How High-Performance Thermoplastics are Powering the Future of Therapeutic Applications

Article #2 of The Engineer’s Guide to 3D Printing with Wear-Resistant Plastic Materials.

This article is a chapter from our comprehensive report on 3D printing with wear-resistant plastics. If you're interested in diving deeper and accessing the full report, we invite you to download it below. Gain a holistic understanding and benefit from the complete insights we've gathered. Don't miss out!

High-Performance Thermoplastics

3D printing allows creating and producing complex object geometries from a variety of materials. It has significantly reduced the design-manufacturing cycle, production cost, and material waste. This can be attributed to the fact that 3D printing relies on digital CAD data, which allows for multiple iterations of a product to be produced faster and cheaper than the traditional manufacturing methods. Furthermore, the precise layer-by-layer fabrication process of 3D printing eliminates the need for sculpting the final product and generates minimal residual materials.[1]

As technology advances, the variety of materials used in 3D printing has also increased. However, one of the challenges in 3D printing is the need for advanced materials that can match performance and high fabrication standards.[2]

Thus, the sector has been focused on developing new high-performance materials that can improve the efficiency and speed of 3D printing and extend its properties and applications. One example is high-performance thermoplastic polymer. It is suitable for 3D printing techniques and supports the production of pieces with high strength-to-weight ratios and properties that can withstand high loads or harsh environments.[3]

Medical Applications

In medical applications, there are high-performance plastics such as PEI, PEEK and PEKK in use. These are base materials, not optimized for wear and friction. Printable High-performance-thermoplastics including solid lubricants are for example, igus’ iglidur A350 and iglidur RW370. These can be processed on high-temperature FFF printers.

The remarkable chemical stability and resistance of high-performance thermoplastic polymers make them well-suited for medical parts, and capable of withstanding autoclave and chemical sterilization processes.

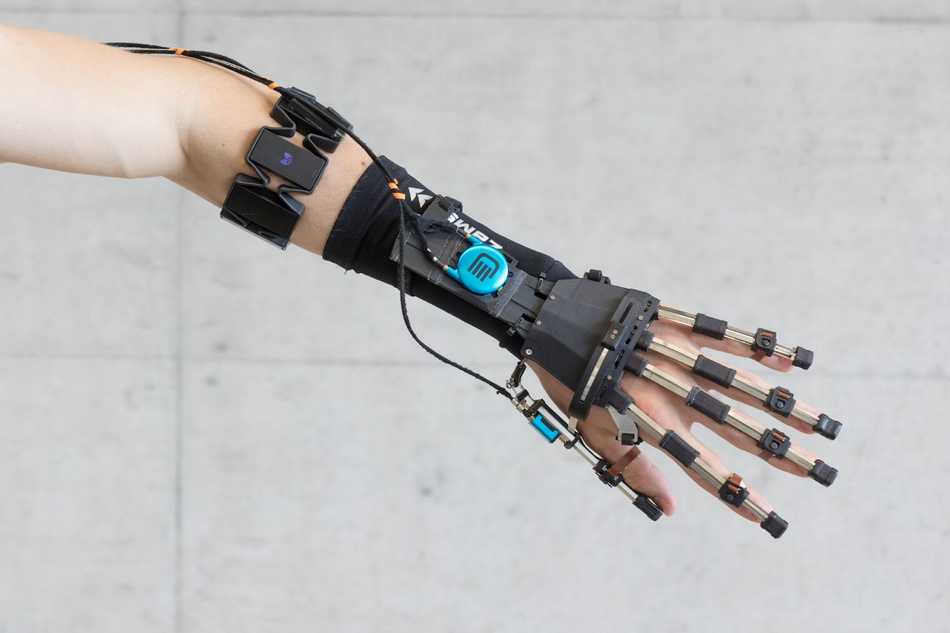

Professor Jumpei Arata of Kyushu University in Japan has developed a hand exoskeleton, the RELab tenoexo, using high-performance igus polymers. The exoskeleton is a fully wearable robotic hand orthosis, designed to assist people with sensorimotor hand impairment. Stroke, spinal cord injury, and cerebral palsy are examples of diseases leading to persistent hand impairment.[7]

The RELab tenoexo is made up of three components: The exoskeleton comprises a hand module, a wristband sensor, and a backpack. Its design allows for a wide range of daily hand activities and therapy tasks, covering approximately 80% of all grasping activities. It has a maximum fingertip force of 6 N per finger, which makes it capable of easily grasping and lifting many everyday objects, including a half-liter water bottle.[8]

How does the RELab tenoex work?

The patient wears a wristband and backpack while the hand module is attached to their hand using leather straps. The exoskeleton is portable and compact, able to be used during everyday life. The hand module weighs 148g, and the backpack 720g, ensuring patient comfort.

The hand module comprises three thin leaf springs made of stainless steel placed on each other and connected by four plastic links. It provides power, precision, and lateral grasp. Additionally, a Bowden-cable-based force transmission system is attached to the middle spring. When moving forward, the fingers close, and the hand opens when pulled back.

When the patient moves the hand, the wristband transmits electromyographic (EMG) signals to a microcomputer located in a backpack. If the patient intends to make a grasping movement, the computer detects this and activates the DC motors, allowing motion. The robotic hand orthosis also has an application that allows users to change the force range and closing speed, select between two grasp types, and configure the control system/intention detection strategies.

However, the prototype faced several issues, such as the delicate finger joint structure. These elements keep the leaf springs together and have a lattice-locking mechanism. The first exoskeleton version used a 3D printer with an ABS filament. The manufacturing method and the material were unsuitable for the manufacture of finger joints due to the high friction, resulting in energy loss when the fingers moved. Furthermore, the resolution of a regular 3D printer was not precise enough to recreate the detailed structure of the finger phalanxes.

Here comes the application of high-performance thermoplastics for medical purposes. ETHZ University (Eidgenössische Technische Hochschule Zurich) eventually found a solution. With the help of selective laser sintering (SLS) technology and the iglidur i6 high-performance thermoplastic from igus, researchers were able to avoid problems with high friction and low resolution, thanks to the igus 3D printing service.[9]

Properties of iglidur i6

The iglidur i6 high-performance thermoplastic for laser sintering has proven to have an extraordinary greater wear resistance and much lower friction than conventional materials, ensuring longer service life for parts. With abrasion resistance 50 times higher than standard 3D printing materials, it's well-suited for moving applications like the RELab tenoexo. Moreover, the SLS process eliminates the need for tooling, making it suitable for manufacturing special and delicate parts.

SLS uses a selective laser that fuses the powder material layer by layer, ensuring some advantages. For instance, unlike FDM printing, there is no need for support structures because the surrounding powder acts as a natural support, avoiding the need for post-processing. Moreover, it guarantees uniform distribution of material and good interlayer bonding, which leads to consistent mechanical properties. The unique material properties of iglidur i6 also make it ideal for creating 3D-printed finger phalanxes in an exoskeleton.[10]

Reducing friction

The self-lubricating SLS material iglidur i6 had been specially developed for manufacturing parts subject to friction and was used successfully for manufacturing the finger joints. 3D printed finger phalanges made of high-performance iglidur i6 polymer ensure optimum force transmission. This material is ideal for moving applications and contains solid lubricants, making it easy to handle without needing additional lubrication. This feature makes it suitable for therapeutic applications.

Delicate parts

Laser sintering as a manufacturing method is ideally suited for replicating complex geometries, filigree structures, and delicate details. This makes it possible to manufacture small volumes and one-off components cost-effectively. iglidur i6 was initially developed to manufacture worm wheels for robot joints and wear parts in general.

Resistance

One of the most outstanding features of iglidur i6 is its resilience and abrasion resistance. A sintered gear made of this abrasion-resistant iglidur plastic was tested under the same conditions as a machined gear made of POM for two months. The gear made of POM exhibited signs of severe wear after 321,000 cycles and failed after 621,000 cycles. In contrast, the gear made of iglidur i6 continued to function after 1 million cycles, with only minor signs of wear.

Light

The iglidur i6 is an impressively lightweight material, making it ideal for applications where weight is a key factor. For instance, it is a perfect choice for a hand orthosis that needs to be worn for long periods. It is worth noting that the hand module, which features finger joints made of iglidur i6, only weighs 148g.

There are more current benefits of the application of high-performance thermoplastics. With the help of SLS technology and iglidur i6 high-performance plastic, it is now possible to produce delicate structures of finger joints without the need for support structures. This also eliminates the need for post-processing. For example, pieces from FDM 3D prints tend to have a slightly rough surface, suggesting the need to smooth out the imperfections through sanding.[11]

Moreover, RELab tenoexo exoskeletons are individually adapted to fit individual patients. The company developed an algorithm that adjusted the digital model of the exoskeleton to the size of the patient's hand with just a few clicks, thereby avoiding any mistakes. This means the exoskeleton can be manufactured to meet individual customer requirements quickly and without complications.

In addition, with the help of an online 3D printing service tool, ETHZ scientists can order the required parts in just a few minutes. The manufacturing process is usually completed overnight, and the finished finger joints can be fitted after just a few days.

This is the only manufacturing method that approaches the speed and cost-effectiveness of 3D printing where a customized small-volume manufacturer is concerned. The adaptable and fast production characteristics of this method are game changers, especially considering that conventional customization methods are complex due to molding or other tool-based methods.

Conclusion

High-performance thermoplastics and SLS have exceptional properties, such as being friction-free, allowing for detailed and precise printing, being self-lubricating, lightweight, and easy to produce. By combining these materials, users can better support their daily activities and receive rehabilitation training.

This article was co-authored by Ana Carla Sorgato.

The Engineer’s Guide to 3D Printing with Wear-Resistant Plastic Materials

Explore the transformative world of 3D printing as we delve into the intricacies of using wear-resistant plastic materials. This guide offers engineers a comprehensive overview of material properties, applications, and best practices. Unlock the potential of durable plastics and revolutionize your manufacturing processes.

References

- Azom. “https://www.azom.com/article.aspx?ArticleID=20017”

- Valino, A. D., Dizon, J. R. C., Espera Jr, A. H., Chen, Q., Messman, J., & Advincula, R. C., 2019. “https://www.sciencedirect.com/science/article/pii/S0079670018303976”

- Anniwaa “https://www.aniwaa.com/insight/am-materials/am-thermoplastics-breakdown-by-performance/”

- Wevolver. “https://www.wevolver.com/article/peek-3d-printing-unlocking-the-potential-of-high-performance-polymers”

- Algarni, Mohammed; Ghazali, Sami., 2021. “https://www.proquest.com/docview/2565095716”

- Bond 3D. “https://www.bond3d.com/market/peek-medical/”

- ETH Zurich. "https://relab.ethz.ch/research/current-research-projects/Robotic%20Hand%20Orthosis%20.html”

- Tobias Bützer, Olivier Lambercy, Jumpei Arata, and Roger Gassert (2021). “https://www.liebertpub.com/doi/abs/10.1089/soro.2019.0135”

- 3dnatives. 2021. “https://www.3dnatives.com/en/3d-printed-finger-joints-igus-110120204/#”

- Igus. “https://www.igus.eu/info/3d-printing-application-exoskeleton”

- All3dp “https://all3dp.com/2/fdm-3d-printing-post-processing-an-overview-for-beginners/”

About igus

igus is a manufacturer of high-performance polymers for movement, based in Cologne (Germany). We have been developing and producing so-called motion plastics, innovative products made from...