Professional sports equipment showcase potential of moldable carbon fiber-based composites

Two case studies demonstrate how both material selection and collaborative design play a role in product outcome.

The KyronMAX® range of materials is suitable for a wide range of applications across industries. This article looks at two case studies where the materials provided considerable benefits to the product's design. Submit your ideas about how to utilizes KyronMAX® ’s range of moldable carbon fiber-based composites to the KyronMAX® Challenge for the chance to win $25,000 of manufacturing services.

KyronMAX® prides itself on being more than just a materials provider. They are a collaborative manufacturing platform that can work with designers and companies at any stage of their design or production process to offer advice, testing, and prototyping. Early in the design process Mitsubishi Advanced Chemical Materials can assist with concept design and simulated analysis, and later down the design pipeline, Mitsubishi’s SPRINT prototyping process can deliver material accurate parts without injection molding tooling. The two featured case studies showcase two of the ways Mitsubishi Advanced Chemical Materials can support product development. The first utilizes a ready-to-go KyronMAX® material product which was directly swapped for the current composite material resulting in a finished part 21% lighter than its previous iteration. The second case study illustrates how KyronMAX® engineers can work from start to finish with a design team to redesign, test, prototype, and manufacture a complete product.

Material intervention meets the target

Professional archery might not be a sport many of us think of. But the equipment used by archers combines many engineering principles that made reinventing a key part of the archer’s bow an exciting challenge for Mitsubishi Chemical Advanced Materials engineers. The design improvement focussed on the idler wheel of the bow. The idler wheel’s main function is to transfer stored energy from the bow’s limbs through the arrow’s string smoothly and rapidly. Understandably the idler wheels experience a significant amount of load and must be able to maintain high levels of intense use.

Image: Pierre-Yves Beaudouin/WikiCommons

Material replacement with existing tooling

The customer had already replaced the aluminum with a lighter weight 50% Nylon Long Glass Fiber (LGF) as the material for the idler’s construction but was experiencing a 14% failure rate due to breakage. The bow making company had purchased new molding tools and wanted to avoid further reinvestment with another material change. At this point, they approached Mitsubishi Chemical Advanced Materials for assistance in improving the idler design.

The Mitsubishi Chemical Advanced Materials team immediately recommended using KyronMAX® S-2220, a 20% Carbon-Fiber filled product and offered to run the molding trials using the customer's existing tool. KyronMAX® polymer technology allows for fiber mixing, increasing the knit-line strength and decreasing failure rates inviting use for higher-strength parts and the production of difficult, complex geometries. In addition, KyronMAX® S-2220 has less than half the filler loading, which helps to increase toughness, improve knit-line strength, faster processability, and consistency while significantly reducing the part stress. Mitsubishi Chemical Advanced Materials were able to help the customer adapt their existing tooling for compatibility with KyronMAX® so they could continue production without new tooling investment. The video below shows the massive strength improvements by the use of KyronMAX® S-2220.

Rapid prototyping delivers for bike suspension redesign

Mitsubishi Chemical Advanced Materials worked with a leading bicycle manufacturer to develop a new suspension part that offers improved strength performance and significant weight reduction. Unable to achieve the desired performance using Long Fibre Technology (LFT) compounds, Mitsubishi Chemical Advanced Materials Engineered Solutions technical team, ran trials using KyronMAX® to test for possible improvements. Combining Mitsubishi Chemical Advanced Materials mold-flow software technology together with the KyronMAX® material files, the team developed favorable process conditions, gate design, validations, and testing of the final composite structure.

Addressing weld lines

Weld lines occur when part or tool design features such as holes divide the melt flow, and the separate flows do not mix completely when they meet. At these points, little or no polymer chain entanglement occurs across the flow-front boundaries. Weld lines can be the weakest points for plastic and compound material parts. Mitsubishi Chemical Advanced Materials have developed several proprietary technologies for reducing weld-lines and therefore increasing the overall mechanical strength of the part. KyronMAX® engineers applied these technologies to the bike suspension part to assess weld line prediction and mitigation.

Finite Element Analysis

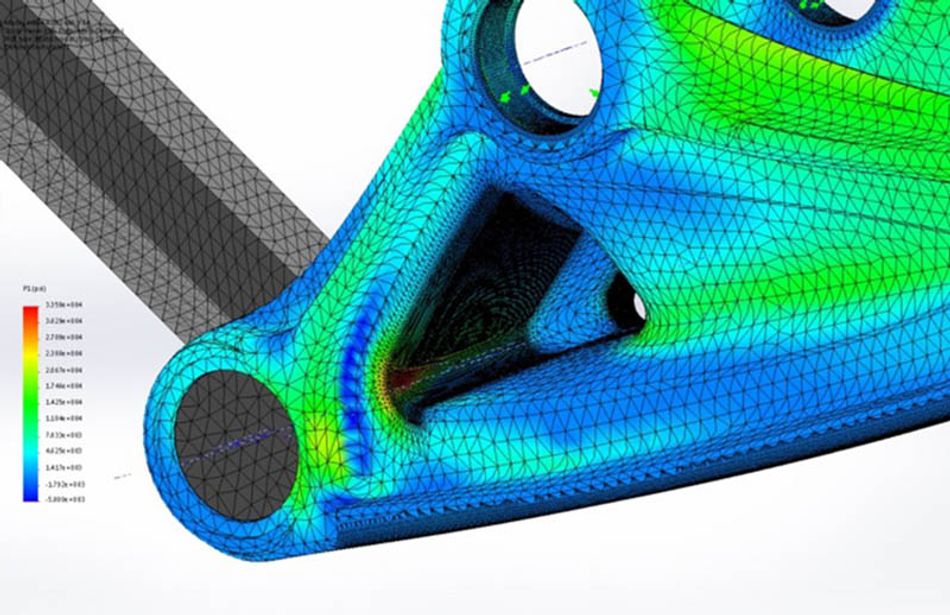

Fiber matrix structure mapping then allowed for a full Finite Element Analysis (FEA) which mechanically tested the structure to predict what the product will do when it encounters real-world forces and wear.

For example, load-cases were simulated in the FEA software using advanced fiber matrix analytics. 400,000 data points were applied for each FEA node to help assess the part. The software then calculated the fiber placement at each node, working out the associated strength based on pre-programmed data. The mesh was then refined using stress analysis.

Making the design reality

Once the part had been structurally improved, it needed to be analyzed to ensure the design could be fabricated and perform as intended. This entailed testing any geometry alterations to ensure the component was designed to meet its requirements. A prototype of the design was then created in the same material as the final product using Mitsubishi Chemical Advanced Materials SPRINT technology (based on AddiFab technology). The SPRINT technology enables the production of functional prototypes in the material of choice and can be used for small production volumes. The flexibility, freedom of design, and speed of 3D printing (of the mold) are combined with the high quality of injection molding. This prototype then underwent real-world testing including simulating the exact load case using a customized jig at one of the Mitsubishi Chemical Advanced Materials innovation labs. This ensured the design process was accurate and the part performed as intended.

The combination of the customer’s application expertise with KyronMAX's material knowledge led to a successful collaboration that resulted in a stronger, more durable part manufacturable. This collaborative approach supported the customer to rapidly test and trial several prototype materials, designs, and solutions to determine what was needed for the final component.

The broad application of the KyronMAX® materials and the Mitsubishi Chemical Advanced Materials collaborative approach to problem-solving opens the possibility for engineers in all stages of the design process and scale to improve their design through testing, prototyping, and material selection.

The KyronMAXⓇ Challenge

The KyronMAX® Challenge invites you to submit a design that utilizes KyronMAX®’s range of breakthrough, high-strength carbon fiber-based composites to solve an engineering or manufacturing challenge. The winning designs will receive $25,000 worth of manufacturing support from KyronMAX® to create a fully developed prototype.

Your submission can be a stand-alone product or a component of a larger design. Successful submissions will need to show how the design utilizes the unique properties of KyronMAX® materials and complements the platform’s capabilities. The KyronMAX® challenge will reward projects that prioritize sustainability while maintaining a high level of feasibility and ingenuity.

For full challenge details, see The KyronMAX® Challenge homepage.

About the sponsor:

Mitsubishi Chemical Advanced Materials is a leading global manufacturer of high-performance materials in the form of semi-finished products and finished parts. The company has locations in 20 countries and more than 2,800 employees. Its specialty engineering thermoplastics and composites are superior in performance to metals and other materials and are used in a wide range of applications, primarily in the capital goods industry. The company is continuously developing new areas of applications in close cooperation with industry leaders in a wide variety of customer markets. The Mitsubishi Chemical Advanced Materials Group is well prepared to further expand its market leadership position.

Supporting the vision of our holding company, Mitsubishi Chemical Holdings Corporation (MCHC), Mitsubishi Chemical Advanced Materials is committed to the realization of KAITEKI, “a sustainable condition which is comfortable for people, society and the Earth”. To realize this vision, the MCHC Group engages in corporate activities that provide products, technologies, and services based on the comprehensive capabilities of the Group in the Performance Products Domain, Industrial Materials Domain, and Health Care Domain, with chemistry as the basis of our activities. We jointly express and promote our commitment under the corporate brand THE KAITEKI COMPANY.