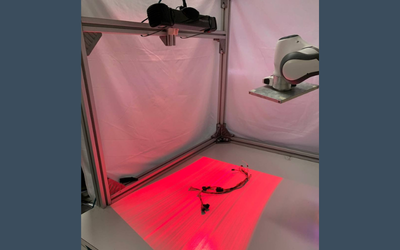

In this application by Rossum Integration s.r.o., empty crates are scanned with the Photoneo PhoXi 3D Scanner to make sure they are not contaminated by candy products previously filled in the crates. After the contamination control, the crates are filled with a material and manipulated by a robot equipped with a special effector, which can grab 4 crates simultaneously.

Tagged with

automation

ORGANIZATIONS. SHAPING THE INDUSTRY.

READY Robotics

Robotics & Automation

READY Robotics is a robotics software company that vastly simplifies robot ...

24 Posts

Avestec Technologies

Automation Machinery Manufacturing

We are a company in flying robotics, specializing in Non-destructive inspec...

23 Posts

Adapta Robotics

Robotics, R&D

Automate Advance Adapt. Enhancing human potential through robotic automatio...

12 Posts

View more

Latest Posts

FFF 3D Printing technology provides Prodrive with a huge range of possibilities to transform the manufacturing and production process for the actual racing cars they produce

World-leading motorsport and advanced technology company Prodrive has implemented additive manufacturing technology to print parts for production use for the actual racing vehicles they build and provide them with a huge range of possibilities that traditional manufacturing methods couldn’t.

RMC Motorsport drastically reduces its production times and manufacturing costs by 3D printing end-use parts for their rally cars

RMC Motorsport, an automotive company dedicated to the rally sector, has internalized & optimized internal processes and achieved greater design capacity by involving 3D printing technology in the manufacturing process of their rally cars.

The client, one of the world's leading manufacturer of automation machines, found RPWORLD to provide qualified prototypes and low volume solutions for monthly order of 40 units. They had a new tooling machine under R&D stage, a key component, the impeller assembly failed, which caused delay of the whole product development process.So the client contacted RPWORLD to address the delay problem.

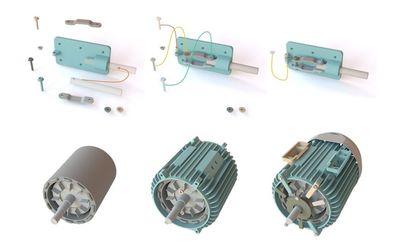

The manufacturing industry (largely) welcomed artificial intelligence with open arms. Less of the dull, dirty, and dangerous? Say no more. Planning for mechanical assemblies still requires more than scratching out some sketches, of course — it’s a complex conundrum that means dealing with arbitrary 3D shapes and highly constrained motion required for real-world assemblies.