Solid-State vs. Li-ion: Which Battery Tech is better for Electric Vehicles?

Article #6 of Innovations in Electric and Autonomous Vehicles Series: Getting the capital equipment in place and ramping up the supply of batteries will help transition the market from liquid- to solid-state. Industry and consumers will both benefit.

This is the sixth article in an 8-part series featuring articles on Innovations in Electric and Autonomous Vehicles. The series presents an insight into the developments and challenges in the automotive sector as it undergoes massive transformations with the arrival of electric and self-driving vehicles. This series is sponsored by Mouser Electronics. Through the sponsorship, Mouser Electronics shares its passion for technologies that enable smarter and connected applications.

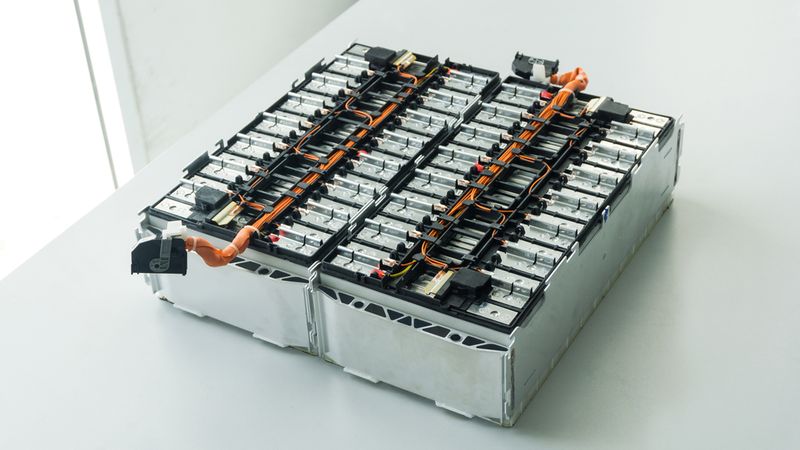

The cost of Li-ion, the leading electric vehicle (EV) battery chemistry technology, will soon settle at a mature market value due to market dominance.[1] With that, there is an opportunity for alternate chemistry innovation to gain a share of the battery segment. One such chemistry, solid-state batteries, is poised to emerge as the leading chemistry for EV batteries.

In this article, we present a comparison between the commonly used Li-ion batteries and the (relatively) new solid-state batteries for EVs. We also analyze some barriers preventing the mass adoption of the new battery technology.

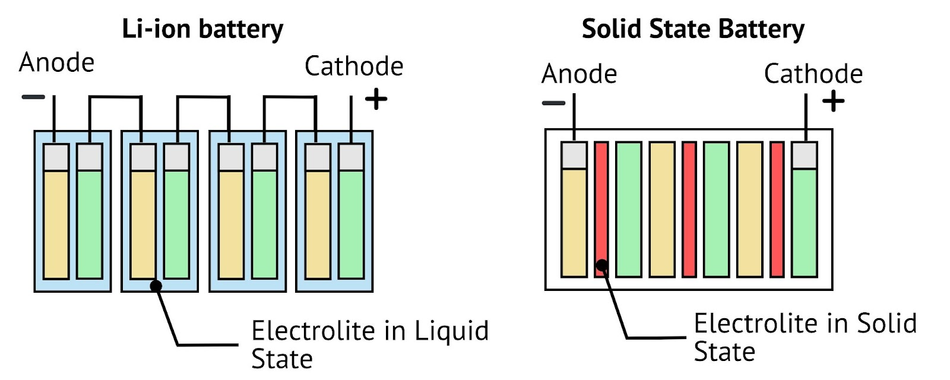

Li-ion vs. Solid-State Electrolytes for Battery Electric Vehicles

Li-ion is still leading the market for liquid-state electrolytes. But Li-ion is not without challenges: The chemistry carries higher costs as skyrocketing demand outstrips supply. In addition, there is an opportunity to improve the top safety concern of flammable liquid catching fire. Safety is one of the most critical success criteria for EVs to inspire public confidence, so the industry and safety regulators are searching for how to reduce the flammability risk.

Solid-state batteries (using lithium metal as one of its elements) address the most pressing safety challenges of Li-ion. They are more stable and contain a higher energy density than Li-ion. In addition, solid-state comes from readily available materials, which reduces the need to mine. It also offers lower flammability, faster charging, and extended range.

Barriers to the Wide-Scale Adoption of Solid-state Electrolytes for Electric Vehicles

With the advantages of safety, charge time, performance, and availability, solid-state is the future of EV batteries. However, there remain a few barriers to wide-scale adoption for battery developers.

First, solid-state batteries will carry a higher development cost due to a lack of existing capital to produce mass quantities.There are also gaps in the solid lithium electrolyte material that degrade battery performance and service life when implemented into Battery Electric Vehicles (BEVs).

In addition, solid-state batteries are prone to cracking, and it is best to charge them at 60°C for optimal performance.

Solid-state EV batteries are not yet mass-produced. As with any development material, optimizing the manufacturing process to scale profitably is essential. As a result, manufacturing challenges through the lack of experience with solid electrolyte materials would substantially delay wide-scale adoption. In addition, these challenges could shut down the EV battery plant, negatively impacting the public's first interaction with the new battery chemistry.

To address development costs, automakers could vertically integrate to cut development costs and decrease supply risks, creating resiliency between original equipment manufacturers (OEMs) in the face of supply shortages. Their goal is to find a better solution for Li-ion batteries while reducing solid-state manufacturing costs.

Having said that, OEMs are already shifting development to solid-state, given all their benefits. Adoption has already started: Toyota announced it will invest $13.5 billion by 2030 into solid-state batteries, and a group including Volkswagen, Ford, and BMW announced solid-state initiatives in the coming years.[2]

Conclusion

Solid-state batteries address the flammability safety concerns with liquid-state batteries, charge faster, and provide a more extended driving range. Commissioning the capital and ramping supply of the batteries will aid the transition from liquid- to solid-state, preparing EVs for long-term success and massive consumer adoption.

This article is based on an e-book by Mouser Electronics. It has been substantially edited by the Wevolver team and Electrical Engineer Ravi Y Rao. It's the sixth article from the Innovations in Electric and Autonomous Vehicles Series. Future articles will introduce readers to some more trends and technologies transforming the automotive sector.

The introductory article presented the different topics covered in the Innovations in Electric and Autonomous Vehicles Series.

The first article discussed the present state of autonomous vehicles.

The second article explains MaaS and how improvements in automotive technologies are speeding up its adoption.

The third article takes a look at how the 3GPP intends to use 5G in V2X applications with significant advantages over current dedicated short-range communication or other Cellular-V2X proposals.

The fourth article explains Driver Monitoring Systems (DMS) and their role in reducing the possibility of mishaps due to human errors

The fifth article examines some of the ways EV technologies will evolve, and some of the obstacles they need to overcome before the automotive industry can transition to fully electric

The sixth article discusses solid-state batteries, a promising alternative to conventional Li-ion batteries

The seventh article explains active noise cancellation and why it’s a very effective solution for eliminating noises in automobiles

The final article focuses on Human Machine Interfaces, the sleek and stylish dashboards that are changing the way we interact with cars

About the sponsor: Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,200 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.

References

[1] David L. Chandler, ‘The reasons behind lithium-ion batteries’ rapid cost decline’, MIT News, 22nd November 2021, [Online], Available from: https://news.mit.edu/2021/lithium-ion-battery-cost-1122

[2] Tim Kelly, ‘Toyota to spend $13.5 bln to develop electric vehicle battery tech by 2030’, Reuters, [Online], Available from: https://www.reuters.com/business/autos-transportation/toyota-spend-over-135-bln-ev-batteries-by-2030-2021-09-07/