Sustainability through Digitalization in Engineering

Engineers can further their sustainability focus during design and development

Image credit: Altair/Belgian Solar Team

Engineers are responsible for creating safe products for all potential users - not just for the time that product is in use but for its whole lifecycle from raw material to recycling and reuse of its parts.

In this article, we will explore how engineers can focus their efforts on sustainability throughout the design and development of products. Through digitalization, using artificial intelligence such as machine learning, and putting high-performance computing to use, engineers can increase the sustainability of the products they produce and the processes they use to create those products.

We will also share details of the Future.Industry event sponsored by Altair from the 4th-6th of October.

Implementing Change in Product Development

The Earth’s climate is changing, and the temperature is rising at a rate higher than that seen in the last 10,000 years - a direct consequence of industrialized human activities that began in the 1800s[1]. It’s our job as engineers to take this evidence and ensure that the products and systems we develop and the processes we employ are not contributing to the increasing climate crisis through digitalization in every step of development.

Materials: Considering circularity

A sustainable design process must start with the materials. Consideration must be given to materials that have already been recycled or that have the capacity to be reused to be recycled at the end of their lifecycle. Further, the availability of that recycling process and accessibility to it must also be considered. For example, building a product with full circularity is only successful if there are clear ways to get the parts/product back to the OEM or designated recycling point.

Using simulation to shorten design time

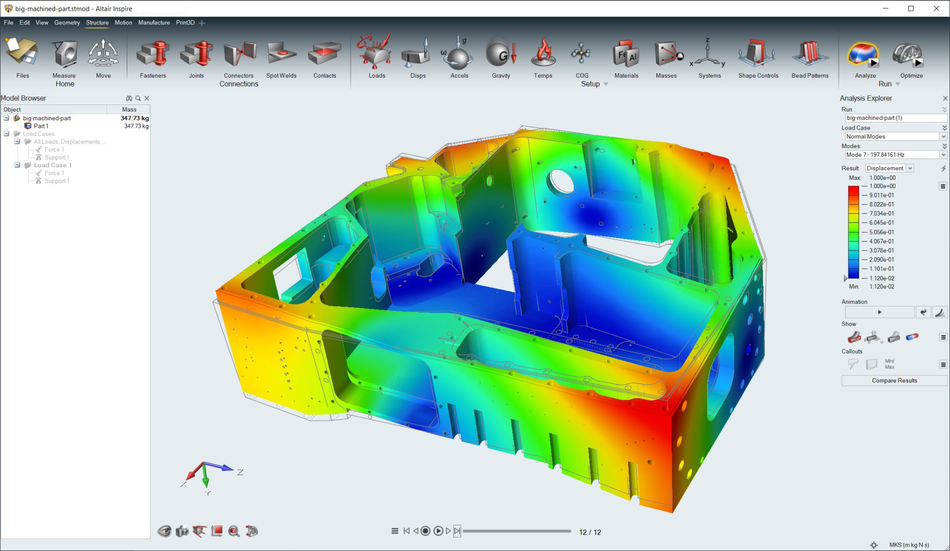

Part of building for circularity may require testing a new material that engineers haven’t considered for a particular product. To understand the material in action before building physical prototypes, simulation tools can be used to build models and test under a variety of conditions. By digitalizing the product design cycle using simulation tools, engineers reduce waste and minimize the energy consumed in the production of the materials, prototypes and during testing. Simulation tools have the capacity to test many different aspects of the design process, including crash testing, impact testing, fatigue loading, stress testing, aerodynamic analysis, weight reduction, and much more.

Intelligent decision making

Another way that product development is being transformed is using artificial intelligence and machine learning. Never before have engineers and scientists had access to such high-quality computing resources fairly affordably. Engineers are also cleverly applying machine learning to help optimize products and create innovative solutions to design problems.

For example, with voice recognition technology, engineers can use machine learning to continually improve their natural language understanding (NLU) engines, instead of needing to manually update models and datasets to improve performance. Not only does this save time and money for companies, but it also reduces the amount of energy spent on physical testing and human-driven model updates when the machine learning algorithms can run efficiently in the background.

How the Altair Future.Industry Event is Leading the Sustainability Charge

Altair is hosting the event, Future.Industry from October 4th through the 6th to bring together the engineering community to discuss how technology is being reimagined to enhance the product development process and in turn, the products themselves.

Future.Industry presents a range of keynote speakers, thought leaders, and Altair’s leadership team who will share their vision for the future, including how sustainability can be improved and incorporated throughout the product development design cycle.

The Future.Industry event is being hosted completely online and will be available in two separate time zones (CEST and EDT) and live translations into various languages to accommodate the engineering community around the globe. Speakers from cutting-edge companies, including BMW, Intel, Tech Mahindra, Samsung, GE, Leonardo, Google, Xscape Photonics, Lucid Motors, EVR Motors, and ArcelorMittal will be present.

The first day of the event will begin with thought leadership around the future of product development to inspire what is possible. The second and third days of the event allow for a more curated and in-depth experience with separate tracks that will apply more to your industry or sustainability in general.

A highlight of the event will be the keynote from Amy Webb, founder and CEO of the Future Today Institute who will present a talk titled, Why do we keep Getting the Future Wrong?

In this presentation, Webb will explain how leaders can harness a futurist’s strategic tools for the benefit of their organizations. She asks us why we keep re-imagining the things we already know about, explains how to pay attention to the signals in order to think about platforms differently, and considers the impacts of what we are already doing.

On day two, you can take part in a panel discussion hosted by Altair on pioneering the future of sustainability through better engineering. During this conversation, you’ll hear more detail on the role of start-ups in transitioning to a circular economy and the role of digitization supporting sustainability initiatives.

There are two other tracks that you could investigate depending on your industry: Electrifying Your Product Portfolio and Driving Sustainability. The former will be very helpful for those invested in electric vehicles and sustainable mobility solutions and will feature case study examples from EVR, while the latter will be applicable in a broader sense to engineers looking for examples of how to design with sustainability in mind.

On day three, the sessions will become more focused on the digitalized solutions that Altair brings to each industry. The sessions are interactive and are your chance to learn from a mixture of industry and Altair experts, sharing knowledge and ideas. Keep an eye out for a session called Accelerating Product Development with End-to-End Electronic System Design, which will further the conversation on sustainable digital solutions.

In addition, there is the main session, titled Solving the Challenge of Electrification in Every Industry, which will cover some of the topics briefly touched upon above, including green energy sources. Finally, the session on the last day, titled Simulation-Driven Design for Manufacturability, will discuss the digital tools that can help save time, energy, and material when designing and developing products.

Register for Future.Industry Today

The Future.Industry Event is completely virtual, allowing companies of all sizes to attend without the required travel of traditional conferences. The global event spans October 4th through the 6th, with parallel learning tracks to ensure you have access to the information and experts that are most aligned with your current projects. Presentations will also have live audio translations in French, Spanish, German, Italian, Portuguese, Japanese, and Korean.

To learn more about the agenda and register your spot to attend, visit the Altair Future.Industry website.

About the sponsor: Altair

Altair is a global technology company, which provides software and cloud solutions in the areas of simulation, high-performance computing (HPC), and artificial intelligence (AI). Altair enables organizations in nearly every industry to compete more effectively in a connected world while creating a more sustainable future.

References:

1. Climate change evidence: How do we know? [Internet]. NASA. Earth Science Communications Team at NASA’s Propulsion Laboratory; 2022 [cited 2022Sep6]. Available from: https://climate.nasa.gov/evidence/