What is a Stator? A Comprehensive Guide for Engineers

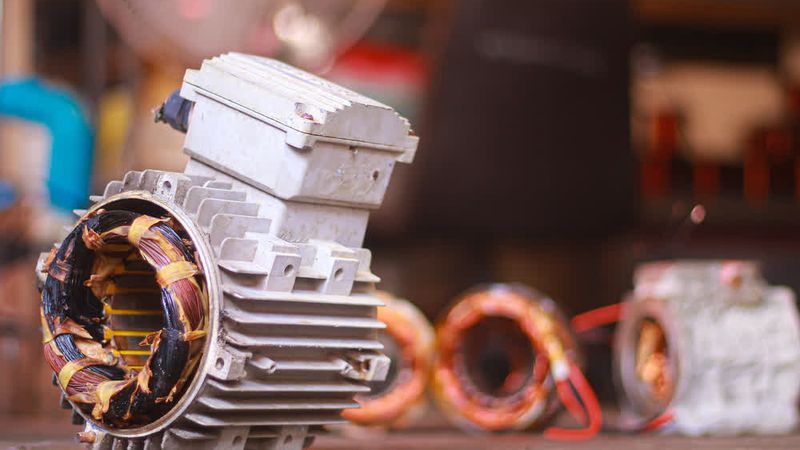

A stator is the stationary part of an electric motor or generator, consisting of coils or windings mounted on an iron core, designed to create a magnetic field when electric current flows through it. Explore the fundamentals, advancements, and applications of stators in modern engineering.

Introduction

A stator is a crucial component in electrical machines, typically found in generators, motors, and alternators. It consists of a stationary set of coils or windings, which work in tandem with the rotor to create a magnetic field, inducing electrical currents and enabling mechanical motion. In essence, the stator's function is to convert electrical energy into mechanical energy, or vice versa, depending on the application.

In modern engineering, stators are indispensable due to their role in ensuring the efficient operation of various machines and systems. They are pivotal in the functioning of electric vehicles, industrial machinery, and renewable energy systems such as wind turbines. The advancements in stator technology have led to significant improvements in efficiency, performance, and reliability, making them a cornerstone of contemporary engineering applications.

This article provides an in-depth look at stators, examining their design, function in electric motors and generators, and the impact of recent technological advancements. We'll also explore maintenance practices essential for maximizing their efficiency and lifespan.

Understanding Stators: The Basics

What is a Stator?

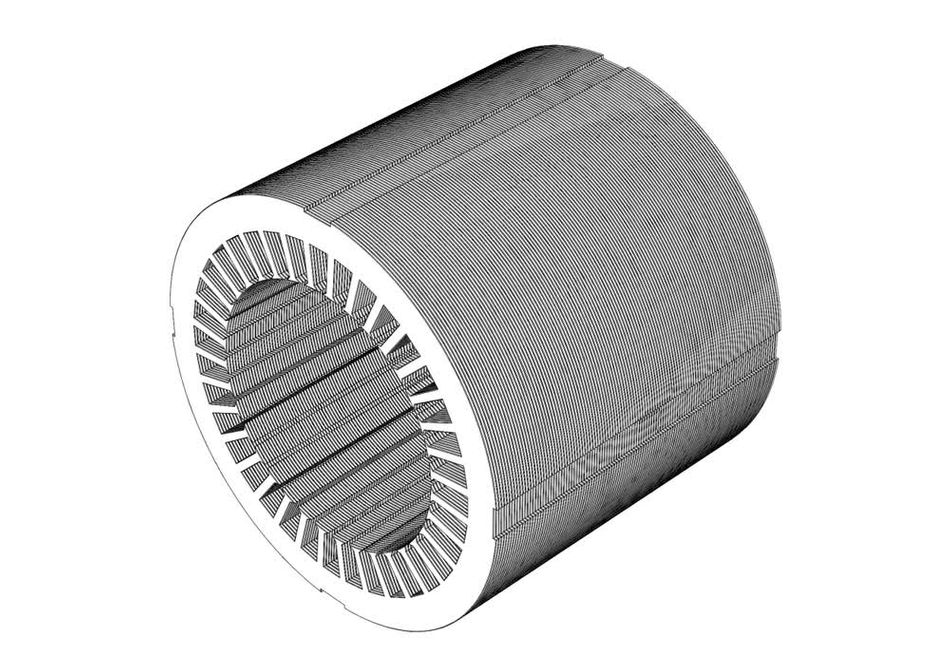

A stator is a stationary component of an electrical machine, such as motors, generators, and alternators, which plays a pivotal role in their operation. Comprising core and field windings or coils, usually made from laminated sheets of electrical steel, the stator is designed to minimize energy losses and optimize performance. Historically, the development of stator technology has been fundamental in advancing electrical machinery, from early generators to today's sophisticated electric vehicles.

The primary function of the stator is to create a magnetic field that interacts with the rotor’s armature, the moving part of the machine. This interaction is crucial for generating motion or inducing electrical current, depending on the machine's operation. For instance, in electric motors, the stator produces a rotating magnetic field that causes the rotor to spin, thus converting electrical energy into mechanical power. Conversely, in generators, the rotor's movement within the stator's magnetic field induces an electrical current in the windings, effectively converting mechanical energy into electrical energy.

Recommended reading: What is Magnetism? Examples of Magnetic Substances

Stators are integral to various modern applications. In electric vehicles, for example, the efficiency and reliability of the stator directly influence the vehicle's performance and range. Industrial machinery also relies heavily on well-designed stators for efficient and consistent operation. In renewable energy systems, such as wind turbines, the stator's design and materials are critical for maximizing energy conversion and minimizing losses.

Core Components of a Stator

The stator is a complex and essential part of electrical machines, comprising several key components that work together.

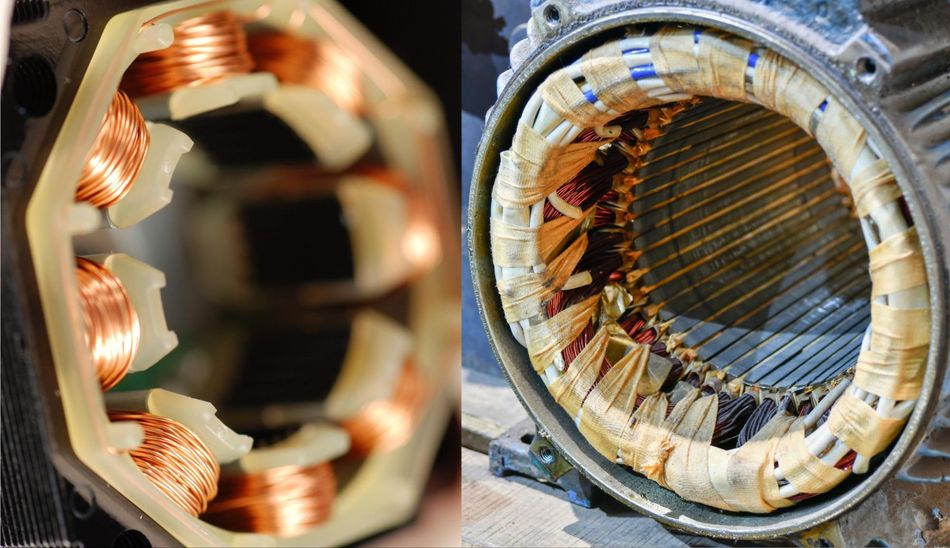

- Stator Core: Historically, the stator core has evolved from solid iron cores to laminated sheets of electrical steel, significantly reducing energy losses due to eddy currents. These laminations, meticulously stacked together, form a core that not only supports the windings but also enhances the magnetic flux efficiency. The use of advanced materials and manufacturing techniques has made modern stator cores more efficient and reliable. For example, high-performance electric vehicles rely on these improved cores to maximize power generation, output and efficiency.

- Windings: The windings, typically made from insulated copper wires or aluminum wires, are crucial for generating the magnetic field. There are two main types of windings used: distributed and concentrated windings. Distributed windings are spread evenly across the stator slots, producing a more uniform magnetic field, which is ideal for applications requiring smooth operation, like industrial machinery. Concentrated windings, grouped in specific slots, offer higher torque, making them suitable for applications like electric motors in electric vehicles. The choice of winding type directly impacts the machine's performance, efficiency, and application suitability.

Insulation: Insulation materials have advanced over the years, moving from basic varnishes to high-tech epoxies and insulating tapes. These materials are essential for preventing electrical short circuits between the windings and the stator core. By protecting the windings from electrical and mechanical stresses, modern insulation and voltage regulators ensures the longevity and safety of the stator by maintaining consistent electrical outputs. For instance, in high-power applications such as wind turbines, advanced insulation materials help maintain performance under extreme conditions.

Cooling System: Efficient cooling systems are vital for dissipating the heat generated during the stator's operation. These systems have evolved from simple air cooling to sophisticated water and oil cooling methods. Effective cooling not only maintains performance but also prevents overheating, which can cause insulation failure and reduce efficiency. In applications like high-speed industrial motors, advanced cooling technologies are crucial for maintaining optimal operating temperatures and extending the stator's lifespan.

How Stator Works?

Stators are essential components in electrical machines, operating through the principles of electromagnetic induction to facilitate the conversion of electrical energy into mechanical energy or vice versa. The interaction between the stator and the rotor is fundamental to this process.

The stator comprising a series of windings or coils connected to an alternating current (AC) power source, acts as an electromagnet. When AC from the power supply flows through these windings, it generates a rotating magnetic field. This magnetic field interacts with the rotor winding, a moving component situated within the stator. In motors, this interaction creates a torque on the rotor, causing it to spin and produce mechanical motion. In generators, the rotor is driven by an external mechanical force, and its movement within the stator's magnetic field induces an electric current in the stator windings, generating electricity. This generated power can then be converted from AC to DC using a rectifier if necessary, depending on the application requirements.

Recommended reading: AC vs DC Motor: Unpacking Their Engineering Applications and Innovations

Electromagnetic induction is the underlying principle that enables the stator to function. According to Faraday's Law of Electromagnetic Induction, a changing magnetic field within a coil of wire induces an electromotive force (EMF) across the coil. In the context of the stator, the rotating magnetic field creates a varying magnetic flux, which induces an EMF in the rotor. This induced EMF drives current through the rotor, resulting in a force that causes the rotor to turn in motors or generates electricity in generators.

The precise design and arrangement of the stator windings are crucial for optimizing the efficiency and performance of the electrical machine. Advanced designs and materials have significantly improved the effectiveness of stators, making them vital components in applications ranging from industrial machinery to electric vehicles and renewable energy systems. Understanding how stators work and their interaction with rotors is essential for engineers developing cutting-edge technologies in these fields.

Recommended reading: Robot Actuators: A Comprehensive Guide to Types, Design, and Emerging Trends

Classification and Types of Stators

Stators can be classified based on various criteria such as construction design, winding arrangement, and intended application. The primary basis of classification typically involves the physical construction, number of phases, and the distribution of windings.

Physical Construction

Salient Pole Stator: Salient pole stators are characterized by poles that physically protrude from the core surface. These are typically used in machines operating at lower speeds, such as hydroelectric generators. The poles are laminated, which helps in reducing eddy currents—a type of electrical power loss that occurs due to swirling currents produced within the conductor by a changing magnetic field. This lamination also aids in handling the mechanical stresses and heat dissipation more effectively during operation.

Cylindrical Stator: This type of stator has a smooth cylindrical shape that allows for higher rotational speeds with reduced turbulence and noise. It is ideal for applications requiring high-speed operation, such as in turbo generators. The uniform surface minimizes air resistance and mechanical imbalances, enhancing operational stability and efficiency.

Winding Arrangement

Concentrated Winding Stator: Concentrated windings are wrapped around each pole separately, rather than being spread across the core. This type of stator is often found in motors where high torque and simplicity are required at a low cost, such as in appliances and automotive applications. Concentrated windings can produce strong magnetic fields at the poles, but they can also result in uneven magnetic fields across the motor, which might affect the smoothness of operation.

Distributed Winding Stator: Distributed windings are spread evenly across the core, which helps in creating a uniform magnetic field around the rotor. This uniformity leads to smoother operation and reduced vibrations and noise, making it suitable for commercial and industrial AC motors where operational quietness and efficiency are crucial.

Number of Phases

Single-phase Stator: Used predominantly in household and light commercial applications, single-phase stators are simpler and cost-effective but less efficient than their three-phase counterparts. They operate with a single alternating current source and are typically found in lower power applications, such as fans, pumps, and small appliances.

Three-phase Stator: Three-phase stators are the standard in industrial applications where high power and efficiency are necessary. They operate with three alternating currents, each out of phase with the others by one-third of a cycle, producing a rotating magnetic field that is more consistent and effective in driving the rotor, thereby enhancing the overall motor performance.

Specialty Stators

Amorphous Metal Stator: These stators use a non-crystalline metal core to significantly reduce hysteresis and eddy current losses. They are particularly valuable in applications demanding high energy efficiency, such as in transformers and high-efficiency motors.

Pole-Changing Stator: Pole-changing stators can alter the number of magnetic poles in use, allowing the motor to operate at different speeds. This flexibility is useful in applications where mechanical speed variation is needed without relying on electronic controls, such as in various industrial drives.

Each type of stator is designed to meet specific operational demands, and the choice depends largely on factors such as required speed, torque, efficiency, environmental conditions, and cost considerations.

Technological Advancements in Stator Design

Innovative Materials

Recent advancements in materials used for stators have significantly enhanced their efficiency and performance. Historically, stator materials evolved from solid iron cores to silicon steel laminations, which dramatically reduced energy losses. Today, cutting-edge materials are pushing these boundaries even further, enabling high-performance electrical machines across various industries.

High-Performance Materials

Amorphous Steel: Amorphous steel, a non-crystalline material, offers lower core losses compared to traditional silicon steel. Its unique structure minimizes eddy current losses, leading to higher efficiency in stator cores. For instance, amorphous steel is increasingly used in high-efficiency transformers and electric vehicle motors, where energy savings are paramount.

Nanocrystalline Alloys: Combining the benefits of both crystalline and amorphous metals, nanocrystalline alloys exhibit excellent magnetic properties and significantly reduced core losses. These alloys are ideal for high-frequency applications, such as in aerospace and advanced industrial machinery, where superior performance and efficiency are required.

Composite Materials: Advanced composite materials, such as carbon-fiber-reinforced polymers, provide high strength-to-weight ratios. These composites are particularly beneficial in applications where weight reduction is critical, like in electric vehicles and wind turbines, contributing to better energy efficiency and performance.

Benefits of Innovative Materials

Efficiency Improvements: The use of amorphous steel and nanocrystalline alloys reduces energy losses, leading to higher overall efficiency in electrical machines. This efficiency translates into significant energy savings and reduced operational costs in industrial applications.

Enhanced Performance: These materials improve magnetic properties and thermal conductivity, resulting in better performance and reliability. For example, the enhanced thermal conductivity of nanocrystalline alloys helps maintain optimal operating temperatures, improving the longevity of the stator.

Weight Reduction: Composite materials significantly reduce the weight of stators, which is particularly beneficial in applications like electric vehicles and aerospace. This weight reduction leads to better fuel efficiency and performance, demonstrating the practical advantages of these advanced materials.

Comparative Characteristics

Material | Core Losses | Magnetic Properties | Weight Reduction | Thermal Conductivity |

Traditional Silicon Steel | Moderate | Good | Low | Moderate |

Amorphous Steel | Low | Excellent | Moderate | High |

Nanocrystalline Alloys | Very Low | Superior | Moderate | High |

Composite Materials | N/A | Varies | High | Varies |

These innovative materials are transforming the design and functionality of stators, enabling more efficient and powerful electrical machines.

Advanced Manufacturing Techniques

The production of stators has seen significant advancements with the adoption of cutting-edge manufacturing techniques. These innovations have revolutionized the industry, enhancing precision, reducing costs, and improving overall performance.

3D Printing

3D printing, also known as additive manufacturing, has emerged as a game-changer in stator production. This technique involves creating stator components layer by layer from digital models, allowing for complex designs that were previously impossible to achieve with traditional methods.

Precision and Customization: 3D printing enables highly precise and intricate designs, which can be customized to meet specific performance requirements. This precision leads to improved efficiency and performance in the final product.

Cost Reduction: By minimizing material waste and reducing the need for multiple machining processes, 3D printing significantly lowers production costs. Additionally, it shortens the production cycle, allowing for faster prototyping and iteration.

Recommended reading: What is 3D Printing: A Comprehensive Guide to its Engineering Principles and Applications

Automated Winding

Automated winding machines are another technological advancement that has transformed stator manufacturing. These machines automate the process of winding coils around the stator core, ensuring consistency and precision.

Consistency and Quality: Automated winding provides uniform and precise coil placement, reducing the likelihood of human error and ensuring high-quality production. This uniformity is crucial for maintaining the performance and reliability of the stators.

Efficiency and Cost Savings: Automation speeds up the winding process, significantly increasing production efficiency. It also reduces labor costs and enhances the scalability of production, making it easier to meet high demand.

Example of ImplementationSiemens has been a leader in utilizing 3D printing for stator production. By incorporating additive manufacturing, Siemens has achieved greater design flexibility and reduced lead times, enhancing their ability to innovate and respond to market demands.[1] These advanced manufacturing techniques are not only enhancing the production of stators but are also driving innovation across the electrical engineering industry. By adopting these methods, companies can achieve higher precision, reduce costs, and improve the overall performance of their products.

Enhancements in Stator Cooling Systems

Effective cooling systems are essential for maintaining the performance and longevity of stators in electrical machines. Historically, cooling methods for stators have evolved significantly, from basic air cooling to advanced liquid cooling systems. This evolution has been driven by the need to manage the heat generated during operation, which can lead to overheating, insulation failure, and reduced efficiency if not properly controlled.

Importance of Cooling

Cooling plays a critical role in preventing overheating, which can cause insulation degradation and mechanical stress. Efficient cooling ensures that the stator operates within safe temperature limits, enhancing reliability and extending its lifespan. Maintaining optimal temperatures also improves the overall efficiency and performance of the electrical machine.

Different Cooling Methods for Stators

Air Cooling with Enhanced Heat Sinks: Traditional air cooling methods have been improved with the introduction of enhanced heat sinks. These heat sinks, made from materials with high thermal conductivity such as copper or aluminum, increase the surface area for heat dissipation. Innovations include micro-channel heat sinks, which provide efficient cooling by increasing the contact surface between the air and the heat sink. This technology has been instrumental in improving the performance of industrial motors and other heavy-duty applications.

Liquid Cooling: Liquid cooling systems use water or oil to dissipate heat from the stator. These systems are highly effective as liquids have a higher thermal conductivity than air, allowing for better heat transfer. Advanced liquid cooling methods, such as direct immersion cooling, involve submerging the stator windings in a dielectric fluid, providing excellent thermal management and significantly reducing the risk of overheating. This method has been particularly successful in high-performance applications where traditional air cooling falls short.

Phase Change Materials (PCMs): Phase change materials are used in cooling systems to absorb and release large amounts of heat during phase transitions (e.g., from solid to liquid). PCMs provide a passive cooling solution that can effectively manage temperature spikes during peak operation periods. These materials are particularly useful in applications where active cooling might be impractical. The integration of PCMs in stator cooling systems has shown significant improvements in thermal management, especially in renewable energy applications. Examples include:

Paraffin Waxes: Commonly used for their high heat absorption during melting, suitable for regulating temperatures in motor housings.

Salt Hydrates: Operate at higher temperatures and are useful in industrial motors or generators that experience higher thermal loads.

Fatty Acids: Such as stearic and lauric acid, effective for moderate temperature applications due to their medium melting points.

Biobased PCMs: Environmentally friendly options derived from natural sources, suitable for sustainable applications.

Applications of Stators in Electric Vehicles

Stators in Electric Vehicles

Stators play a crucial role in the operation of electric vehicle (EV) motors. In these motors, the stator generates a rotating electromagnetic field that interacts with the rotor to produce torque, driving the vehicle's wheels. This interaction is fundamental to converting electrical energy stored in the vehicle's battery into mechanical energy used for propulsion.

Role of Stators in Electric Vehicle Motors

Historically, the evolution of electric vehicles has seen significant advancements in stator technology. Early electric vehicles used basic stator designs that were less efficient and heavier. Modern EVs now utilize advanced stators with high-efficiency windings and materials. The stator windings in EVs are connected to the battery via a power inverter, which converts the direct current (DC) from the battery into alternating current (AC). This AC current flows through the stator windings, generating a rotating magnetic field. As the rotor interacts with this field, it spins, driving the vehicle's drivetrain.

Impact on Efficiency and Performance

The design and efficiency of the stator directly impact the overall performance of the electric vehicle. High-quality stator materials and advanced winding techniques can significantly reduce energy losses, leading to higher motor efficiency. This efficiency translates into longer driving ranges and better energy utilization. Additionally, an optimized stator design can improve the motor's power density, allowing for more compact and lighter motors without sacrificing performance.

Examples of Leading Electric Vehicle Manufacturers and Their Stator Technologies

Tesla: Tesla has been a pioneer in developing advanced stator technologies for its electric vehicles. The Tesla Model S, for instance, features a high-efficiency permanent magnet synchronous motor with a precisely wound stator that maximizes efficiency and performance. Tesla's use of innovative cooling methods, such as liquid cooling for the stator, ensures that the motor operates at optimal temperatures, further enhancing efficiency and reliability.

Nissan: Nissan's Leaf, one of the best-selling electric cars globally, utilizes a highly efficient induction motor with a well-designed stator. The stator in the Nissan Leaf is constructed with high-grade electrical steel and precision windings that reduce energy losses. This design contributes to the Leaf's impressive range and performance, making it a popular choice among EV consumers.

BMW: BMW's i3 electric vehicle incorporates an advanced synchronous motor with a finely engineered stator. The stator uses innovative winding techniques to maximize magnetic field strength while minimizing losses. BMW's focus on lightweight materials and compact design ensures that the i3's motor is both efficient and powerful, providing a responsive driving experience.

These examples demonstrate how leading electric vehicle manufacturers leverage advanced stator technologies to enhance the efficiency and performance of their vehicles. By focusing on innovative materials, precise manufacturing techniques, and effective cooling systems, these companies continue to push the boundaries of electric vehicle technology, setting new standards for efficiency and performance.

Industrial Machinery and Automation

Stators are fundamental components in a wide range of industrial machinery, playing a critical role in various equipment. Historically, the evolution of stator technology has paralleled the advancements in industrial machinery, leading to more efficient and reliable operations. These machines rely on stators to convert electrical energy into mechanical motion, which is essential for numerous industrial processes.

Recommended reading: 7 Types of Industrial Robots: Advantages, Disadvantages, Applications, and More

Use of Stators in Various Types of Industrial Equipment

In industrial machinery, electric motors powered by stators are ubiquitous. From conveyor belts to robotic arms, electric motors drive the automation and efficiency of manufacturing processes. The stator's role is to generate a magnetic field that induces rotation in the rotor, creating the mechanical force needed to operate the machinery. This principle is applied in various equipment, including:

Compressors: Used in HVAC systems and refrigeration, compressors rely on stators to drive the compression of gasses, crucial for maintaining desired temperatures.

Pumps: In industries like oil and gas, chemical processing, and water treatment, pumps powered by electric motors with stators are essential for moving fluids efficiently.

Fans: Industrial fans used for ventilation and cooling systems also depend on stators to drive airflow, ensuring optimal environmental conditions within factories and plants.

Benefits of Stators in Industrial Machinery

Increased Efficiency: Modern stators are engineered to minimize energy losses, resulting in higher efficiency. This efficiency not only reduces operational costs but also contributes to the sustainability of industrial processes by lowering energy consumption.

Enhanced Reliability: Stators built with high-quality materials and precision manufacturing techniques offer superior reliability. This reliability is crucial in industrial settings where equipment failure can lead to significant downtime and financial losses.

Common Issues and Solutions

Stators in electrical machines often face several challenges that can affect their performance and longevity. Identifying these issues and implementing effective solutions is crucial for maintaining the efficiency and reliability of the equipment.

Overheating: Overheating is a prevalent issue in stators, caused by excessive current, inadequate cooling, or environmental factors. Persistent overheating can lead to insulation damage and reduced efficiency. Historically, industrial environments with high ambient temperatures or poor ventilation have exacerbated this problem, leading to frequent stator failures.

Insulation Failure: Insulation failure occurs due to thermal degradation, electrical stress, or mechanical damage. This can result in short circuits, reduced performance, and potential equipment failure. In the early days of electrical machine design, inadequate insulation materials often led to frequent breakdowns and maintenance issues, emphasizing the need for high-quality insulation solutions.

Mechanical Wear: Mechanical wear and tear happen over time due to continuous operation, vibrations, or misalignment. This wear can lead to reduced efficiency, noise, and eventual failure of the stator. Historically, heavy-duty industrial applications have seen significant challenges with mechanical wear, necessitating robust design and maintenance strategies.

Overcoming Challenges in Stator Technology: Solutions and Preventive Measures

Overheating

Improved Cooling Systems: Implement advanced cooling methods such as liquid cooling or enhanced air cooling to dissipate heat more effectively. For instance, liquid cooling systems used in high-performance electric vehicles have successfully reduced overheating incidents.

Regular Maintenance: Schedule regular inspections and maintenance to ensure cooling systems are functioning correctly. Maintenance protocols established in industrial plants can serve as models for effective cooling system management.

Temperature Monitoring: Use temperature sensors to continuously monitor the stator temperature and prevent overheating by triggering alarms or shutdowns when necessary. Modern smart monitoring systems can provide real-time data and predictive maintenance alerts.

Insulation Failure

High-Quality Insulation Materials: Use insulation materials with high thermal and electrical resistance to withstand operating conditions. Advanced materials like epoxy resins and polyimide films have been developed to offer superior performance compared to traditional materials.

Proper Installation Techniques: Ensure that insulation is applied correctly to avoid gaps or weak spots that can lead to failure. Training programs for technicians can help in adhering to best practices in insulation application.

Regular Testing: Conduct regular insulation resistance tests to detect early signs of degradation and take corrective action. Utilizing advanced diagnostic tools can enhance the accuracy and effectiveness of these tests.

Mechanical Wear

Lubrication and Alignment: Regularly lubricate moving parts and ensure proper alignment to minimize wear and tear. For example, automated lubrication systems in modern machinery ensure consistent application and reduce manual maintenance requirements.

Vibration Monitoring: Use vibration sensors to detect and address abnormal vibrations that can cause mechanical damage. Implementing these sensors in critical machinery has proven effective in early detection and prevention of mechanical wear.

Component Upgrades: Upgrade to more durable materials and components designed to withstand higher stresses and longer operational periods. Advances in material science have produced components with enhanced wear resistance, suitable for heavy-duty applications.

By addressing these common issues with effective solutions and preventive measures, engineers can significantly enhance the performance and lifespan of stators in electrical machines. Regular maintenance and monitoring are key to identifying potential problems early and ensuring that the stators operate efficiently and reliably.

Maintenance and Longevity

Regular maintenance is crucial for maintaining the performance and extending the lifespan of stators in electrical machines. Effective maintenance practices can prevent common issues such as overheating, insulation failure, and mechanical wear, ensuring the reliability of the equipment.

Importance of Regular Maintenance

Regular maintenance helps to identify and address potential problems before they lead to significant failures. By keeping the stator and its components in optimal condition, maintenance routines ensure that the machine operates efficiently, reducing downtime and maintenance costs. Preventive maintenance also enhances safety by minimizing the risk of electrical and mechanical failures that could cause accidents.

Specific Maintenance Practices

Inspection and Cleaning:

Regularly inspect the stator for signs of wear, damage, or contamination. Clean the stator to remove dust, debris, and other contaminants that can interfere with its performance.

Tools: Inspection cameras, cleaning brushes, and industrial vacuums.

Lubrication:

Ensure that all moving parts are adequately lubricated to reduce friction and wear. Use the appropriate lubricants recommended by the manufacturer.

Tools: Grease guns, oil dispensers, and lubricant analyzers.

Temperature Monitoring:

Continuously monitor the temperature of the stator to prevent overheating. Install temperature sensors and thermal imaging cameras to detect abnormal temperature rises.

Tools: Temperature sensors, thermal imaging cameras, and data loggers.

Vibration Analysis:

Perform regular vibration analysis to detect misalignment, imbalance, or mechanical wear. Early detection of these issues can prevent more severe damage.

Tools: Vibration analyzers, accelerometers, and balancing machines.

Insulation Testing:

Conduct periodic insulation resistance tests to ensure the integrity of the stator's insulation. High-quality insulation materials and proper installation techniques are essential for preventing insulation failure.

Tools: Insulation testers, multimeters, and high-voltage test equipment.

Conclusion

Stators are integral to the functionality of modern electrical machines, providing the necessary magnetic fields that drive motors and generators. Throughout this article, we explored the foundational concepts of stators, delved into recent technological advancements such as innovative materials and advanced manufacturing techniques, and examined their critical applications in electric vehicles, industrial machinery, and renewable energy systems. We also addressed common challenges like overheating, insulation failure, and mechanical wear, and discussed effective maintenance practices to extend stator lifespan.

The continuous innovation in stator technology is vital for enhancing the efficiency, reliability, and performance of electrical machines. Advances in materials, manufacturing techniques, and cooling systems are driving the development of more robust and efficient stators, meeting the growing demands of various engineering applications. As we move forward, ongoing research and development will further push the boundaries of what is possible, making stators an ever more critical component in modern engineering.

Frequently Asked Questions (FAQs)

- What are the main functions of a stator in an electric motor? What does a stator do?

A stator, a critical component of AC as well as DC motors, is a stationary part of the motor that generates a rotating magnetic field that interacts with the rotor, the rotating part, to produce motion. This interaction is fundamental to the motor's operation, converting electrical energy into mechanical energy. The stator's efficiency in generating this magnetic field directly impacts the overall efficiency of the motor, making it a crucial component for optimal performance. - How do advancements in materials impact stator performance?

Advancements in materials significantly enhance stator performance by improving efficiency and reducing losses. For example, amorphous steel and nanocrystalline alloys offer lower core losses and better magnetic properties compared to traditional silicon steel. These materials enable the stator to operate more efficiently, with less heat generation and improved overall performance, benefiting applications such as electric vehicles and high-performance industrial motors. - What maintenance practices are essential for stators?

Key maintenance practices for stators include regular inspection and cleaning, lubrication of moving parts, temperature monitoring, vibration analysis, and insulation testing. Each of these practices is crucial for ensuring the stator's optimal performance and longevity. For instance, regular cleaning prevents contamination that can affect the stator's operation, while insulation testing helps detect early signs of degradation, allowing for timely corrective action. Effective maintenance not only enhances reliability but also prevents costly repairs and downtime. - What are the common signs of stator failure in electric motors and how can they be addressed?

Common signs of stator failure include excessive heat production, unusual noises, and a drop in motor performance or efficiency. These symptoms can often be attributed to issues such as insulation failure, physical damage to the windings, or degradation of the core material. Addressing stator failure typically involves inspecting the stator for damage, testing the insulation resistance, and replacing faulty components. Regular maintenance and monitoring can help detect early signs of wear and prevent more significant problems.

References

[1] Siemens Digital Industries Software. Using additive manufacturing to spur innovation [Internet]. Siemens; 2019. Available from: https://resources.sw.siemens.com/en-US/white-paper-additive-manufacturing-for-innovation

Table of Contents

IntroductionUnderstanding Stators: The BasicsWhat is a Stator?Core Components of a StatorHow Stator Works?Classification and Types of StatorsPhysical ConstructionWinding ArrangementNumber of PhasesSpecialty StatorsTechnological Advancements in Stator DesignInnovative MaterialsAdvanced Manufacturing TechniquesAutomated WindingEnhancements in Stator Cooling SystemsImportance of CoolingDifferent Cooling Methods for StatorsApplications of Stators in Electric VehiclesStators in Electric VehiclesRole of Stators in Electric Vehicle MotorsImpact on Efficiency and PerformanceExamples of Leading Electric Vehicle Manufacturers and Their Stator TechnologiesIndustrial Machinery and AutomationUse of Stators in Various Types of Industrial EquipmentBenefits of Stators in Industrial MachineryCommon Issues and SolutionsOvercoming Challenges in Stator Technology: Solutions and Preventive MeasuresOverheatingInsulation FailureMechanical WearMaintenance and LongevityImportance of Regular MaintenanceSpecific Maintenance PracticesConclusionFrequently Asked Questions (FAQs)References