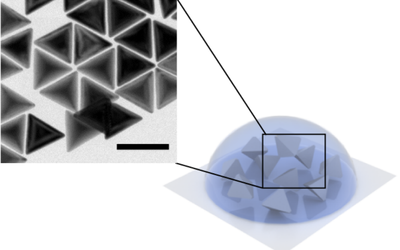

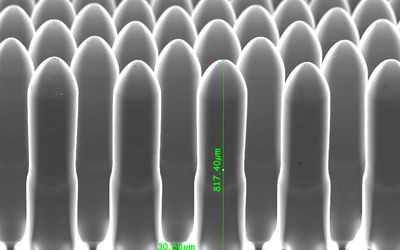

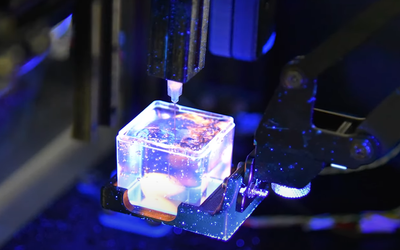

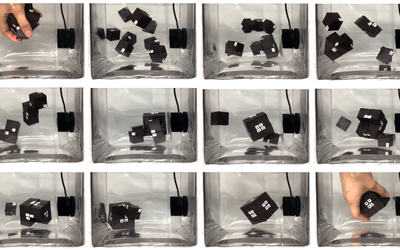

Engineers at Caltech have developed a method for 3-D printing pure and multicomponent metals, at a resolution that is, in some cases, an order of magnitude smaller than previously possible. The process, which uses water-based chemistry and 3-D printing, was described in a paper published in Nature on October 20.

Be the first to know.

Get our materials weekly email digest.

Tagged with

Materials

ORGANIZATIONS. SHAPING THE INDUSTRY.

The Next Byte

Entertainment

The Next Byte Podcast is hosted by two young engineers - Daniel and Farbod - who select the most interesting tech/engineering cont...

165 Posts

ETH Zurich

University for science and technology

Freedom and individual responsibility, entrepreneurial spirit and open-min...

43 Posts

View more