Optimizing battery performance in wireless sensor applications

In many sectors, sensor networks are composed of thousands of individual sensors, many powered by primary batteries. Certain issues related to limited power autonomy need to be taken into consideration before successfully deploying such networks.

Credit: irrigationonline.co.uk

In many sectors, sensor networks are composed of thousands of individual sensors, many powered by primary batteries. Certain issues related to limited power autonomy need to be taken into consideration before successfully deploying such networks. Severe conditions can affect battery life, depleting the battery faster and rendering the sensor inoperable, which will in turn affect the quality of measurements and automation.

Additionally, every battery which needs to be replaced by personnel involves labour-induced operational costs and generates e-waste, causing ever more environmental harm. According to a recent report by the EU-funded project EnABLES, by 2025 around 78 million batteries(1) powering IoT devices will be dumped globally every day if nothing is done to improve their lifespan.

The power bottleneck imposed by batteries needs to be solved in order to benefit from the huge amount of data measured, remote sensor management and smart decision making. Energy harvesting and battery management technology provide a credible solution to improving battery autonomy and are ideally suited for sensing applications. With the development of an innovative Power IC portfolio, Nexperia offers tangible solutions to improve sensors by reaffirming its commitment to empowering engineers in enhancing system efficiency and combating battery waste.

Scenario 1: Energy harvesting enables Plug & Forget sensors

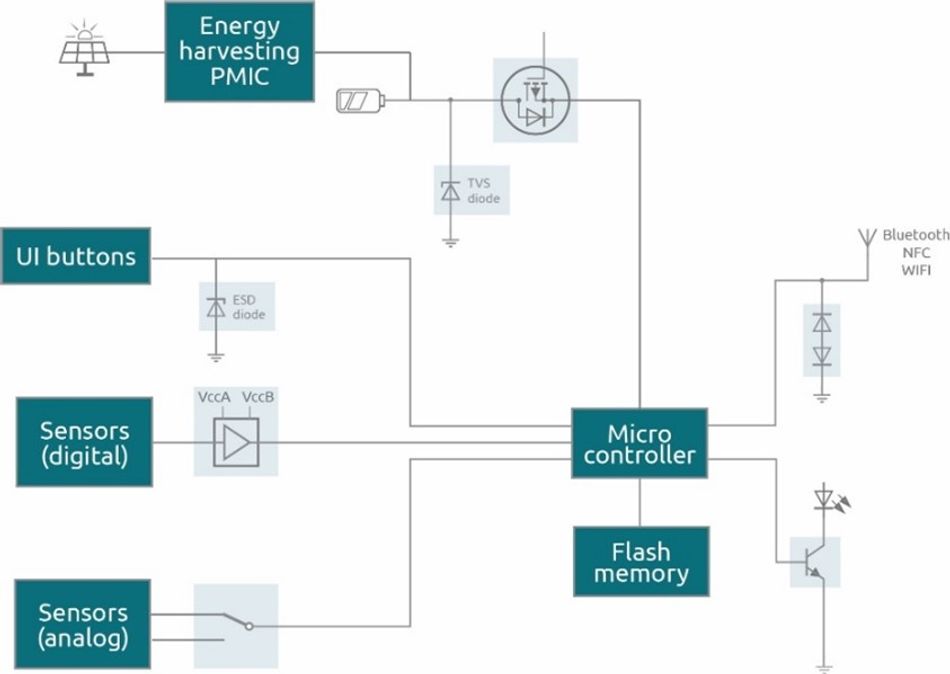

In the dynamic world of intelligent building technology, the integration of cutting-edge sensors plays a pivotal role in enhancing efficiency and sustainability. Designers are increasingly incorporating an array of remote wireless environmental sensors. Enabling uninterrupted sensor operation, energy harvesting technology can successfully drive this innovation. With plug-and-forget IoT sensors, retrofitting or newly equipping buildings becomes easy, ensures long-term sustainability, and reduces maintenance efforts. The energy-harvesting PMICs serve as the backbone of these systems, converting voltage from photovoltaic (PV) cells into rechargeable storage elements, such as lithium-ion batteries.

These intelligent sensors boost multifunctionality, encompassing a diverse range of capabilities essential for comprehensive environmental monitoring and control. From temperature and humidity to air quality and motion detection, these sensors offer unparalleled insights into building conditions. The incorporation of PIR motion sensors further enhances security measures, detecting and responding to intrusions with remarkable precision. Also, the integration of CO2 sensors underscores the commitment to occupant health and well-being, facilitating optimal ventilation and air quality management.

The synergy between advanced sensors and energy harvesting technology represents a paradigm shift in smart building design. By harnessing the power of innovation, these systems empower building owners and operators to achieve unprecedented levels of efficiency, sustainability, and occupant comfort.

Example of a smart building sensor with unlimited battery life

With a solar panel area of only 10 cm2 and thanks to Nexperia NEH2000BY’s impressive 80% conversion efficiency, close to 1.1 mWh is converted and used to charge the battery. With this setup, more energy is harvested and converted than is consumed, thereby making the application fully energy autonomous and eliminating the need to replace batteries.

Scenario 2: Battery Management IC boosts coin-cell battery life

A large number of wireless building sensors operate at 3V and use such little power that they can run on coin cells. This primary non-rechargeable battery type is cost efficient and easy to buy. Many sensor applications however use pulsed loads which deplete the battery quickly.

Nexperia’s NBM7100A/B and NBM5100A/B are revolutionary new battery management ICs that can extend the life of a typical Lithium coin cell battery by up to an order of magnitude (10x) while increasing the peak output current available to a pulse load by up to 25x. These ICs contain two high-efficiency DC/DC conversion stages and an intelligent learning algorithm.

The first conversion stage transfers energy from the battery to a capacitive storage element at a low rate. The second stage utilizes the stored energy to provide a regulated (programmable from 1.8 V to 3.6 V) high pulse (up to 200 mA) current output. The intelligent learning algorithm monitors the energy used during repetitive load pulse cycles and optimizes first-stage DC-DC conversion to minimize the residual charge in the storage capacitor. When not performing an energy conversion cycle (standby state), these devices consume less than 50 nA.

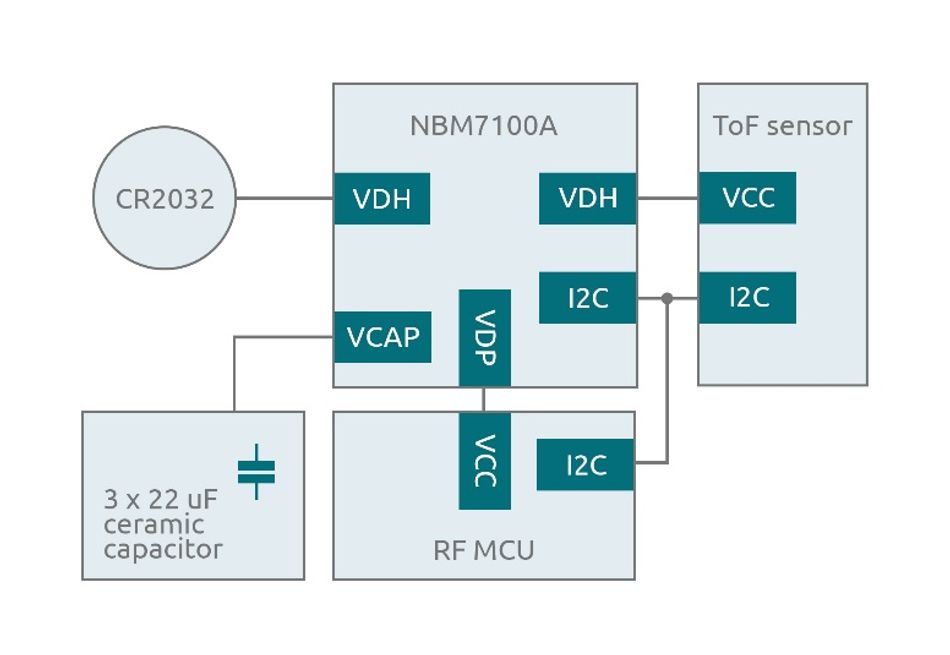

Time-of-Flight sensor with optimized battery performance

Figure 2 depicts an exploration into the application of a time-of-flight sensor, an interesting technology for IoT (Internet of Things) contexts due to its multifaceted utility.

Time-of-Flight (ToF) sensors are very versatile; They boost the ability to measure distances to objects, facilitating tasks ranging from open/close detection to presence sensing and fill state determination. However, this versatility comes with a caveat – the substantial power demand necessary to drive the laser diode which is part of the ToF sensor.

In this particular case study, a time-of-flight (ToF) module was employed, characterized by a 33ms operational time, a current consumption of 40mA, and a minimum operating voltage requirement of 2.8V.

Battery Life Boosters enhance operational efficiency

Herein lies the challenge: a CR2032 battery, with its source resistance exceeding 10 Ohms, cannot reliably sustain the required 2.8V supply voltage for the TOF module. Even under optimal conditions, the loaded state voltage of the battery dips to 2.6V when fully charged. Consequently, accommodating such power demands necessitates the adoption of larger batteries, such as two AAA cells, inevitably impacting the overall product size.

Enter the NBM7100, a game-changer capable of generating a stable 3.0V output voltage, that significantly enhances operational efficiency. With this solution in place, approximately 500,000 measurement cycles become achievable, equivalent to a lifespan of roughly one year when utilizing the sensor once per minute.

Moreover, the NBM7100A's VDP output seamlessly supplies continuous voltage to an RF Microcontroller, while the VDH output caters to the ToF sensor's power needs.

This innovative approach confers the added advantage of reducing standby current consumption. By selectively powering off the VDH supply during idle phases, leakage current is drastically minimized, plummeting from approximately 10uA to a maximum of 50nA.

This exemplary case underscores the pivotal role of battery lifetime boosters in facilitating the creation of more compact product designs, ultimately enhancing usability and user experience.

In summary, with energy harvesting enabling Plug & Forget sensors and battery management ICs boosting the coin-cell battery performance, they are both valuable options to power sensors in smart building and many other segments with efficiency and sustainability.