How To Calculate Electric Car Efficiency With A Vehicle Performance Model

The Vehicle Performance Model, or the VPM, is our main tool to develop the cleanest car on the market, Lightyear One.

Lightyear's Vehicle Performance Engineer Wouter Jansen

This article was discussed in our Next Byte podcast.

The full article will continue below.

The Vehicle Performance Model, or the VPM, is our main tool to develop the cleanest car on the market, Lightyear One.

What makes this model an engineering feat is its importance in the design process. So, instead of physically building all of the concepts, we use the VPM to find the perfect and most efficient architecture.

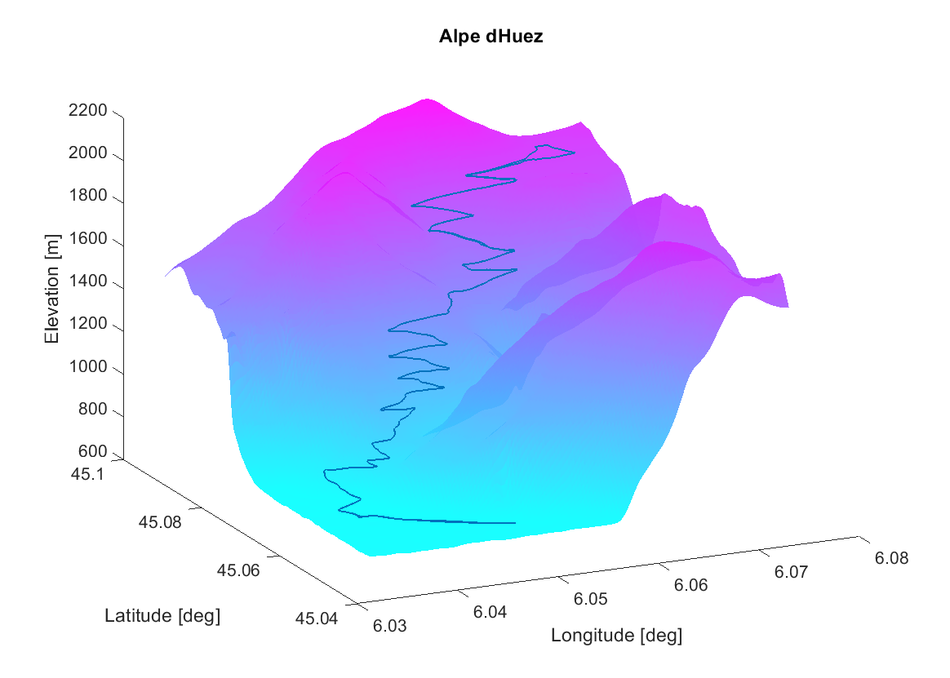

Fig 1: Use cases, like the Alpe d’Huez mountain pass pictured above, are used as an input for the model, to validate the vehicle's capabilities on steep inclines and sharp hairpin turns.

What is Lightyear’s VPM?

The Vehicle Performance Model was co-created by ex-Tesla employee Wouter Jansen, current Vehicle Performance Engineer at Lightyear.

The model has been non-stop improving and adapting for over 8 years, with its main goal being to accurately predict energy consumption and solar yield. The results are then used to select the concepts that lead to the most efficient solar car out there.

The VPM delivers what can only be described as the digital form of the car. This gives engineers the ability to figure out how the smallest change in, for example, the shutter grill can affect the performance of Lightyear One.

The model is a forward simulation, which works by calculating, for each timestep, all forces acting on the car, like the aerodynamic drag, rolling resistance, gravity, etc. All of these are added up and subtracted from the motor torque, resulting in the force that determines the acceleration.

Typical drive cycles are simulated, like the WLTC or Artemis, in which a control loop compares the vehicle speed to the cycle, to control the motor torque. Using detailed models of the motors, inverters, battery, and auxiliary systems of the car, the VPM then computes the total current drawn from the battery.

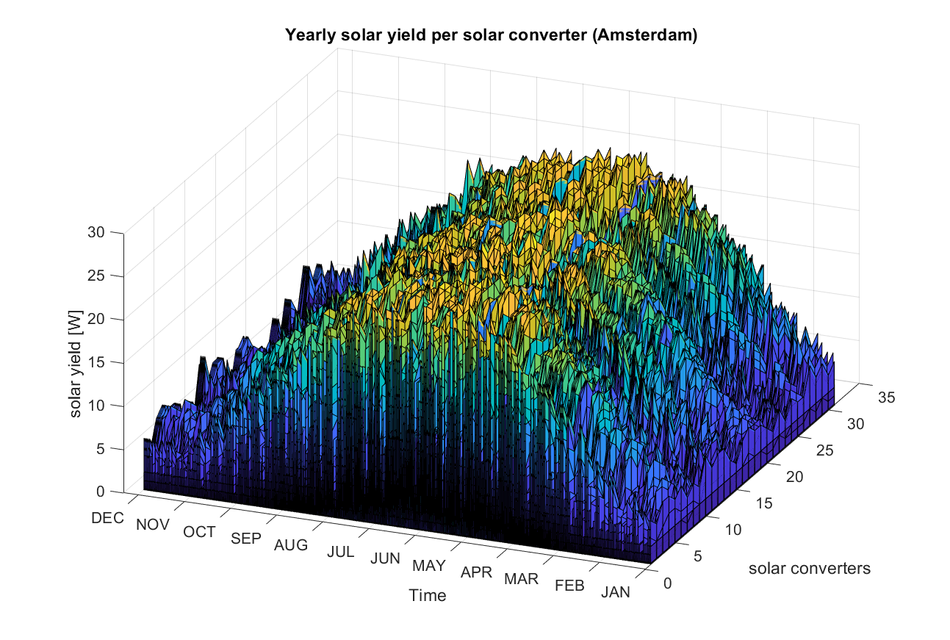

The resulting energy consumption can be used to calculate the range on the simulated drive cycle. Since Lightyear is developing a solar car, the VPM also computes the amount of energy generated by the solar panels and how much of that gets converted to the battery (Fig. 2).

Fig 2. Visualisation of the simulated yearly solar yield in Amsterdam. It is calculated per hour, for each of the 31 groups the solar panel is divided in. The 'wave' shape shows the difference in solar conversion in summer and wintertime.

The process of using the VPM is based on continuous advancement. That’s why the steps we take are created for a circular course of action:

- Develop an initial model

- Validate said model

- Generate various concept architectures

- Model these concepts

- Simulate the performance of the new concepts

- Analyse the final results

- Pick the most efficient concept

- Repeat this process until it is optimised

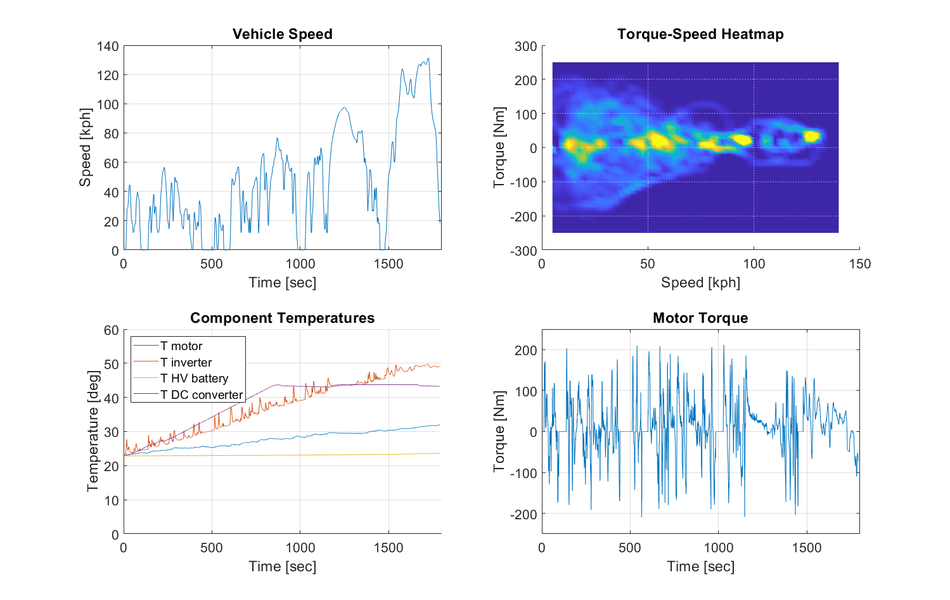

Fig 3. Simulation of a standardised automotive energy consumption procedure (WLTC), that is often used to measure vehicle range. It shows the vehicle speed, what temperatures some components have, and how the motor torque changes overtime. It also shows a torque-speed graph, which is the motor’s operating points.

In the video above, Lightyear's Vehicle Performance Engineer — Wouter Jansen explains the Vehicle Performance Model and its benefits.

The constant running of the Vehicle Performance Model shows how much we want to constantly improve and optimise our Lightyear One. Seeing how this is both a technological venture, as well as a step towards a better world, Lightyear is the perfect place for engineers who want a new challenge or to make their mark.

If our project caught your attention, you can always stay tuned to Lightyears’ latest Tech developments, or check out our vacancies.