What is an Actuator? Types, Principles, and Applications

Actuators are an integral part of instrumentation systems that power the machines that exist today. These devices make it possible for the machines to interact with their surroundings the way they do. In this article, we take a closer look at the omnipresent technology.

Introduction

From the perspective of systems engineering, functions of any engineering product can be classified into three distinct categories; the collection of input, processing and producing an output.

For electromechanical systems, the input is detected and measured by a device called a sensor. The task of a sensor is to sample the signals available to it and convert them into a form understandable by the system. The system then processes the information and decides how to respond. But how exactly does a system respond?

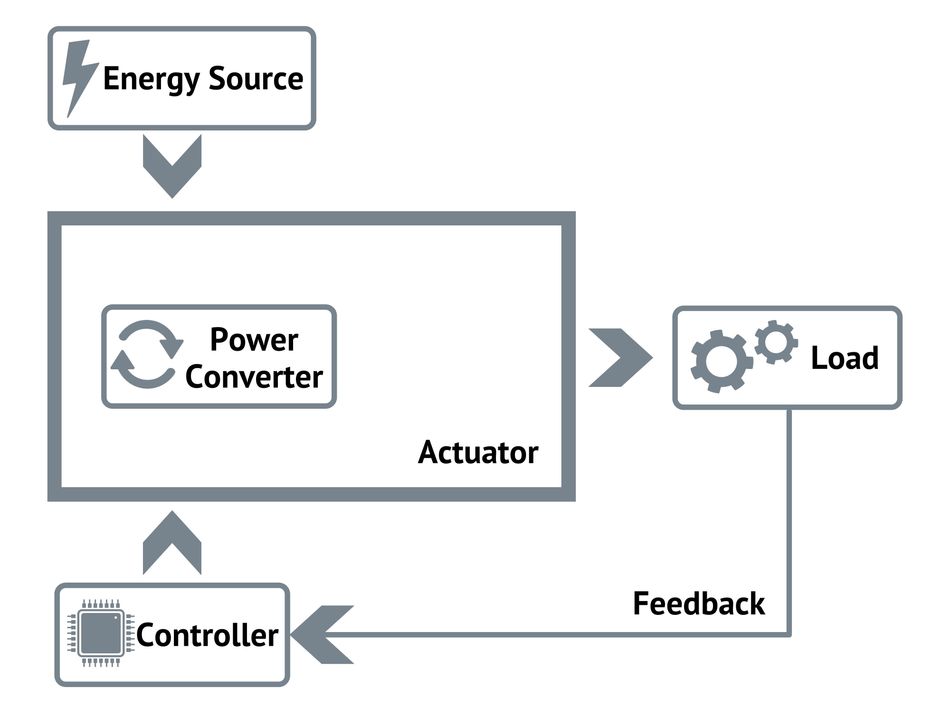

The answer is, with the help of an Actuator. Typically, an actuator consists of:

Energy source: Energy sources provide actuators with the ability to do work. Actuators draw electrical or mechanical energy from external sources for carrying out their operation. The energy available to the actuator can be regulated or unregulated depending on the system that it is a part of.

Power converter: If the energy source attached to the actuators is unregulated, it requires some additional apparatus to regulate it and convert it into a form suitable for the actuation action. Hydraulic control valves or solid-state power electronic converters are examples of converters used in industrial actuators.

Controller: In addition to enabling the operation of the power converter, a control unit is responsible for generating actuating electrical/control signals. In some systems, it provides the user with an interface to provide inputs or check the system’s status.

Load: The mechanical system attached to the actuator that uses the motion of the actuator is called the load. Characteristics like Force/Torque and Speed are carefully tuned before interfacing an actuator with the load.

At the core of an actuator's operation is the conversion of input energy into mechanical motion. This energy can come in various forms, such as electrical, hydraulic, or pneumatic, and is transformed into linear movement or rotary motion to perform a specific task. The type of motion generated depends on the actuator's design and the application's requirements.

Control systems play a significant role in actuator operation, ensuring that the motion generated is accurate, precise, and responsive to the system's needs. These control systems receive input signals, process them, and send output signals to the actuator, dictating its movement. Feedback mechanisms are often employed to monitor the actuator's position and performance, allowing for adjustments to be made in real-time to maintain optimal operation.

The efficiency of an actuator is determined by its ability to convert input energy into useful mechanical motion with minimal energy loss. Factors such as friction, heat generation, and mechanical resistance can impact an actuator's efficiency, making it essential to consider these aspects when designing and selecting actuators for specific applications. Additionally, the actuator's response time, accuracy, and repeatability are critical performance metrics that influence its suitability for various tasks.

Classification of actuators based on the motion

The most apparent and basic classification of actuators is based on the type of motion that it produces.

Rotary Actuator

The actuators that can provide a circular motion at their output can be classified under the category of rotary actuators. When it comes to rotational motion, it is hard to think of any other device than the motors, which we shall discuss in the next section of this article.

Linear Actuators

The actuators that can provide motion in a straight line at their output can be classified under the category of linear actuators. Hydraulic or Pneumatic actuators are the most common linear actuators used in the industry. We will also discuss these devices in detail.

Classification of actuators based on the energy source

The energy source can be another means of classification for the actuators.

Electromagnetic Actuators

Electromagnetic actuators make use of electrical energy and magnetic fields to perform actuation. These actuators are among the most commonly used actuators in the industries.

AC and DC Servo Motor actuators

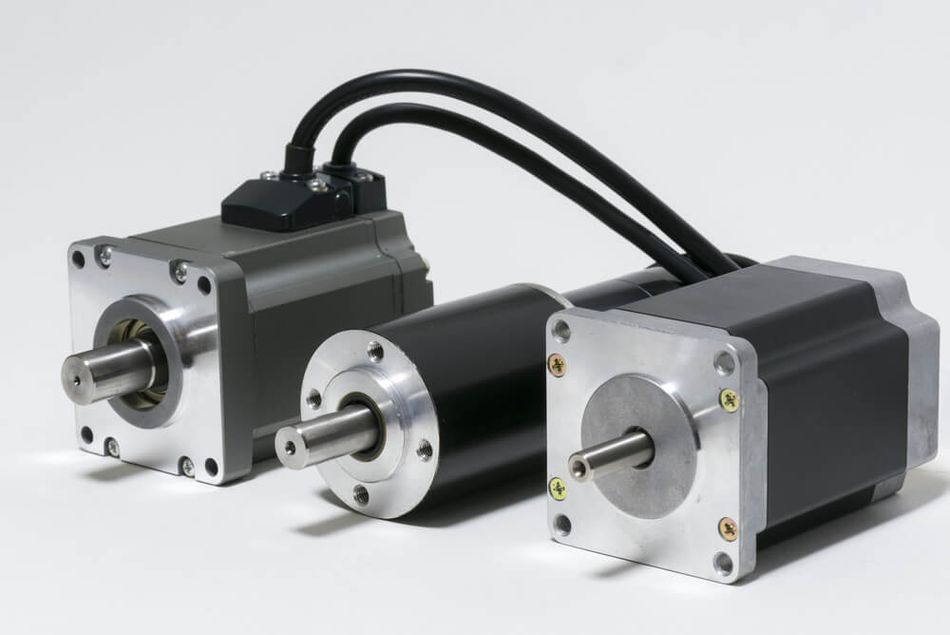

Servo drives can be powered by an AC or DC power supply and consist of a motor, feedback unit, control unit, and sometimes a gearbox. The working of a servo motor greatly differs from that of ordinary AC or DC motors. To operate a servo motor, a control signal is required in addition to the power.

Initially, when a voltage is applied to the terminals of a servo motor, it begins to rotate. The position of the shaft is continuously monitored by a rotary encoder, and the voltage-current levels are kept in check by the voltmeter-ammeter combination. The controller then computes the motor’s actual speed, compares it with the target speed, and adjusts the voltage and current levels to reduce the error between the target speed and actual speed.

Stepper Motor Actuators

Stepper motors are used for applications where the angular position of the shaft needs to be accurately controlled. The control scheme of the stepper motor is simple, accurate and doesn’t require any feedback. This is the reason why they are often more affordable.

The stator of the stepper motor contains multiple teeth, each acting as a pole for the rotor. When a particular pole or a set of poles are energised, the rotor reorients itself to allow maximum MMF to pass through it. When the next step of the poles is energised, the rotor shifts its position. This allows the rotor to complete a revolution in several distinct steps, and that’s how the motor gets its name.

Solenoid Actuators

A solenoid actuator consists of a conducting coil wound on a ferromagnetic core with a flat head on one side and a spring connected on the other. The whole apparatus is placed in a hollow cylindrical body. Whenever electric current flows through the wire, the coil acts as an electromagnet, attracting the ferromagnetic core in one direction and compressing the spring during the process.

Fig. 4: Solenoid Valves are used in controlling flow of liquids in industrial processes

Fig. 4: Solenoid Valves are used in controlling flow of liquids in industrial processesOnce the power supply is removed, the spring pushes the core back to the original position. The strength of the actuator depends upon the number of turns in the coil. The setup looks and acts a lot like a piston.

Fluid Power Actuators

The actuators that make use of liquids or gasses are called fluid power actuators. On a very superficial level, we can think of a fluid power actuator as a moving disk inside a hollow cylinder filled with fluid forming a piston. The movement of the disk appears as the motion of the actuator. Advanced fluid actuators with dual-acting cylinders make use of fluid for both extension and retracement strokes.

Hydraulic Actuators

These actuators make use of liquids as a driving force to produce mechanical work. Hydraulic Actuators are probably the most widely used linear actuators in real-life applications. These devices are used when stable, but high actuating thrust/high forces are required in a small region.

Pneumatic Actuators

The design and construction of pneumatic actuators are very similar to that of hydraulic actuators. The difference is that instead of using a liquid, energy from compressed gases or vacuum is used to facilitate the actuation process.

Further reading: What Is Pneumatics? Answered by Our Experts - Rowse

Mechanical Actuators

These actuators are used to interconvert rotary and linear motion in machines. Some examples of mechanical actuators are rack and pinion arrangements, crankshafts, gears, pulleys, and chains.

Thermal Actuators

Thermal actuators make use of materials that expand or contract by the application of heat. These actuators can be used to sense temperatures and shut off a supply to the system they are a part of. Thermal actuators combine the functions of a temperature switch and an actuator in a single package.

Special Actuators

Apart from the commonly used actuators, some actuators are still under research and find their application in limited fields.

Piezoelectric Actuators

Piezoelectric materials exhibit a contraction/expansion whenever a voltage is applied to them. By applying a controlled signal, this property of piezoelectric materials can be used to build actuators for small but highly precise and rapid positioning mechanisms. [2]

Shape Memory Alloy Actuators

Shape Memory Alloys (SMAs) undergo a change in their molecular arrangement when they are heated or cooled. When a force is applied to alloys like Nitinol (Nickel-Titanium), they experience a deformation that can be reversed with heating.

Heating can be done directly by application of thermal energy or with the help of electric power. This property of SMAs can be used to build actuators [3]

Supercoiled Polymer Actuators

It gets challenging to downsize conventional actuators like electric motors beyond a certain limit, making them unsuitable for miniature machines. This is where Supercoiled Polymer Actuators (SPAs) come in. Supercoiling is a property of DNA strands that makes it possible for them to relieve stress by twisting around themselves. SPAs are inspired by a similar design that lets them reversibly change their shape and size when stimulated. These structures respond quickly and can last for millions of cycles. [4]

Hydrogel actuators

Hydrogel actuators demonstrate a change in their shape with changes in the temperature, light, pH and concentration of certain substances. The fact that hydrogels can be effective only in aqueous medium limits their applications to some specific specialized fields.

Fig. 8: Bending behaviour of Polydimethylsiloxane Hydrogel actuator in aqueous solution. Source: The Faboratory at Yale University

Fig. 8: Bending behaviour of Polydimethylsiloxane Hydrogel actuator in aqueous solution. Source: The Faboratory at Yale UniversityResearch shows that some hydrogel actuators can be optically and sonically camouflaged as their properties are similar to that of water. [5] [6]

Further reading: Powering Soft Robotics: A Deeper Look at Soft Robotics Actuators

Actuator Performance Metrics

Evaluating the performance of an actuator is crucial for selecting the most suitable option for a specific application. Several key metrics are used to assess actuator performance, providing valuable insights into their capabilities and limitations.

Force and torque: Force and torque output are essential metrics for actuators, as they indicate the amount of force or torque an actuator can generate. These values are typically provided by the manufacturer and are crucial for determining whether an actuator can handle the required loads in a given application.

Speed and response time: Speed and response time are also critical performance metrics. Speed refers to the rate at which an actuator can move, while response time indicates how quickly the actuator can react to a control signal. Faster speeds and shorter response times are desirable for applications requiring rapid and precise movements, such as robotics and automation systems.

Accuracy and repeatability: Accuracy and repeatability are essential for applications that demand precise positioning and control. Accuracy refers to the actuator's ability to reach a specific position or angle, while repeatability measures the consistency with which the actuator can return to that position or angle. High accuracy and repeatability are vital for applications such as CNC machining and assembly processes.

Efficiency: Efficiency is a measure of how effectively an actuator converts input energy into mechanical motion. Higher efficiency is desirable, as it reduces energy consumption and minimizes heat generation during operation. Factors such as friction, mechanical resistance, and energy losses in the transmission mechanism can impact an actuator's efficiency.

Understanding these performance metrics and their implications for different applications is crucial for selecting the most appropriate actuator and optimizing system performance. By carefully considering these factors, engineers and designers can make informed decisions when choosing actuators for their projects.

Actuator Control Systems

Control systems play a vital role in actuator operation, ensuring accurate, precise, and responsive motion in various applications. These systems receive input signals, process them, and send output signals to the actuator, dictating its movement. Feedback mechanisms are often employed to monitor the actuator's position and performance, allowing for real-time adjustments to maintain optimal operation.

There are various types of control systems used with actuators, each offering different advantages and disadvantages depending on the application requirements.

Open-loop control systems: Open-loop control systems do not use feedback to adjust the actuator's movement. Instead, they rely on a predetermined sequence of commands to control the actuator. Open-loop systems are generally simpler and less expensive than closed-loop systems but may be less accurate and less adaptable to changes in the system or environment.

Closed-loop control systems: Closed-loop control systems incorporate feedback mechanisms to monitor the actuator's position and performance, adjusting the control signals in real-time to maintain the desired motion. Closed-loop systems offer higher accuracy and adaptability compared to open-loop systems but can be more complex and expensive to implement.

Proportional-Integral-Derivative (PID): Proportional-Integral-Derivative (PID) controllers are a common type of closed-loop control system used with actuators. PID controllers use a combination of proportional, integral, and derivative control actions to minimize the error between the desired and actual actuator position. This approach allows for precise control and rapid response to changes in the system or environment.

Model-based control systems: Model-based control systems use mathematical models of the actuator and its environment to predict and optimize its performance. These systems can be highly accurate and adaptable but may require significant computational resources and expertise to develop and implement.

When selecting a control system for an actuator, it is essential to consider factors such as the required accuracy, response time, and adaptability, as well as the complexity and cost of implementation. By carefully evaluating these factors, engineers and designers can choose the most appropriate control system for their specific application, ensuring optimal actuator performance and system efficiency.

Further reading: Robotic actuators: The muscle power of Industry 4.0

Actuator Applications

An actuator that can generate sufficient force has suitable load-speed characteristics, works in the operating range with high efficiency, and comes with a robust design is considered ideal for a given application. Their significance in industrial applications like robotics, automotive, aerospace, and medical devices is paramount.

Industrial automation and robotics are the two fields where it is just impossible to imagine getting anything done without actuators. These parts enable production machines to move from one place to another and grab objects. Actuators are also widely used in heavy construction equipment and agricultural machinery to enable several different sets of movements. Another beautiful application of actuators can be in solar panels. As the sun rises and sets during the day, the solar panels equipped with actuators keep changing their angle to harness maximum solar energy.

Coming to household applications, actuators can be found in almost every smart home appliance, from furniture to robotic vacuum cleaners that require any sort of maneuver. A lot of toys too contain some small actuators built-in them. The applications are endless.

Here is a brief case study that explains the use of actuators in the Automotive and Aerospace industry:

Automotive Industry

Actuators play a critical role in the automotive industry, contributing to the functionality, safety, and performance of modern vehicles. They are used in various systems and components, enabling precise control and movement in response to driver inputs and environmental conditions.

Engine and transmission control systems rely on actuators to manage essential functions such as throttle control, fuel injection, and gear shifting. These actuators ensure optimal engine performance, fuel efficiency, and smooth gear transitions, contributing to a comfortable and efficient driving experience.

Suspension systems use actuators to adjust the vehicle's ride height, damping, and stiffness, adapting to different road conditions and driving styles. Active suspension systems, in particular, employ actuators to continuously adjust the suspension settings in real-time, providing improved handling, comfort, and safety.

Braking systems incorporate actuators to apply and release the brakes, ensuring effective stopping power and vehicle stability. Advanced braking systems, such as anti-lock braking systems (ABS) and electronic stability control (ESC), use actuators to modulate brake pressure in response to wheel slip and vehicle dynamics, enhancing safety and control during critical driving situations.

Fig. 9: Modern disc brakes in cars, powered by actuators, showcase the fusion of safety and precision in automotive engineering

Fig. 9: Modern disc brakes in cars, powered by actuators, showcase the fusion of safety and precision in automotive engineeringSteering systems utilize actuators to assist the driver in turning the vehicle, reducing the effort required to steer and improving responsiveness. Electric power steering (EPS) systems, for example, use electric actuators to provide variable levels of steering assistance based on vehicle speed and driver input, offering improved fuel efficiency and a more precise steering feel compared to traditional hydraulic systems.

Climate control systems employ actuators to regulate airflow, temperature, and humidity within the vehicle cabin, ensuring a comfortable environment for occupants. These actuators control the operation of fans, vents, and heating or cooling elements, maintaining the desired temperature and air quality settings.

In summary, actuators are integral to the operation and performance of modern vehicles, contributing to enhanced safety, comfort, and efficiency. As automotive technology continues to evolve, the demand for advanced actuators with improved performance and reliability is expected to grow, driving further innovation in this critical field.

Aerospace Industry

Actuators play a crucial role in the aerospace industry, where they are used in various systems and components to ensure precise control, reliability, and safety. From aircraft flight control systems to spacecraft propulsion, actuators are essential for the proper functioning of aerospace vehicles and equipment.

Flight control systems in aircraft rely on actuators to manipulate control surfaces such as ailerons, elevators, and rudders. These actuators respond to pilot inputs and autopilot commands, adjusting the control surfaces to achieve the desired changes in pitch, roll, and yaw. The precision and responsiveness of these actuators are critical for maintaining aircraft stability and control during flight.

Landing gear systems use actuators to extend and retract the landing gear, ensuring safe takeoffs and landings. These actuators must be reliable and robust, as they are subjected to significant loads and harsh operating conditions. Additionally, actuators are used in braking systems and steering mechanisms for the landing gear, providing precise control during ground operations.

Engine control systems in aircraft and spacecraft employ actuators to manage critical functions such as fuel flow, thrust vectoring, and nozzle adjustments. These actuators ensure optimal engine performance, fuel efficiency, and safe operation under various flight conditions.

Spacecraft propulsion systems utilize actuators to control the orientation and thrust of rocket engines and thrusters. These actuators are essential for maintaining spacecraft attitude, trajectory, and velocity during orbital maneuvers and interplanetary missions. The performance and reliability of these actuators are critical for mission success, as they must operate in the harsh environment of space and endure extreme temperature variations.

Payload deployment systems in satellites and spacecraft use actuators to deploy instruments, antennas, and solar panels. These actuators must be precise and reliable, as they are responsible for ensuring the proper functioning of critical systems and maintaining the spacecraft's power supply.

In the aerospace industry, the demands for high performance, reliability, and safety place stringent requirements on actuator design and operation. As aerospace technology continues to advance, the development of innovative actuator solutions will remain a key area of focus, driving improvements in efficiency, precision, and overall system performance.

Medical Industry

Actuators in the medical industry are pivotal, ensuring precision, safety, and adaptability in various medical devices and procedures. Their role is indispensable in both diagnostic and therapeutic applications, making them a cornerstone of modern medical technology.

Surgical robots, for instance, employ actuators to achieve intricate movements during procedures. These actuators allow for a high degree of precision, enabling surgeons to perform complex surgeries with minimal invasiveness. The result is reduced recovery times and enhanced patient outcomes.

Medical imaging devices, such as MRI and CT scanners, utilize actuators to adjust the position of the patient or the imaging component. This ensures optimal imaging angles and patient comfort, leading to more accurate diagnostics.

Drug delivery systems, especially those used in targeted therapies, rely on actuators to release precise drug amounts at specific intervals. This ensures that patients receive the correct dosage at the right time, optimizing therapeutic effects and minimizing side effects.

Prosthetics and orthotics also benefit from actuators. Modern prosthetic limbs, for instance, use actuators to mimic natural movements, allowing users to walk, grip, or perform other functions more naturally and comfortably. Similarly, orthotic devices employ actuators to provide support and enhance mobility for individuals with musculoskeletal disorders.

Fig. 10: A prosthetic arm uses multiple actuators to replicate the intricate movements and functions of a natural limb, enhancing mobility and user experience.

Fig. 10: A prosthetic arm uses multiple actuators to replicate the intricate movements and functions of a natural limb, enhancing mobility and user experience.Ventilators, crucial in critical care settings, use actuators to control airflow and pressure, ensuring patients receive the right amount of oxygen based on their medical needs.

In the medical industry, the emphasis on patient safety, comfort, and positive outcomes necessitates the continuous evolution of actuator technology. As medical science progresses, the integration of advanced actuators will be paramount, paving the way for more innovative, efficient, and patient-centric solutions.

Industrial Automation

Actuators are the backbone of industrial automation, driving efficiency, precision, and scalability in manufacturing and processing environments. Their role is crucial in ensuring that industrial processes are streamlined, consistent, and adaptable to changing demands.

In assembly lines, actuators enable robotic arms to pick, place, and assemble parts with high precision. This not only speeds up the production process but also ensures product consistency and quality.

Material handling systems, such as conveyors and sorters, employ actuators to move, sort, and manage products or raw materials efficiently. This ensures that the right materials reach the right place at the right time, optimizing the production flow.

In industrial applications involving control valves, actuators regulate the flow of liquids or gases, ensuring that processes are carried out under optimal conditions. Whether it's regulating the fluid pressure in a compressor or adjusting a butterfly valve in a pipeline, actuators are at the heart of process control.

Heavy machinery, especially in sectors like mining and construction, relies on heavy-duty actuators to perform tasks such as digging, lifting, and drilling. These actuators must exhibit high durability and reliability, given the harsh operating conditions they often face.

CNC machines, which are pivotal in modern manufacturing, use actuators to achieve precise cuts, drills, and other operations. The linear movement provided by these actuators, often driven by a lead screw, ensures that products are manufactured to exact specifications.

In the realm of industrial automation, actuators are the silent workhorses that drive productivity and innovation. As industries continue to embrace automation and digitization, the role of actuators will only become more pronounced, heralding a new era of industrial efficiency and excellence.

Actuator Selection Criteria

Choosing the right actuator for a specific application is crucial to ensure optimal performance, efficiency, and reliability. Several factors must be considered when selecting an actuator, as each type has its unique advantages and limitations. By carefully evaluating these factors, engineers and designers can identify the most suitable actuator for their needs.

- Force or torque requirements: Force or torque requirements are among the most critical factors to consider when selecting an actuator. The actuator must be capable of generating sufficient force or torque to move the load in the desired manner. It is essential to review the manufacturer's specifications and ensure that the actuator meets or exceeds the application's force or torque demands.

- Speed and response time: Speed and response time are also important considerations, as they determine how quickly the actuator can move and react to control signals. Applications requiring rapid and precise movements, such as robotics and automation systems, will benefit from actuators with higher speeds and shorter response times.

- Accuracy and repeatability: Accuracy and repeatability are vital for applications that demand precise positioning and control. The actuator's ability to reach a specific position or angle and consistently return to that position or angle should be evaluated to ensure it meets the application's requirements.

- Environmental conditions: Environmental conditions must be taken into account when selecting an actuator, as they can significantly impact the actuator's performance and lifespan. Factors such as temperature, humidity, dust, and vibration should be considered, and the actuator should be rated for operation under the specific conditions of the application.

- Size and weight: Size and weight constraints may also influence the choice of actuator, particularly in applications where space is limited or weight is a critical factor. Actuators with compact designs and lightweight materials may be more suitable for these applications.

- Power source and control system compatibility: Power source and control system compatibility are essential factors to consider, as the actuator must be able to interface with the available power source and control system. Ensure that the actuator's voltage, current, and control signal requirements are compatible with the existing infrastructure.

- Cost and maintenance requirements: Cost and maintenance requirements should also be evaluated when selecting an actuator. While initial cost is an important consideration, it is essential to assess the long-term costs associated with maintenance, repairs, and replacement to determine the total cost of ownership.

By carefully considering these factors and evaluating the specific requirements of the application, engineers and designers can select the most appropriate actuator, ensuring optimal performance, efficiency, and reliability.

Further reading: What is a Sensor? An In-Depth Exploration and Comprehensive Guide to Engineering Principles and Applications

Conclusion

Actuators are essential components in a wide range of industries and applications, providing precise control and movement in response to various inputs and conditions. Yet innovations in the domain get little coverage in the media compared to cutting edge technologies like Artificial Intelligence (AI), Blockchain, Internet of Things (IoT), 3D printing, etc.

Understanding the principles, types, and performance metrics of actuators, as well as the factors to consider when selecting an actuator, is crucial for engineers and designers to ensure optimal performance, efficiency, and reliability.

As technology continues to advance, the development of innovative actuator solutions will remain a key area of focus, driving improvements in various fields, including automotive, aerospace, and industrial automation.

Frequently Asked Questions

What is an actuator?

An actuator is a mechanical or electromechanical device that converts energy, typically electrical, hydraulic, or pneumatic, into controlled motion or force. Actuators are used in various systems and applications to provide precise control and movement in response to input control signals or environmental conditions.

What are the main types of actuators?

The main types of actuators include electric, hydraulic, and pneumatic actuators. Electric actuators use electric motors to generate motion, hydraulic actuators rely on pressurized hydraulic fluids to create force, and pneumatic actuators utilize compressed air or gas to produce movement.

How do I choose the right actuator for my application?

To choose the right actuator, consider factors such as force or torque requirements, speed and response time, accuracy and repeatability, environmental conditions, size and weight constraints, power source and control system compatibility, and cost and maintenance requirements. Evaluating these factors will help you select the most suitable actuator for your specific application.

What are some common applications of actuators?

Actuators are used in a wide range of applications, including automotive systems (engine control, suspension, braking), aerospace systems (flight control, landing gear, engine control), industrial automation (robotics, assembly lines, material handling), and consumer products (appliances, electronic devices).

How do I measure the performance of an actuator?

Actuator performance can be measured using metrics such as force or torque output, speed, response time, accuracy, repeatability, and efficiency. These metrics help evaluate the actuator's ability to meet the specific requirements of the application and provide a basis for comparison between different types and models of actuators.

References

[1] Inamuddin, Boddula, R., & Asiri, A. M. (2020). Actuators: Fundamentals, principles, materials and applications. Srivener Publishing. Wiley Press.

[2] Craig D. Near "Piezoelectric actuator technology", Proc. SPIE 2717, Smart Structures and Materials 1996: Smart Structures and Integrated Systems, (1 May 1996); https://doi.org/10.1117/12.239027

[3] D. Grant and V. Hayward, "Variable structure control of shape memory alloy actuators," in IEEE Control Systems Magazine, vol. 17, no. 3, pp. 80-88, June 1997, DOI: 10.1109/37.588180.

[4] Micro muscles inspired by DNA supercoiling - University of Wollongong. UOW. (n.d.). Retrieved October 20, 2021, from https://www.uow.edu.au/media/2021/micro-muscles-inspired-by-dna-supercoiling.php.

[5] Leonid Ionov, Hydrogel-based actuators: possibilities and limitations, Materials Today, Volume 17, Issue 10, 2014, Pages 494-503, ISSN 1369-7021, https://doi.org/10.1016/j.mattod.2014.07.002.

[6] Yuk, H., Lin, S., Ma, C. et al. Hydraulic hydrogel actuators and robots optically and sonically camouflaged in water. Nat Commun 8, 14230 (2017). https://doi.org/10.1038/ncomms14230

[7] Janocha, H. (2010). Actuators: Basics and applications. Springer.

[8] Marketing, C. M. C. (2021). What are different types of actuators? Creative Motion Control. Retrieved October 20, 2021, from https://www.creativemotioncontrol.com/types-of-actuators/.

Table of Contents

IntroductionClassification of actuators based on the motionRotary ActuatorLinear ActuatorsClassification of actuators based on the energy sourceElectromagnetic ActuatorsFluid Power ActuatorsMechanical ActuatorsThermal ActuatorsSpecial ActuatorsActuator Performance MetricsActuator Control SystemsActuator ApplicationsAutomotive IndustryAerospace IndustryMedical IndustryIndustrial AutomationActuator Selection CriteriaConclusionFrequently Asked QuestionsReferences