Optimizing FPSO Inspection Processes

Utilizing SKYRON Technology

FPSOs (Floating Production Storage and Offloading units) demand meticulous inspection due to exposure to harsh marine environments, including waves, currents, and saltwater corrosion. Additionally, given the nature of the asset, corrosion monitoring in hull tanks and oil storage is critical. Advanced inspection and monitoring can help prevent catastrophic events. Ultrasonic Testing (UT) and Visual Testing (VT) are imperative methods employed to ensure the structural integrity of these vessels. These inspections identify corrosion, erosion, or damage that may compromise their strength, allowing for timely repairs and maintenance to prevent costly downtime or accidents caused by tank failures.

Assessing assets such as FPSO tanks presents numerous challenges, including high temperatures and limited access through conventional methods like scaffolding or rope access in confined spaces. However, the industry is evolving by embracing innovative technologies like Unmanned Aerial Vehicles (UAVs). While UAVs can operate autonomously, they are typically controlled remotely by a human pilot. Additionally, specialized equipment tailored for high-temperature environments is being integrated to enhance inspection efficiency and effectiveness.

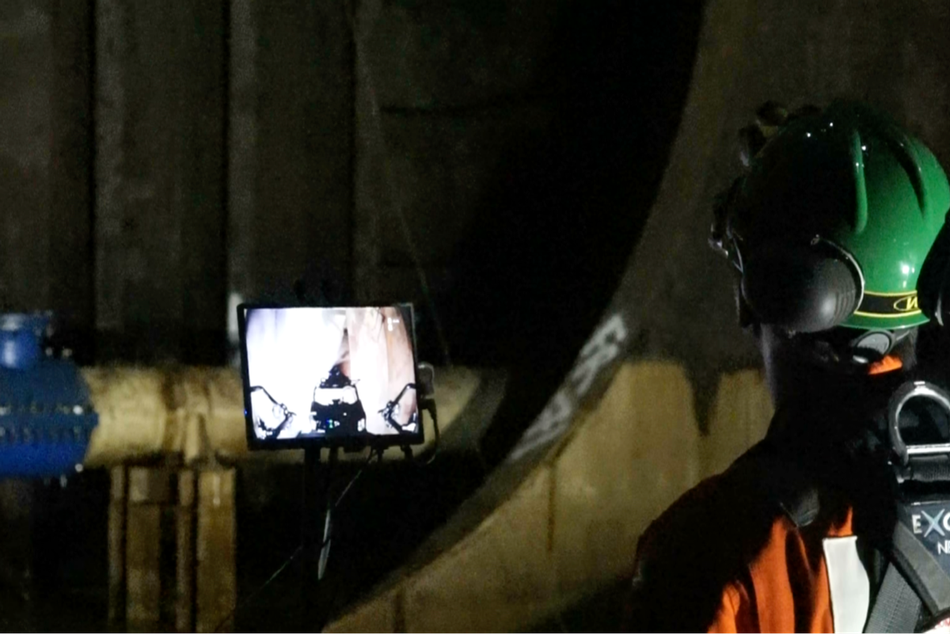

Recently, Avestec achieved a successful milestone by conducting a comprehensive inspection of an FPSO tank, employing the cutting-edge technology of SKYRON. The mission was meticulously designed to conduct both UT and VT inspections within the confined spaces of the FPSO tank. Leveraging SKYRON's advanced capabilities, the VT inspection meticulously captured General Visual Inspection (GVI) and Close Visual Inspection (CVI) HD images, while UT readings were diligently collected from the tank’s surfaces. Despite facing scorching ambient temperatures reaching up to 46°C, SKYRON's performance remained unparalleled, thanks to its integrated proprietary cooling system, ensuring peak efficiency even in the most challenging conditions. SKYRON is also equipped with two long-range video systems optimized for operation in metallic confined spaces. One link transmits HD video for inspection, and the other transmits low-latency FPV (First Person View) video for navigation. The FPV allows inspectors to stay in a safe place and have a view of the areas being inspected.

All GVI (General Visual Inspection), CVI (Close Visual Inspection), and UT (Ultrasonic Testing) measurements were captured using SKYRON, with ABS surveyor approval. This serves as a significant step toward method approval, as SKYRON can be considered a new approach for FPSO inspections, eliminating the need for humans to work at height using ropes or scaffolding.

In conclusion, SKYRON proves to be a game-changer in FPSO inspections, offering enhanced safety for inspectors, faster assessment processes, and reduced costs. Its ability to operate in challenging environments, coupled with its advanced capabilities, positions SKYRON as a reliable solution for ensuring the integrity of FPSOs worldwide.