Extending the Battery Life of Hearables and Wearables with Single-Inductor Multiple-Output Switching Architecture

Article #5 of Power Management for Tomorrow’s Innovations Series: Single-Inductor Multiple-Output (SIMO) architecture enables design engineers to extend the battery life, and reduce the circuit board size for hearables and wearables

Source: iFixit

This article was first published on

www.ifixit.comThis is the fifth article in an 8-part series featuring articles on Power Management for Tomorrow’s Innovations. The series focuses on power management and optimization techniques for modern electronic systems. This series is sponsored by Mouser Electronics. Through the sponsorship, Mouser Electronics shares its passion for technologies that enable smarter and connected applications.

It is not convenient to have to stop and recharge your earbuds when you are on a long hike or working out. It is expected that hearables, wearables, and other tiny, battery-powered electronic devices will perform reliably for prolonged periods of time. From a design standpoint, these user expectations are a tall order to meet.

The form factor constraints dictate the need for a small Lithium-ion battery, which must last a long time between charge cycles and be utilized sparingly. Power supplies, in turn, must meet the distinct and diverse voltage requirements of the sub-systems within the design. In this article, we explain the Single-Inductor Multiple-Output (SIMO) architecture that provides an optimal solution for these systems, integrating functionality that would otherwise require multiple discrete components. We discuss how this architecture significantly reduces the overall product size and the associated costs.

SIMO Architecture Overview

In a traditional switching-regulator topology, each switching regulator needs a separate inductor since each voltage rail must be serviced by an individual inductor as shown in fig. 1. The inductors are physically large and costly, creating a limitation for small form factor products.

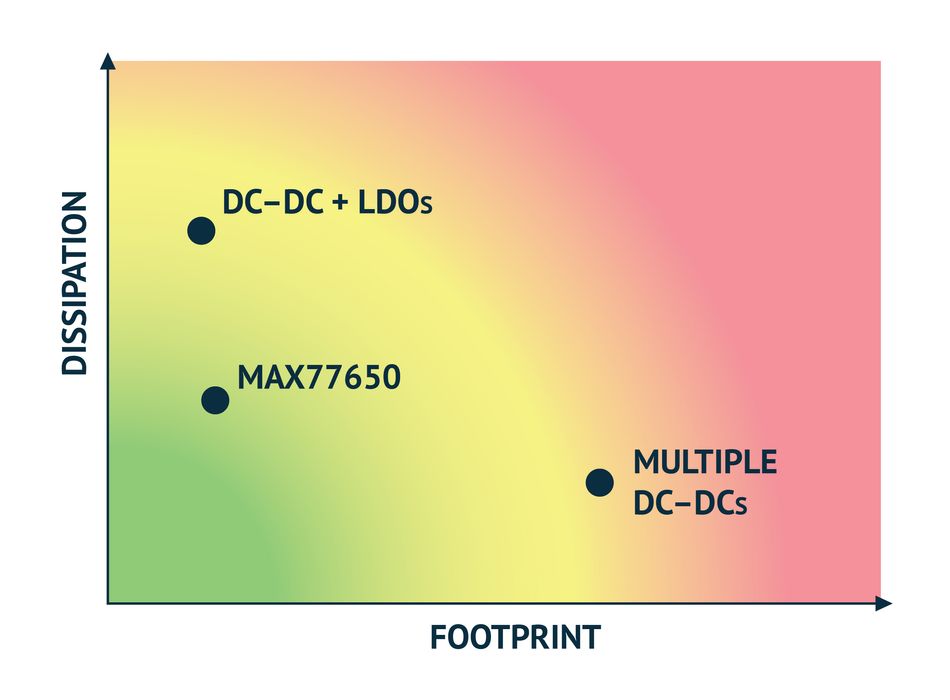

Linear regulators offer another option—they are fast, compact, produce low noise, but are also lossy. There’s also a hybrid alternative of using multiple Low-Dropout Regulators (LDOs), in conjunction with DC-DC converters. However, while this configuration would result in intermediate power and heat dissipation, it still yields a larger design than LDOs alone.

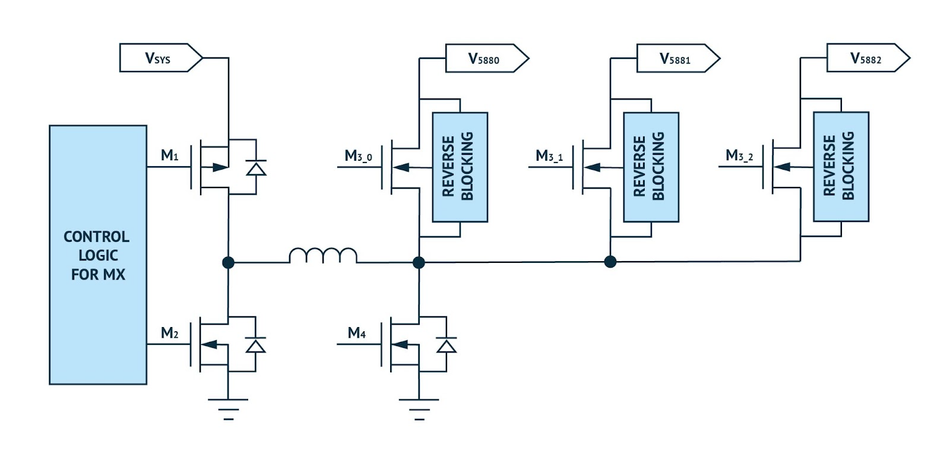

The featured buck-boost SIMO converter can regulate up to 3 output voltages over wide output voltage ranges using a single inductor. The buck-boost topology helps to better utilize the inductor since it requires less time to service each channel as compared to a buck-only SIMO. The weakness of a buck-only SIMO is magnified as one or more output voltages approach the input voltage. A buck-only SIMO will suffer when an output voltage approaches the battery voltage. Currently, a buck-only SIMO requires the inductor for too much time, which impacts other channels.

Sometimes, an inductor cannot be avoided in the system. Even though they are small, an LDO can never provide a boost feature by itself. Since the SIMO requires only one inductor, solutions that require at least one boost voltage are almost always better with a buck-boost SIMO. Fig. 2 shows the block diagram of the SIMO architecture.

The inductor saturation current (Isat), a measure of the inductance drops to a certain percentage that corresponds to a particular electrical current, is proportional to the inductor’s core size for given core material and construction.

Here are some advantages of using one inductor in a SIMO architecture compared to using separate DC-DC converters:

Better Z-height

Cost savings

Footprint improvements

Uses time multiplexing

Lower RMS current rating for inductors

Overcoming the Challenges with SIMO Architecture

SIMO architecture provides a unique way to reduce the size, and costs of the power supply. However, the architecture comes with a few small tradeoffs that can be solved only with a thoughtful design approach.

Using SIMO architecture results in an increase in the harmonic content of the supply system, which can have an impact on the overall power quality. The increase in harmonic content is due to the high output voltage ripple caused by a single inductor providing buckets of energy to alternate outputs.

Also, as a SIMO is heavily loaded, it becomes time-limited and there can be a delay in servicing each channel, which can further increase output voltage ripple. Using larger output capacitors offsets these sources of output voltage ripple while maintaining a net footprint/Bill of Materials (BOM) advantage.

Ultra-Low Power Management Integrated Circuits (PMICs) by Analog Devices for Extending the Battery Life of Low Power Devices

Analog Devices’ MAX77650/MAX77651 Ultra-Low PMICs provide a careful balance of the battery life and performance while managing the tradeoffs associated with SIMO architecture. These PMICs were designed with micropower SIMO buck-boost DC-DC converters. An integrated 150mA LDO in the PMICs provides ripple rejection for noise-sensitive applications such as audio.

The SIMO converter utilizes the whole battery voltage range, as each output has the benefit of being a buck-boost configuration, which creates output voltages that are above, below, or equal to the input voltage. Since the peak inductor current for each output is programmable, you can optimize the balance between efficiency, output ripple, Electromagnetic Interference (EMI), Printed Circuit Board (PCB) design, and load capability.

This way, SIMO architecture finds the optimal balance between low power consumption and form factor. Low power consumption can be very important for very small applications that are unable to dissipate much heat. Fig. 4 shows a comparision between DC-DC LDOs, Multiple DC-DC converters, and the SIMO-based MAX77650 in terms of dissipation and footprint (both values, the lower the better).

The SIMO control scheme in the MAX77650/MAX77651 involves a proprietary controller that ensures that all the outputs get serviced in a timely manner. If there aren’t any regulators requiring service, the state machine simply rests in a low-power state.

Once the controller recognizes that a regulator needs service, it charges the inductor until the peak current limit is reached. The SIMO architecture also offers a soft-start feature, which minimizes in-rush current.

Conclusion

For hearables, wearables, and similarly small, battery-operated electronics, long battery life is essential for customer satisfaction. Compared to traditional buck-boost topologies, the SIMO architecture reduces component count and extends battery life.

This article examined PMICs integrated with SIMO switching regulators that can be used by engineers for meeting the challenges of ultra-low-power and space-constrained applications.

This article is based on an e-book by Mouser and Maxim Integrated (a part of Analog Devices). It has been substantially edited by the Wevolver team and Electrical Engineer Ravi Y Rao. It's the fifth article from the Power Management for Tomorrow’s Innovations Series. Future articles will introduce readers to some more power management and optimization techniques for modern electronic systems.

The introductory article covered the fundamentals of power electronics, the technology behind highly-efficient power conversion in different electrical/electronic systems.

The first article shares some design techniques for efficient power management in EVs. It covers how manufacturers can build significantly better vehicular electric power systems with systematic planning and innovative power electronic solutions.

The second article introduced readers to silent switching and how it prevents EMI at the source, rather than adding shields and filters to the product later.

The third article describes current measurement techniques using LTC297x series components by Analog Devices. It presents some application circuits and compares different approaches for current sensing in power electronic converters.

The fourth article discussed the problems associated with phase noise and experimentally showcased how power supply designs can be optimized to deal with them.

The fifth article featured Single-Inductor Multiple-Output architecture that integrates different power supply functionalities to drastically reduce the overall size and costs for wearables.

The sixth article describes how vehicular asset-tracking devices are powered with small, efficient power solutions and protected from electrical stresses.

The seventh article explains how designers can implement and validate proven power supply circuits for enabling the reliable operation of healthcare devices.

The final article dealt with a specific IoT power management solution for small, and portable gadgets. It showcases a nano-Power boost converter that ‘operates on fumes’ to make the most out of all the available energy.

About the sponsor: Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,100 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.

References

[1] Cary Delano, Gaurav Mital, ‘SIMO Switching Regulators: Extending Battery Life for Hearables and Wearables’, Maxim Integrated - Mouser, [Online], Available from:

[2] Mitchell Sternberg, Erkan Acar, David Ng, and Sydney Wells, ‘How to Select the Best Power Solution for RF Signal Chain Phase Noise Performance’, Analog Devices, [Online], Available from:

https://www.analog.com/en/technical-articles/how-to-select-the-best-power-solution.html