How Strong Are 3D Printed Parts? A Comprehensive Analysis

Part strength is sometimes seen as a weakness of 3D printing. But how strong are 3D printed parts really, especially compared to injection molding?

How strong are 3D printed parts compared to injection molded parts?

Additive manufacturing offers several unique and important advantages, such as speed, design freedom, and affordability in low volumes. However, one of the major obstacles to the widespread adoption of the manufacturing process is part strength.

Because the 3D printing process constructs parts one layer at a time, it can produce weaknesses throughout the part, as well as specific defects like layer lines and deformations. But how serious is this limitation? How strong are 3D printed parts compared to molded parts? And is the process only suitable for flimsy prototypes or cannot be used for more important applications?

This article asks the question “How strong are 3D printed parts” with a particular focus on FDM 3D printing, looking at how users can improve their 3D printed part strength without turning to other processes.

How Strong Are FDM 3D Printed Parts?

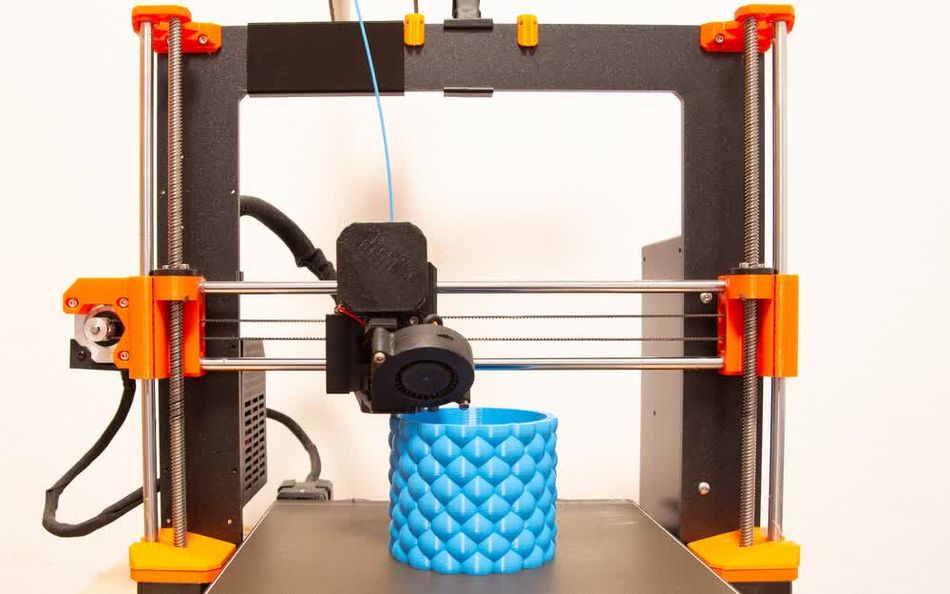

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), produces parts with varying strength based on material choice, print settings, and design. This process involves depositing molten thermoplastic layer by layer, creating unique mechanical properties.

Material selection is crucial. PLA is strong but brittle, making it suitable for rigid, non-load-bearing applications. ABS offers better impact resistance but is less stiff. PETG balances flexibility and toughness, while advanced materials like nylon, polycarbonate, and carbon-fiber-reinforced filaments provide exceptional strength and durability. Industrial-grade filaments like PEEK and ULTEM are used in automotive and aerospace due to their superior mechanical properties and heat resistance.[1]

Despite these strengths, FDM parts have inherent weaknesses. The most notable is anisotropy—parts are strongest along the horizontal plane but weakest between layers, where delamination can occur. Poor adhesion between layers reduces tensile and shear strength, making proper print settings essential.

Print orientation, infill density, wall thickness, and post-processing methods like annealing can mitigate these weaknesses. Structural design improvements such as fillets at stress points also enhance durability.

Other 3D Printing Technologies

The table below looks at how alternative 3D printing technologies compare to FDM in terms of part strength. While vat photopolymerization 3D printers are often comparable in price to extrusion printers, other technologies can be significantly more expensive.

Technology | Typical Part Strength | Cost |

FDM (Fused Deposition Modeling) | Moderate; strong along layers, weaker between layers | Low to Medium |

Vat Photopolymerization (SLA/DLP) | High surface detail, brittle unless using engineering resins | Low to Medium |

SLS (Selective Laser Sintering) | High; durable, isotropic parts with good mechanical properties | High |

Material Jetting | Moderate to high; brittle unless reinforced | High to Very High |

Metal (e.g., DMLS, SLM) | Very high; comparable to traditionally manufactured metal parts | Very High |

Are 3D Printed Parts as Strong as Molded Parts?

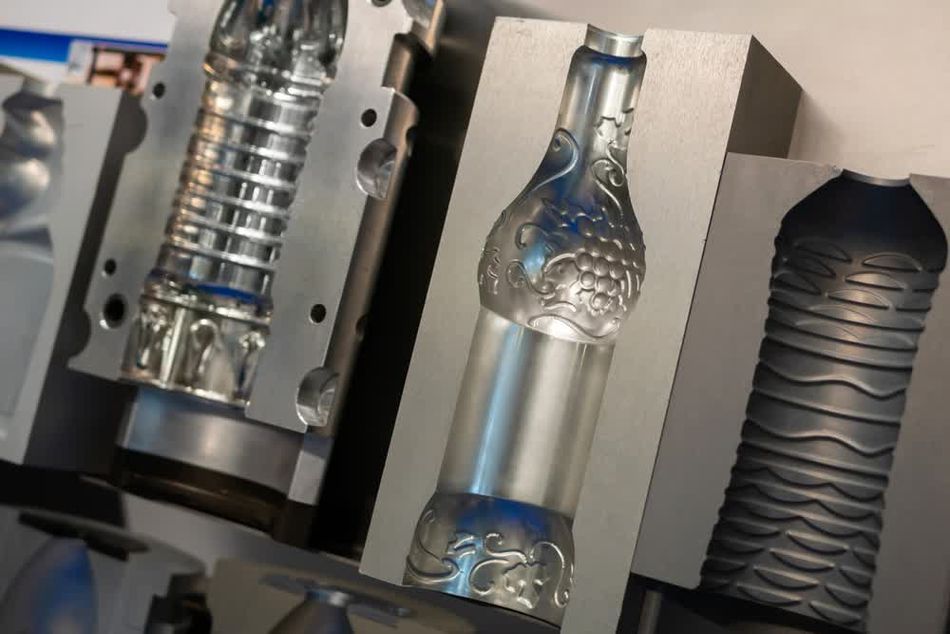

FDM 3D printed parts are generally not as strong as injection molded parts due to differences in how they are made. Injection molding produces solid, homogeneous parts with consistent mechanical properties, while FDM creates objects layer by layer, introducing potential weak points between layers.

FDM parts are strongest along the horizontal plane but are prone to delamination when stressed along the vertical axis.[2] In contrast, injection molded parts have uniform strength throughout. Material selection also plays a role; while FDM can print strong materials like nylon and carbon-fiber composites, injection molding supports a wider range of high-strength polymers.

However, with optimized print settings, high-performance filaments, and post-processing techniques, FDM parts can approach the strength of injection molded parts in some applications.

The Strongest 3D Printing Materials

Material selection plays an important role in achieving strong 3D printed parts. Here we look at the strongest affordable 3D printing filaments and also the strongest engineering filaments, which are more expensive and can only be used on premium machines.

Strong Consumer-Level Materials

PETG is strong, impact-resistant, and easy to print, making it ideal for functional parts with good flexibility and chemical resistance.

PLA+ (Enhanced PLA) is more durable and less brittle than regular PLA, while retaining ease of printing and affordability.

Nylon (Polyamide) is tough, wear-resistant, and strong, though it requires a heated bed and controlled environment for best results.

ABS is durable and impact-resistant, suitable for mechanical parts, though it requires good ventilation due to odor and warping risks.

Polycarbonate (PC Blend) is extremely strong and heat-resistant, with affordable blends offering easier printing on standard FDM printers.

Strong Engineering Materials

PEEK is an ultra-strong, high-temperature-resistant material often used in aerospace and medical applications but requires specialized printers.

ULTEM (PEI) offers exceptional strength, heat resistance, and chemical stability, ideal for demanding industrial applications.

Carbon-fiber-reinforced filaments, like nylon or PETG composites, provide lightweight yet rigid parts suitable for structural use.

Polycarbonate (pure) delivers high strength, toughness, and heat resistance, ideal for engineering-grade parts but demands precise print settings.

Nylon 12CF (Carbon-Fiber Nylon 12) combines the toughness of nylon with the rigidity of carbon fiber, excellent for high-stress applications.

Recommended reading: PEEK 3D Printing: Unlocking the Potential of High-Performance Polymers

How to Make 3D Printed Parts Stronger

Part Design

Create strong 3D printed parts with thoughtful CAD design focused on minimizing stress points and distributing loads effectively. Avoid sharp corners, which concentrate stress and can lead to cracking. Instead, use fillets or chamfers to create smoother transitions. Reinforce key areas with ribs, gussets, or thicker sections to increase structural integrity without significantly adding weight.

Consider load paths and how forces will act on the part. Use organic, curved shapes when possible, as they better handle distributed forces. Design for symmetry and balanced geometry to prevent warping and mechanical failure.

Infill Patterns

Infill patterns play a critical role in determining the strength of 3D printed parts. For maximum mechanical strength, high-strength infill patterns like cubic and gyroid are commonly used.

The basic grid pattern provides adequate strength along both axes due to its crisscross structure, making it ideal for load-bearing parts. However, the cubic pattern offers similar strength while being more material-efficient. Gyroid infill stands out for its continuous, wavy structure, providing isotropic strength while reducing weight.

For flexible materials like TPU, one of the best infill patterns is the concentric pattern. Its circular layers mimic natural structures, allowing for uniform flexibility and resistance to tearing. This pattern evenly distributes stresses, making it ideal for wearable or impact-resistant parts.

Other 3D Printer Settings

Print orientation greatly affects strength. Align parts so critical features face the strongest print axis, parallel to the print bed. Additionally, slower print speeds improve layer bonding by allowing better material adhesion. Higher nozzle temperatures enhance interlayer strength but should stay within material limits to prevent stringing or overheating.

Increasing wall thickness and enabling more perimeter shells boosts part durability. Use a lower layer height for finer bonding, though this extends print time. Adjusting the cooling fan speed—lower or off for materials like ABS—helps prevent weak layer adhesion. Correct bed leveling and proper extrusion settings also ensure consistent, strong prints.

Post-Processing Techniques

Post-processing can significantly enhance the strength of 3D printed parts. Annealing is a common method where parts are heated in an oven to relieve internal stresses and improve layer adhesion. For materials like PLA, annealing at around 80-100°C can increase heat resistance and tensile strength, though it may cause slight warping. Longer annealing times are particularly effective on carbon fiber-reinforced filaments.[3]

Coatings like epoxy resin or polyurethane create a protective outer layer, boosting impact resistance, waterproofing, and surface finish. Applying fiberglass or carbon-fiber wraps can reinforce critical areas.

That being said, post-processing for part strength is more critical for non-extrusion processes. For instance, vat photopolymerization generally requires post-curing for stronger parts, while most metal printing technologies require extensive heat treatment to produce high-quality parts.

Recommended reading: The Ultimate Guide to 3D Printing Post-Processing Techniques

How to Calculate the Strength of a Printed Object

Testing the strength of 3D printed parts involves several key methods, each targeting specific mechanical properties like tensile, impact, and flexural strength. These tests ensure that printed components meet performance requirements for real-world applications.

Tensile Strength Testing

Tensile strength measures a material’s resistance to being pulled apart. Standardized test specimens, typically shaped like dog bones, are printed according to ASTM D638 or ISO 527 standards. The test involves placing the specimen in a tensile testing machine, where controlled pulling force is applied until failure occurs. The maximum stress endured before breaking indicates tensile strength.

Consider factors like print orientation, layer height, and material type, as tensile strength is often weakest along the Z-axis due to layer adhesion. Comparing results from different orientations can highlight how print settings affect structural integrity.

Impact Strength Testing

Impact strength tests measure a material’s ability to absorb energy during sudden impacts. A common method is the Charpy or Izod impact test, where a notched test specimen is struck by a swinging pendulum. The energy absorbed during fracture indicates the material's toughness.

For 3D printed parts, ensure consistent print settings and part orientation to obtain accurate results. Tough materials like nylon, PETG, and polycarbonate usually excel in these tests, while PLA tends to be brittle. Adding notches simulates real-world stress concentrators, making the test more representative.

Flexural Strength Testing

Flexural strength indicates a material’s resistance to bending forces. The three-point bending test is commonly used, where a printed specimen is supported at two ends while a force is applied at the center until it breaks. ASTM D790 provides standard guidelines for this test.

Flexural testing highlights how well a material handles compressive and tensile forces simultaneously. For FDM parts, print orientation matters: parts printed with layers aligned along the bending axis perform better. Materials like ABS and carbon-fiber composites offer high flexural strength, making them suitable for load-bearing applications.

Recommended reading: How to Solve Common 3D Printing Problems

Conclusion

On the whole, the strength of 3D printed parts depends on factors like printing technology, material selection, design, and process settings. While FDM parts are inherently weaker along layer lines due to anisotropic properties, careful design, proper orientation, and use of advanced materials like fiber-reinforced filaments can significantly boost strength. Post-processing methods such as annealing and coating further enhance durability.

Ultimately, 3D printed parts can be remarkably strong when engineered and manufactured correctly, rivaling traditional manufacturing methods in many applications from prototyping to end-use production.

Frequently Asked Questions

What factors determine the strength of 3D printed parts?

Part strength depends on factors such as the material used, print orientation, layer adhesion, infill pattern, and wall thickness. Post-processing techniques like annealing or applying protective coatings can further enhance strength.

Which 3D printing technology produces the strongest parts?

Metal 3D printing (including processes like DMLS/SLM) produces the strongest parts, followed by industrial processes like SLS for plastics due to its isotropic properties. FDM can also create strong parts with the right machinery, materials, and print settings.

How can I increase the strength of FDM 3D printed parts?

Use strong filaments like fiber-reinforced nylon, optimize print orientation, use a strong infill pattern, and increase wall thickness. Post-processing methods like epoxy coating or annealing can also improve strength.

How are 3D printed parts tested for strength?

Common tests include tensile testing (pulling force), impact testing (sudden force resistance), and flexural testing (bending resistance). These tests follow ASTM or ISO standards for consistent, accurate results.

References

[1] Kafi A, Wu H, Langston J, Atak O, Kim H, Kim S, Fahy WP, Reber R, Misasi J, Bateman S, Koo JH. Evaluation of additively manufactured ultraperformance polymers to use as thermal protection systems for spacecraft. Journal of Applied Polymer Science. 2020 Oct 5;137(37):49117.

[2] Ahn SH, Baek C, Lee S, Ahn IS. Anisotropic tensile failure model of rapid prototyping parts-fused deposition modeling (FDM). International Journal of Modern Physics B. 2003 Apr 10;17(08n09):1510-6.

[3] Stojković JR, Turudija R, Vitković N, Górski F, Păcurar A, Pleşa A, Ianoşi-Andreeva-Dimitrova A, Păcurar R. An experimental study on the impact of layer height and annealing parameters on the tensile strength and dimensional accuracy of FDM 3D printed parts. Materials. 2023 Jun 25;16(13):4574.

Table of Contents

How Strong Are FDM 3D Printed Parts?Other 3D Printing TechnologiesAre 3D Printed Parts as Strong as Molded Parts?The Strongest 3D Printing MaterialsStrong Consumer-Level MaterialsStrong Engineering MaterialsHow to Make 3D Printed Parts StrongerPart DesignInfill PatternsOther 3D Printer SettingsPost-Processing TechniquesHow to Calculate the Strength of a Printed ObjectTensile Strength Testing Impact Strength TestingFlexural Strength Testing ConclusionFrequently Asked QuestionsReferences