Using heat transfer simulation to engineer a rocket-launching balloon

Article #1 Simulation Education Series. How engineers can use cutting-edge simulation software to design out-of-this-world machinery and transport solutions.

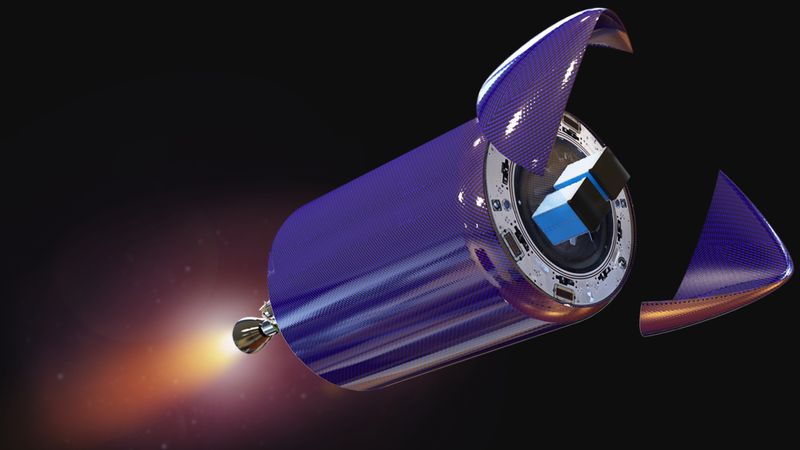

Image credit: SpaceRyde/Ansys

This is the first article of a 3-part series looking at engineering fundamentals and exploring how they are applied in innovative engineering case studies. We further demonstrate how free online courses can elevate your knowledge – no matter your engineering experience. The SpaceRyde case study described in this article is based on the article on this story available on Ansys.com.

Heat transfer is an integral part of many engineering design problems. Nearly all major engineering design projects need heat transfer analysis, simulation, or testing. And while some engineers are specialists in that discipline, seasoned in using heat transfer simulation for complex systems, others may only have a basic understanding. No matter the level of expertise, engineers need to make sure they are educated in heat transfer in order to deliver the best possible solution to customers, colleagues, and end-users.

In this article, we’ll look at the basics of heat transfer, and explore an engineer’s role in understanding and applying the rules in heat transfer. Further, we look at heat transfer through a use case featuring the SpaceRyde team who use heat transfer simulation in the design and development of their rocket-launching balloon solution. Finally, we look at the range of free courses from Ansys that engineers can tap into for self-guided learning of heat transfer foundations and simulation.

An engineer’s guide to heat transfer

Heat transfer is an engineering discipline concerned with the use, conversion, generation, and exchange of heat from one system or object to another. Heat transfer is a vital part of almost every engineered system because both ambient environmental and operational conditions lead to heat generation and/or transfer. For example, the performance of a turbine is determined by the inlet and outlet temperatures of the air it ingests and exhausts - both of which are impacted by the temperature outside and radiation from the sun. The temperature of the turbine will also increase under working conditions as the rotors and stators spin to compress and expand air through the system and combustion occurs, leading to heat transfer within the system due to conduction and convection. Each heat transfer mode impacts the turbine’s efficiency, safety, and longevity. Precisely understanding the heat transfer during operation is key to optimizing the engineering design and maintenance protocols of systems and machines.

The 3 modes of heat transfer

There are three basic modes of heat transfer: conduction, convection, and radiation, which we’ll define and examine through a couple of examples.

1. Conduction

Conduction is the transfer of heat through the vibration of molecules. In conduction, a medium is required, meaning a substance of some kind (solid, liquid, or gas), and therefore conduction cannot occur in a vacuum. The molecules exposed to the heat source will vibrate with increasing amplitude and cause neighboring molecules to increase their vibrational frequency, which results in a transfer of heat. A simple example of conduction is when you heat up a frying pan on the stove. The burner transfers heat to the pan through physical contact. Another example is conduction through an engine block as the metallic components heat when combustion occurs in the cylinders, the surrounding engine block will increase its temperature.

2. Convection

Convection is the transfer of heat due to a moving fluid. In the case of natural convection, the fluid that is heated will become less dense and rise to the surface of the container it is contained in. These convection currents occur in our homes, offices, and in the atmosphere. Fluids like air can also be forced over hot surfaces, allowing for heat to be transferred from the solid to the fluid. For example, with a cooling fin in an electronic device or a car’s radiator. This is called forced convection, using fans or ram air from the inlet of a car, to pass over a hot surface, transferring the heat to the fluid.

3. Radiation

Radiation is the transfer of heat through electromagnetic waves. All matter above absolute zero transmits heat through electromagnetic radiation, and no medium is required for that transfer of heat. In other words, there doesn’t need to be physical contact of a fluid over a solid or a solid over a solid, etc. The most common example of radiation is the sun heating up your car, your house, or even your skin through ultraviolet radiation. There are other types of radiation, including microwaves, which are used to heat food. Ultraviolet radiation is also used to cure certain epoxies and paints on finished products.

Calculating and simulating heat transfer

Understanding and carefully controlling the transfer of heat improves the performance and reliability of engineered products. Thus, heat transfer analysis and testing occur for devices small and large, from the smartphone in your pocket to the complex gas turbines used to power an aeroplane. The analysis can be conducted both through calculations using simplified models and empirical equations and through using more advanced heat transfer simulation software.

While there are empirical relations and data that relate to the simplest of heat transfer cases, most engineering problems are too complex for a hand calculation to be accurate.

Simulation software makes it possible to predict heat transfer more accurately. In addition, the software has all the material properties built-in, meaning engineers do not have to look up coefficients or equations to conduct their analysis. By using a tool that allows for multi-physics simulations, engineers can take their analysis one step further and combine systems so that performance is analyzed in a more holistic environment. For example, the heat transfer characteristics of a car’s radiator could be analyzed based on the known inlet temperatures of the coolant within the radiator, and the predicted speed and temperature of the air passing through it. But engineers would get a much better picture of the performance if they simulated the entire vehicle’s aerodynamics, including the radiator and its blockage coefficients. In this way, they would determine the inlet velocity of the fluid impacting the radiator, which would then be used in the heat transfer calculations to determine how well the radiator performed.

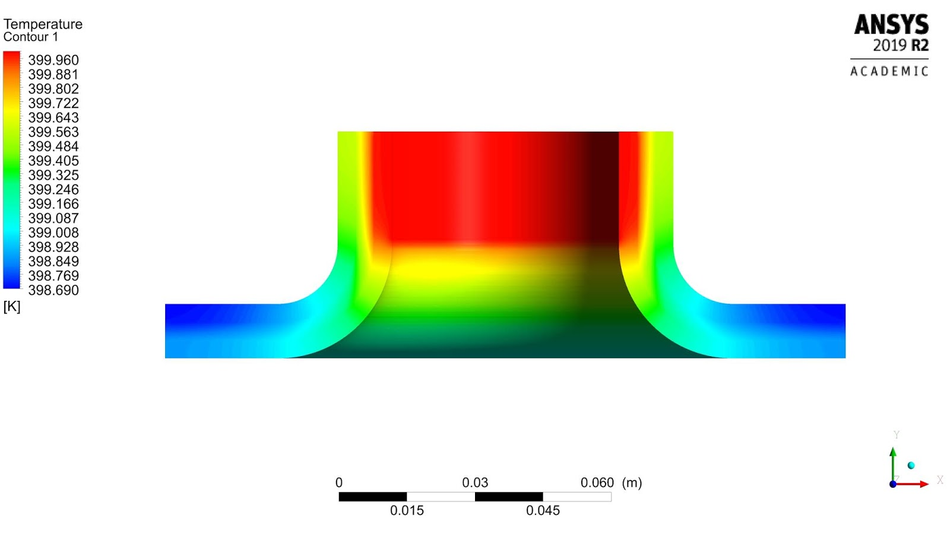

Testing will often also accompany simulations to verify the predictions from the software, by running the system and measuring physical temperatures using sensors on key components. This correlative exercise may only be conducted once or twice over the course of a large project in order to establish any limitations of simulation. The benefit of simulation over only testing or calculations is that the visualization of heat distribution from the software provides more data and insight for engineers. Having the entire system’s heat distribution from simulation versus a few temperature sensors and probes from physical testing is a very handy tool for engineers looking to maximize durability and performance.

Why heat transfer properties are important for a rocket-launching balloon startup

SpaceRyde is a startup based in Ontario, Canada that provides a more affordable and environmentally friendly solution for launching satellites into orbit. Rather than the rocket launching from the ground and needing to travel through dense layers of the atmosphere, SpaceRyde makes clever use of commercially available hardware and an atmospheric balloon that takes a satellite and custom-designed, ultra-light rocket up to high altitude where it is then launched in near-vacuum conditions.

The engineers at SpaceRyde knew that heat transfer would be an important aspect of their design and development. First, they knew that they would need to investigate heat transfer within the rocket system itself. Because they had a custom design for their light-weight solution, heat transfer simulation was used to ensure the strength, durability, and minimal damage to the entire rocket and structural system that was attached to the balloon. In addition, the atmospheric conditions for the operation of the rocket were simulated to both determine how that impacted the heat transfer through the system as well as the performance of the rocket itself under reduced pressure and temperature in the stratosphere.

SpaceRyde’s heat transfer simulations were crucial to getting things as close to “right” as possible before their test flights, which saved them time in design and money on costly prototypes. The heat transfer simulations were used to replicate the conditions of the upper atmosphere where the rocket would be launched. Creating those conditions at sea level would be extremely difficult and, if possible, with specialized equipment it would also prove a large expense for a startup. So, SpaceRyde applied to become part of the Ansys Startup Program, in order to make use of the product bundles from Ansys at startup costs.

SpaceRyde also used heat transfer simulation to learn more about the temperatures that not only the rocket and support structure would see, but also the balloon and tethers, being in close proximity to the rocket during launch. Engineers on the team learned a great deal about how they could optimize their design through the use of Ansys heat transfer software. In addition, the built-in support hours from the Ansys Startup Program offered help with troubleshooting analysis setup, results postprocessing, and interpretation of the results. Using their results, SpaceRyde engineers improved the design of the balloon and rocket system prior to physical tests, saving time and money during development. They had the free courses at their disposal and the built-in support from the company as part of the startup program. With those tools at their disposal, they improved the design of the balloon and rocket system prior to physical tests, saving time and money during development.

SpaceRyde has completed two successful test flights of their balloon rocket launcher: the rocket launcher qualification flight and Flight #1 of their rocket from the stratospheric balloon. Currently, SpaceRyde is filling up their 2023 roster of clients who are looking to use their stratospheric balloons as a taxi for their satellites up to orbital and suborbital levels.

Ansys Free Innovation Courses

Sneak peek into the free Ansys Introduction to Heat Transfer course

The free Ansys Introduction to Heat Transfer Innovation Course provides a strong foundation in heat transfer fundamentals for engineers at all levels. No matter your specialty, having knowledge of heat transfer basics will be one more important tool in your design abilities. Even if you won’t be performing the analysis of heat transfer on your team, when you design, optimize, or build a system, you should be aware of the heat transfer implications, and be able to communicate any concerns or changes to heat transfer dynamics to your team.

Within the course, the following topics are covered:

- The three heat transfer modes (conduction, convection, and radiation)

- Application of principles to real-life examples

- Ansys simulation files and guided videos on how to simulate heat transfer using Ansys Student

- A realistic solar panel heat transfer simulation project

The physical consequences of heat transfer come to life when engineers see how to apply these principles through simulation out in the field. It also helps spark ideas and questions about how heat transfer simulation may be applied in engineering environments that the engineering learner frequently encounters.

If you’re motivated to get learning, you can download a free product that contains the Ansys Workbench-based bundle, called Ansys Student. Anyone who would like to learn more about heat transfer and then apply their knowledge within the Ansys simulation tools can get started right away.

Access heat transfer simulation tools for your projects

The SpaceRyde team and their efforts to simulate heat transfer during the design and development of their balloon rocker-launcher solution have shown how powerful, cost effective, and efficient simulation can be to an engineering team. Specifically, heat transfer simulation was pivotal in the analysis of their solution. Because of the extreme conditions for the rocket launch, heat transfer simulation allowed for development of the rocket components and the entire balloon launching system in order to ensure performance, durability, and accuracy.

Heat transfer simulation software, along with the free course from Ansys, can help engineers who are new to in-depth heat transfer simulation and optimization get up to speed quickly. For engineers who are already well versed in heat transfer, they may be able to conduct multi-physics simulations that combine their expertise with aerodynamics (via CFD), structural analysis (via FEA), or even electromagnetics. Each of these aspects of simulation can be explored through the Ansys suite of products, either for startups looking for an affordable way to get started with simulation or for curious minds who are looking to learn more by downloading Ansys Student or one of the other free student products offered by Ansys.

This is the first article in a three-part series.

Article one examined heat transfer simulation.

Article two provided an overview of mechanical analysis.

Article three looked at contact mechanics.

About the sponsor: Ansys

Ansys provides engineering simulation software used to predict how product designs will behave in real-world environments. Founded in 1970, Ansys employs more than 4,400 professionals, many of whom are expert M.S. and Ph.D.-level engineers in finite element analysis, computational fluid dynamics, electronics, semiconductors, embedded software, and design optimization.