YuMi - IRB 14000

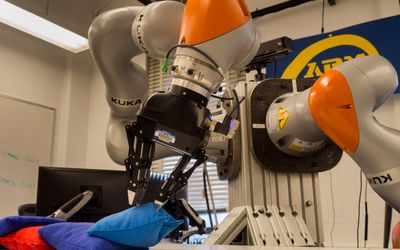

YuMi is specifically designed to meet flexible and agile production needs of the consumer electronics industry. The robot has equal application in any small parts assembly environment thanks to its dual arms, flexible hands, universal parts feeding system, camera-based part location, lead-through programming, and state-of-the-art precise motion control.

Specifications

| Payload | 0.5 |

| Reach | 559 |

| Accuracy | 0.02 |

| Footprint | 339 x 497 |

| Mounting interface | |

| Mounting position | |

| Weight | 38 |

Overview

The robot has equal application in any small parts assembly environment thanks to its dual arms, flexible hands, universal parts feeding system, camera-based part location, lead-through programming, and state-of-the-art precise motion control.

YuMi can operate in very close collaboration with humans thanks to its design. It has a lightweight rigid magnesium skeleton covered with a floating plastic casing wrapped in soft padding to absorb impacts. YuMi is compact, with human dimensions and human movements.

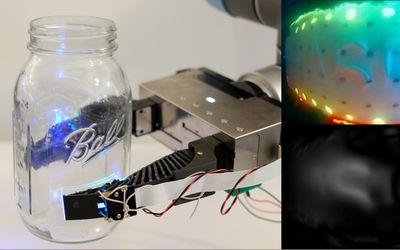

If YuMi senses an unexpected impact, such as a collision with a coworker, it can pause its motion within milliseconds, and the motion can be restarted by pressing play on a remote control. YuMi also has no pinch points so that nothing sensitive can be harmed as the axes open and close.

References

An overview and vision of the technology. Followed up with technical data. Describes the integration. Explains the table mounting, and the controller. Lastly it describes the key applications, and segments.