MARBLE - Mobile Autonomous RoBot for Litter Emptying

An autonomous mobile robot with an arm developed for opening and emptying litter bins.

Technical Specifications

| Base Platform | Innok Robotics GmbH |

| Hub Drives | Number: 4 |

| Battery | 960 Wh |

| Robot Arm | Model: Jaco (Kinova) |

| Object Detection: Intel Real Sense Camera | |

| Navigation | Several sensors |

| Obstacle detection | Two 2D LIDAR sensors; ultrasonic sensors |

| Self-localization | IMU; GPS; speed sensor |

| Container volume capacity | 140L (4 load of wastes; 35L each load) |

| Compression rate of built-in press | 3:1 |

Overview

This tech spec was submitted by Michel van der Schoor as part of the University Technology Exposure Program.

Problem / Solution

Berliner Stadtreunigung (BSR) is Berlin’s municipal waste management or garbage collection service. They clean the streets and empty the trash bins through conventional human labor and garbage trucks. However, the trucks take up a lot of the street space, consume a lot of fuel, and must be accompanied by a few personnel. With the advent of new technology, the old-fashioned method of gathering garbage from litter bins can be significantly optimized to be more efficient and avoid carbon dioxide emissions.

MARBLE is an automated robot developed for urban services, specifically emptying litter bins. The goal is to support the current service and improve city waste management for a cleaner and healthier environment in the city. MARBLE approaches the garbage containers from the pedestrian’s side and does not interfere with the street traffic. This electronic robot is an alternative to the gas-powered vehicle to decrease the local emission of CO2 and contribute to developing a sustainable city.

Design

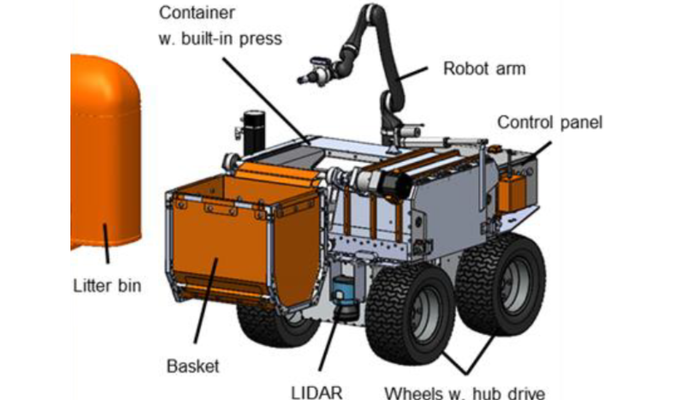

MARBLE primarily comprises a base platform with the control panel and interface module with a robotic arm and container with a built-in press.

The base platform carries the interface module on the top. It is powered by a 960Wh battery and has four hub drives or wheels, providing a long active time and high maneuverability on the city terrain.

The control panel at the back connects all the actuators and sensors with the computer and controller. Several sensors attached in front and rear supports MARBLE’s autonomous navigation. Two 2D LIDAR sensors and some ultrasonic sensors detect any obstacles coming into the robot’s pathway. An IMU, GPS, and speed sensor provides the robot with self-localization.

The interface module on top of the base platform holds a service module. It is designed to be compatible with different service modules that carry out a variety of services needed in an urban environment. MARBLE’s service module of a robot arm and container with a built-in press is for emptying litter bins.

A robot arm with a specifically designed tool to open the litter bins is installed on top of the interface module. The arm has an intel real sense camera attached to detect the litter bins and the open mechanism via object detection. Instead of the usual triangular socket, a tool with a spring mechanism for opening the bins snaps into the lock when pressed against it and rotates.

The basket in front catches the waste from the litter bin, then conveys it to the press. To unload the trash, the far side of the container opens up, and the piston used for compression pushes everything out to be compressed. The basket also closes the litter bin by simply pressing the bottom plate back into the lock.

The container with a built-in press takes up most of the space of the prototype and interacts with the litter bins in Berlin. The maximum volume capacity of the container is about 140L or four loads of waste, with each waste about 35L. The built-in press can achieve a compression rate of 3:1.

Currently, MARBLE is a prototype. The researchers are presently exploring a new concept of using a magnet and a small electro-magnetic lever instead of a lock and a robot arm.

References

Recommended Specs

Continue Reading

Investigating the carbon implications of AM-enabled distributed production of spare parts in the automotive industry

A student write-up that tries to compare the environmental impact and complexity of manufacturing automobile parts through conventional methods and modern distributed manufacturing techniques like 3D printing.