Ultra-Precise Deposition for the Fabrication of Next-Generation MicroLED and QD-LED Displays

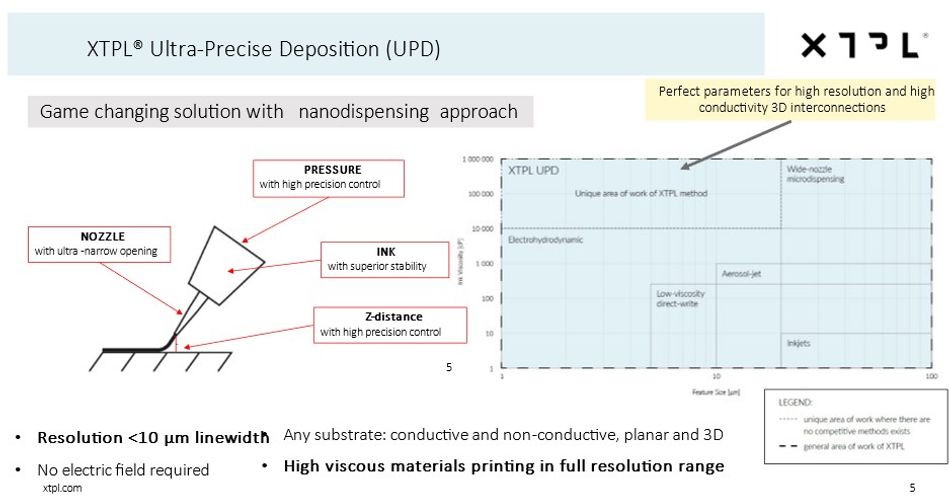

A unique new approach of printing functional materials with unparallel precision and repeatability. Technology called Ultra-Precise Deposition (UPD) is a nanodispensing method capable to print high density and high viscous materials with the resolution down to 1 µm in feature size and with high ratio of width to height after single pass. For this method material extrusion is controlled by a pressure, which means it is not supported with high electric field. Thanks to this there are no limitation if the substrate is conductive or dielectric.

Ultra-Precise Deposition

XTPL developed an unique an totally new approach of printing functional materials with unparallel precision and repeatability. Technology called Ultra-Precise Deposition (UPD) is a nanodispensing method capable to print high density and high viscous materials with the resolution down to 1 µm in feature size and with high ratio of width to height after single pass. For this method material extrusion is controlled by a pressure, which means it is not supported with high electric field. Thanks to this there are no limitation if the substrate is conductive or dielectric.

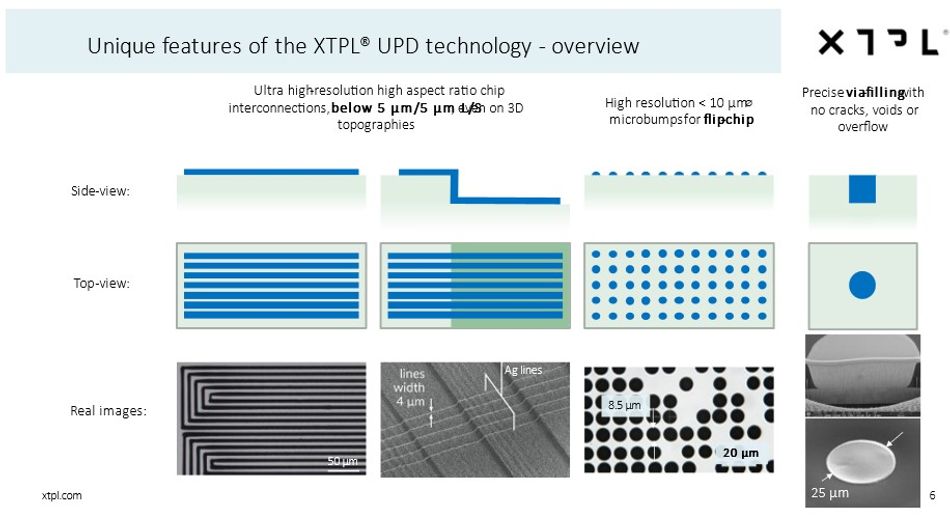

The combination of unique parameters of the UPD approach opens new possibilities, previously not covered by any other printing methods. First of all, the resolution of the conductive traces can reach 1/1 µm L/S. What is more, similar resolution can be achieved even on complex, 3D topographies. This enables printing high density interconnections through even 90° steps (for example wire-bonding alternative for chip interconnections).

Two more unique features were originally tested for conductive structures, but can have a huge benefit for printing other materials like QD ink. These features are micro-bumps deposition and via/micro-cavity filling with the highest repeatability comparing to other printing methods. The biggest needs for QD Color Conversion are ultra-high resolution, possibility of using high solid content inks for high efficiency and repeatability for high homogeneity of the display.

The precise microdots deposition capability can be used for deposition of micro-bumps for flip chip application. Currently the results presented on the slide below are made using highly-concentrated silver paste (CL85). The dot diameter is around 8 µm, and the dot height is around 800 nm, which gives a relatively high aspect ratio compared to printed electronics techniques, like inkjet or EHD, and competitive repeatability. The cross-section analysis of the dots shows parabolic geometry, which, for example, simplifies the deposition of subsequent layers without the risk of cracks. A photo of Albert Einstein made of hundreds of thousands of 8 µm micro-bumps presents also the stability of the process over the time.

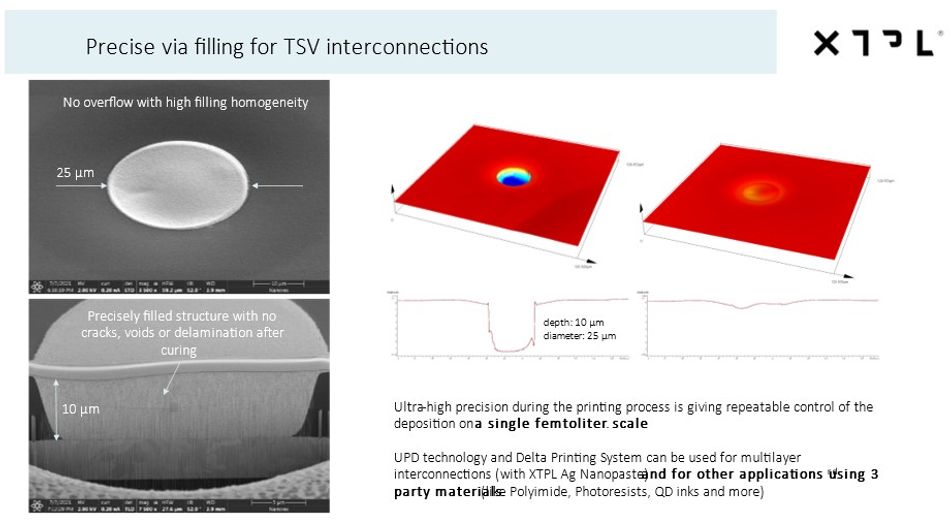

The ability of UPD to extrude ink with femtoliter precision allows not only to print microdots but also to fill microcavities. This feature may help manufacture high-resolution multilayers or through silicon via interconnections. To fill a microcavity, one has to precisely position the printing nozzle and dispense a certain amount of material. In the slide below you can see microcavity with a depth of 10 μm and a diameter of 25 μm, which we uniformly fill with a silver paste (85 wt.% of solid content).

Similar capabilities of precise microcavity filling can be used in deposition of QD material into structures like photoresist windows or nanorings to significantly increase color conversion efficiency (CCE).

Compared to other digital additive manufacturing techniques like inkjet and EHD, UPD technology allows to fill the structures with high uniformity and repeatability with use of inks with higher concentration of QDs. Combination of unique capabilities of the UPD printing method provides a solution for efficient fabrication of QD color conversion for next generation Micro-LED displays.