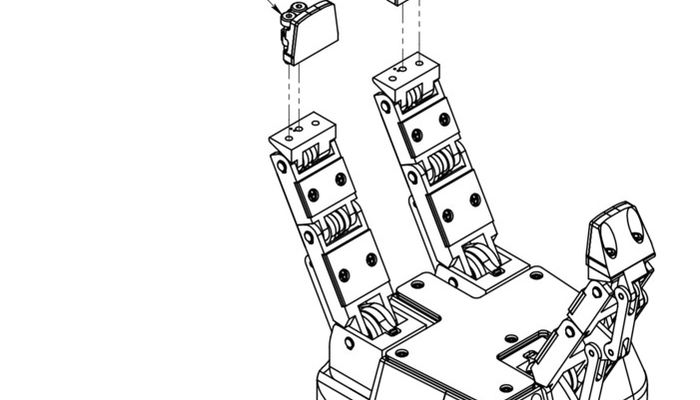

3-Finger Adaptive Robot Gripper

A 3-finger robot hand with force torque sensor which can hand pick an object and measure it's weight. A 3-finger adaptive gripper is for advanced manufacturing and robotic research. It adapts to the object’s shape for a solid grip, which enables the user to focus on the task and not the grasping. The Adaptive Gripper has three articulated fingers, that each have three joints (three phalanxes per finger) The Gripper can engage up to ten points of contact with an object (three on each of the phalanges plus the palm).

Technical Specifications

| Gripper Opening | 0 to 155 |

| Gripper Weight | 2.3 |

| Object diameter for encompassing | 20 to 155 |

| Maximum recommended payload (encompassing grip) | 10 |

| Maximum recommended payload (fingertip grip) | 2.5 |

| Grip force (fingertip grip) | 30 to 70 |

| Output Voltage | 24 |

| Output Current | 2 |

| Ripple | 2-3 |

| Output Regulation | 10 |

Overview

Operation Mode

Two different types of movements can be performed with the Gripper. The first determines the type of grip being used and simultaneously changes the orientation of Fingers B and C. This movement is referred to as the 'Operation Mode'. The Operation Mode is determined by the user before the grip as a function of the size or shape of the object being gripped and for the task that has to be done.

Operation Modes:

- The basic mode is the most versatile Operation Mode. It is best suited for objects that have one dimension longer than the other two. It can grip a large variety of objects.

- The wide mode is optimal for gripping round or large objects.

- The pinch mode is used for small objects that have to be picked precisely. This Operation Mode can only grip objects between the distal phalanxes of the fingers.

- The scissor mode is used primarily for tiny objects. This mode is less powerful than the other three modes but is precise. In scissor mode, it is not possible to surround an object. Here, FingersB and C move laterally towards each other while Finger A remains still.

The second movement of the Gripper is the closing and opening of the fingers. This action is performed with a single input from the user. Each finger is not controlled independently; the Gripper itself closes each finger until it reaches a stable configuration, on an object or against the Gripper palm. Note that a user can specify the relative speed at which the fingers will close and the relative force that will be applied to an object.

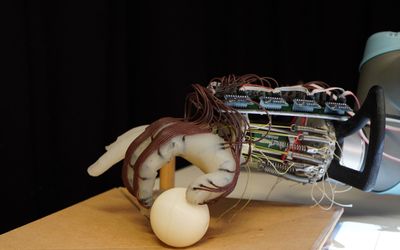

Two types of grips occur when closing the 3-Finger Adaptive Robot Gripper on an object: Fingertip Grip or Encompassing Grip.

- The Fingertip Grip is when an object is only held by the distal phalanxes. This type of grip is similar to what is done with conventional industrial parallel grippers. In this situation, the stability of the grip is maintained because of the friction between the fingers and the object.

- The Encompassing Grip is when the fingers surround an object. The object is encompassed within the fingers and the stability of the grip is no longer related to friction. We suggest using the Encompassing Grip whenever possible to increase grip stability.

Power supply

The Gripper needs to be supplied by a DC voltage source. This power supply is not included with the Gripper. The following table shows the specifications regarding the power supply required to operate the Gripper properly. The gripper requires an output voltage of 24 V DC and a current of 2 Ampere.

Control

The Robotiq 3-Finger Adaptive Robot Gripper is controlled from the robot controller using an industrial protocol (EtherNet/IP, DeviceNet, CANopen, EtherCat, etc.). The programming of the Gripper can be done with the Teach Pendant of the robot or by offline programming. Since the Robotiq 3-Finger Gripper has its internal controller, high-level commands such as "Go to requested position" are used to control it. The embedded Robotiq controller takes care of the regulation of the speed and the force prescribed, while the mechanical design of the fingers automatically adapts to the shape of the object(s)

The Gripper controller has an internal memory that is shared with the robot controller. One part of the memory is for the robot output, gripper functionalities. The other part of the memory is for the robot input, gripper status. Two types of actions can then be done by the robot controller:

- Write in the robot output registers to activate functionalities

- Read in the robot input registers to get the status of the Gripper.

References

Contains a general presentation of the robotic gripper, the installation instructions, the user interface, maintenance and more.

Contains multiple video's of this robotic gripper in action.