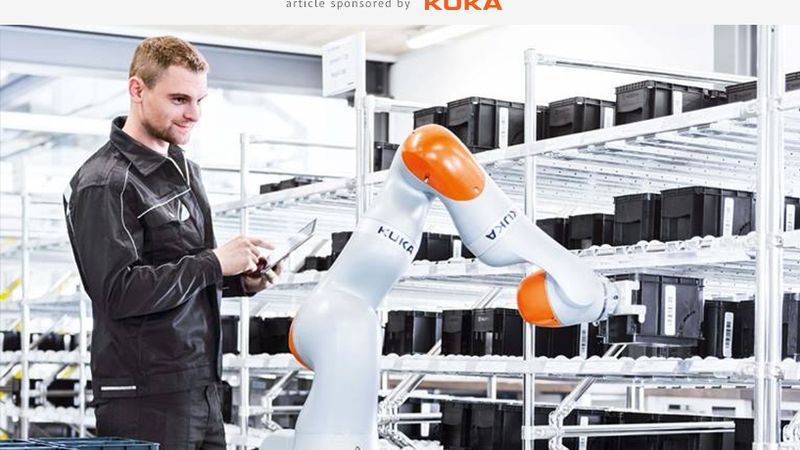

In human-robot collaboration, human and machine work hand in hand. The human operator controls and monitors production, the robots perform the physically strenuous work. Both contribute their specific capabilities.

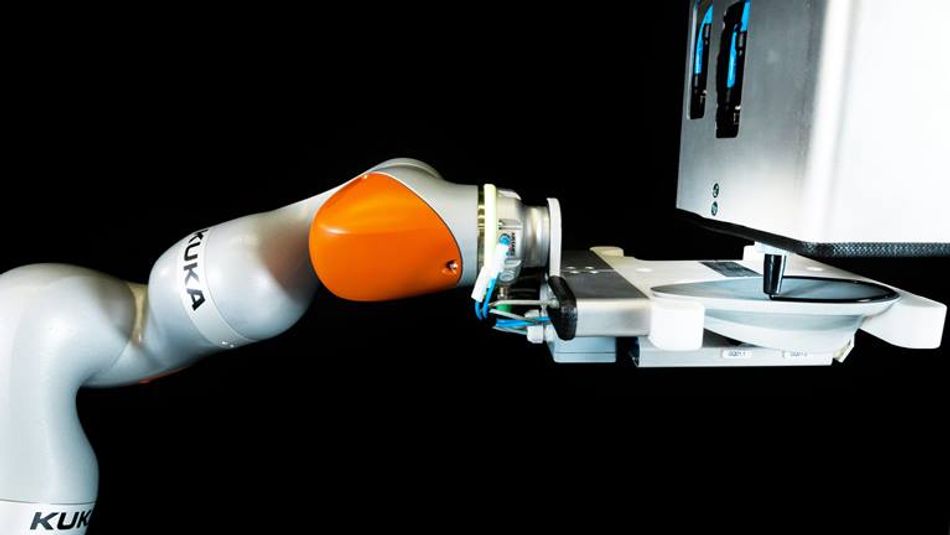

Image: Kuka

One key element of the future production landscape is highly flexible Human-Robot Collaboration (HRC). This article describes 3 case studies which illustrate how collaborative robots change the way people will manufacture.

KUKA, one of the world's largest suppliers of industrial robots, has written a free, downloadable white paper called "Shaping future production landscapes." The white paper describes 'megatrends' that impact manufacturing and 3 key factors to designing production infrastructures that can meet the requirements of the future.

Intro

Human-robot collaboration

In human-robot collaboration, the robot assists the human operator. This means: The machine does not replace the human, but complements his capabilities and relieves him of arduous tasks. These can include overhead work, for example, or the lifting of heavy loads. Autonomous, collaborative robots are also used to supply production workstations.

In the ideal 'factory of the future' there is no separation between automated and manual workstations. Humans and robots collaborate optimally – without separation and without safety fencing.

Human-robot collaboration: the advantages

HRC-capable robots (often labeled 'Collaborative Robots' or 'Cobots') are rendered mobile and capable of performing different tasks flexibly using mobile platforms. They can thus be individually deployed at whatever location and for whatever purpose corresponds to production requirements – dependent on the required batch size, for example.

Furthermore, these types of robots offer maximum flexibility by means of so-called spontaneous automation: They support a user as an assistant in the case of workload peaks and resource bottlenecks in production operations.

Human-robot collaboration changes industrial production and manufacturing and can bring a number of advantages over traditional automation or manual labor:

- Increased flexibility in production

- Relief of employees by performing ergonomically unfavorable work steps that could not previously be automated

- Reduced risk of injuries and infections

- High-quality performance of reproducible processes – without requiring type-specific or component-relevant investment.

- Increased productivity and improved system complexity thanks to integrated sensors

HRC Case Studies

To give you an idea of the impact of collaborative robots in the workspace we've gathered 3 case studies to show you the impact of these robots and the challenges they overcome.

Case Study 1: Lightweight robots supporting operators in adhesive bonding processes.

All images courtesy KUKA

System and machine builder Dürr uses two sensitive LBR iiwa robots in final assembly. Without a safety fence, they perform key tasks in the application of adhesive beads. This improves quality, saves time and lowers unit costs.

The LBR iiwa detects any fault that arises when the GPS antenna cover is loaded

For application of adhesive to the GPS antenna cover, the assembly worker places the workpiece into the robot gripper manually. The gripper sucks onto it and moves it to the adhesive nozzle on the application tower. The robot slowly moves the GPS antenna cover upwards to the application nozzle. If it encounters an obstacle, it moves back a little thanks to its collision detection ability and starts the motion over from the beginning. Only after three attempts does it move back into the starting position. Otherwise, the adhesive application process starts and the adhesive bead is applied carefully while the robot executes the path. Finally, back at the starting point, the assembly worker removes the GPS antenna cover and mounts it on the vehicle.

Precise adhesive beads thanks to the seventh axis of the LBR iiwa

For the automated process of gluing the tank into place in final assembly, the skilled worker guides the tank to a turntable with the aid of a manipulator. There he cleans it, moves it into the correct position and transfers it directly to the robot for further processing. When the starting point is reached on the stationary tank, the nozzle opens under pressure so that no air bubbles are created. The robot then applies the adhesive bead onto the tank very evenly. Sensors on the application head monitor the accurate height of the bead. Thanks to its seventh rotating axis, the robot glues in a radius of 360 degrees – without re-orienting or having to interrupt the bead. As soon as the robot has completed its task, the skilled worker fits the tank into the vehicle body at the specified position.

Dürr has already sold ten systems in the field of adhesive bonding, and is working on HRC solutions for the robot-based adhesive bonding of small washers and other components.

Case Study 2: Human-robot collaboration during the adjustment of headlights.

To reduce the strain on the workers, two KUKA LBR iiwa cobots perform the unergonomic task of adjusting fog lights at Ford. Parallel to this, human colleagues can adjust the main headlights.

The initial situation

In the automotive industry, vehicle fog lights have previously been adjusted manually by human operators. While stooped over, the human operator searches for the hard-to-reach opening for the adjusting screws in the bumper area. Once he has found the adjusting screw, he positions the tool on it extremely carefully without damaging the adjustment opening on the bumper.The solution

To provide relief for the human worker during this ergonomically unfavorable work and simultaneously achieve improved of the adjustment, Ford VOME (Vehicle Operation Manufacturing Engineering), Dürr Assembly Products and KUKA have jointly developed an innovative alternative concept for the conventional process as part of a feasibility study. The solution called for the use of the KUKA LBR iiwa cobot. The sensitive robot adjusts the fog lights fully automatically. In doing so, humans and robots work on the same vehicle without additional safety equipment.Teamwork

While the human operator adjusts the conventional headlights, the cobot adjusts the hard-to-reach fog lights. Two lightweight robots are already in use in four headlight/driver assistance system test stands for the new Ford Focus C519 at the Ford plant in Saarlouis.

The secret of the HRC concept

With its size and joint torque sensors, the robot detects contact immediately and reduces its level of force and speed instantly. These characteristics make it possible to work with human operators in confined spaces. Furthermore, with its high-performance servo control, the cobot detects contours quickly under force control. In combination with an end effector specially developed by Dürr (consisting of a camera system and an adjustment screwdriver), the robot positions the adjustment screwdriver according to the hole coordinates acquired by the camera system. The adjusting screw itself is located approximately 80 mm behind the hole in the bumper. Thanks to sensitive movements, the cobot optimally positions the adjustment tool into the screw head.

Redundant safety is provided by the HRC-capable, heavy-duty aluminum gantry from Dürr Assembly Products – on which the KUKA LBR iiwa is positioned in a ride-on installation above the light collecting box directly in front of the headlight to be adjusted. The advantage here: additional robot positioning can be dispensed with.

Case Study 3: Using a cobot to install pump wells.

In the future, BSH Hausgeräte GmbH will be using a KUKA flexFELLOW to carry out the installation of pump wells on the dishwasher production line.

The initial situation

The BSH Hausgeräte GmbH factory in Dillingen, Germany is Europe’s largest and most modern factory for dishwashers. Around 10,000 machines leave the production line every day in two-shift operation. There are a total of seven production lines for manufacturing dishwashers.

Screw fastening of the pump covers in the dishwasher is an ergonomically inconvenient task as the employee has to lean into the dishwasher housing to perform the task. The mechanical assistant now takes on this monotonous step in the process.

The task

Its contribution has already been tested successfully over several months as part of a pilot system. In addition to relieving the human operator of a cumbersome task, the robot also contributes by documenting its work and indicating whether the screws have been tightened correctly or not.

The solution

The key challenge when designing the system was to ensure that the manual workstation remained unchanged and that the automation solution could be integrated into the existing assembly line. Its sensitive and responsive capabilities enable it to recognize if, for example, a pump well component is not positioned correctly and then presses it into place.

The advantages of using a cobot:

- Reduction of the manual workload in an ergonomically inconvenient task

- Automated documentation of work steps

- Indication of correct screw fastening operation

Using its responsive capabilities, the cobot can then calibrate itself independently at its workstation, use a search run mode to find the screw positions, re-apply pressure to the component if it is not correctly positioned and finally tighten the four screws.

Further Reading

- Specifications of the KUKA LBR iiwa

- "Shaping future production landscapes," KUKA's white paper describing the 'megatrends' that impact manufacturing and 3 key factors (people, technology and adaptation) to designing production infrastructures that can meet the requirements of the future.