Advanced Flow Sensing: High Accuracy and Long Lifespan

This article discusses how the ultrasonic flow sensing module provides precise, maintenance-free fluid measurement.

Traditional mechanical flow sensors, which rely on moving parts, face significant challenges in harsh environments, such as wear and tear, fluid contamination, and pressure drops. These issues lead to inefficiencies and costly maintenance and are exacerbated in applications where precision and durability are paramount, such as water heaters, purifiers, industrial coolant systems, and water management.

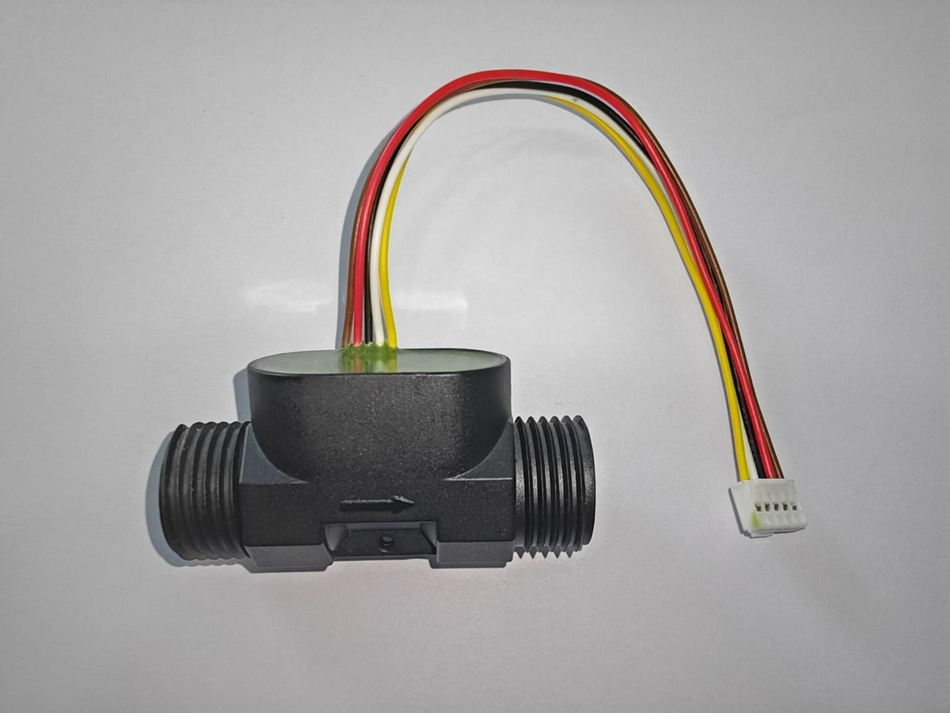

To address these challenges, ScioSense has developed the UFM-01 Ultrasonic Flow Sensing Module. The UFM-01 leverages advanced ultrasonic technology to provide highly accurate and contactless flow measurements, eliminating the drawbacks of mechanical sensors. The UFM-01 stands out for its contactless measurement capabilities because of no moving parts, which ensures long-term reliability by eliminating the wear and tear associated with traditional mechanical flow sensors.

The UFM-01 is engineered to deliver precise flow measurements across a wide range of applications. Its design is centered around ease of integration, making it an ideal choice for engineers seeking to enhance system performance.

Technological Advantages

Traditional mechanical flow sensors that use turbine rotors or actuators often face significant challenges in fluid measurement as they rely on moving parts, which are prone to wear and tear, especially in abrasive or corrosive environments. This wear and tear leads to not only fluid contamination but also reduced accuracy over time, which necessitates constant maintenance and even replacements. Traditional mechanical flow sensors also introduce obstructions into the flow path, causing pressure drops in the system and reducing energy efficiency. Moreover, their performance is often affected by changes in fluid viscosity, temperature, and pressure, leading to inconsistent measurements.

UFM-01 Ultrasonic Flow Sensing Module bypasses all these challenges by using sound waves to measure fluid velocity, eliminating the need for moving mechanical parts and thus increasing durability. Moreover, due to the non-intrusive nature of these ultrasonic sensors, they do not affect the liquids and are well suited for food applications.

Technical Specifications of UFM-01

Flow range

A wide flow range is always crucial for any flow sensor as it ensures that the sensor can accommodate fluctuations in flow rates without compromising performance. The UFM-01 supports a wide flow range of 10 to 2000 liters per hour, making it suitable in both low and high-flow scenarios for a broad spectrum of applications. For example, in water distribution systems, the sensor can handle everything from small leaks to full-flow scenarios, which eliminates the requirement for multiple sensors to cover different flow ranges.

Accuracy

Accuracy is also a critical aspect of flow measurement, especially in processes where precise control of fluid flow is necessary. In this regard, the UFM-01 offers an accuracy of ±5% for flow rates above 60 liters per hour, which ensures that the measurements are dependable even at higher flow rates. This level of accuracy is particularly important in applications like boilers, where incorrect flow measurements can lead to inefficiencies or even safety hazards.

Communication Interfaces

The UFM-01 is equipped with a universal asynchronous receiver/transmitter (UART) protocol with 2400 bits per second baud rate and 8 data bit capacity, as well as single-wire communication interfaces, which facilitate easy integration into a variety of systems. These interfaces allow the sensor to communicate seamlessly with microcontrollers, data loggers, or other digital systems, enabling real-time monitoring and control. Moreover, the ease of integration reduces development time and complexity, making the UFM-01 a convenient choice for both new designs and retrofit applications.

Power Requirements

The UFM-01 operates at 5V with a low power consumption of just 2mA. This low power draw is beneficial in systems where energy efficiency is critical, such as in continuous monitoring applications or embedded systems where minimizing power consumption helps reduce overall system costs. The efficient power usage of the sensor module also ensures its reliability within power-constrained environments, contributing to the longevity and stability of the entire system without overloading power supplies.

Application Areas

The versatility of the UFM-01 makes it suitable for a wide range of applications, as discussed here:

Water Management

In water distribution and management systems, accurate flow measurement across a wide range is crucial for efficient resource utilization and conservation. The UFM-01 serves this exact purpose by allowing users to measure flow rates across a wide range. This precise measurement capability supports effective water management strategies, enabling operators to promptly identify inefficiencies and implement corrective actions.

The UFM-01 helps both households and industries to conserve water, reduce waste, and optimize the distribution of this vital resource. For instance, the UFM-01 supports applications like smart faucets that dispense exact volumes of water for cooking and cleaning, as well as irrigation systems that deliver water based on real-time soil moisture levels. Similarly, in tankless water heaters, the sensor measurements are used to ensure that hot water is delivered only when needed, avoiding the energy waste of maintaining a hot water tank. In this way, the UFM-01 not only helps save water but also supports broader environmental goals by reducing energy consumption and lowering carbon footprints.

Coolant Systems

The UFM-01 is an ideal choice to monitor coolant flow in industrial processes. Coolant systems are critical for maintaining the proper temperature of machinery and processes, and any disruption in coolant flow can lead to overheating equipment damage or process inefficiencies. In this regard, UFM-01's dual capability of providing flow rate as well as temperature measurements provides users with a complete picture of coolant systems, allowing for real-time adjustments to maintain optimal thermal management and preventing costly downtime.

Food and Beverage Processing

In food and beverage processing, maintaining cleanliness and safety is paramount. The UFM-01 is particularly suited for the food and beverage industry as it measures flow without direct contact with the fluid, eliminating the risk of contamination and providing a hygienic and non-intrusive environment. This feature is crucial in applications such as beverage dispensers, coffee machines, and other food-grade systems, where even minimal contamination can lead to significant quality and safety issues.

Benefits for Engineers

The UFM-01 ultrasonic flow meter is developed to provide a multitude of benefits for engineers looking to simplify the design and deployment of flow-sensing solutions.

Ease of Integration

UFM-01 is designed by prioritizing user-friendliness as it comes equipped with standard mechanical and communication interfaces to ensure seamless integration into existing systems. This sensing unit is equipped with a versatile 5-pin connector, a spool piece, and a serial communication module, making it adaptable to diverse application needs. A key feature that simplifies installation is the inclusion of a standard BSP ½" thread, which allows for simple and secure attachment to water lines. These standard interfaces and mounting options enable the UFM-01 to accelerate the development process, allowing engineers to bring products to market more swiftly and with fewer integration challenges.

Food-Grade Applications

The UFM-01 is designed for use with food-grade material, making it ideal for applications involving consumable products. This feature is critical for industries such as food and beverage, pharmaceuticals, and biotechnology, where stringent safety and hygiene standards are imperative. Moreover, the sensor is engineered to function effectively in drinking and non-drinking-water systems, withstanding temperatures ranging from 1 to 60°C. Engineers can confidently deploy the UFM-01 in environments where product safety is paramount, knowing that it meets regulatory requirements and protects consumer health.

Enhanced Precision and Reliability

The UFM-01 excels in delivering high accuracy and reliability in flow measurements. The advanced ultrasonic technology of UFM-01 provides precise readings, even in challenging environments. Moreover, since it is constructed with no moving, it offers an unlimited lifetime if operated in accordance with the specifications mentioned in the datasheet. For engineers, this reliability translates into lower operational costs and enhanced trust in the performance of their designs.

Maintenance

Another huge benefit for engineers using UFM-01 is that its design eliminates the need for regular maintenance, providing a hassle-free solution for long-term operation. The risk of failure is significantly reduced due to the absence of moving parts, minimizing the likelihood of breakdowns. This also translates to a longer lifespan and high accuracy over time, lowering operational costs while ensuring reliable performance throughout the sensor's life.

The Developers of UFM-01 Ultrasonic Flow Sensing Module

The manufacturer behind UFM-01 technology is ScioSense, a leading innovator in sensor technology dedicated to providing cutting-edge solutions that address the evolving needs of various industries. ScioSense has established itself as a trusted partner for engineers and developers seeking advanced sensing capabilities with a strong reputation for quality and reliability. Their team has 30 years of combined experience in the semiconductor industry, and their UFM-01 Ultrasonic Flow Sensing Module is a testament to their commitment to delivering exceptional products that enhance system performance and efficiency.

Call to Action

UFM-01 Ultrasonic Flow Sensing Module is a great option for engineers looking for a reliable and efficient flow measurement sensor. Whether working on water management systems, control devices, or food processing equipment, the UFM-01 offers a reliable and accurate solution for flow measurement. To learn more, request a sample, or provide feedback on the module, visit ScioSense's website. This is just the first iteration, and the company is keen for engineers to share their needs and ideas with them.

References

UFM-01 Ultrasonic Flow Sensing Module. ScioSense [Online], Available at: https://www.sciosense.com/ufm-01-ultrasonic-flow-sensing-module/

Check your flow to save water and energy. ScioSense [Online], Available at: https://www.sciosense.com/check-your-flow-to-save-water-and-energy/