Types of CNC Machines: Advanced Solutions for Engineers

Delve into the types and capabilities of CNC machines, empowering engineers with a comprehensive understanding of their diverse applications. This guide equips engineers to leverage CNC technology for innovative solutions across industries.

Introduction

CNC (Computer Numerical Control) machines have transformed manufacturing processes across industries. They offer precise control through computer programming, ensuring exacting standards and efficiency. CNC milling machines craft components with unmatched precision, while CNC lathes are vital for automotive part production. By leveraging CNC technology, industries achieve superior quality, minimize errors, and optimize workflows. With a range of specialized types of CNC machines such as routers and plasma cutters, CNC machines cater to diverse manufacturing needs, driving productivity and innovation across sectors.

The Basics of CNC Machines

CNC (Computer Numerical Control) machines are automated tools controlled by a computer executing pre-programmed sequences of machine control commands. These machines combine mechanical design with software-based control, allowing for high precision and repeatability in manufacturing processes.

Through the seamless integration of mechanical design and software-based control, CNC machines revolutionize manufacturing by providing unparalleled precision and repeatability. By executing pre-programmed sequences of commands, they enable the automated production of intricate components across various industries. This sophisticated technology not only enhances efficiency but also ensures consistency in output, reducing the margin for error and waste. With continuous advancements in CNC technology, manufacturers can stay ahead of the curve, meeting the demands of increasingly complex production requirements while maintaining the highest standards of quality and reliability.

Common Types of CNC Machines

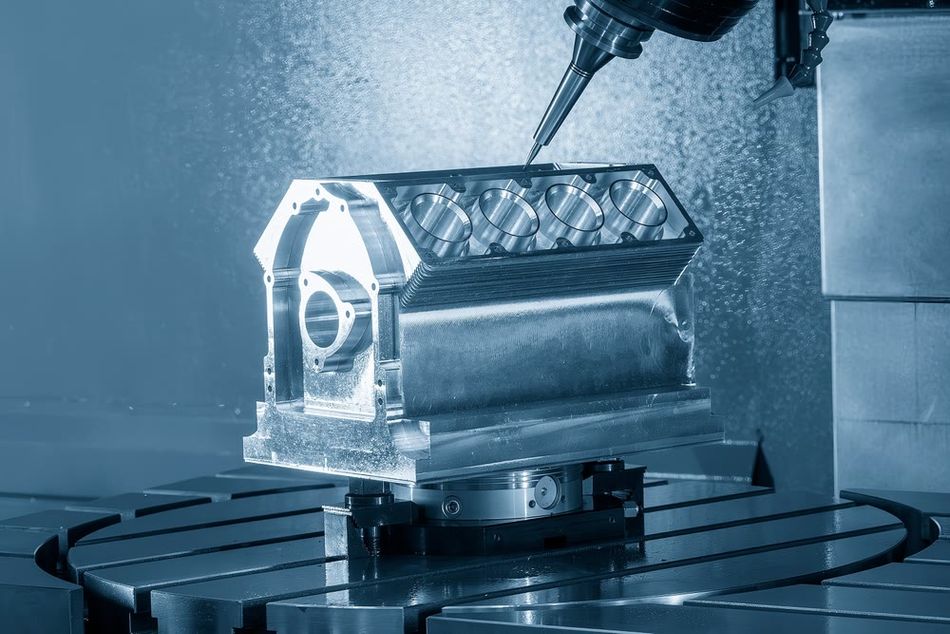

CNC Milling Machines

Axis Configuration: Typically 3-axis (X, Y, Z) with options for 4-axis and 5-axis machines, allowing for complex geometries and increased flexibility. Advanced models may offer additional rotational axes, such as A and B axes, enabling simultaneous machining from multiple angles and facilitating the production of complex components with intricate features.

Drive Systems: CNC milling machines use ball screws and servo motors for precise and responsive movement, employing high-torque servo motors to handle heavy cutting loads and maintain accuracy during high-speed machining operations, ensuring consistent performance even under demanding conditions.

Precision Levels: Achieving tolerances within micrometers is essential for intricate parts, complemented by the integration of advanced tooling systems like automatic tool changers and tool length measurement devices to optimize tool performance and ensure precise machining results. Environmental control features are also implemented to minimize thermal expansion and contraction effects.

Applications: CNC milling machines are widely used in aerospace for producing components with stringent tolerances, such as turbine blades and structural parts, and find applications beyond aerospace in various industries including automotive, medical, and defense, for manufacturing a wide range of components with high precision and reliability. It is an essential tool for both rapid prototyping and high-volume production, offering efficient and cost-effective solutions for producing complex parts with consistent quality and accuracy.

CNC Lathes

Axis Configuration: Typically equipped with a 2-axis or 3-axis system (X, Z) for controlling the movement of the cutting tool along the workpiece.

Chuck Types: Offer a range of chuck options, including 3-jaw and 4-jaw chucks to securely hold various workpiece shapes and sizes.

Turret Configurations: Feature multiple tool holders enabling rapid tool changes and diverse operations like turning, boring, and threading.

Applications: Ideal for producing cylindrical parts, such as engine shafts, bushing, threaded parts, and hydraulic components, which require precise rotational symmetry. CNC lathe machines play a crucial role in achieving efficient and precise machining operations.

CNC Water Jet Cutters

Cutting Mechanism: Utilize a high-pressure stream of water infused with abrasive particles to accurately slice through diverse materials, offering a non-thermal cutting method that prevents heat damage to the workpiece.

Precision Levels: Deliver exceptional precision, enabling the creation of intricate shapes and maintaining tight tolerances.

Material Compatibility: Versatile in handling a broad spectrum of materials, encompassing metals (steel, aluminum, titanium), stone, glass, ceramics, composites, and plastics.

Applications: Across automotive, aerospace, architectural, and manufacturing sectors, CNC water jet cutters are pivotal tools for intricate part cutting, material shaping, and artistic design creation, facilitating the production of complex components and artistic sculptures.

CNC Routers

Cutting Mechanism: The CNC router machines involves a rotating spindle with cutting tools that remove material from the workpiece. Controlled by a CNC controller, the spindle moves along programmed paths on the X, Y, and Z axes, enabling precise and intricate cuts on various materials.

Table Sizes: Range from small desktop models for hobbyists to large industrial tables for large-scale production.

Spindle Options: Various power levels and RPM ranges to suit different materials and cutting speeds.

Materials Processed: Commonly used for cutting wood, plastics, foams, and soft metals, making them versatile tools in furniture manufacturing and sign making.

Applications: CNC routers are widely used in furniture manufacturing for producing custom pieces and cabinetry with intricate designs. They are essential in sign making, engraving detailed text and images, and creating 3D lettering and logos on various materials. Additionally, CNC routers facilitate rapid prototyping and the creation of detailed architectural models for product development and design validation.

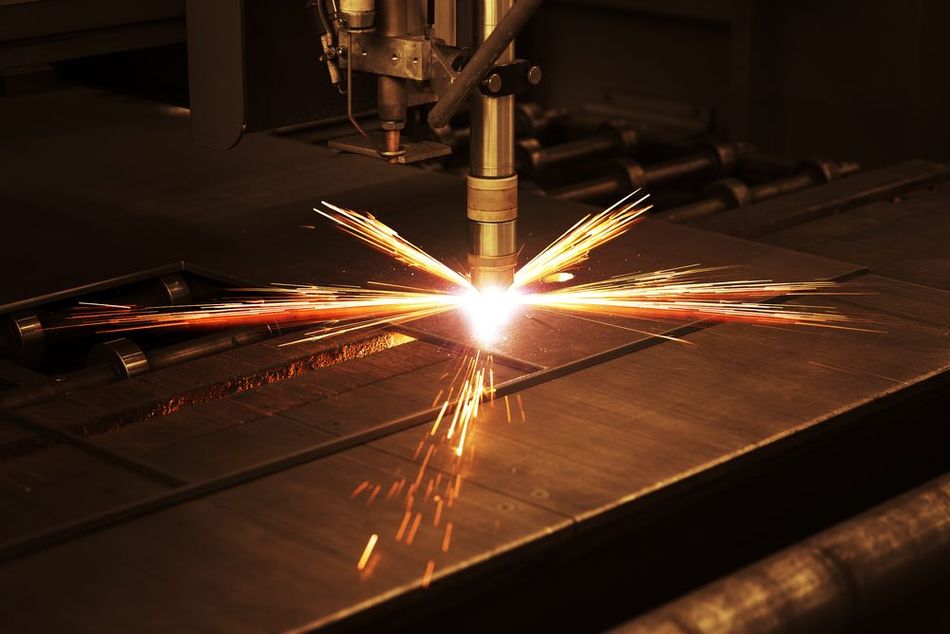

CNC Plasma Cutters

Cutting Techniques: CNC plasma cutting machines utilize a plasma torch, emitting a high-velocity jet of ionized gas (plasma), to precisely cut through electrically conductive materials.

Material Compatibility: Suitable for cutting a wide range of metals including steel, stainless steel, aluminum, brass, and copper.

Precision Levels: Capable of high-speed cutting with tolerances up to ±0.5 mm, ideal for sheet metal fabrication and custom metal artwork.

Applications: They are ideal for creating custom metal artwork, decorative panels, and industrial components. Additionally, they are essential in automotive repair and manufacturing for quickly and accurately producing metal parts.

Recommended reading: What Is CNC Plasma Cutting

CNC Grinders

Grinding Methods: CNC grinding machines employ various methods such as surface grinding for flat surfaces, cylindrical grinding for round objects, and centerless grinding for continuous production. These machines use abrasive wheels to precisely shape and finish materials, ensuring high surface quality and dimensional accuracy.

Wheel Types: Various abrasive wheels (e.g., diamond, CBN) are employed depending on the material being processed and the desired finish, enabling precise and efficient material removal.

Automation Integration: Many CNC grinders feature automation integration capabilities, allowing for unmanned operation and increased productivity, particularly in high-volume manufacturing environments.

Material Applications: Used for finishing hardened materials such as tool steels, ceramics, and carbide, ensuring high surface quality and dimensional accuracy, while also being capable of grinding other materials with equal precision.

CNC Drilling Machines

Axis Configuration: A 3-axis system (X, Y, Z) is usually equipped to accurately position the drill bit for hole drilling operations. Some models may offer additional axes for enhanced functionality.

Drive Systems: Utilize precision ball screws and servo motors to ensure accurate and responsive movement of the drilling tool, allowing for precise hole placement and depth control.

Precision Levels: Capable of achieving tight tolerances, often within micrometers, ensuring consistent and accurate hole dimensions. This precision is critical for applications requiring exacting specifications.

Applications: Widely utilized across industries for drilling holes in various materials such as metal, wood, plastic, and composites. Common applications include aerospace for manufacturing aircraft components, automotive for engine and chassis parts, and general machining for creating precise assemblies.

CNC Turners

Working Mechanism: CNC turners utilize computer-controlled lathes to shape cylindrical workpieces with precision. The machine rotates the workpiece while cutting tools remove material, guided by programmed instructions, ensuring accuracy and efficiency in production. CNC turners offer versatility in manufacturing various components across industries with high precision and repeatability.

Tooling: Specialized turning machine tools, including inserts and tool holders, are optimized for machining cylindrical workpieces with precision and efficiency.

Spindle Speed Control: Enable precise control over spindle speed, allowing for optimal cutting performance and surface finish based on material and machining requirements.

Live Tooling Capabilities: Some CNC turning machines feature live tooling options, enabling additional operations such as drilling, milling, and tapping directly on the turning center.

Applications: Employed across industries for the production of cylindrical parts such as shafts, pins, and bushings in automotive, aerospace, and medical device manufacturing. CNC turners play a crucial role in achieving efficient and precise machining operations, contributing to the production of high-quality components.

CNC Laser Cutters

Cutting Mechanism: CNC laser cutting machines utilize a high-powered laser beam to precisely melt, burn, or vaporize material for accurate cutting, offering versatility in achieving intricate designs and complex shapes, while minimizing material waste and maximizing efficiency.

Precision Levels: Offer high precision with the ability to cut intricate and detailed shapes, achieving tight tolerances.

Material Compatibility: Suitable for a wide range of materials, including metals (steel, aluminum, brass), plastics, wood, ceramics, and fabrics.

Applications: Commonly used in industries such as automotive, aerospace, and electronics for cutting detailed parts, engraving, and marking.

CNC Electrical Discharge Machine (EDM)

Cutting Mechanism: CNC Electrical Discharge Machines (EDM) employ electrical discharges to remove material from the workpiece, providing precise machining for intricate shapes and hard materials. This technology offers advanced capabilities for manufacturing components with intricate geometries and hardened surfaces.

Precision Levels: EDM Provides high-precision machining with tolerances reaching fractions of a micron, ideal for producing complex and highly accurate parts. It allows for the machining of parts with complex geometries that are difficult or impossible to achieve with conventional machining methods.

Material Compatibility: Suitable for machining electrically conductive materials such as steel, titanium, carbide, and exotic alloys, enabling the machining of hardened materials that are challenging to machine using conventional methods.

Applications: Widely used in tool and die making, mold manufacturing, and aerospace industries for producing complex shapes, sharp corners, and fine details in hardened materials. CNC EDM machines are also employed in the production of medical devices, micro-components, and precision parts for various industries.

These types of machines are integral to modern manufacturing, enabling the production of highly precise and complex parts across various industries. By understanding the capabilities and applications of each type, engineers can better select the appropriate CNC machine for their specific manufacturing needs.

Core Components and Functions

CNC machines are composed of several key components, each critical to their operation and precision. Understanding these components helps in optimizing the machine's performance and troubleshooting potential issues.

Controller

The controller acts as the brain of the CNC machine, interpreting digital instructions from the computer and converting them into precise movements of the machine’s axes.

- PC-based Controllers: These use a standard PC to run CNC software that generates the necessary machine control commands. They are versatile and can be easily updated or modified with new software, making them highly adaptable to different machining needs. PC-based controllers allow for more complex operations, leveraging the processing power of modern computers to handle sophisticated machining tasks.

- Microcontroller-based Controllers: Microcontroller-based controllers represent a specialized category of hardware units meticulously crafted for CNC operations. They offer high reliability and fast processing speeds, essential for complex and high-precision tasks. Examples include Arduino and other embedded systems tailored for CNC applications. These controllers boast compact designs and seamless integration capabilities, allowing for direct incorporation into CNC machines.

Drive/Motor

The drive system in a CNC machine translates control signals from the controller into precise physical movements. The choice between stepper motors and servo motors depends on the specific requirements of the machining process.

- Stepper Motors: Known for their precise control and ability to maintain position without feedback, stepper motors are ideal for applications requiring high precision. They are relatively inexpensive and easy to control, but can lose steps under high load or speed, affecting accuracy. Stepper motors are commonly used in applications where holding torque and simplicity are paramount, such as 3D printers and small-scale CNC machines.

- Servo Motors: Servo motors provide closed-loop control for continuous position adjustment, offering higher precision and faster response times than stepper motors. While more complex and costly, they excel in applications needing high-speed, high-precision movements, like industrial robotics and advanced CNC machining. Encoders provide continuous feedback to ensure real-time correction, enhancing accuracy and reliability.

Machine Interface

Human-Machine Interfaces (HMIs) provide the interface through which operators interact with the CNC machine. The evolution of HMIs has dramatically improved the usability and functionality of CNC machines, making them more accessible and efficient to operate.

- Touchscreen Panels: These allow operators to input commands and adjust settings intuitively. The graphical user interface (GUI) provides a user-friendly way to control the machine, reducing the learning curve for new operators and enhancing operational efficiency.

- Control Panels: These include buttons, switches, and dials for manual operation and quick adjustments. Control panels offer a tactile interface that can be crucial for fine-tuning operations and performing manual overrides.

- Display Screens: Show real-time data on machine status, operational metrics, and error messages, facilitating efficient machine management. Advanced display screens can integrate with monitoring software to provide comprehensive insights into machine performance, enabling predictive maintenance and reducing downtime.

Feedback System

Feedback mechanisms are vital for maintaining the precision and accuracy of CNC machines. They provide real-time data on the position and speed of the machine’s components, allowing for continuous adjustments.

Encoders: Measure the position of the machine’s axes and provide feedback to the controller. Encoders can be optical, magnetic, or capacitive, each offering different levels of precision and robustness. Optical encoders are used in the applications requiring exact positioning, magnetic encoders are more robust and suitable for harsh environments. Capacitive encoders, on the other hand, offer advantages in applications where high precision is required alongside resistance to contamination or environmental factors.

Resolvers: Resolvers are highly reliable and can operate in harsh environments, making them suitable for industrial CNC machines. The ability to provide continuous feedback on the exact position of the machine components ensures that the CNC system can maintain high accuracy even during complex machining operations.

Recent Technological Advancements in CNC Machines

The field of CNC machining has seen significant technological advancements, enhancing the capabilities and efficiency of these machines. These developments have expanded the potential applications of CNC machines and improved their performance metrics.

Multi-Axis Machining

Multi-axis machining has revolutionized the production of complex parts by enabling movement along multiple axes. While traditional CNC machines operate on three axes (X, Y, and Z), advanced machines now incorporate five or even seven axes.

5-Axis Machines: These machines add two rotational axes to the standard three, allowing for the machining of complex geometries in a single setup. This capability reduces the need for multiple setups, thereby increasing precision and reducing production timThe development of 5-axis machining addressed the growing need for precision and efficiency in producing complex components, especially in high-stakes industries like aerospace and defense.

7-Axis Machines: These machines include two additional rotational axes on the workpiece or tool, providing even greater flexibility and precision. This setup is particularly useful in applications requiring detailed and complex machining, such as medical implants and high-precision automotive components. The evolution to 7-axis machines represents a significant leap in manufacturing technology, allowing for the creation of parts that were previously unachievable with traditional methods.

Hybrid CNC Systems

Hybrid CNC Systems signify a groundbreaking advancement in manufacturing technology by integrating both additive and subtractive processes. These systems combine the strengths of both techniques to produce highly complex parts with greater efficiency.

Additive Manufacturing: This process involves adding material layer by layer to create a part. It is particularly effective for creating intricate geometries and reducing material waste.

Subtractive Manufacturing: Conventional CNC machining technique removes material from a workpiece to achieve the desired shape and finish.

Hybrid systems use additive manufacturing to build up the basic shape of a part and then employ subtractive techniques to achieve the final precision and surface finish. This combination allows for the production of parts that would be difficult or impossible to create using either technique alone. The practical benefits of these systems include reduced lead times, lower production costs, and the ability to fabricate components with superior structural integrity.

High-Speed Machining

High-speed machining has significantly improved the efficiency and quality of CNC operations. Advances in spindle speeds, feed rates, and cutting tool technology have enabled higher material removal rates and better surface finishes.

Spindle Speeds and Feed Rates: Modern CNC machines can achieve spindle speeds of up to 100,000 RPM and feed rates exceeding 1,000 inches per minute. These improvements allow for faster machining times and increased productivity. The technological innovations in spindle and feed mechanisms have drastically cut down production times and enhanced the capability to handle tough materials.

Surface Finishes: High-speed machining techniques produce superior surface finishes, reducing the need for secondary finishing processes. This is particularly important in industries such as mold making, where surface quality is critical.

These technological advancements in CNC machining not only enhance the capabilities and precision of the machines but also lead to significant improvements in production efficiency and product quality. By adopting these advanced techniques, manufacturers can stay competitive in a rapidly evolving industrial landscape.

Innovations in CNC Software

Advanced CAD/CAM Software

Modern CAD/CAM systems has transformed CNC operations by integrating advanced features that enhance both design and manufacturing processes. AI-powered toolpath optimization systematically analyzes design geometries to generate optimal toolpaths, effectively slashing machining time and enhancing surface finish quality. Moreover, these modern systems come equipped with simulation and verification tools, empowering engineers to visualize and rectify potential machining issues prior to production. This proactive approach not only minimizes errors but also reduces material wastage, ensuring a more efficient and cost-effective manufacturing process.

Real-Time Monitoring Systems

Real-time monitoring systems are essential for modern CNC operations, providing continuous data feedback on machine parameters like spindle speed, feed rate, temperature, and vibration. Benefits include:

Improved Efficiency: Operators can make immediate adjustments based on real-time performance metrics.

Predictive Maintenance: Identifies potential issues before they cause machine failure, reducing downtime and maintenance costs.

Enhanced Quality Control: Ensures parts are manufactured within specified tolerances, maintaining high quality standards.

Adaptive Control Systems

Adaptive control systems enable CNC machines to adjust operations dynamically based on real-time feedback. They enhance performance by:

Optimizing Cutting Parameters: Automatically adjusts feed rates, spindle speeds, and cutting depths in response to machining conditions.

Reducing Tool Wear: Extends the life of cutting tools by optimizing cutting conditions.

Increasing Throughput: Allows machines to operate at higher speeds with greater precision.

Improvements in CNC Programming Languages and Integration Protocols

Advancements in CNC programming languages, especially G-code enhancements, have improved machine flexibility and functionality. Modern G-code standards support more complex commands, enabling intricate machining operations. Integration protocols like MTConnect and OPC UA facilitate real-time data exchange and interoperability, enhancing smart manufacturing systems' efficiency.

Recent trends in CNC programming include the adoption of high-level programming languages and the integration of artificial intelligence (AI) and machine learning (ML) algorithms. Furthermore, AI and ML technologies are being employed to optimize tool paths, predict machining outcomes, and automate programming tasks.

Enhancements in Material Processing

Advanced Composites

Advanced composites, such as carbon fiber-reinforced polymers (CFRP), have become increasingly prevalent in industries like aerospace, automotive, and sports equipment due to their high strength-to-weight ratio. Processing these materials with CNC machines presents unique challenges, such as delamination and fiber pull-out. Techniques such as high-speed machining and the use of specialized cutting tools with diamond-like coatings are employed to overcome these issues. Additionally, CNC machines equipped with adaptive control systems can dynamically adjust cutting parameters to mitigate these challenges, ensuring clean cuts and maintaining the integrity of the composite structures.

High-Strength Alloys

High-strength alloys, including titanium and Inconel, are essential in applications requiring exceptional strength and resistance to extreme temperatures, such as in the aerospace and power generation industries. Machining these materials requires specific techniques due to their hardness and tendency to cause tool wear. High-speed machining with carbide and ceramic tools, combined with advanced coolant systems to dissipate heat, enables efficient processing of high-strength alloys. These techniques not only improve the machining efficiency but also extend the life of cutting tools, reducing operational costs.

Ceramics and Superalloys

Ceramics and superalloys are known for their hardness and thermal stability, making them ideal for use in high-stress environments like turbine engines and cutting tools. However, their brittleness and toughness pose significant machining challenges. Solutions include using ultra-hard cutting tools, such as those made from polycrystalline diamond (PCD) and cubic boron nitride (CBN), and employing high-precision CNC machines that can maintain tight tolerances. Advanced techniques like laser-assisted machining (LAM) have also been developed, where a laser preheats the material to reduce its hardness, allowing for easier cutting and improved surface finishes.

New Processing Techniques

Recent advancements in CNC technology have enabled the development of new processing techniques that enhance the machinability of advanced materials. For example, cryogenic machining involves using liquid nitrogen as a coolant to reduce tool wear and improve surface quality when machining high-strength alloys. Another innovative technique is ultrasonic machining, which uses high-frequency vibrations to assist in cutting hard and brittle materials like ceramics. These methods not only improve the efficiency and quality of material processing but also open up new possibilities for the use of advanced materials in various industries.

Recommended reading: Picking the best material for CNC

Real-World Applications of Advanced CNC Machines

Aerospace Component Manufacturing

Advanced CNC machines are crucial in aerospace component manufacturing, where precision and reliability are paramount. Aerospace components, such as turbine blades and engine mounts, must meet extremely tight tolerances and stringent material specifications to ensure safety and performance in flight.

Technical Requirements:

Tolerances: Often within ±0.001 mm to ensure aerodynamic efficiency and structural integrity. Precision is critical because even minor deviations can affect an aircraft's performance and safety.

Material Specifications: Use of high-strength alloys like titanium and Inconel to withstand extreme temperatures and stresses. These materials are chosen for their ability to maintain strength and stability under the harsh conditions of aerospace environments.

Case Example: A leading aerospace company uses 5-axis CNC machines to produce turbine blades. The machines' ability to simultaneously move along five axes allows for the creation of complex geometries in a single setup, significantly reducing production time and enhancing precision.

Medical Device Fabrication

The medical device industry demands high precision and flawless surface finishes, as these factors are critical to the performance and safety of medical implants and instruments. CNC machines enable the production of intricate and precise medical components that meet stringent health standards.

Precision and Surface Finish Requirements:

Precision: Sub-micron level accuracy to ensure proper fit and function within the human body. High precision is essential to avoid complications and ensure the longevity of medical implants.

Surface Finish: Polished surfaces with Ra values often below 0.1 micrometers to prevent bacterial growth and ensure patient safety. Smooth finishes are crucial to minimize the risk of infection and promote better integration with human tissues.

Case Example: A medical device manufacturer uses CNC milling machines to produce titanium hip implants. The machines' precision ensures that each implant fits perfectly within the patient’s anatomy, while the superior surface finish minimizes the risk of infection and promotes quicker healing.

Automotive Prototyping

CNC machines play a vital role in automotive prototyping, allowing for the rapid creation of complex and high-precision parts. This capability is essential for developing and testing new vehicle designs and components efficiently.

Complex Automotive Parts:

Engine Components: Precision machining of engine blocks, cylinder heads, and intake manifolds. These parts require high accuracy to ensure optimal engine performance and durability.

Chassis Parts: Fabrication of suspension components, control arms, and subframes. CNC machines produce these parts with the necessary precision to meet safety and performance standards.

Case Example: An automotive company utilizes CNC machines to prototype new engine designs. The machines' ability to quickly and accurately produce complex parts enables the company to test and refine their designs efficiently, accelerating the development cycle and improving overall vehicle performance.

Integration with Other Technologies

IoT

The integration of IoT with CNC machines has revolutionized monitoring and maintenance. IoT-enabled CNC machines use sensors to collect real-time data on parameters like temperature, vibration, spindle speed, and tool wear, transmitting this data to a central monitoring system. The benefits of IoT integration are:

Predictive Maintenance: Identifies potential issues before they cause failures, reducing downtime and maintenance costs.

Enhanced Efficiency: Real-time data allows for immediate adjustments, optimizing machining processes.

Remote Monitoring: Provides insights and alerts to operators from any location.

Robotics

CNC machines and robots collaborate in automated manufacturing cells, enhancing production efficiency and precision. Robots handle tasks like loading and unloading workpieces, changing tools, and material handling, integrated with CNC operations for a fully automated workflow.

Integration Details:

Communication Protocols: Standards like OPC UA and MTConnect ensure synchronized operations between CNC machines and robots.

Control Systems: Advanced systems coordinate CNC machines and robotic arms for precise task execution.

Benefits:

Increased Productivity: Automation speeds up production cycles and boosts throughput.

Consistency and Precision: Robots ensure consistent material handling, reducing human error.

Flexibility: Automated cells can be reprogrammed for various tasks.

Additive Manufacturing

Combining CNC machining with additive manufacturing (3D printing) creates a hybrid process that optimizes both technologies. The additive phase initiates the manufacturing process by depositing material layer by layer, forming the rough shape of the part with intricate geometries. Subsequently, CNC machining refines the part, ensuring precise dimensions and high-quality surface finishes. This integration offers unparalleled design flexibility, enabling the production of complex components previously unattainable through traditional methods.

Benefits:

Design Flexibility: Easily create complex geometries.

Material Efficiency: Minimizes waste by adding material only where needed.

Enhanced Precision: CNC machining ensures exact specifications and high-quality finishes.

Technical Details and Challenges

Integration Processes:

Data Interchange: Formats like STEP and STL transfer design data between additive and subtractive phases.

Control Systems: Integrated systems manage transitions between 3D printing and CNC machining.

Challenges:

Complexity: Requires sophisticated control systems and protocols.

Cost: High initial setup costs for IoT sensors, robotics, and hybrid machines.

Skill Requirements: Operators need specialized training for integrated systems.

Addressing Technical Limitations

Accuracy Limits

CNC machines are renowned for their precision, often achieving tolerances within micrometers. However, maintaining this level of accuracy is challenged by factors like thermal expansion and mechanical wear. Prolonged machining operations can cause thermal expansion leading to dimensional inaccuracies. For example, a heating spindle can shift its position slightly, affecting the final dimensions of the part. High-end CNC machines can maintain tolerances as tight as ±0.001 mm, but typical industrial machines usually operate within ±0.01 mm. Advanced compensation algorithms are being developed to dynamically adjust for thermal expansion and mechanical wear, utilizing real-time data to maintain high precision.

Material Constraints

CNC machines encounter significant challenges when working with extremely hard or brittle materials like ceramics and advanced composites due to rapid tool wear and the risk of material cracking or breaking during machining. Ceramics, for example, are notorious for their hardness and brittleness, often resulting in frequent tool breakage and subpar surface finishes. To combat these issues, advanced cutting tools made from superhard materials like polycrystalline diamond (PCD) and cubic boron nitride (CBN) are being developed. These tools offer enhanced durability and sharpness retention, reducing the need for frequent tool changes and ultimately improving machining efficiency in processing these challenging materials.

Recommended reading: How to Avoiding Quality Problems in CNC Machining Industry

Ongoing Research and Future Technologies

Efforts to overcome the current limitations of CNC machines are focused on several innovative areas:

Advanced Compensation Algorithms: These algorithms use machine learning and AI to predict and correct deviations in real-time, compensating for thermal expansion and tool wear. By integrating sensor data, these systems can dynamically adjust machining parameters, significantly enhancing precision. AI-driven compensation algorithms have been shown to reduce error rates by up to 50%, while hybrid manufacturing techniques have demonstrated a 40% reduction in material waste and a 30% improvement in production speed.

Improved Materials: Researchers are developing materials with low thermal expansion coefficients for both machine components and cutting tools. These materials help maintain dimensional stability under varying thermal conditions, improving accuracy and reducing the need for frequent recalibration.

Hybrid Manufacturing Techniques: Combining additive manufacturing with traditional CNC machining offers new ways to handle difficult-to-machine materials. Additive processes can build up complex shapes layer by layer, followed by CNC machining to achieve precise dimensions and high-quality surface finishes. This approach reduces tool wear and allows for more efficient use of materials.

Advanced Cutting Tools: Innovations in cutting tool materials and coatings are enhancing the capability to machine hard and brittle materials. Superhard materials like PCD and CBN, along with advanced coatings that reduce friction and wear, are being developed to improve durability and performance.

Research findings have shown that implementing these technologies can significantly enhance the performance and capabilities of CNC machines.

Recommended reading: Expert Guide to CNC Machining Surface Finishes: Tips and Practices for Success

Conclusion

Throughout this article, we have explored the fundamental aspects and recent advancements of CNC technology, highlighting its transformative impact on modern engineering. The advent of CNC technology marked a significant shift from manual machining to automated precision, enabling complex designs that were previously unattainable.

The importance of CNC machines extends beyond automation. They enable engineers to push the boundaries of design and manufacturing, fostering innovation and improving product quality. Looking to the future, the potential of CNC technology is immense. Ongoing research and development in areas such as AI-driven compensation algorithms, hybrid manufacturing techniques, and advanced materials promise to enhance the precision, efficiency, and adaptability of CNC machines even further. These advancements will likely lead to smarter and more flexible manufacturing solutions.

Frequently Asked Questions

Q: What are the different types of CNC machines?

A: CNC machines include milling machines, lathes, routers, plasma cutters, and grinders. Each type is designed for specific applications and offers unique capabilities, such as milling machines' ability to perform precise multi-axis operations and plasma cutters' efficiency in cutting through thick metals.

Q: How do CNC machines achieve high precision?

A: CNC machines achieve high precision through advanced control systems that manage tool movements with extreme accuracy. Compensation algorithms and high-quality materials help mitigate factors like thermal expansion and mechanical wear.

Q: What materials can CNC machines process?

A: CNC machines can process a wide range of materials, including metals (steel, aluminum, titanium), plastics, wood, foam, glass, stone, composites, and ceramics. The choice of material depends on the specific application and requirements.

Q: What challenges arise when machining hard and brittle materials?

A: Hard and brittle materials, such as ceramics and advanced composites, pose challenges like rapid tool wear and material cracking. Advanced cutting tools made from superhard materials and innovative machining techniques, such as laser-assisted machining, are used to address these issues.

Q: How is IoT integrated with CNC machines?

A: IoT integration involves equipping CNC machines with sensors that collect real-time data on parameters like temperature, vibration, and tool wear. This data is transmitted to a central system for monitoring and predictive maintenance, enabling more efficient and reliable operations.

Q: What role do robotics play in CNC machining?

A: Robotics enhance CNC machining by automating tasks such as loading and unloading workpieces, changing tools, and handling materials. This integration improves efficiency, precision, and flexibility in manufacturing processes, allowing for higher throughput and reduced human error.

Q: What are the benefits of combining CNC machining with additive manufacturing?

A: Combining CNC machining with additive manufacturing offers numerous benefits, including the ability to create complex geometries with greater efficiency and precision, reduced material waste, enhanced design flexibility, and the ability to produce parts with varying material properties.

Q: What maintenance requirements are essential for CNC machines?

A: Key maintenance requirements include routine tasks such as lubrication, cleaning, and calibration, as well as periodic replacement of worn parts and software updates to ensure optimal performance. Regular maintenance helps prevent unexpected breakdowns and extends the lifespan of the machines.

Q: How can CNC programming be optimized?

A: CNC programming can be optimized by using advanced CAD/CAM software, employing efficient toolpaths, and integrating real-time feedback systems to dynamically adjust machining parameters. These practices help reduce cycle times and improve the accuracy of the machining process.

Q: What future advancements are expected in CNC technology?

A: Future advancements in CNC technology include AI-driven compensation algorithms for real time error correction, hybrid manufacturing techniques combining additive and subtractive processes, development of advanced materials, integration of IoT for real-time monitoring and predictive maintenance, and continuous improvements in precision and adaptability for enhanced efficiency and versatility.

References:

[1] Autodesk. Types of CNC Machining. Autodesk; 2017.

[2] Mamilla V, Venkata. Study on computer numerical control (CNC) machines. Int J Adv Sci Res. 2016.

[3] Retaish Mahajan, Dr. Sachin Saini, Er. Ajay Singh Rana. Advancements in CNC Machine System for Enhanced Part Development. Int J Innov Res Eng Manag (IJIREM). 2023.

[4] Beaucamp A, Charlton P, Blunt L. Machining of freeform biological surfaces on an advanced 7-axis CNC polishing machine. 2005.

[5] Yan, Xiangsong. (2022). Research and Application of CNC Machining Method Based on CAD/CAM/Robot Integration. Advances in Multimedia. 2022.

Table of Contents

IntroductionThe Basics of CNC MachinesCommon Types of CNC MachinesCNC Milling MachinesCNC LathesCNC Water Jet CuttersCNC RoutersCNC Plasma CuttersCNC GrindersCNC Drilling MachinesCNC TurnersCNC Laser CuttersCNC Electrical Discharge Machine (EDM)Core Components and FunctionsControllerDrive/MotorMachine InterfaceFeedback SystemRecent Technological Advancements in CNC MachinesMulti-Axis MachiningHybrid CNC SystemsHigh-Speed MachiningInnovations in CNC SoftwareAdvanced CAD/CAM SoftwareReal-Time Monitoring SystemsAdaptive Control SystemsImprovements in CNC Programming Languages and Integration ProtocolsEnhancements in Material ProcessingAdvanced CompositesHigh-Strength AlloysCeramics and SuperalloysNew Processing TechniquesReal-World Applications of Advanced CNC MachinesAerospace Component ManufacturingMedical Device FabricationAutomotive PrototypingIntegration with Other TechnologiesIoTRoboticsAdditive ManufacturingTechnical Details and ChallengesAddressing Technical LimitationsAccuracy LimitsMaterial ConstraintsOngoing Research and Future TechnologiesConclusionFrequently Asked QuestionsReferences: