Tagged with

product design

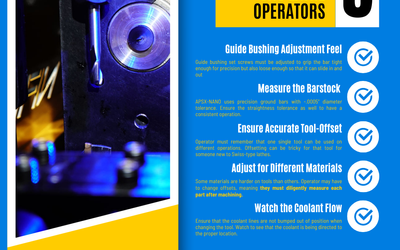

ORGANIZATIONS. SHAPING THE INDUSTRY.

Xometry Europe

On-Demand Manufacturing

From instant quotes to expert insights—Xometry powers smarter manufacturing...

23 Posts

View more

Latest Posts

The acceptance of plastic machining as a manufacturing process is due to the wide array of plastic CNC materials available. Furthermore, with the introduction of computer numerical control, the process becomes more accurate, faster, and suitable for making parts with tight tolerance. How much do you know about plastic CNC machining? This article discusses the materials compatible with the process, available techniques, and other things that can help your project.

Online Manufacturer supports assembly work at the world's largest stellarator fusion reactor with CNC-machined special parts

FACTUREE supplies components for fusion research facility at the Max Planck Institute for Plasma Physics

In this article, we will delve into the diverse world of CNC materials. We will provide you with a comprehensive guide to selecting the right materials for CNC machining, including a detailed list of commonly used materials. Additionally, we will touch on some lesser-known materials that you may not have considered before.

This blog comprises a collection of articles on innovation written by Hubert Martens, the CEO and founder of Salvia BioElectronics. Originally shared on LinkedIn, Martens intended to spark a conversation about innovation and introduce the innovation model he and his team developed over their careers.

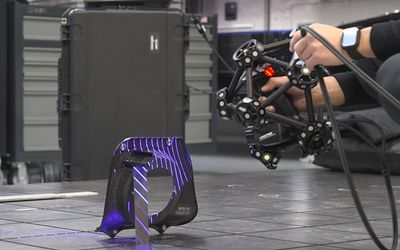

Endurance racing does not only require the best and latest technology. It also involves having the ability to harness it for multiple hours in a row without causing disaster. When you are competing at the highest level and against the best of the best, attention to detail is everything. This means leaving no stone unturned, no issue unresolved. Only then can a racing team truly be at the top of its game.

The surface finish is an integral part of the CNC machining process because a lot of applications require both aesthetic and functional design. Modern industrial designers have all the right tools and checks to ensure that their designs are functional. So, CNC machining surface finishes is an area where they can cause their product to stand out from the crowd.