Amphenol Commercial Waterproof USB Type-C Connectors

Waterproof USB Type-C connectors with IPX8 protection.

Technical Specifications

| Product Category | USB Type-C Connectors |

| Supported Protocols | USB 2.0, USB 3.2 Gen 1, Gen 2, and USB 4 |

| Durability | 10000 cycles |

| Power Rating | Up to 240W |

| High-Speed Transmission | Up to 40Gb/s |

| Waterproof Rating | IPX8 |

| Applications | Medical, Data, Automotive, Marine, Outdoor Electronics, Industrial and Instrumentation |

Overview

The Waterproof USB Type-C Connectors fromby Amphenol Commercial are designed for applications demanding high-speed data transmission, audio, and video signals. These connectors support USB 2.0, USB 3.1 Gen 1 and Gen 2, USB 3.2, and USB 4, enabling speeds up to 40Gb/s and power ratings up to 240W. Designed for durability, the connectors feature IPX8-rated waterproofing, ensuring reliable performance even in challenging conditions.

Their low-profile, reversible design enhances usability, while their copper alloy terminals ensure superior signal integrity. This makes them ideal for industrial, medical, automotive, and communication applications. With optimized contact design for superior signal integrity, these connectors are perfect for emerging high-speed, audio, and video product designs.

Waterproof USB Type-C Connectors Features

Waterproof USB Type-C Connectors offer a convenient all-in-one solution, combining power delivery, data transfer, and video output capabilities within a single connector. This streamlined design simplifies integration and reduces the need for multiple cables and connectors, providing a more efficient and user-friendly experience. Let’s explore some of their notable features:

Protocol Support and Power Delivery

Amphenol Commercial Waterproof USB Type-C Connectors support a wide range of USB protocols, including USB 2.0, USB 3.2 Gen 1, USB 3.2 Gen 2, and USB 4. This flexibility allows the connectors to meet the needs of diverse applications, from data transfer to video output and high-power delivery. With a current rating of up to 5A and power delivery of up to 240W, these connectors are optimized for fast charging and high-power devices.

High-Speed Transmission and Versatility

These connectors support a wide range of USB protocols, including USB 2.0, USB 3.2 Gen 1, Gen 2, and USB 4. Capable of achieving transmission speeds of up to 40Gb/s, they are optimized for high-speed data, audio, and video signal output. The connectors feature a 24-pin assignment, making them suitable for various protocol requirements. They are also backwards compatible with older USB versions, ensuring broad applicability.

Durability and Mechanical Performance

Designed for durability, Waterproof USB Type-C Connectors are built to withstand up to 10,000 mating cycles. They feature a mid-plate tongue design that improves reliability and prevents damage due to mishandling. The connectors also meet stringent mechanical performance standards, with insertion forces between 5N to 20N and extraction forces between 8N to 20N, ensuring long-lasting, reliable connections.

Waterproof Technology

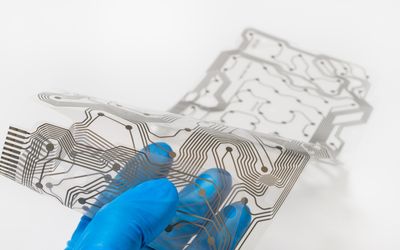

The connectors are designed with unique liquid silicone rubber (LSR) technology and an O-ring sealing system, achieving IPX4 to IPX8 waterproof ratings. This ensures reliable performance in harsh environments where moisture resistance is critical. The liquid silicone rubber bonds with the outer shell, preventing water ingress and enhancing the connector's durability.

Applications

The Waterproof USB Type-C Connectors find wide application in various industries due to their robust design and reliable performance. In the automotive sector, they are used in car media players, hubs, and chargers, ensuring reliable connectivity and power delivery. Consumers benefit from these connectors in devices such as connector hubs, flash drives, mobile phones, tablets, and VR cameras. In the data storage industry, these connectors are employed in hard disk drives and solid-state drives. Industrial and instrumentation applications include industrial computers and point-of-sale systems, where their durability and reliability are crucial. These connectors are also utilized in medical equipment, where their resistance to moisture and harsh environments is essential for ensuring safe and effective operation.

Where to find it

Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components.