Pressing For Change at Atna

Article #3 of our simulation series. Advanced simulation tools helped this German startup design a press machine that plays a role in reducing carbon emissions.

ATNA Industrial Solutions GmbH started as a spin-off of the German Technical University Bergakademie Freiberg (TU Freiberg) following a research project funded by the German program EXIST for business startups. As part of this two-year project, four engineers developed a new hydraulic press machine for briquetting – a technology compressing material into solid shapes/ briquettes – and built their first prototype.

The success of this prototype, which delivered high quality at a high throughput, inspired the team to start ATNA – a startup with the vision to revolutionize briquetting by building better and more efficient briquetting presses. The concept of briquetting has become popular for various raw materials (wood, straw, coal) and waste materials (sludge, PU foam, plastic shreds) and so the demand for flexible and efficient pressing machines is high.

The Challenge

The demand for biomass briquetting is steadily increasing as the use of brown coal fuel is being dramatically reduced to meet CO2 emission targets in the near future. Many big plants across Europe will stop producing brown coal briquettes by the end of 2022. To address this trend and growing demand for alternative fuel options, ATNA set out to develop a new generation of briquetting presses.

While conventional briquetting presses such as the roller press achieve high throughputs, they have limitations in producing high-quality briquettes of difficult raw material. On the other hand, conventional hydraulic presses can achieve a high quality, but deliver only a low throughput. ATNA’s goal was to design an improved hydraulic press which can achieve the high throughput of a roller press while delivering a high briquette quality.

To begin to design this system, the team used a CAD embedded FEA system available to them, to study subassemblies. However, limitations in the system made this a cumbersome and time-consuming task and ATNA were not able to analyze the entire system. As a result, simulation was strictly limited to absolutely necessary calculations of forces and resulting stresses on the parts. To accomplish their design targets, however, the startup needed simulation tools that help them to get the bigger picture and would deliver an overall assessment of their new designs to speed up their development process.

Thomas Müller co-founder and Commercial Manager, ATNA Industrial Solutions will present at the Don’t Be Late to Simulate event on November 30. Thomas will discuss the story of ATNA outlining the challenges and benefits of using simulation and how it now drives their design process. Learn more about Thomas’s presentation here.

Simulation Solutions with Altair

ATNA was offered to implement Altair SimSolid® under the global Altair Startup program which is tailored to the needs of high-tech startups offering access to all types of simulation, high-performance computing, and artificial intelligence solutions at an affordable price. Altair SimSolid® is a simulation package that enables fast structural analyses. It eliminates geometry preparation and meshing: the two most time-consuming, expertise-extensive, and error-prone tasks performed in a conventional structural simulation. For the ATNA engineers, the structural simulation tool allowed them to virtually simulate entire machines quickly and efficiently with a high degree of accuracy.

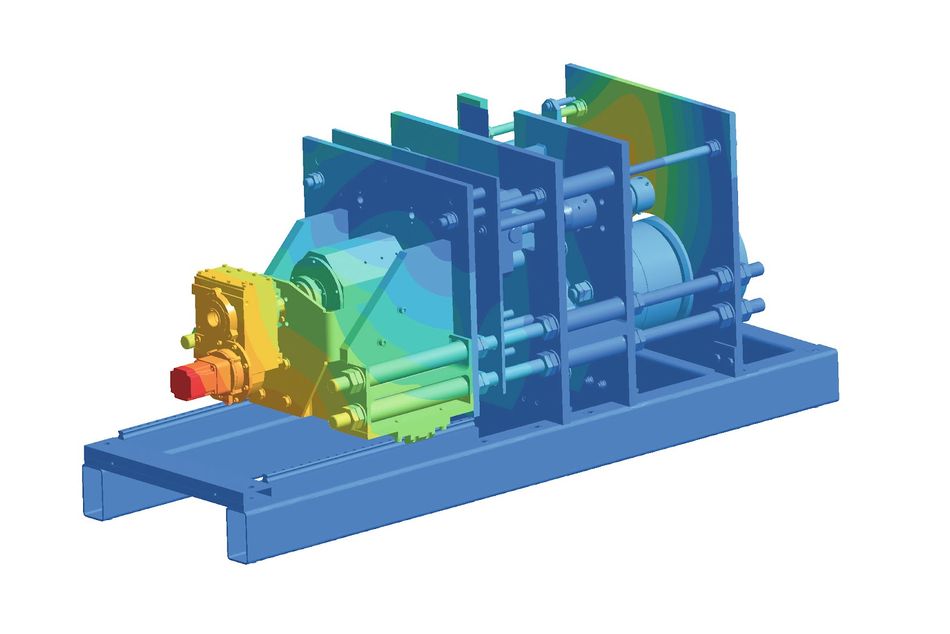

Altair® SimSolid®simulation result of all load-carrying elements of the ATNA briquetting press.

Altair® SimSolid®simulation result of all load-carrying elements of the ATNA briquetting press.The developers applied SimSolid to structurally design their briquetting press that can produce briquettes in a multistage pressing process (pre-compacting, pre-pressing, main pressing, and extraction) and realized high throughputs with low energy consumption. SimSolid enabled the ATNA team to study complete complex assemblies, including more than 2800 parts, accurate forces, and resulting stresses of the entire system, and provided an overall structural insight on the machine’s behavior.

It allowed the engineers to make assessments during design revisions by running simulations on the fly to detect disadvantageous operational conditions and design faults. While it took the ATNA engineers several days to calculate even small model changes with the traditional finite element method (FEM) tool, SimSolid provided them with initial results within 30 seconds.

ATNA also applies SimSolid to customize presses tailored to customer requirements, such as special operating conditions including high pressures up to 5600 kilonewtons. With SimSolid, ATNA can now study how the design affects the deflection of these pressures and thus the entire structure.

Why fast innovation is more important than ever

Responding to the climate crisis must be a priority for engineers everywhere. Simulation will play a key role in delivering the exponential innovation needed to transform industries away from fossil-fuel dependency. In the past simulation was limited to large design teams with expansive budgets, but now specialized simulation software is available more democratically and designers at all levels can incorporate simulation from the very beginning of their design cycles.

Simulation offers the possibility for rapid iteration and testing as seen by Atna to help develop products not only with more speed but with a finished product that is more efficient, and specific. Simulation can be applied not only in the design stage of product development but in the monitoring and revision of existing systems such as through the use of digital twins as well as a low resource method to speculate on future technologies and products.

Speed up of the simulation process with Simsolid at ATNA

This is the third of five articles in a series about simulation tools sponsored by simulation software provider Altair. Future articles will cover case studies on using simulation in product design, workshops on how to get started with advanced simulation software, and explore the applications of multiphysics simulation.

Altair are hosting the free virtual global event, Don't Be Late To Simulate on November 30, 2021, | 2:00 p.m. (Paris) and at 8:00 a.m. (New York).

Thomas Müller co-founder and Commercial Manager, ATNA Industrial Solutions will present the session titled, Simulation under Pressure: How SimSolid Changes Everything in FEA about ATNA’s use of simulation. He will discuss the design process of ATNA outlining the challenges of fulfilling both customer flexibility and rigorous adherence to quality and safety standards. With limited resources, ATNA was able to use simulation as a design tool to deliver a machine design that exceeded both expectations. To check out this session, or any of the others register on the event page here.

Article #1 is about how simulation tools improve the development process, enabling engineers to deliver better products in less time.

Article #2 demonstrates why CAD-based Simulation Can Become a Game of Cat and Mouse.

Article #4 previews a workshop that will take place at the Don’t be Late to Simulate event on November 30.

Article #5 speaks for the advances in software and increased access to inexpensive compute power means more and more engineers can use Multiphysics analysis to improve their design processes.

About the sponsor: Altair

Altair is a global technology company, which provides software and cloud solutions in the areas of simulation, high-performance computing (HPC), and artificial intelligence (AI). Altair enables organizations in nearly every industry to compete more effectively in a connected world while creating a more sustainable future. Wherever you are and whatever you’re doing, Altair’s solutions surround you – keeping you safer, more connected, and more productive. They can be found in big places and small — on highways, hospitals, and hockey rinks, in stadiums, skyscrapers, and subways, and in banks, bikes, and boats.