Medics: 3D printing medical models to make surgery safer

The careful study of materials for 3D printed medical models has enabled Medics to simulate bone structure in prototypes, offering physicians the most realistic, highly customized simulation possible, and at the same time, eco-friendly and with a simplified storage and refill process.

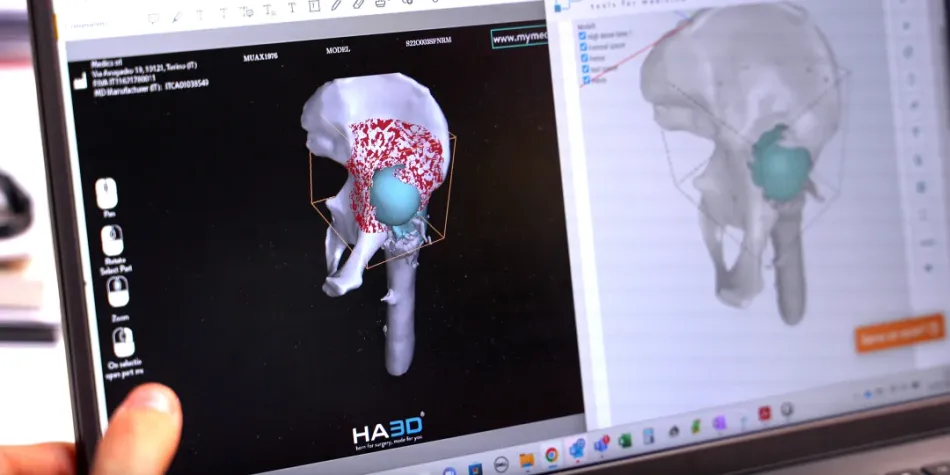

Manipulation of the models using augmented reality allows surgeons to virtually plan their precise movements

Medics is an Italian company created in 2016 as a startup dedicated to 3D printed medical models.

It was founded from a desire to make surgical procedures safer, better planned, and as minimally invasive as possible, offering an approach that benefits the patient, the surgeon, and the hospital facility.

Medics does so by supporting surgeons in pre-operative planning and intra-operative management of high-complexity surgeries through patient-specific 3D anatomical reconstructions called Hyper Accuracy 3D® (HA3D®).

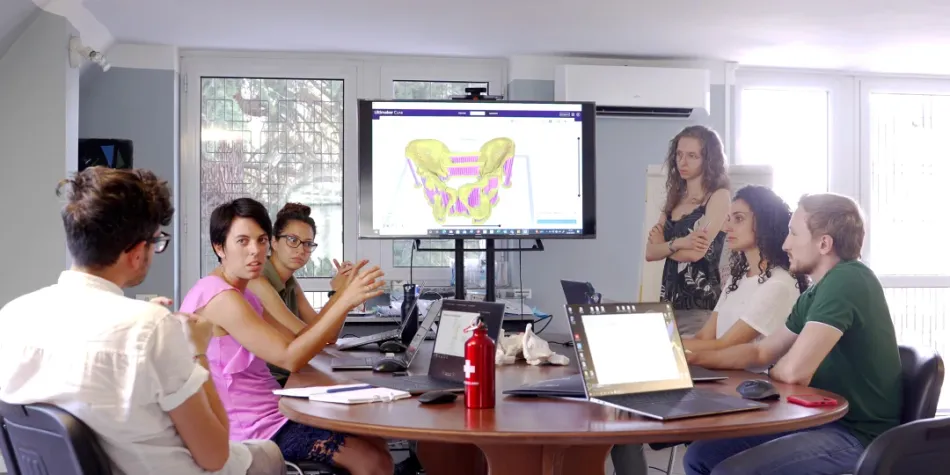

These are created from the patient's DICOM images (CT, AngioTAC, MRI) by a team of biomedical engineers and are designed to realistically reproduce the anatomical area undergoing surgery.

All 3D printed medical models are printed directly in the hospital facility thanks to the remote printing capabilities of the Ultimaker S5 Pro Bundle. The models are then certified as Medical Devices, having been made with the most advanced image processing and additive manufacturing technologies.

Why use 3D printing?

The benefits associated with the use of 3D models are countless.

For surgeons, HA3D® 3D printed medical models allow them to:

Have better visual-spatial perception of the anatomical area to be operated on

Reduce the effort to memorize specific actions inherent in classical surgical planning, based on the exclusive support of two-dimensional images

Simulate the entire operation to predict the outcome of surgery more accurately, reducing intra- and post-operative risks and complications

Interact with the 3D reconstruction even intraoperatively, using it as a reference

For the patient, on the other hand, being operated on by a professional who has trained using a customized anatomical 3D printed medical model means receiving "tailor-made", safer, and less invasive treatment.

The benefits associated with the use of HA3D® 3D printing medical modelsare also for the hospital.

These make it possible to:

Limit surgical and hospitalization time, reducing related costs

Decrease of intra- or post-operative risks and complications and, consequently, medico-legal issues

Beyond this, 3D printing medical models also has significant value for education.

Thanks to this workflow, younger surgeons can learn by practicing in complete safety, reducing the risks of error, infection, and unforeseen events.

Not just 3D printed reconstructions and guides

HA3D® 3D printed medical modelsare not the only products offered by Medics.

ICON3D™ is a SaMD (Software as a Medical Device) for intra-operative visualization and manipulation of virtual HA3D® anatomical models.

The goal of ICON3D™ is to provide support for complex surgery by allowing the surgeon to reproduce interactive, patient-specific pre-operative planning during the operation itself.

This optimizes the surgeon's perception of the patient's actual anatomy, visualization of the endoscopic video stream, even in touch-less mode.

A pioneering approach to surgery

From 2016 to date, Medics has never stopped innovating.Its cutting-edge approach has allowed this start-up to grow significantly from a small local business to an industry leader.

The project, originally created to meet the needs of orthopedic surgery, has expanded to other surgical specialties as well.

Today, it also offers 3D printed medical models for the urology and general surgery divisions, as well as custom-made surgical guides.

These are created to ensure the most efficient, replicable, and accurate as possible – even in cases of congenital malformations.

It is also developing solutions capable of meeting the unique needs of gynecological surgery and thoracic surgery.

3D printed medical models made directly and remotely in the hospital

Medics' mission is also supported by an extremely easy model creation process.

For this reason, the creation of anatomical models by Medics' 3D printed medical modelsis particularly accessible and simple: The printers can be placed directly in hospitals and operated completely remotely.

This allows surgeons to have the physical model of the bone or organ they need to operate on, ready to use, and without shipping, in roughly 24 hours – without having to manage the printing process or the machine.

This simplicity was also achieved through Medics' collaboration with 3D Italy, a leading three-dimensional printing company with a nationwide presence.

Together, the companies studied and tested different printers and materials, to meet the most suitable solution for the medical world.

The use of the Ultimaker S5 Pro Bundle enables complete remote management of printing, through cloud capabilities and with the support of accessories particularly appropriate to the needs of the hospital sector.

These include the Ultimaker Material Station, which allows up to six reels of printing filaments to be stored, protecting them from humidity and degradation. And also the Ultimaker Air Manager which maintains air quality by filtering up to 95% of ultrafine particles during the printing process.

Conclusion: Redefining surgical planning

The careful study of materials for 3D printed medical models has enabled Medics to simulate bone structure in prototypes, offering physicians the most realistic, highly customized simulation possible, and at the same time, eco-friendly and with a simplified storage and refill process.

Today, Medics can offer 3D printed medical models that can redefine the standards of surgical planning and management.