Liquid metals: a material that never ceases to amaze

In this article you will learn more about liquid metals, a material that never ceases to amaze. It is water-like at room temperature but with metallic properties. Here you will see how researchers want to make them printable or turn them into conductive, stretchable, and washable fibers for e-textiles.

Liquid Metals: Stretchable Barriers, Conductive Fibers, and Microchannel filling

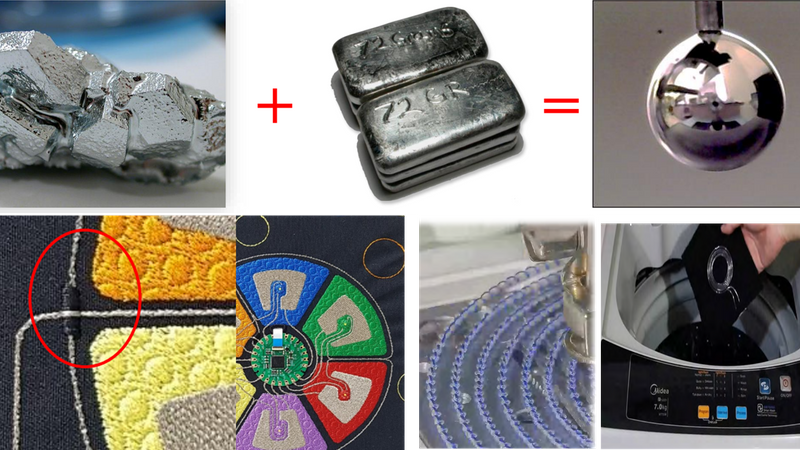

Liquid metals are extremely versatile. They are composed of GaIn liquid [Ga and In have melting temperatures of 30C and 157C]. The material has no vapor pressure and has viscosity like water, but with metallic properties.

Dr. Michael Dickey from North Carolina State University recently presented interesting results at TechBlick [www.TechBlick.com], showing self-healing structures, conductive fibers, stretchable barriers, and filled microfluidic channels using liquid metals. This article originally appeared here.

These liquid metals almost instantaneously form a thin [few nm thick] non-conducting GaOx passivating layer which stabilises the structure. The oxide layer can easily be broken [with mechanical force] to form a conductive pattern.

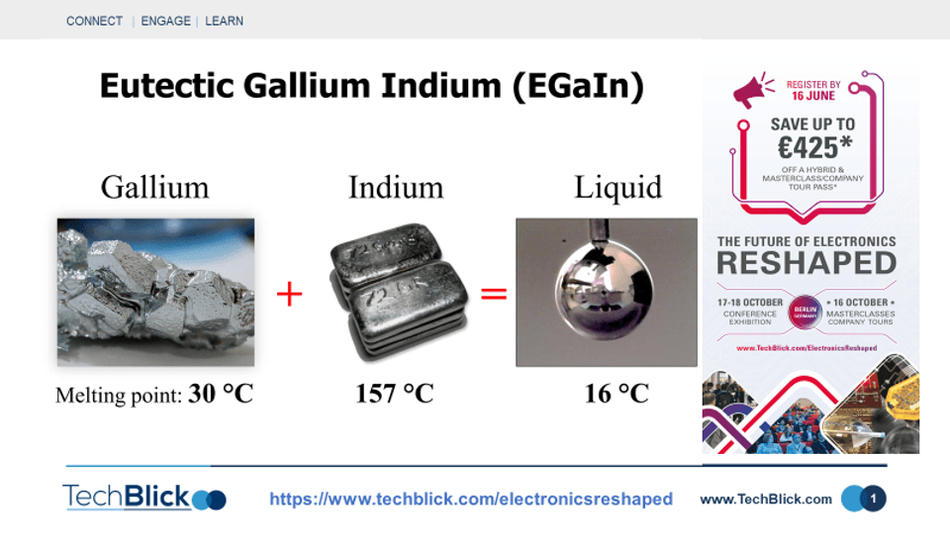

As can be seen in slide [2], these materials can be applied to fibers in two ways: filling the fibers/tube or adding the particles to the outer surface of the fiber/thread. In the first approach, a material can be formed with the elasticity of rubber and the conductivity of metal.

As shown in slide [3], the conductance changes with strain [up to 500% demonstrated]. Note that the conductivity of the liquid metal itself does not alter with strain, but the cross-section of rubber fiber changes, thus changing overall conductance.

To learn more about this amazing technology join us Berlin on 17-18 OCT 2023 to RESHAPE the Future of Electronics: https://www.techblick.com/electronicsreshaped

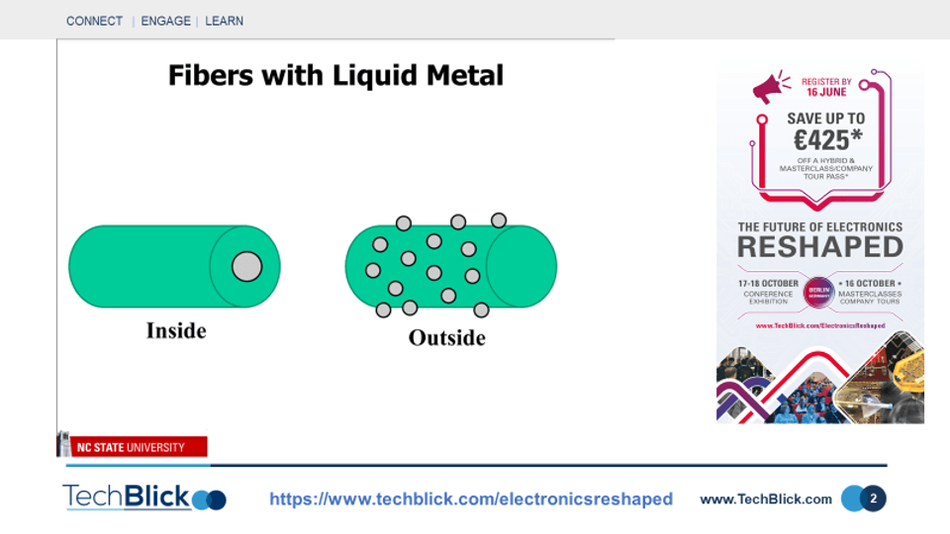

As shown in slide [4], to apply these materials to the outer surface, a droplet suspension of liquid metal nanoparticles [100 nm to a few micrometer in diameter] needs to be formed through, for example, sonication. The droplets become stabilized thanks to the presence of the oxide layers again.

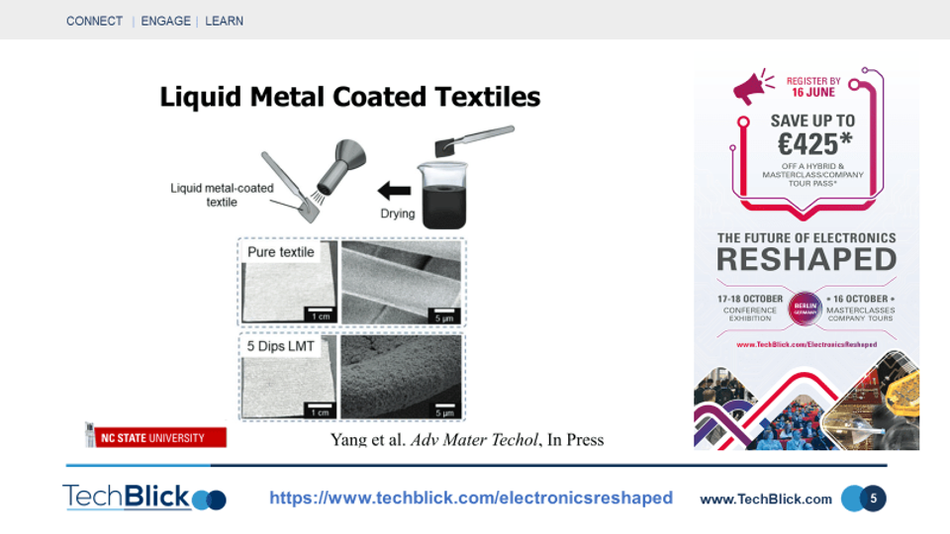

As shown in slide [5], the fiber can then be dipped several times into the solution and dried. This way, textile threads covered fully with a networking of liquid metal nanoparticles can be formed.

At this point, the network of liquid metal nanoparticles is non-conducting due to the presence of oxides. However, with the application of a simple mechanical force, it can be made conductive. These technologies can enable the surface of the textile to be used as the base, for example, for deposition of copper layers.

This is a novel approach, although mechanical and thermal stability of the liquid metals on the fibers remains an open question.

Join us and the global community in Berlin on 17-19 OCT 2023 to RESHAPE the Future of Electronics - explore the world-class agenda, masterclass programme, and expo floor here https://www.techblick.com/electronicsreshaped

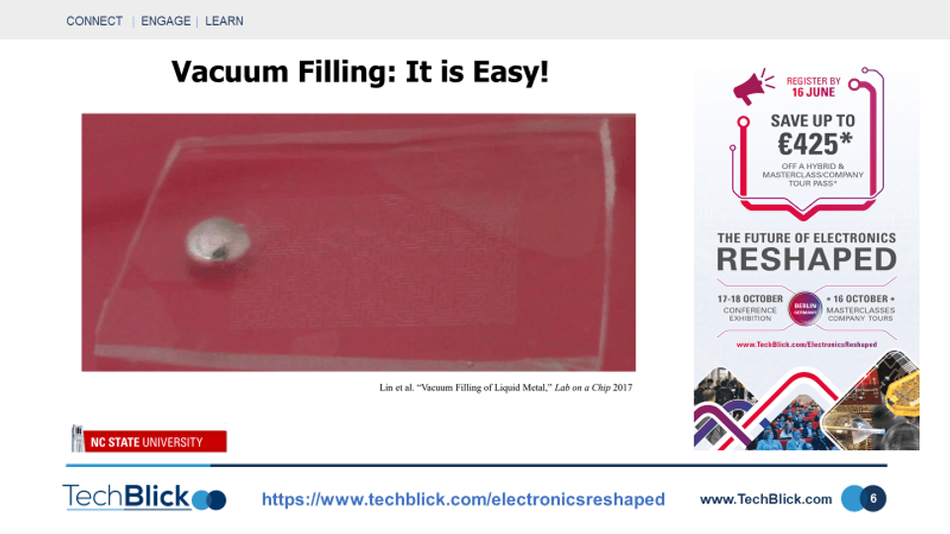

Slide [6] shows an interesting application: vacuum filling liquid metals. Here, the polymer material includes microfluidic channels. The entire system is under vacuum, thus the channels are under vacuum too. The liquid droplet is placed atop the structure. At this point, pressure is reintroduced, pushing the liquid metal through the microfluidic channels. This is a unique capability as filling such microchannels is not easily achievable with other materials such as nanoparticle inks or particle filled pastes.

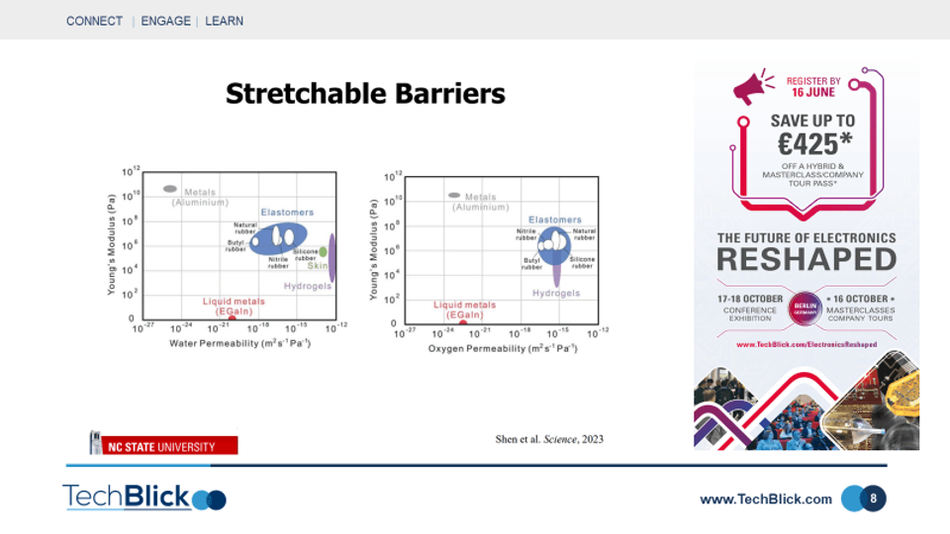

Slide [7] shows one of the most interesting applications of liquid metals. Traditionally, polymers are used as packaging but they have poor barrier properties. To compensate, a thin metal coating is generally applied. This improves barrier properties, but renders the hybrid structure [metal+polymer] rigid.

A novel solution is to apply liquid metals to the polymer structure, achieving booth good barrier and elasticity properties. Liquid Metals can have good permeability [not as good as metals but comparable] whilst not compromising the stretchability of polymers. To demonstrate the utility of this, a stretchy pouch battery was made.

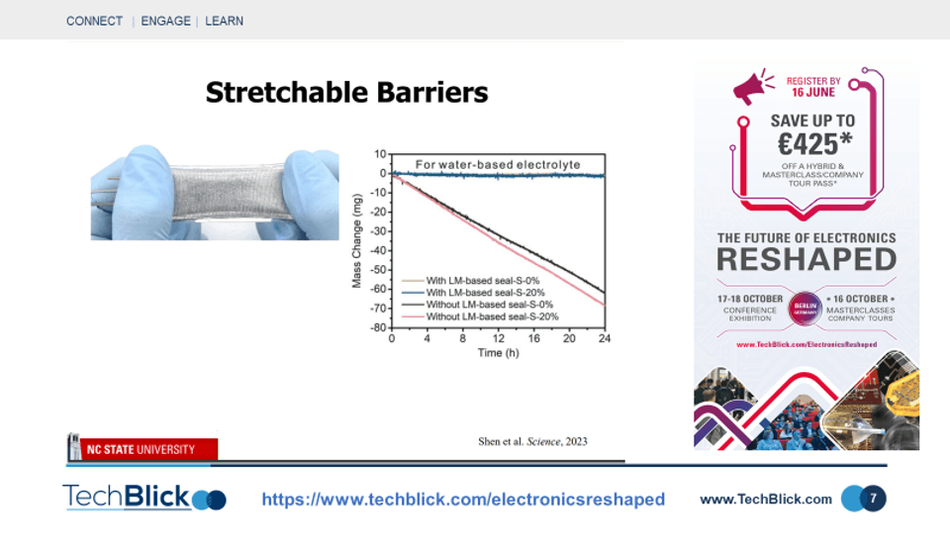

As shown in slide [8], the battery with liquid metal based seals, unlike those without liquid metal seals, report no change in mass as a function of time even when stretched. This is an interesting use case in that it opens a new technology for stretchable barrier technology.

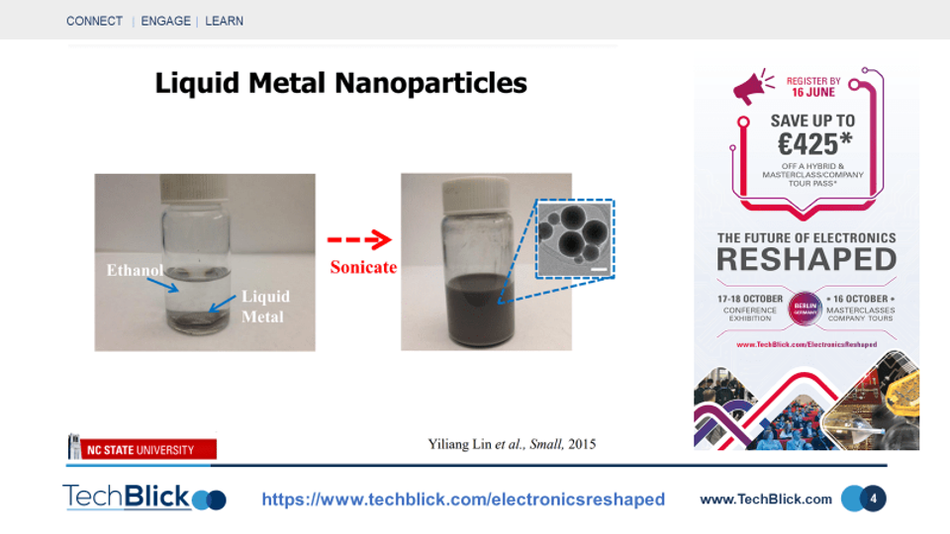

Liquid metal fibers for embroidered e-textiles: conductive, stretchable, washable

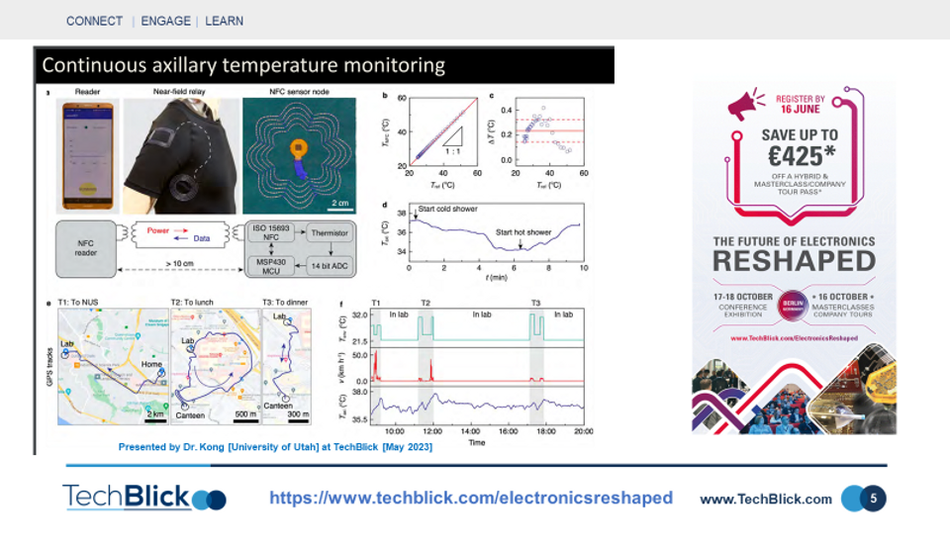

Liquid metals never cease to amaze. In e-textiles, they offer the potential to have highly conductive wires that can be washed and highly stretched! One interesting application is in digital embroidery of electronic textiles using liquid metal fibers. Dr. Yong Lin Yong from University of UTah presented some interesting work at a recent TechBlick conference [May 2023]. This work was a collaboration with Prof. @John Ho from National University of Singapore

Join us and the global community in Berlin on 17-19 OCT 2023 to RESHAPE the Future of Electronics - explore the world-class agenda, masterclass programme, and expo floor here https://www.techblick.com/electronicsreshaped

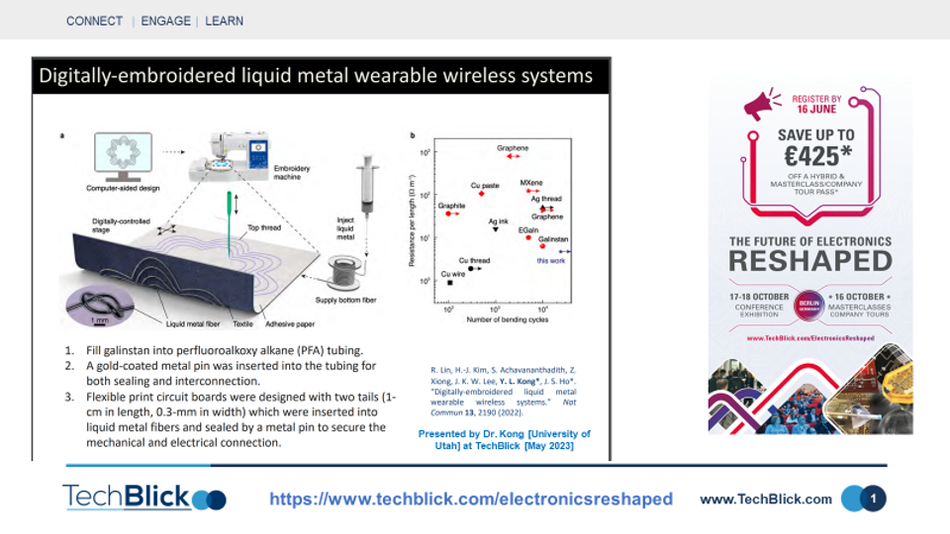

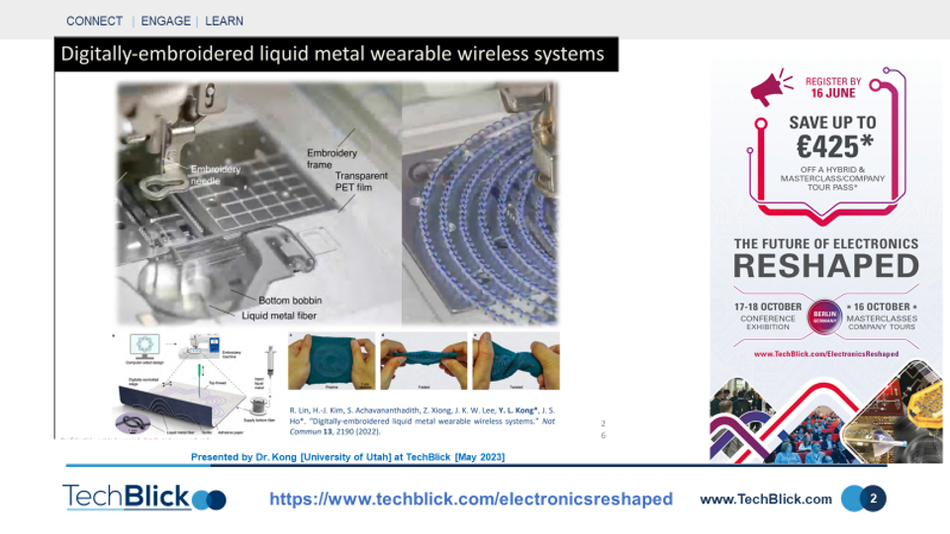

Here, off-the-shelf PFA is filled with liquid metals using a syringe to form a stretchable conductive thread [600um diameter] which could be embroidered.

As seen in slide [1] the resistivity per length is better than most ink or coated conductive thread solutions, although of course bulk Cu metal wires are still more conductive. Theses liquid metal filled conductive threads can then be digitally embroidered using embroidery machines [slide 2] to make, for example, antennas with high Q-factors [slide 3]

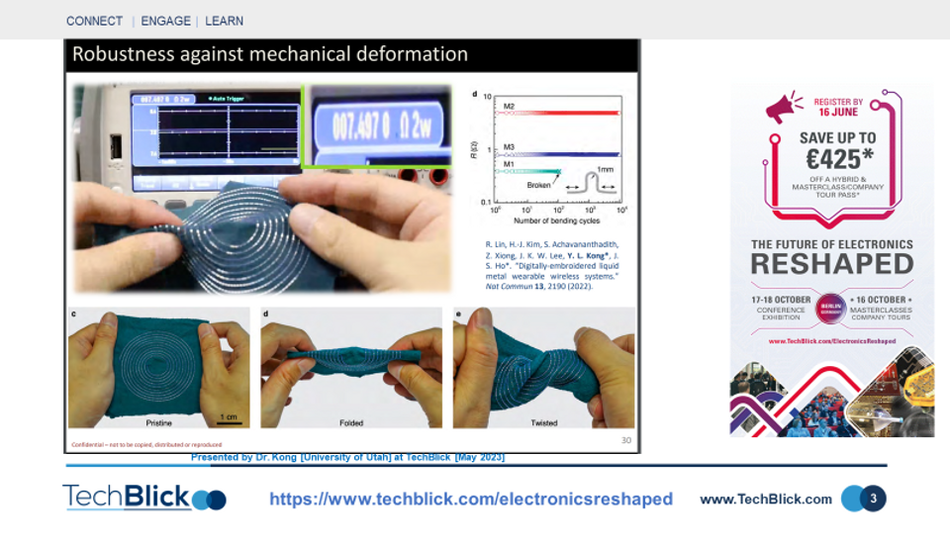

Slide [3] compares the resistivity of liquid metal filled fibers [M3] against Cu wires [M1] and conductive threads [M2]. Cu wires beat liquid metals in conductivity but fall short on stretchability [see how they break] whilst liquid metals beat conductive threads. Thus liquid metals are a good solution for embroidered electronic textiles where high conductivity and high stretchability are required

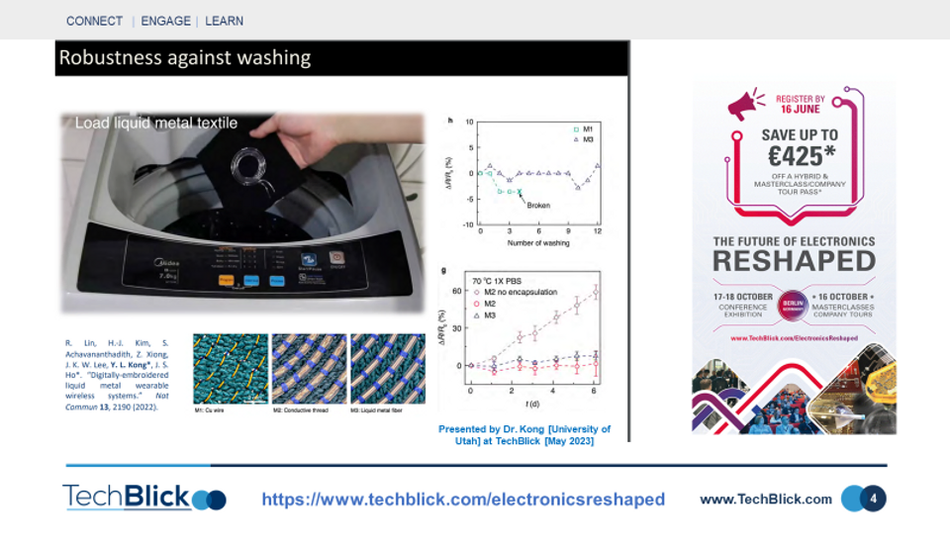

Washing is also an important criteria for e-textiles. Slide [4] shows that the results, showing that Cu wires can break in washing machines whilst liquid metal filled fibers survive washing machine treatment

Slide [5] shows a digital embrioded NFC sensor that actually works. The user had used these sensors on runs. Interestingly the sensors continue to work under contact with water - which is excellent for sensing applications and ease of use. The high conductivity of the liquid metal conductive threads means also a high Q factor for the NFCs

In short, liquid metals are a promising solution for e-textiles, ticking many of the requirement boxes including high conductivity, compatibility with embroidery, washability, stretchability, etc. There is much development still to be done - ensuring better cost structure and availability, temperature stability, etc but this is a space to watch

Making Liquid Metals Truly Printable

Liquid metals are truly a unique material. They offer amazing properties like extremely high stretchability with no change of resistance which can be useful in many textile, wearable, and/or robotic applications.

To learn more about this amazing technology join us Berlin on 17-18 OCT 2023 to RESHAPE the Future of Electronics: https://www.techblick.com/electronicsreshaped

They are typically based on a GaIn alloy with a eutectic bled that is liquid at room temperature. A thin layer of oxide spontaneously forms around the liquid droplets, helping to mechanically stabilize them.

In general, they are not easy to print. Currently, companies offer a gel version of them which can be dispensed under an applied electric force. This is an important advancement but dispensing has its own limitations.

In any case, such materials are not a drop-in solution for the printed electronics industry. Furthermore, the choice of the substrates on which one can print is typically limited to high surface energy substrates. This constraints applicability. Finally, control of sintering [removing oxide shell] and temperature stability can be challenges.

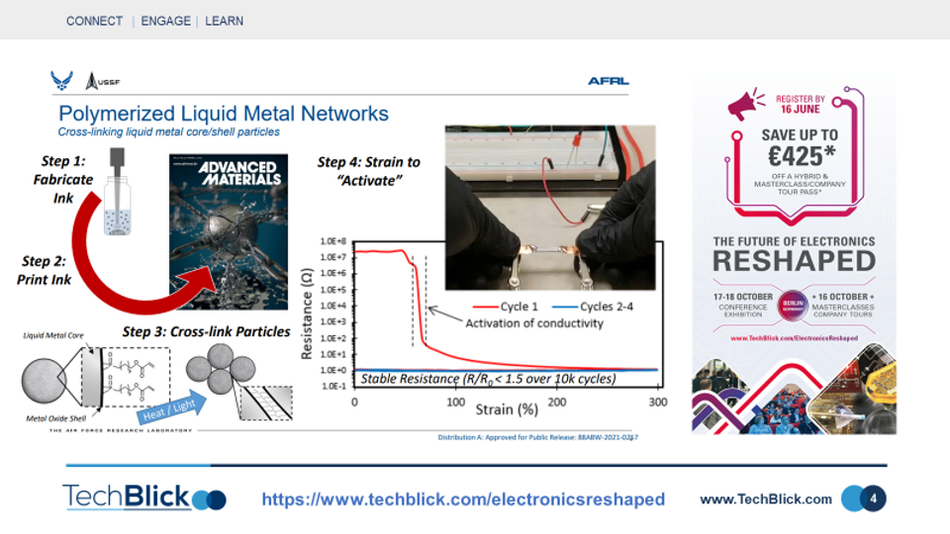

The researchers at the Air Force Research Lab - led by Christopher Tabor- are pioneering work on making liquid metals actually printable, meaning that one could use screen, gravure or other printing systems to additive deposit these materials. They presented their latest results at the TechBlick event on Wearable Technology and E-Textiles [more details here https://www.techblick.com/. This article originally appeared here.

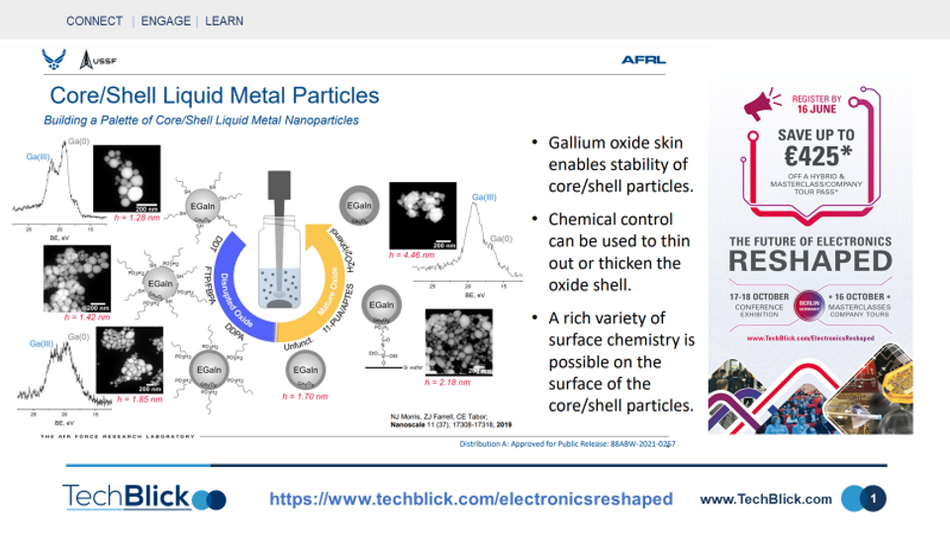

To achieve this, they must put these liquid metals into a colloidal ink with reliable and consistent ‘mechanical’ sintering. The first step towards this is the control of the shell oxide. In slide [1], you will see different thickness levels of the oxide (GaxOy) formed around a GaIn droplet, ranging from 1.28nm to some 4.46 [the natural growth without control would yield about 3um].

This control is important for two reasons: (1) it enables control of the mechanical sintering which is based on the rupturing of the oxide shells through mechanical force and (b) it offers a controlled surface for build up of chemical [e.g., ligand] layers

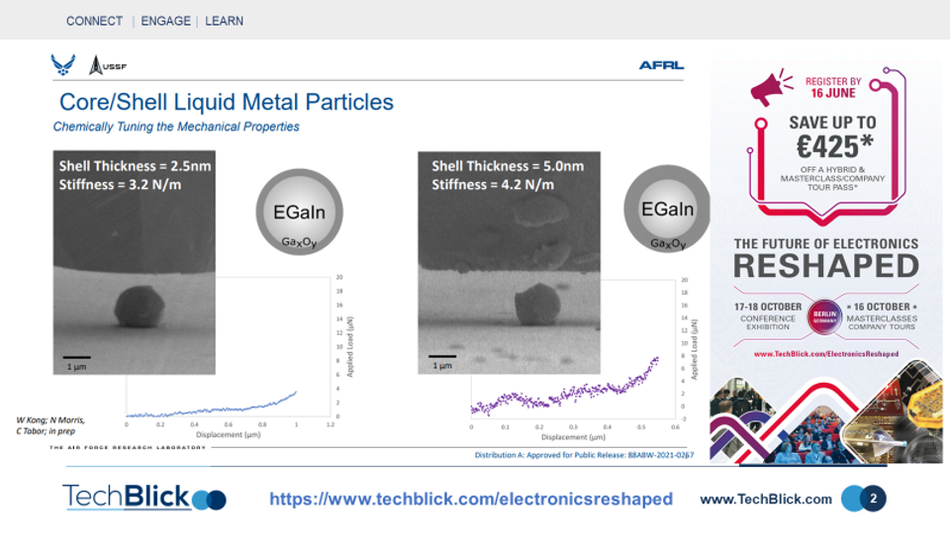

Point (1) is shown in slide [2], where one can see the thickness of the shell determines the applied force needed to break the shell [note: breaking the shell is needed because otherwise the network of GaIn droplets would be non conductive. Once the shells are broken and the liquid metal flows together to form a conductive line, this process becomes irreversible. This is the so-called 'mechanical' sintering]

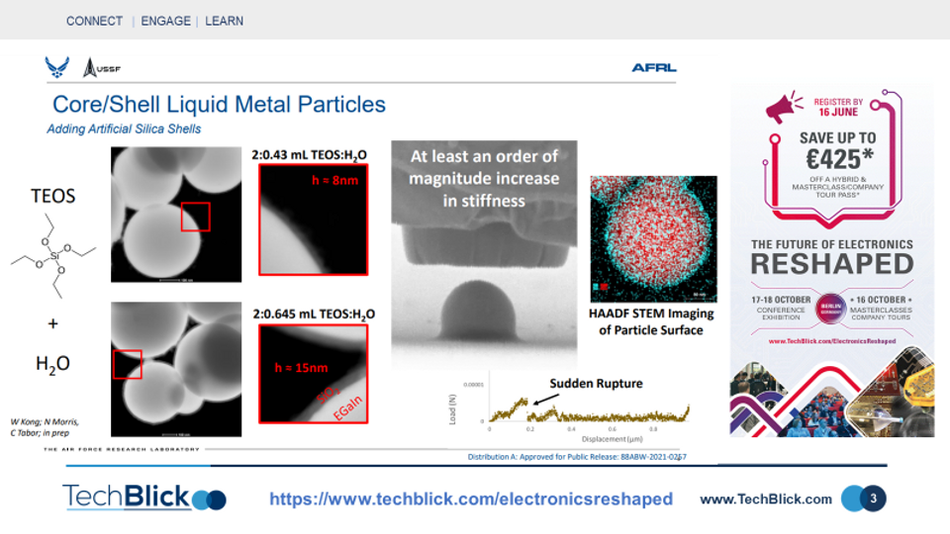

Next [slide 3] you can see how silica was added to the shells, increasing the stiffness and also enabling a ‘sudden’ rupture. Critically, this silica layer then enables formulation and addition of further ligands and polymers to enable printing on substrates with different surface tensions. In other words, it is a surface platform on which to formulate.

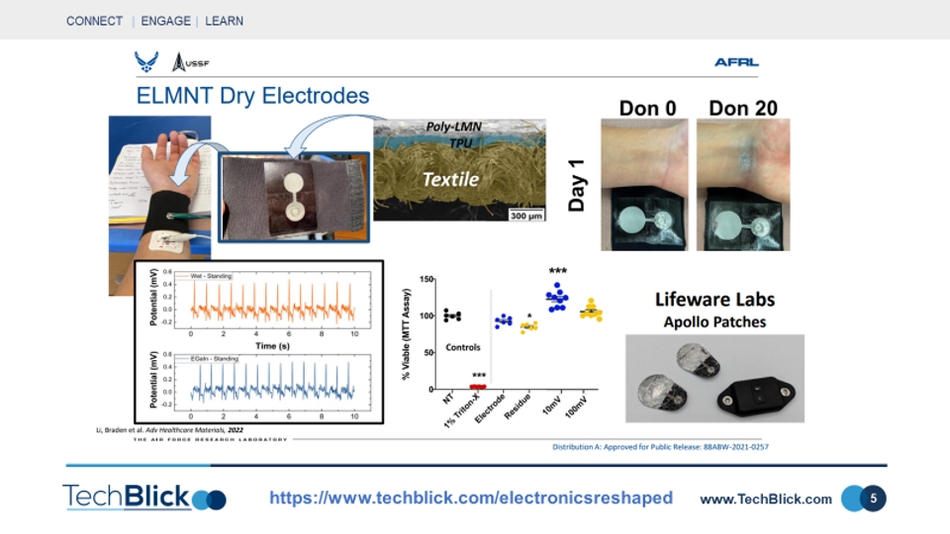

In slide [4] you can see that an ink has been formulated in colloidal form. This can be ‘printed’. In this case, a network of droplets are formed on the substrates, connected through the tortuous polymeric network of additions to the shell. In this state, the material is mechanically stretchable but still non conductive [the shell brings electronic transport]. However, the stretching itself will break the shells, allowing the liquid metals to form a highly stretchable conductive network.

Interestingly, the material can be stretched some 400% without any chance in resistance, which is never the case with other particle-based conductive inks [which are more printable and conductive but less stretchable]

This technology is currently being commercialized in partnerships with UES, Inc.

Many applications have been showcased as one can see in slide 5 including

Dry electrodes for measuring physiological parameters with direct skin contacts [so far studies do not show adverse impacts on bio cells]

Integrated resistive heating into textile which can stretch

Stretchable cables

This is an amazing material system that continues to amaze. In our view, it is one of the ‘hot’ development areas in printed electronics. This work shows that liquid metals can also be optimized for printing, although there is much work to be done in proving consistency of mechanical sintering, imprioving trade-off in conductivity vs shell modification, in thermal stability, in linewidth control, in compatbility with various substrates. Of course, traditional ink systems are versatile and mature technology, developed over many decades. In contract, printable liquid metals are a novice technology, but one with a clear promising roadmap. Watch this space

To learn more about this amazing technology join us Berlin on 17-18 OCT 2023 to RESHAPE the Future of Electronics: https://www.techblick.com/electronicsreshaped

age Caption