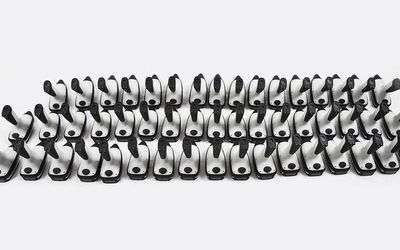

What are Robotic Assembly Lines? History, Components, Advantages, Limitations, Applications, and Future

Robotic assembly lines have revolutionized production processes, enabling manufacturers to achieve high levels of efficiency, productivity, and quality.