The 2023 Manufacturing Robotics Report: Materials

New frontiers in robotics materials.

The first fully soft autonomous robot. Source: Harvard, Wyss Institute

The 2023 Robotics Manufacturing Report was created to enable you to be up to date and understand the complexity and depth of robotics and to help you gain specific insights into the current status of robotics manufacturing.

Over the five articles of the report, we will examine the core technologies that make up a robotics project and shed light on the trends and challenges in creating them.

Read the introduction chapter here.

Read the full report now.

The field of robotics has been progressing remarkably fast in recent years, challenging conventional ideas of robot architecture and function. In an article published in 2018 by the journal Science Robotics, an expert panel of scientists identified a set of challenges for the future of robot design and manufacturing. It is significant that, among these challenges, the first is the development of new materials for robotics.[1]

Additional challenges that are connected to materials science include the design of bio-hybrid and bioinspired robots, taking inspiration from living organisms to create multifunctional and autonomous systems. In addition, the adaptability of robots to extreme and complex environments is related to the mechanical and self-healing properties of innovative robotics materials.

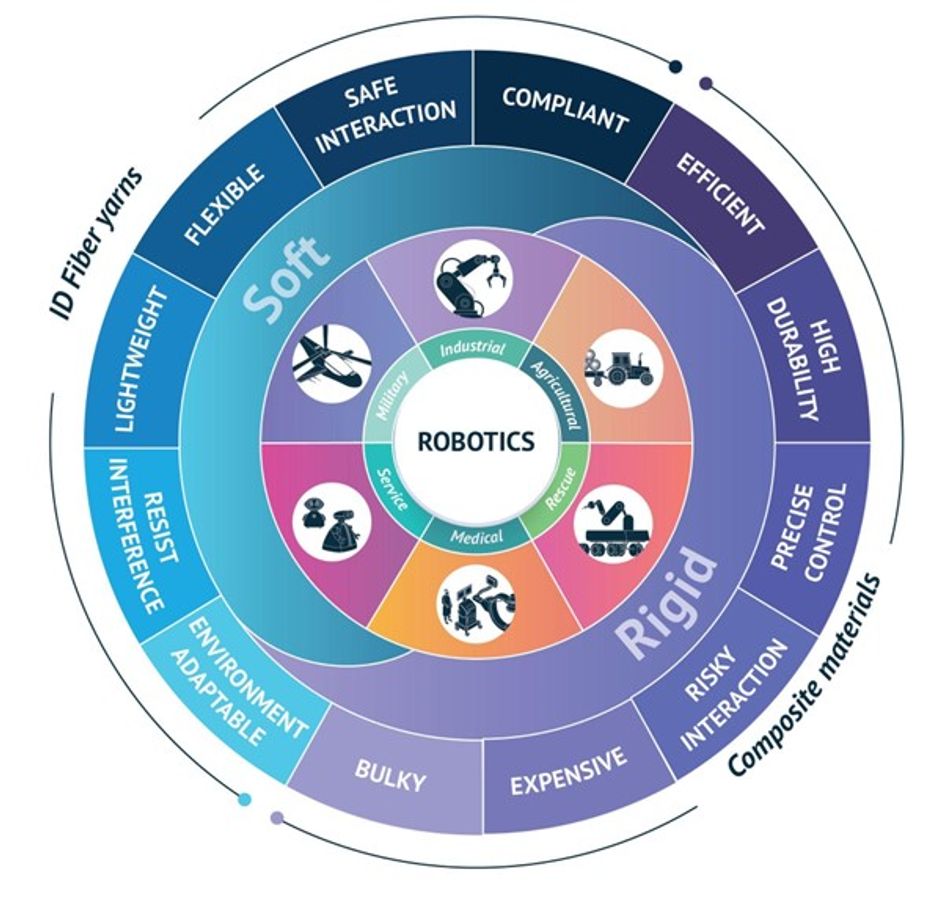

To understand the rapidly advancing field of robotics materials, it is necessary to introduce a distinction between traditional robotics and soft robotics. Traditional robotics relies on mechatronic systems for the design of robots. These robots are typically powered by electromechanical motors and are assembled from independent components and materials, each performing a separate function (actuation, sensing, structural). Traditional robotics is based on rigid materials, such as steel, aluminium, hard plastic, alloys, and composite materials.

On the other hand, soft robotics aims to integrate different functions, including actuation, sensing, adaptivity, and locomotion, into one single material. In this context, soft robots take advantage of smart and multi-functional materials, such as elastomers, gels, fabrics, and biological materials, which allow the body of the robot to comply with the surrounding environment.[3]

Traditional robotics materials

Today, steel, aluminium, cast iron, and hard plastic are among the most frequently used materials for industrial robots. By creating materials that make these robots stronger, lighter, stiffer, and more precise, materials science has considerably supported their success in the industry. Robots, however, have rarely been employed outside of factories, since doing so calls for a level of agility and adaptability that standard robots made of hard materials struggle to provide.

Among the emerging materials for traditional robotics, carbon fibre-reinforced composites can greatly improve energy consumption, performance, and the safety of robots. Since carbon fibre-based composites are much lighter and more durable than metal, these materials are promising for the future of robotics. However, their manufacturing cost is still high and mass production remains challenging.[4]

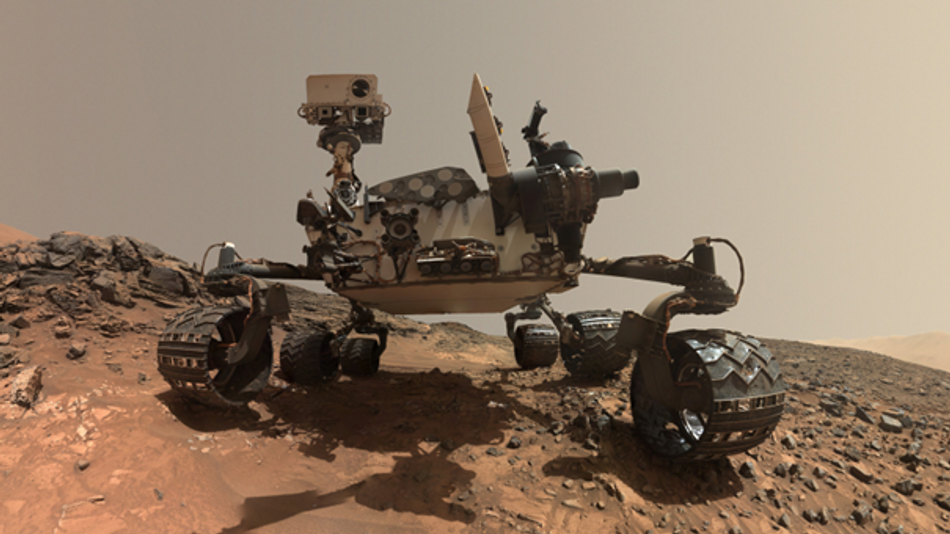

Shape-memory alloys (SMAs), such as the nickel-tin alloy Nitinol, can be programmed to recover a specific shape when heated. Although their applications are still limited, SMAs may gradually replace heavy hydraulic actuators in robots while increasing durability. Nitinol components are already being used in robotics for space applications. The tyres on the NASA Mars Curiosity rover were entirely composed of shape-memory Nitinol.

A new generation of robotics materials

Compared to traditional robotics, soft robotics is based on a new generation of deformable, flexible, and smart materials. One of the main classes of soft robotics materials is elastomeric materials, such as natural and synthetic rubbers, silicones, like polydimethylsiloxane (PDMS), and soft composites. Elastomers are mechanically compliant and have high elastic modulus so that they can recover their shape even after very significant deformations.[5]

The first fully autonomous soft robot was designed in 2016 and features an elastomer-based body.[7] This robot, called “Octobot” from its octopus-inspired shape, is controlled by microfluidic logic and actuated by a gas-producing chemical reaction. It is actuated by an embedded pneumatic network (EPN) that exploits the ability of elastomers to expand without breaking when gas is released. The main advantage of using elastomers compared to rigid materials for robotics is the possibility of movement in limited space and the ability to distribute impact loads more effectively across the entire robot body.

Another class of evolving robotics materials is smart materials. These materials are intrinsically multifunctional, combining sensing, actuation, and structural purposes in a single component. Smart materials can change their shape in response to several stimuli including electric fields, temperature, light, and pH.[3]

Among smart materials, electromechanically active polymers (EAPs), also known as artificial muscles, are deformed in response to applied voltages. In soft robotics, they are used to produce actuators by sandwiching the polymer between two compliant electrodes.[8] Shape-memory polymers, on the other hand, are programmed to recover a specific shape upon heating. These have interesting applications in the aerospace and biomedical fields.[3]

Fabricating soft-bodied robots

Compared to traditional robots, the large-scale fabrication of soft robots is still in its infancy. In recent years, however, new manufacturing possibilities have emerged. Since soft robots are mostly polymer-based, there are two main approaches to their manufacture, namely, cast-moulding, and additive manufacturing.

Cast moulding is commonly used for soft robots that do not require elaborate structures. In the case of silicone rubbers and other catalysed polymers, crosslinking takes place from the mixing of two components; therefore, degassing the polymer mixture before hardening is crucial to prevent defects in the final component. If traditional moulding is not sufficient, approaches such as dip-coating and rotational moulding are effective to shape complex internal volumes.[9]

Additive manufacturing (AM), also known as 3D printing, is the easiest way to shape highly elaborate components. It is based on the deposition of small volumes of materials to create the desired shape. Although it was originally designed only for hard, thermoplastic polymers, in recent years AM has been extended to soft materials such as elastomers and hydrogels, becoming one of the most promising manufacturing approaches for soft robots. In this context, AM techniques have been applied to smart materials, with an approach known as 4D printing.[10] When exposed to specific environmental conditions, 4D-printed components morph into a pre-programmed shape. Read more about the impact of AM in the manufacturing chapter.

Sustainability of robotics materials

Electronic waste, or e-waste, management is one of the most pressing issues of the 21st century. It is estimated that more than 100,000 tons of electronic devices are discarded each day, with only a very small percentage of this waste being recycled. Due to their complex compositions, consumer electronics – which often include rare and toxic materials – are typically landfilled.[6]

Because of this, innovative robotics materials need to take the circularity mindset into account, promoting new and more sustainable technologies. Compared to traditional robotics, soft robotics is an opportunity for the industry to greatly reduce its environmental impact. Because they often rely on multifunctional materials, soft robots have less complex architectures, with the same material often serving multiple purposes (e.g., actuation and structural). Because of this, they are intrinsically easier to recycle.

In addition, biocompatible and biodegradable materials can be used for soft robotics applications. These materials include both natural polymers, such as collagen, cellulose, and chitosan, and synthetic polymers, such as polycaprolactone (PCL) and polylactic acid (PLA).[11] Finally, self-healing materials can be used in soft robotics to significantly extend the lifetime of robots. Self-healing materials incorporate the ability to autonomously repair damage.[12]

Applications for soft robotics

The expected compound annual growth rRate (CAGR) for the soft robotics industry between 2022 and 2027 amounts to 35.1%, with North America as the largest market. This testifies to the growing interest in soft robotics solutions in various fields, with medical and surgical applications predicted to register the highest growth.[13]

In the biomedical field, soft robotics offer unprecedented opportunities to design smart prosthetic limbs at a fraction of the cost required for traditional devices. For example, a soft robotic elastomeric hand (see image below) actuated via a pneumatic system, was recently designed to provide real-time tactile feedback to patients.[14] Soft robotics may also enable growth in minimally invasive surgery (MIS), providing quicker and safer surgical procedures without damaging surrounding tissues.

Another promising field for soft robotics is the production of soft grippers for handling fragile objects. With more and more industries, including the food industry, progressing towards automation, a new generation of versatile robotic grippers is being developed. Due to their light weight, dexterity, and robustness, soft-bodied robots are also a promising technology for space applications.[15]

Overall, the intersection between robotics and materials science offers great opportunities for diverse fields of technology. Thanks to the development of smarter materials and advanced manufacturing techniques, a new generation of soft-bodied, bio-inspired, and sustainable robots are on the rise.

Designing for the future: Understanding Life Cycle Analysis with Protolabs

Life cycle analysis (LCA) is a tool used to evaluate the environmental impact of a product or service throughout its entire life cycle, from raw material extraction to disposal. LCA is essential for designers to understand the impact of their robotics products, provide transparency to potential customers and endeavour to lower environmental impact.

Some of the challenges associated with LCA include:

Data availability: LCA requires a large amount of data, including information on the materials and energy used in production, transportation, use, and disposal. This data can be difficult to obtain, particularly for small or niche products such as robotics.

Complexity: LCA can be a complex process, involving many different stages and multiple impacts. This can make it difficult to compare the environmental impact of different products or services, particularly when working with completely new products and markets.

Uncertainty: There is often a degree of uncertainty in the data used in LCA, which can make it difficult to make definitive conclusions about the environmental impact of a product or service. As robotics is an emerging industry, reliable long term data is harder to acquire.

Relevance: LCA is often used to evaluate the environmental impact of a product or service within a specific context, such as a particular geographic region. This can make it difficult to generalise the results to other regions or contexts.

To overcome these challenges, Protolabs worked with leading designers and engineers at Design Council's Design for Planet festival to develop five tips for including LCA in your next product development.

1. Make sure that you include the planet in the scope of the design brief

To be effective you need to ensure that you think about the effects of the product on the planet and its people within the brief. Think about what is important and how you will measure these impacts.

2. Consider materials carefully and optimise material use for product and packaging

For production, you need to consider how to optimise rather than maximise material use. Leveraging design methodologies, such as generative design, can lead to lean products that are also stronger, lighter, and more aesthetic.

3. Analyse where there are highest levels of waste and energy

The more you understand your own processes and what to measure the better you will be able to pinpoint high levels of waste – whether of raw materials or energy – and then take action to eliminate, reduce or recycle, and reuse. Look for manufacturing partners that also have transparent energy and material information at hand.

4. Design for end of life and disassembly

Abide by Design for Planet principles of circularity and regeneration. The disposal of old products has an impact on the environment, so the challenge is to minimise this by designing it for end of life and disassembly rather than consigning it to landfill. Also consider how the product may be reused beyond its original life, so consider modularity of replacement parts, reuse, and upcycling. And even better, can what you’re designing actually regenerate natural resources?

5. Share what works and what doesn’t so we can learn collectively

We can all learn from our experience so we need an open-source model that demonstrates what works well, supports how things can be done correctly, and helps us to learn from mistakes. Designers need to experiment, try different things, and learn from their collective experience. Consider how you will share your experiences with other designers so that we can all move towards more sustainable products.

The 2023 Manufacturing Robotics Report

Introduction chapter: The 2023 Manufacturing Robotics Report

The 2023 Manufacturing Robotics Report: Materials

The 2023 Manufacturing Robotics Report: Robotic Projects and Tech Specs

The 2023 Manufacturing Robotics Report: Hardware

The 2023 Manufacturing Robotics Report: Manufacturing

References

1. Yang G-Z, Bellingham J, Dupont PE, Fischer P, Floridi L, Full R, et al. The grand challenges of Science Robotics [Internet]. Vol. 3, Sci. Robot. 2018. Available from: http://robotics.sciencemag.org/

2. Fu C, Xia Z, Hurren C, Nilghaz A, Wang X. Textiles in soft robots: Current progress and future trends. Vol. 196, Biosensors and Bioelectronics. Elsevier Ltd; 2022.

3. Mazzolai B, Mondini A, Del Dottore E, Margheri L, Carpi F, Suzumori K, et al. Roadmap on soft robotics: multifunctionality, adaptability and growth without borders. Multifunct Mater. 2022 Sep 1;5(3).

4. Lan X, Zhao X. Application of carbon fiber composite materials in the field of industrial robots. In: ACM International Conference Proceeding Series. Association for Computing Machinery; 2019. p. 310–5.

5. Gariya N, Kumar P. A review on soft materials utilized for the manufacturing of soft robots. In: Materials Today: Proceedings. Elsevier Ltd; 2021. p. 11177–81.

6. Hartmann F, Baumgartner M, Kaltenbrunner M. Becoming Sustainable, The New Frontier in Soft Robotics. Vol. 33, Advanced Materials. John Wiley and Sons Inc; 2021.

7. Wehner M, Truby RL, Fitzgerald DJ, Mosadegh B, Whitesides GM, Lewis JA, et al. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature. 2016;536(7617):451–5.

8. Bar-Cohen Y, Anderson IA. Electroactive polymer (EAP) actuators—background review. Mech Soft Mater. 2019 Dec;1(1).

9. Schmitt F, Piccin O, Barbé L, Bayle B. Soft robots manufacturing: A review. Vol. 5, Frontiers Robotics AI. Frontiers Media S.A.; 2018.

10. Sydney Gladman A, Matsumoto EA, Nuzzo RG, Mahadevan L, Lewis JA. Biomimetic 4D printing. Nat Mater. 2016;15(4):413–8.

11. Rossiter J, Winfield J, Ieropoulos I. Here today, gone tomorrow: biodegradable soft robots. In: Electroactive Polymer Actuators and Devices (EAPAD) 2016. SPIE; 2016. p. 97981S.

12. Terryn S, Langenbach J, Roels E, Brancart J, Bakkali-Hassani C, Poutrel QA, et al. A review on self-healing polymers for soft robotics. Vol. 47, Materials Today. Elsevier B.V.; 2021. p. 187–205.

13. Soft Robotics Market - Growth, Trends, Covid-19 Impact, and Forecasts (2022-2027) [Internet]. Available from: https://www.mordorintelligence.com/industry-reports/soft-robotics-market

14. Gu G, Zhang N, Xu H, Lin S, Yu Y, Chai G, et al. A soft neuroprosthetic hand providing simultaneous myoelectric control and tactile feedback. Nat Biomed Eng [Internet]. 2021; Available from: http://dx.doi.org/10.1038/s41551-021-00767-0

15. Zhang Y, Li P, Quan J, Li L, Zhang G, Zhou D. Progress, Challenges, and Prospects of Soft Robotics for Space Applications. Adv Intell Syst. 2022 June 30;2200071.