Lunar Rover Arm Brings Increased Functionality to space missions.

The student winners of the High-Temperature Carbon-Fiber 3D printing challenge have ambitions to build better rovers.

Mitsubishi Chemical Advanced Material’s startup accelerator, Growth Garage concluded the High-Temperature Carbon-Fiber 3D printing challenge in December 2021. In this challenge, the participants were asked to incorporate the strength and properties of the KyronMax® carbon-fiber 3D printing filament with the flexibility and sustainability of 3D printing in their design. The challenge focused on three main criteria: technical and commercial feasibility, scalability, and sustainability. We are composing a series of articles featuring the finalists and winners of the challenge so that the readers get a comprehensive view of their product, motivation and vision for the future.

Student Winners: Concordia University Team’s Lunar Rover Arm

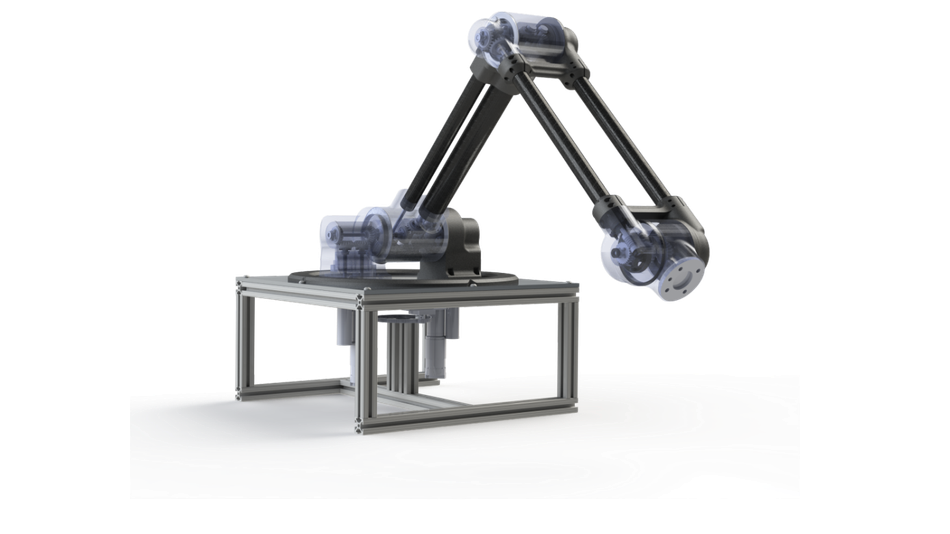

In this article, we feature the Student Award Winners from Concordia University based in Montreal, Canada. The student project is currently being carried out by a group of seven undergraduate students who are developing a robotic arm which would be installed on a lunar rover for excavation and sample collection activities. The project is based on specifications provided by the Canadian Space Agency.

"The parameters that we are dealing with are mainly extreme fluctuations in the ambient temperature on lunar surfaces. We must equip the lunar arm to not only operate in the extreme heat of the lunar day, but also during the extremely cold weather of the lunar night. Our task is to design and manufacture a preliminary prototype which can survive in these conditions," explained Aidan. Additionally, the lunar surfaces also tend to have significant levels of radioactivity. It is imperative to ensure that the lunar arm is protected against these conditions.

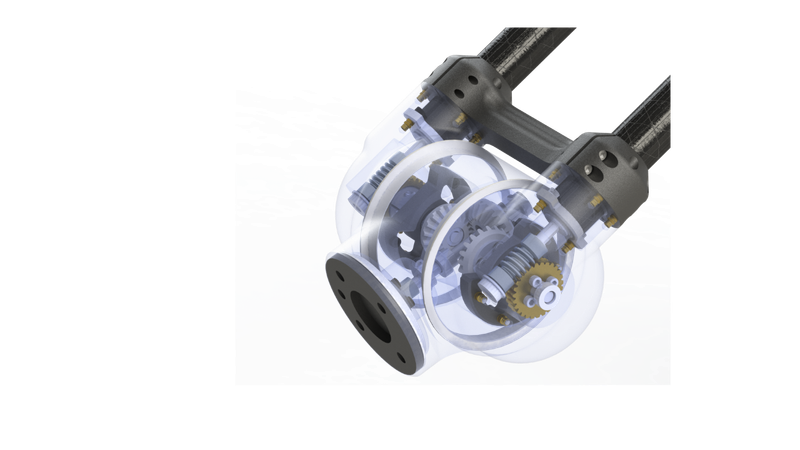

Typically, robotic arms employ motors housed within the arm to provide articulation at several joints. It isn’t feasible to implement this mechanism in environments with extreme temperature fluctuations. In order to protect the electronic components, the actuators and electronics are enclosed inside the insulated and heated enclosure of the rover located below the arm. "To address these problems, we have decided to implement a complete mechanical motion transmission, which allows us to enclose the electronic components such that they don’t get exposed to the surroundings," explained the team lead, Aidan Mitchell.

Light, flexible and energy efficient

The scope of activities that would be performed by the lunar arm are restricted to excavation and sample collection. The robot assembly uses a shaft and gear motion transmission, which ensures a smooth mechanical motion. "The base of the assembly is equipped to have five degrees of freedom, which enables the arm to perform 360-degree motions. The second motor moves the top joint, enabling the excavation motion," said Aidan. The lunar arm must be light in order to ensure that the energy spent on its transportation is minimal. At the same time, it should have enough force and lift capacity to be able to collect soil samples.

KyronMax® offers more design flexibility

"We are opting to use 3D printing, as we want to build prototypes with complex geometries, quickly and economically. When we were conducting the material research, we stumbled upon the 3D printing challenge. After researching more about the KyronMax® material, the team realized that it is perfect for our project. The main value proposition of KyronMax® is its high strength, which makes our task easier of creating a light and strong prototype,” explains Mitchell.

Knowledge and Mentorship

Being the winners of the student award, the lunar arm team would receive support and mentorship from MCAM and Growth garage for design optimization, material selection, and creation of business plans. "As students, we are always looking for avenues and opportunities for gaining knowledge, and receiving guidance and support from experts in the field. We are really looking forward to working with the MCAM team to steer our project towards the path of success," concluded Aidan.

Follow Growth Garage's LinkedIn page for more interesting stories about 3D printing entrepreneurs in various fields.

The Composite Engineering Challenge

We are inviting innovators, entrepreneurs, and early adopters at universities, (pre-) startups, and scaleups that need fiber-reinforced composites to realize their prototype, part, product, or application.

We welcome projects, programs, and companies in the field of new mobility (EV, e-motor, battery casing, etc.), autonomous (delivery) vehicles, people movers, robotics, aerospace, space, bicycles, UAV, AAV, bionics (wheelchairs, exoskeletons, prosthetics), alternative energy (production, storage, transport), self-sensing or self-healing, sport & leisure, alternative (low carbon footprint) fibers and more!

The winning entry will be rewarded with a partnership with Growth Garage, Business Incubator of the MCG Advanced Materials Division.

This partnership package is valued at $25,000 and will be tailored to the winning team’s needs according to their current business and product development stage.

READ MORE ABOUT THE CHALLENGE HERE.

Key Dates

|