KyronTEX® Recyclable Thermoplastic Material

Strong, lightweight, and sustainable thermoplastic materials for high-volume and high-speed production.

Technical Specifications

| Product Type | Recyclable Thermoplastic |

| Reinforcement | CF, GF, rCF, and combinations of NCF, GF & rCF |

| Thermoplastic Polymer Types | PP, PA, PC, PPS, PEI, PEEK, PEKK, etc |

| Density Range | 0.3 to 1.8 gm/cm3 |

| Applications | Automotive, Aerospace, Sport & Leisure Industry |

Overview

KyronTEX® is a recyclable thermoplastic composite material that leverages efficient and scalable textile manufacturing methods. Its exceptional drapability, coupled with options like random and continuous fibers, or sandwich sheets, makes KyronTEX® ideal for crafting intricate, high-performance components in large dimensions and high production volumes. KyronTEX is a lightweight alternative for design engineers, best suited for flexible design applications, ensuring strength and functionality. Hence, it’s suited for complex designs such as motorcycle helmets, high-end structures like aircraft panels, etc.

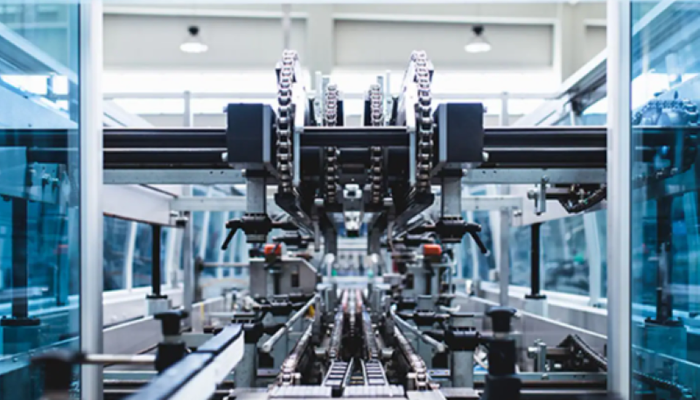

Large-Scale Production and Produces Complex Geometrical Structure Design

KyronTEX® promotes the rapid production of carbon fiber-reinforced thermoplastic composites (CFRTP) through an innovative dry impregnated organofleece technology, enabling highly efficient large-scale manufacturing. It features an automated process that combines high throughput with continuous inline quality measurements, ensuring consistent and superior quality.

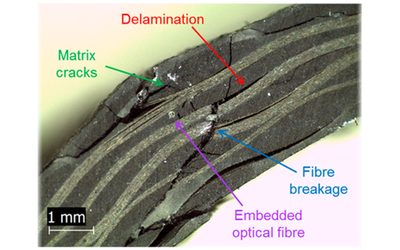

The resulting carbon fiber composite fabric, created without the need for intermediate lamination, is ready for the direct production of intricate, highly complex parts. Unlike conventional thermoplastic solutions, KyronTEX® facilitates the realization of complex geometries with its unique drapability.

This characteristic allows for smaller radii without compromising fiber performance. The predictability of fiber movement during compression molding eliminates guesswork, reducing the number of necessary assembly steps. Moreover, KyronTEX® simplifies recycling through the production of single-material parts. This technological advancement enhances efficiency and precision in the manufacturing process and contributes to the development of sustainable and high-performance composite materials in various applications.

Versatile Drapable Carbon Composite at a Reduced CO2 Footprint

Enhancing the production of intricate components, KyronTEX® owes its versatility to the distinctive drapability of organofleeces, simplifying the manufacturing process and cutting costs. The efficient utilization of KyronTEX® thermoplastic technology allows for the swift production of intricate parts in minutes instead of hours. The drapability ensures sandwich panel production and allows for integration with parts of varying densities. As a result, KyronTEX has applications in the sports, leisure, and mobility industries (automotive and aerospace).

KyronTEX® seamlessly bonds with other components through welding or integrates swiftly with alternative materials through hybrid over-molding. Hence, it can be integrated with a diverse range of materials without necessarily replacing them. The integration capability reduces the necessity for intricate connectors or fasteners.

As an eco-friendly option, KyronTEX® is entirely recyclable, enabling repurposing and reuse. It reduces the carbon dioxide footprint, thanks to a highly optimized recycling process. These recycling processes can collect and repurpose post-industrial waste and end-of-life parts, contributing to sustainable practices in material usage. Therefore, while KyronTEX is a suitable option for complex geometry and strength-intensive designs, it also contributes to sustainable manufacturing practices.