DC Motor & DC Gear Motor Basics

Get up to speed on what makes DC motors spin!

What is a DC Motor?

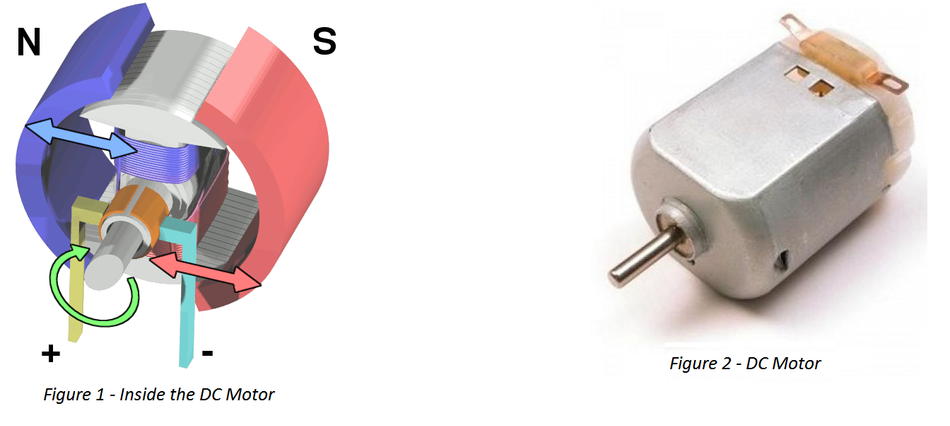

A Direct Current (DC) motor is a rotating electrical device that converts direct current electrical energy into mechanical energy. An Inductor (coil) inside the DC motor produces a magnetic field that creates rotary motion as voltage is applied to its terminal. Inside the motor is an iron shaft, wrapped in a coil of wire. This shaft contains two fixed magnets, North and South, on each side which causes both a repulsive and attractive force, producing torque.

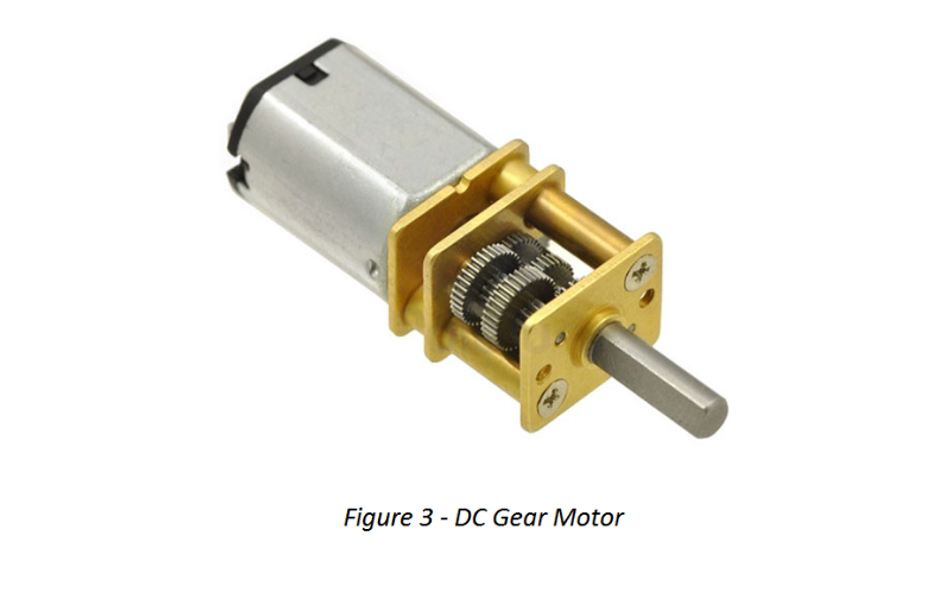

What is a DC Gear Motor?

A gear motor is an all-in-one combination of a motor and gearbox. The addition of a gear head to a motor reduces the speed while increasing the torque output. The most important parameters in regards to gear motors are speed (rpm), torque (lb-in), and efficiency (%). In order to select the most suitable gear motor for your application you must first compute the load, speed and torque requirements for your application. Not all gear motors are the same. There are Spur Gear Motors, Planetary Gear Motors and Worm Gear Motors, each one excelling at a different task. Read our article, The Motors Inside Autonomous Robots, to get a better understanding of these different types of gear motors.

The Motor Selection Process

The motor selection process, at the conceptual design phase, can be challenging. The following key points can help you determine and select the most appropriate motor or gear motor for our application.

Design Requirements – A design assessment phase where the product development requirements, design parameters, device functionality, and product optimization are studied.

Design Calculations – Calculations used to determine which motor would be the best solution for your application. Design calculations determine gear ratio, torque, rotating mass, service factor, overhung load, and testing analysis.

Types of DC Motors/Gear motors – The most common electrical motors convert electrical energy to mechanical energy. These types of motors are powered by direct current (DC).

Motor Specifications – Once the design calculations are performed, and the application parameters are defined, you can use this data to determine which motor or gear motor will best fit your application. Some of the most common specs to consider when selecting a motor or gear motor would be:

Voltage

Current

Power

Torque

RPM

Life Expectancy / Duty Cycle

Rotation (CW or CCW)

Change in Rotation / Dwell Time

Shaft Diameter and Length

Enclosure Restrictions

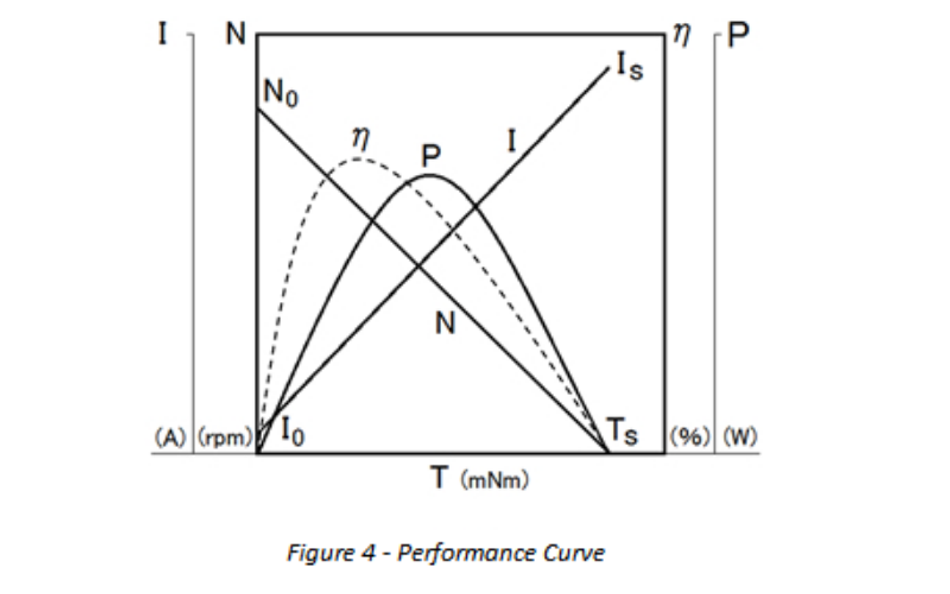

Gear Motor Performance Curves

A motor's performance and gearbox performance are combined into one graph by displaying three specific parameters. These three parameters are speed, torque and efficiency. These performance curves are essential when selecting a gear motor for your application.

Speed/Revolutions (N) – (unit: rpm) indicated as a straight line that shows the relationship between the gear motors torque and speed. This line will shift laterally depending on voltage increase or decrease.

Efficiency (η) – (unit: %) is calculated by the input and output values, represented by the dashed line. To maximize the gear motors potential it should be used near its peak efficiency.

Torque (T) – (unit: gf-cm) this is the load borne by the motor shaft, represented on the X-axis.

Current (I) – (unit: A) indicated by a straight line, from no load to full motor lock. This shows the relationship between amperage and torque.

Output (P) – (unit: W) is the amount of mechanical energy the gear motor puts out.

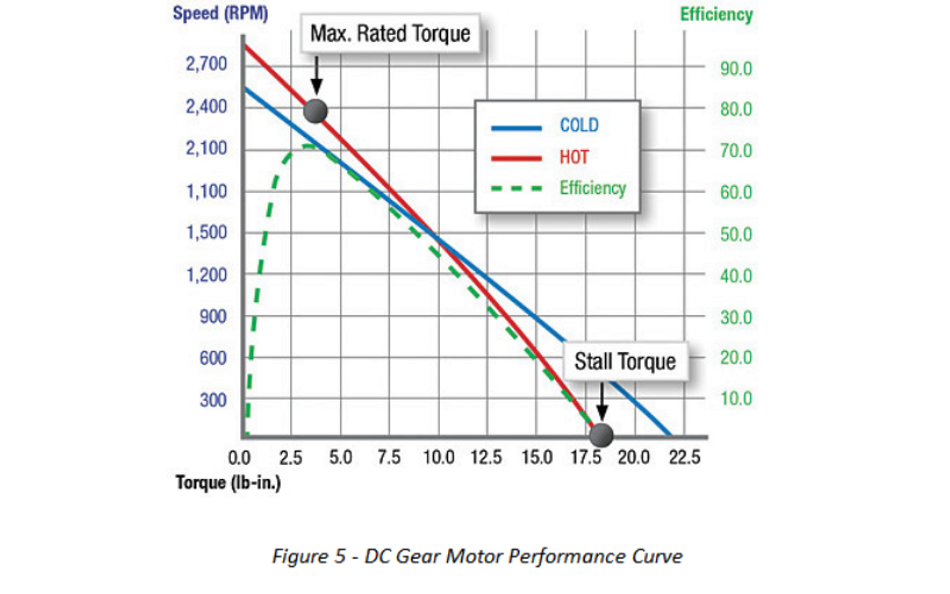

For example, let’s consider the performance curve below (figure 5) for a DC gear motor.

Maximum operating efficiency (70%) for this motor would occur at 3.75 lb-in / 2,100 rpm.

As torque increases the speed and efficiency decrease. The result of increased torque is poor output performance and the device will eventually fail to function once the motor reaches its stall torque (18 lb-in).

Gear motor performance curves are a helpful tool when selecting a motor for your application. To get the most out of the performance curves it’s important to thoroughly understand the application's requirements. You can use your load and speed requirements to help determine the required torque. Most DC motor and gear motor manufacturers provide performance curves upon request.