Critical Design Considerations in Estimating the State of Lithium-ion Batteries

Article 4 of our Energy Storage Series: Accurate state of health and state of charge estimations is essential for safe and efficient battery use.

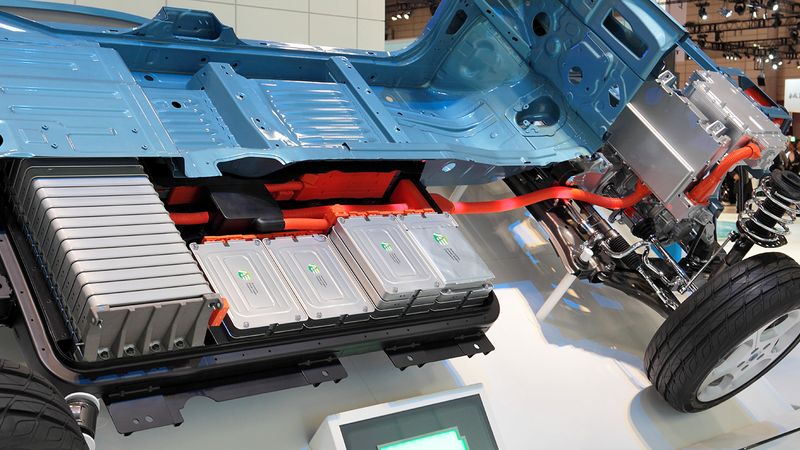

Image Credit: Tennen-Gas

This is the fourth article in a 5-part series exploring Energy Storage Systems (ESS). The series will provide insight into emerging technologies, covering topics including battery manufacturing, testing, and application.

The articles were originally published in an e-magazine co-authored by Martin Murnane and Adel Ghazel and have been substantially edited by Wevolver to update them and make them available on the Wevolver platform. This series is sponsored by Mouser, an online distributor of electronic components. Through their sponsorship, Mouser Electronics supports the growth of a sustainable future fuelled by renewable and distributed generation technologies.

Introduction

Lithium-ion batteries get employed in many vital applications, including energy storage (ESS), electric vehicles (EV), and EV chargers. In these applications, it is crucial to measure the state of charge (SOC) of the cells, which is defined as the available capacity (in Ah) and expressed as a percentage of its rated capacity. The SOC parameter can enable one to assess the potential energy of a battery. It is critically important to estimate the state of health (SOH) of a battery, which gives a measure of the battery’s lifetime, i.e. the battery’s ability to store and deliver electrical energy compared with a new battery. This article reviews the algorithms utilized for SOC and SOH estimation based on the coulomb counting method, the voltage method, and the Kalman filter method.

Battery SOC Measurement Principle

Accurate SOC estimation is one of the main tasks of battery management systems. It helps improve the system performance and reliability, and lengthen the lifetime of the battery (SOH). Precise SOC estimation of the battery can avoid unpredicted system interruption and prevent the batteries from being overcharged and over discharged, both of which can cause permanent damage to the battery's internal structure. However, since battery discharge and charge involve complex chemical and physical processes, accurate estimations of the SOC are not apparent under various operation conditions.

The general approach for measuring SOC is to accurately measure both the coulombs and current flowing in and out of the cell stack under all operating conditions and the individual cell voltages of each cell in the stack. This data gets employed with previously loaded cell-pack data for the exact cells getting monitored to develop an accurate SOC estimate. The additional data required for such a calculation includes the cell temperature, whether the cell is charging or discharging when the measurements get made, the cell age, and other relevant cell data obtained from the cell manufacturer. Sometimes it is possible to get characterization data from the manufacturer of how their Li-ion cells perform under various operating conditions. Once a SOC has been determined, it is up to the system to keep the SOC updated during subsequent operation, essentially counting the coulombs that flow in and out of the cells. This approach's accuracy can be derailed by not knowing the initial SOC to an accurate enough state and by other factors, such as self-discharge of the cells and leakage effects.

Technical Specifications

This article encompasses the design and development of a coulomb counting evaluation platform to get utilized for SOC and SOH measurement for a typical energy storage module, which in this case is a 48V module, typically comprising 12 to 16 Li-ion cells. The Battery Management System (BMS) periodically measures each cell's voltage value and the battery pack’s current voltage, utilizing appropriate ADCs and sensors, and will run the SOC estimation algorithm in real-time. This algorithm uses measured voltage and current values and some other data collected by temperature sensors.

SOC and SOH Estimation Methods Overview

Regarding SOC and SOH estimation methods, three approaches mainly find employment: (1) a coulomb counting method, (2) voltage method, and (3) Kalman filter method.

Coulomb Counting Method

The coulomb counting method, also known as ampere-hour counting and current integration, is the most common technique for calculating the SOC. This method employs battery current readings mathematically integrated over the usage period to calculate SOC values given by:

Where SOC(t0) is the initial SOC, Crated is the rated capacity, Ib is the battery current, and Iloss is the current consumed by the loss reactions.

The coulomb counting method then calculates the remaining capacity by merely accumulating the charge transferred in or out of the battery. This method's accuracy is linked primarily to a precise measurement of the battery current and accurate estimation of the initial SOC. With a previously known capacity, which might be memorized or initially estimated by the operating conditions, the SOC of a battery can be calculated by integrating the charging and discharging currents over the operating periods. However, the releasable charge is always less than the stored charge in the charging and discharging cycle. In other words, there are losses during charging and discharging. These losses, also with the self-discharging, cause accumulating errors. For more precise SOC estimation, these factors should get consideration. Additionally, the SOC should get recalibrated regularly, and the declination of the releasable capacity should get considered for a more precise estimate.

Voltage Method

The SOC of a battery, (its remaining capacity) can be determined using a discharge test under controlled conditions. The voltage method converts a reading of the battery voltage to the equivalent SOC value using the known discharge curve (voltage vs. SOC) of the battery. However, the voltage is more significantly affected by the battery current because of the battery’s electrochemical kinetics and temperature. It is possible to make this method more accurate by compensating the voltage reading by a correction term proportional to the battery current and by using a lookup.

Kalman Filter Method

The Kalman filter is an algorithm to estimate the inner states of any dynamic system—it can also determine the SOC of a battery. Kalman filters were introduced in 1960 to provide a recursive solution to optimal linear filtering for both state observation and prediction problems. Compared to other estimation approaches, the Kalman filter automatically provides dynamic error bounds on its state estimates. By modeling the battery system to include the wanted unknown quantities (such as SOC) in its state description, the Kalman filter estimates their values and gives error bounds on the estimates. It then becomes a model-based state estimation technique that employs an error correction mechanism to provide real-time predictions of the SOC. It can get extended to increase the capability of real-time SOH estimation using the extended Kalman filter. Notably, the extended Kalman filter is applied when the battery system is nonlinear, and a linearization step is needed. Kalman filtering is an online and a dynamic method, and it requires a suitable model for the battery and precise identification of its parameters. It also needs a large computing capacity and an accurate initialization.

Other methods for SOC estimation include impedance spectroscopy, based upon cell impedance measurements, employing an impedance analyzer in real-time for both charge and discharge. Although this technique can get used for Li-ion cells SOC and SOH estimation, it was omitted in this article since it is based on external measurements utilizing instrumentation. The methods based on the electrolytes’ physical properties and artificial neural networks are not applicable for Li-ion batteries.

Technical Principle

Next, we’ll dive into the technical aspect of the topic, however for a more detailed description and equations, refer to the full article, A Closer Look at SOC\SOH Estimation Techniques. The releasable capacity (Creleasable) of an operating battery is the released capacity when it gets completely discharged. Accordingly, the SOC is defined as the percentage of the releasable capacity relative to the battery rated capacity (Crated), given by the manufacturer.

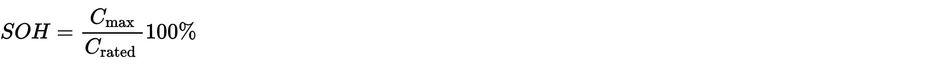

A fully charged battery has the maximal releasable capacity (Cmax), which can be different from the rated capacity. In general, Cmax is, to some extent, different from Crated for a newly used battery and will decline with the used time. It can get utilized for evaluating the SOH of a battery.

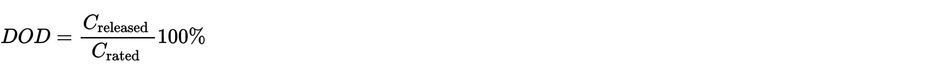

When a battery is discharging, the depth of discharge (DOD) can get expressed as the percentage of the capacity that has gotten discharged relative to Crated,

Where Creleased is the capacity discharged by any amount of current. With a measured charging and discharging current (Ib), the difference of the DOD in an operating period (Ʈ) can be calculated by

where Ib is positive for charging and negative for discharging. As time elapsed, the DOD is accumulated

To improve the accuracy of estimation, the operating efficiency denoted as ŋ is considered and the DOD expression becomes,

With ŋ equal to ŋc during the charging stage and equal to ŋd during the discharging stage. Without considering the operating efficiency and the battery aging, the SOC can get expressed as

Considering the SOH, the SOC is estimated as

The estimation process is based on monitoring the battery voltage (Vb) and Ib. The battery operation mode can be understood from the amount and the direction of the operating current. The DOD is adding up the drained charge in the discharging mode and counting down with the accumulated charge into the battery for the charging mode. After correction with the charging and discharging efficiency, a more accurate estimation can get realized. The SOC can then get estimated by subtracting the DOD quantity from the SOH one. When the battery is open-circuited with zero current, the SOC is directly obtained from the relationship between the OCV and SOC.

Note that the SOH can get reevaluated when the battery is either exhausted or fully charged, and manufacturers specify the battery operating current and voltage. The battery may be considered drained when the loaded voltage (Vb) becomes less than the lower limit (Vmin) during the discharging. In this case, the battery can no longer be used and should get recharged. At the same time, a recalibration to the SOH can get made by reevaluating the SOH value by the accumulative DOD at the exhausted state. On the other hand, the used battery may be considered fully charged if (Vb) reaches the upper limit (Vmax), and (Ib) declines to the lower limit (Imin) during charging. A new SOH is obtained by accumulating the sum of the total charge put into the battery and is then equal to SOC. In practice, the fully charged and exhausted states occur occasionally. The accuracy of the SOH evaluation can be improved when the battery is frequently fully charged and discharged.

Thanks to the simple calculation and the uncomplicated hardware requirements, the enhanced coulomb counting algorithm can be easily implemented in all portable devices, as well as electric vehicles. Additionally, the estimation error can be reduced to one percent (1%) at the operating cycle next to the reevaluation of the SOH.

This article was originally written by Martin Murnane for Mouser and substantially edited by the Wevolver team. It's the fourth article of a 5-part series exploring Energy Storage Systems (ESS). Future articles will explore Communication Solutions for Essential Monitoring of Solar PV and Energy storage, electric vehicles production futures, and battery monitoring systems for lithium-ion solutions.

Article one outlined the Energy Storage Systems in healthcare applications.

Article two explained communication systems for energy storage.

Article three gave an overview of battery stack monitoring systems for li-on batteries.

Article four provided a deep analysis of the critical design considerations in estimating the state of lithium-ion batteries.

Article five looked at solutions for scaling electric vehicle production.

About the sponsor: Mouser

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 800 industry-leading manufacturers. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.