What is Programmable Automation

Understanding the role of programmable automation in the field of industrial applications, its architecture, implementations, benefits, and standing amongst other types of industrial automation techniques.

Introduction

Programmable automation stands as a cornerstone in the evolution of modern engineering, reshaping industries by introducing advanced control systems and adaptable software configurations. This transformative technology enables machines to execute a variety of tasks with precision and efficiency, catapulting production processes into new realms of automation. Compared to fixed automation, programmable automation allows more flexibility as machines can be reprogrammed to perform various tasks, which directly impacts productivity and efficiency in production lines. With roots stretching back to early computer numerical control (CNC) systems, programmable automation has grown to encompass a wide array of applications—from intricate assembly operations in automotive manufacturing to customized mass production in consumer electronics.

These applications illustrate programmable automation’s pivotal role in driving forward the innovations at the heart of Industry 4.0, not merely enhancing existing practices but also forging new methods in manufacturing and assembly. The exploration of these advancements underscores the breadth and depth of programmable automation’s impact across diverse sectors, signaling its enduring influence on the future directions of engineering.

Suggested Reading: What is Industrial Automation? A Comprehensive Guide

Core Principles Behind Programmable Automation

Understanding Control Systems and Software Architectures

Programmable automation relies on advanced control systems that manage the operation of machines and processes with high precision and minimal human intervention. These systems utilize a variety of control algorithms tailored to specific tasks enhancing the versatility and efficacy of automation solutions.

Real-time processing frameworks play a crucial role in enabling prompt response to process changes and maintaining continuous production without delays.

In terms of software architectures programmable automation systems are built on principles of modularity and scalability. This approach allows for:

Easy integration of new modules without disrupting existing operations.

Scalability to increase production capacity or add functionalities with minimal adjustments.

Flexibility in customizing operations to meet specific requirements of different industries.

Such architectural foundations provide the infrastructure needed for robust and adaptable automation systems that can evolve with technological advancements and changing industry demands.

How PLC’s and RTUs Fit in the Scope of Programmable Automation

Just like in any other type of automation, Programmable Logic Controllers (PLCs) and Remote Terminal Units (RTUs) have an essential role in programmable automation systems. They work together to control and monitor industrial processes.

Programmable Logic Controllers:

Brain of the System: PLCs are the central control units that execute programs to control various devices and processes.

Input/Output Capabilities: They have digital and analog input/output modules to interface with sensors, actuators, and other devices.

Programming: PLCs are programmed using specialized software to define the logic and sequence of operations.

Real-time Control: They can make decisions and respond to changes in real-time, ensuring efficient and reliable operation.

Remote Terminal Units:

Remote Control: RTUs are remote devices that can be controlled and monitored by a central PLC or SCADA system.

Data Acquisition: They collect data from various sensors and transmit it to the PLC for processing.

Control Functions: RTUs can execute simple control functions locally, but often rely on the PLC for complex decision-making.

Communication: RTUs communicate with the PLC using various protocols like Modbus, DNP3, or proprietary protocols.

Here is how these two components work together in a programmable automation system:

Data Acquisition: RTUs gather data from sensors (e.g., temperature, pressure, flow rate) and transmit it to the PLC.

Control Decisions: The PLC processes the received data, compares it with setpoints, and makes control decisions.

Command Execution: The PLC sends commands to the RTUs to control actuators (e.g., valves, motors) based on the control decisions.

Monitoring: The PLC continuously monitors the process and adjusts control actions as needed.

Suggested Reading: What is PLC? An Integral Component of Industrial Automation

The Role of Sensors and Actuators

Sensors and actuators are the linchpins of programmable automation systems translating digital commands into physical actions and providing real-time data essential for automation.

Sensors

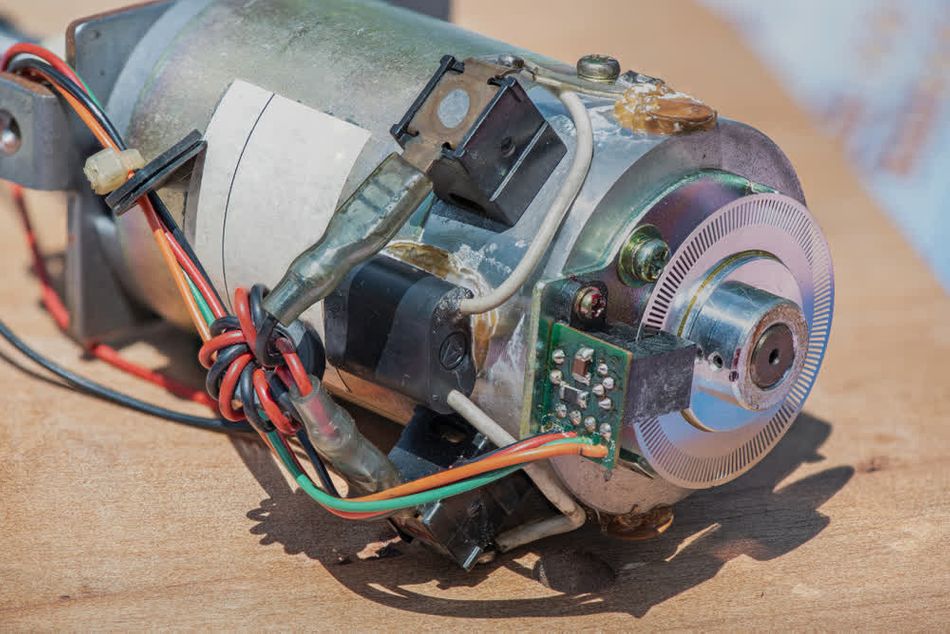

Sensors detect environmental and system inputs which are critical for precise operations such as temperature pressure or proximity. Commonly integrated sensors in automation include photoelectric sensors for detecting object presence without contact and temperature sensors critical in regulated environments like pharmaceutical manufacturing. In programmable automation, CNC machines typically use optical encoders for positioning feedback from motors.

Actuators

Actuators act upon these inputs executing movements and operations like rotations positioning or controlled pressures that drive the actual automation process. Actuators such as servo motors enable precise control in robotics and pneumatic cylinders are extensively used for quick forceful movements in assembly lines.

Together, these components create a synergy that underpins the functionality and sophistication of modern automated systems, ensuring seamless, efficient, and responsive operations to dynamic operational conditions.

Cutting-Edge Innovations in Programmable Automation

Advancements in Machine Learning Algorithms

Machine learning algorithms have significantly advanced programmable automation especially in areas such as predictive maintenance and operational optimizations. These algorithms enable systems to predict potential failures and optimize processes autonomously increasing efficiency and reducing downtime. Neural networks for instance can analyze and learn from huge datasets to recognize patterns that precede equipment failures.

Similarly, decision trees help in decision-making processes by simplifying complex decision paths into more manageable branches which enhances operational efficiency.

For example in automotive manufacturing neural networks are used to predict the wear and tear of machinery parts allowing timely maintenance schedules that prevent unexpected breakdowns.

Integration with the Internet of Things (IoT)

The convergence of programmable automation with Internet of Things (IoT) technologies represents a significant leap forward in engineering capabilities enabling more dynamic connected and efficient systems. Key aspects of this integration involve sophisticated communication protocols like MQTT (Message Queuing Telemetry Transport) and CoAP (Constrained Application Protocol) which facilitate reliable and secure data exchange between devices and platforms even in high-latency networks.

This integration significantly improves system responsiveness and flexibility. It allows for real-time monitoring and control which are crucial for optimizing operational efficiency and predictive maintenance schedules. Enhanced functionalities include improved asset tracking inventory management and energy consumption optimization which directly benefit sectors such as manufacturing healthcare and urban planning.

Among the notable projects leveraging both programmable automation and IoT smart factories stand out. These facilities use interconnected sensors and actuators to monitor production lines automatically adjusting operations in response to sensor data to minimize downtime and reduce waste. Another example is in precision agriculture where IoT-enabled devices provide data to automate irrigation and fertilization processes enhancing yield and sustainability.

Suggested Reading: What Is IIoT?

Integration with SCADA Systems

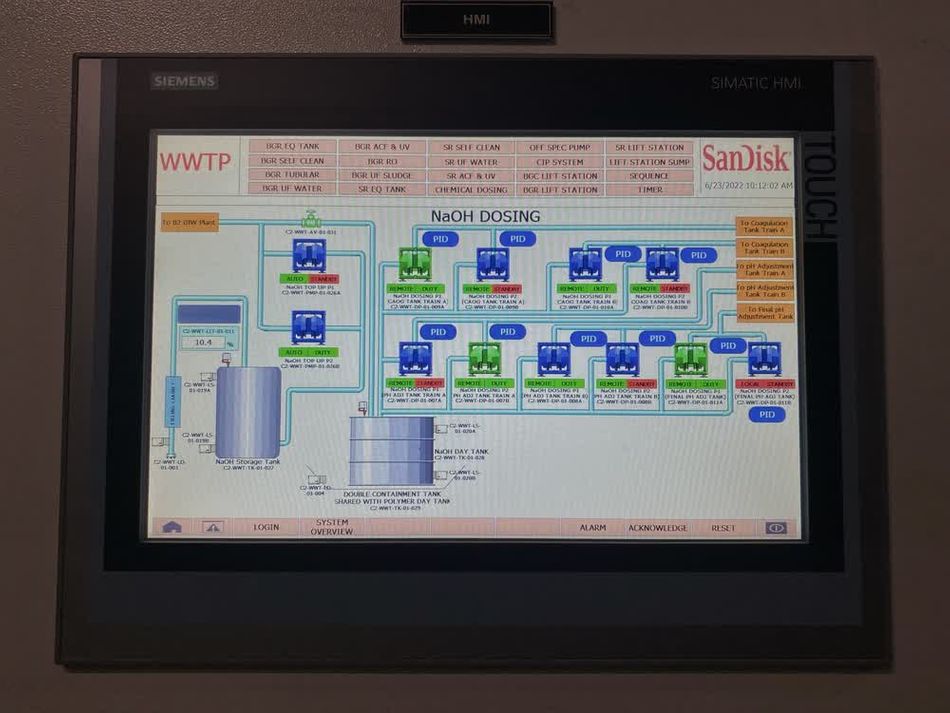

SCADA (Supervisory Control and Data Acquisition) systems are powerful tools that, when integrated with programmable automation, enable efficient and reliable control of industrial processes.

Data Acquisition: SCADA systems collect real-time data from various sources, including PLCs, RTUs, and sensors. This data provides insights into the process's status, performance, and potential issues.

Process Monitoring: The collected data is displayed on human-machine interfaces (HMIs), allowing operators to monitor the process and identify anomalies.

Control and Automation: SCADA systems can control and automate various aspects of the process, such as starting and stopping equipment, adjusting parameters, and responding to alarms.

Alarm and Event Management: SCADA systems can generate alarms and notifications for critical events, such as equipment failures, process deviations, or security breaches.

Historical Data Storage: SCADA systems store historical data for analysis, trend identification, and optimization purposes.

Benefits of SCADA Integration with Programmable Automation:

Enhanced Efficiency: Optimized process control and reduced downtime.

Improved Safety: Real-time monitoring and automated responses to potential hazards.

Better Decision Making: Data-driven insights for informed decision-making.

Remote Monitoring and Control: Remote access to the system for monitoring and control.

Increased Productivity: Automation of repetitive tasks and optimization of resource utilization.

Example: Water Treatment Plant

In a water treatment plant, SCADA systems can monitor parameters like pH, chlorine levels, and flow rates. If any parameter deviates from the setpoint, the SCADA system can automatically adjust control valves or chemical dosing to bring the process back to normal. Additionally, SCADA systems can generate alarms and notifications to alert operators of potential issues, allowing for timely intervention

Visualizing Programmable Automation - Examples from the Industry

Programmable automation is applied across the industrial spectrum in different ways. In this section, we discuss some of the major applications of programmable automation.

CNC Machines

CNC (Computer Numerical Control) machines are a prime example of programmable automation in manufacturing. These machines are controlled by computer programs that dictate the precise movements of cutting tools to shape and machine various materials.

How it works:

Program Creation: A CNC programmer creates a program using specialized software, defining the desired shape, dimensions, and cutting paths.

Code Input: The program, often in G-code or similar format, is input into the CNC machine's control unit.

Machine Control: The control unit interprets the code and sends signals to the machine's motors and drives.

Tool Movement: The machine's tools, such as drills, mills, or lathes, move in precise motions to shape the material.

The advantages of programmable automation in CNC Machines are:

Precision: CNC machines can achieve high levels of accuracy and repeatability.

Flexibility: They can be reprogrammed to produce different parts, making them adaptable to various manufacturing needs.

Efficiency: Automated processes reduce labor costs and increase production rates.

Complex Shapes: CNC machines can create intricate and complex shapes that would be difficult or impossible to produce manually.

Example:

Consider a CNC milling machine used to create a custom metal part. The programmer designs the part's shape on computer-aided design (CAD) software and generates the G-code. This code is then input into the CNC machine's control unit. The machine's motors, driven by the control unit, move the cutting tool in precise X, Y, and Z axes to remove material and shape the part according to the G-code instructions.

Industrial Robots

Industrial robots are another prime example of programmable automation. These robots are equipped with mechanical arms and grippers, controlled by sophisticated software. They can perform a wide range of tasks with precision and speed.

How it works:

Programming: Engineers program the robot's movements and actions using specialized software. This involves defining the robot's path, speed, and the tasks it needs to perform.

Execution: The robot's control system interprets the program and sends signals to its actuators, which control the movement of its joints.

Task Performance: The robot executes the programmed tasks, such as picking and placing objects, welding, painting, or assembly.

Example:

In automotive manufacturing, robots are extensively used for tasks like welding, painting, and assembly. A robotic arm can be programmed to weld specific parts of a car body with high precision and consistency. The robot's movements are controlled by a computer program that defines the welding path, speed, and welding parameters. This automation not only improves efficiency but also ensures the quality and consistency of the final product.

Benefits of Programmable Automation in Industrial Robots:

Increased productivity: Robots can work tirelessly, 24/7, without breaks or fatigue.

Improved quality: Consistent performance and precision reduce defects.

Enhanced safety: Robots can handle dangerous tasks, reducing the risk of workplace injuries.

Flexibility: Robots can be reprogrammed to perform different tasks, adapting to changing production needs.

Cost-effectiveness: In the long run, automation can lead to significant cost savings.

Robotic surgery is another prime example of programmable automation in healthcare, involves the use of robotic arms controlled by surgeons to perform minimally invasive procedures.

How it works:

Precise Control: Surgeons use specialized consoles to control the robotic arms, which translate their hand movements into precise actions.

Enhanced Vision: High-definition 3D cameras provide surgeons with magnified views of the surgical site.

Minimally Invasive Procedures: Robotic arms allow for smaller incisions, reducing patient trauma and recovery time.

Improved Accuracy: Robotic arms offer greater precision and dexterity compared to human hands, leading to more accurate and controlled surgical procedures.

Suggested Reading: No Code Robotics Enable Automation For Everyone

Summarizing the Benefits and Drawbacks of Programmable Automation

Programmable automation is an innovative addition to industrial automation. However, it comes with its own set of pros and cons. Here is a quick review of its major benefits and potential drawbacks.

Benefits of Programmable Automation

Flexibility - Programmable automation can adapt to various tasks and products, making it ideal for dynamic production environments.

Cost-Effective for Multiple Products - Reprogramming reduces the need for new equipment, making it efficient for diverse product lines.

Suitable for Medium-Volume Production - Balances flexibility and efficiency for moderate production runs.

Disadvantages of Programmable Automation

Slower Production Speed - Compared to fixed automation, it may have lower production rates.

Increased Complexity - Requires skilled programmers and complex control systems.

Moderate Initial Investment - Significant upfront costs for programmable equipment and software.

How Programmable Automation Compares with Other Automation Types

Industrial automation has several types and programmable automation provides multiple advantages against its contemporaries. Here is a quick comparison of programmable automation with major automation types.

Flexibility—Programmable automation allows the user to program the same machine for different tasks so that it can handle a range of operations. On the other hand, fixed automation has no room for flexibility and only addresses specific tasks. Likewise, flexible automation combines fixed and flexible automation, offering medium flexibility.

Initial Cost - Programmable automation is moderately costly as it involves programming and control system updates. On the other hand, fixed automation requires task-specific equipment so its initial cost is much higher. Similarly, flexible automation has a relatively higher initial cost due to the involvement of complex robotic systems.

Operational Cost - Programmable automation involves a medium operational and maintenance cost and adds energy consumption cost due to regular programming. Fixed automation has a low operational cost while flexible automation offers a mid-range operational cost.

Product Variety - Since programmable automation can perform various tasks, it has a wider range of product variety. Fixed automation can handle a highly limited product range while flexible automation offers a mid-range flexibility in terms of product variety.

Production Rates - Programmable automation has a medium to high production rate, based on the programming complexity. Fixed automation has a higher production rate while flexible automation also offers a medium to high range of production rate.

The following table summarizes the comparison of programmable automation with other automation types.

Feature | Programmable Automation | Fixed Automation | Flexible Automation |

Flexibility | High | Low | Medium |

Initial Cost | Medium | High | High |

Operating Cost | Medium | Low | Medium |

Product Variety | High | Low | Medium |

Production Rate | Medium | High | Medium |

Suggested Reading: 6 Types of Automation: A Comprehensive Guide for Engineers

Overcoming Challenges in Programmable Automation

Handling System Complexity and Scalability Issues

Addressing complexity in design and scalability issues is pivotal in the development of programmable automation systems. As systems grow in scale and functionality managing their complexity without compromising performance becomes increasingly challenging.

Technical solutions to these challenges include modular design principles that allow systems to be expanded or modified without extensive reconfigurations. Scalability is also facilitated by employing advanced software frameworks that can dynamically adjust resources based on real-time demands.

Recent breakthroughs in both software and hardware have significantly improved scalability features. For instance, containerization technology allows individual parts of systems to be isolated and scaled independently enhancing both security and performance.

On the hardware front developments in multi-core processors and scalable cloud infrastructures enable systems to handle larger data loads and more complex processing tasks efficiently and cost-effectively.

Security Concerns in Automated Systems

Security within programmable automation systems is paramount as these systems often control critical infrastructure and sensitive data. Key security risks include unauthorized access data breaches and disruptions to operational integrity.

To mitigate these risks a variety of strategies and technologies are employed.

Encryption plays a crucial role in protecting data in transit and at rest ensuring that even if data is intercepted it cannot be easily deciphered.

Secure protocol design is another critical measure; protocols such as TLS (Transport Layer Security) and IPSec (Internet Protocol Security) are widely implemented to secure communications between devices and networks in automated systems.

Additionally, regular security audits and updates are performed to strengthen systems against emerging threats and vulnerabilities.

Conclusion

Programmable automation stands as a cornerstone in the ongoing evolution of engineering, offering transformative capabilities that extend well beyond current applications. Its potential to further enhance efficiency, reduce operational costs, and foster innovation ensures its relevance in the future landscape of global industries. These benefits are paired with responsive adaptations to challenges such as system complexity, scalability issues, and security concerns—issues that are continually addressed through technological advancements and strategic implementations.

As the field progresses, the integration of emerging technologies such as artificial intelligence and the Internet of Things (IoT) promises to elevate the capabilities of programmable automation systems even further. This ongoing innovation cycle not only solves existing challenges but also opens new avenues for application, securing a pivotal role for programmable automation in shaping future engineering endeavors.

FAQS

What is the initial cost implication of implementing programmable automation?

The initial costs can vary significantly based on the complexity and scale of the automation system. Generally, it includes expenses for hardware, software, system integration, and employee training. Long-term savings in labor and operational efficiency often offset these initial investments.

How does programmable automation contribute to sustainability in engineering practices?

Programmable automation optimizes the use of resources, reduces waste, and improves energy efficiency. Automated systems can be programmed for precise material handling and optimal machinery use, leading to significant reductions in energy and material consumption.

What are the career implications for engineers specializing in programmable automation?

As the demand for automation grows, engineers with expertise in programmable automation are increasingly sought after. Specializing in this field can lead to career opportunities in industries such as manufacturing, automotive, and electronics, where process efficiency and innovation are highly valued.

What is the initial cost implication of implementing programmable automation?

The initial costs can vary significantly based on the complexity and scale of the automation system. Generally, it includes expenses for hardware, software, system integration, and employee training. Long-term savings in labor and operational efficiency often offset these initial investments.

How does programmable automation contribute to sustainability in engineering practices?

Programmable automation optimizes the use of resources, reduces waste, and improves energy efficiency. Automated systems can be programmed for precise material handling and optimal machinery use, leading to significant reductions in energy and material consumption.

What are the career implications for engineers specializing in programmable automation?

As the demand for automation grows, engineers with expertise in programmable automation are increasingly sought after. Specializing in this field can lead to career opportunities in industries such as manufacturing, automotive, and electronics, where process efficiency and innovation are highly valued.

References:

Table of Contents

IntroductionCore Principles Behind Programmable AutomationUnderstanding Control Systems and Software ArchitecturesHow PLC’s and RTUs Fit in the Scope of Programmable AutomationThe Role of Sensors and ActuatorsCutting-Edge Innovations in Programmable AutomationAdvancements in Machine Learning AlgorithmsIntegration with the Internet of Things (IoT)Integration with SCADA SystemsVisualizing Programmable Automation - Examples from the IndustryCNC MachinesIndustrial RobotsSummarizing the Benefits and Drawbacks of Programmable AutomationBenefits of Programmable Automation Disadvantages of Programmable AutomationHow Programmable Automation Compares with Other Automation TypesOvercoming Challenges in Programmable AutomationHandling System Complexity and Scalability IssuesSecurity Concerns in Automated SystemsConclusionFAQS