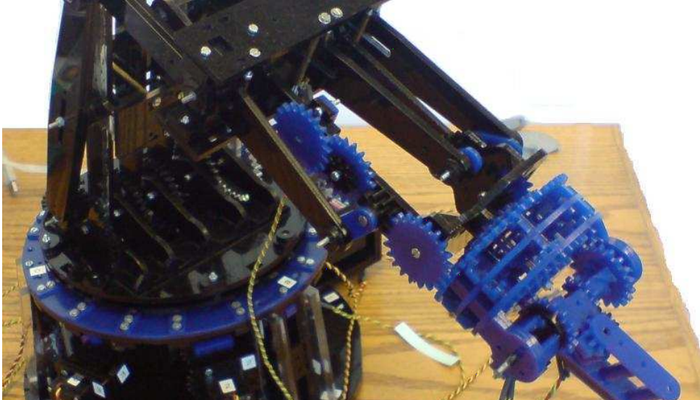

6 DOF Industrial Robot Arm

An industrial robot arm with a hybrid kinematic design.

Technical Specifications

| degrees of freedom |

Overview

The location of the motors in SKMs robotic arms create a large inertia and a weight distribution that reduces accuracy and generates vibrations. On the other hand PKMs are lighter and faster, but usually have a smaller working space and are less tested and less used than SKMs. This 6 degree-of-freedom robotic arm was developed to include the advantages of both systems and is actuated by 6 motors mounted on the base of the robot. The kinematic controlled of the robot possed a strong development challenge and is still being developed.

References

Focuses on the design of a novel robotic arm design having a hybrid nature. Discusses the various advantages of various robotic arms and compares their features. Also touches on the control of the proposed robotic arm along with issues with the method.

Discusses a 2-DOF TPR with only revolute and prismatic joints. The inverse and forward kinematics problems, workspace, conditioning indices, and singularity are presented. Also included are the future plans for the proposed the device.