M-TRAN

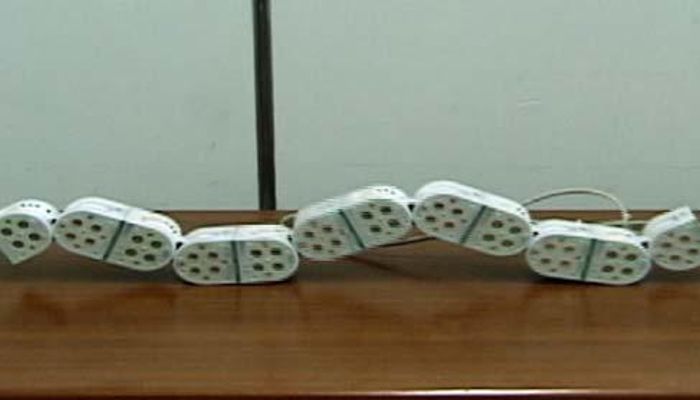

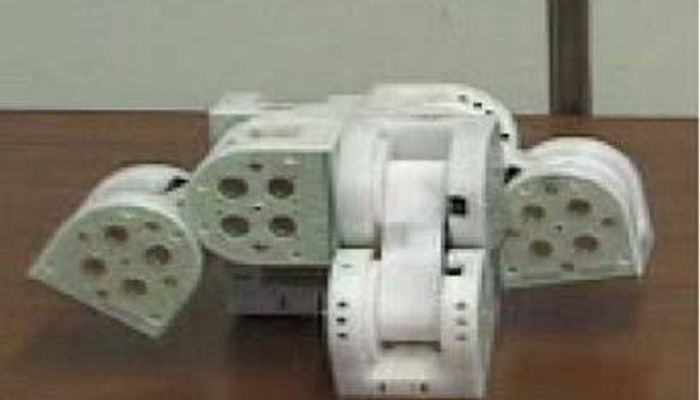

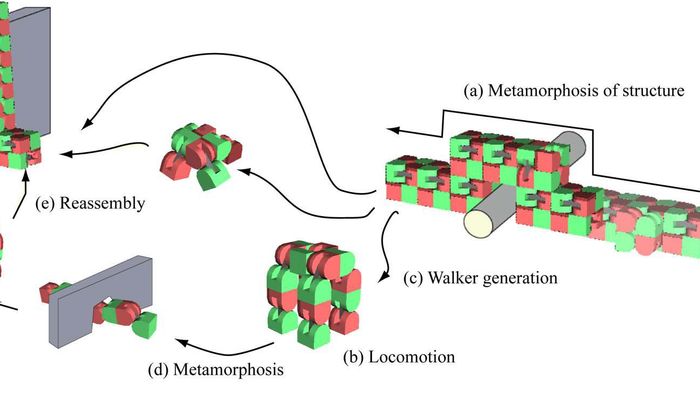

M-TRAN (Modular Transformer) is a self-reconfigurable modular robot. The modules can form a 3-D structure which changes its own configuration, and a 3-D structure which generates smaller robots. The M-TRAN system can change its 3-D structure and its motion in order to adapt itself to the environment. In small sized configuration, it walks in a form of legged robot, then changes into a snake-like robot to enter narrow spaces. A large structure can gradually change its configuration to make a flow-like motion, climb a step by transporting modules one by one, and produce a tower structure to look down. It can also generate multiple walkers.

Technical Specifications

| Height | 66 |

| Width | 66 |

| Length | 132 |

| Weight | 0.44 |

| CPU | |

| Power supply | 12 |

| Maximum torque of each axis | 23 |

| Connecting force | 25 |

| Elapsed time for detachment | 5 |

| Power consumption for detachment | 180 |

| Electrical resistance of module | 1.3 |

Overview

The M-TRAN system can change its 3-D structure and its motion in order to adapt itself to the environment. In small sized configuration, it walks in a form of legged robot, then changes into a snake-like robot to enter narrow spaces. A large structure can gradually change its configuration to make a flow-like motion, climb a step by transporting modules one by one, and produce a tower structure to look down. It can also generate multiple walkers.

The design of M-TRAN has the advantages of both two types of modular robots, lattice type and chain (linear) type. This hybrid design, 3-D shape of the block parts, and parallel joint axes are all keys to realize a flexible self-reconfigurable robotic system. Possible applications of the M-TRAN are autonomous exploration under unknown environment such as planetary explorations, or search and rescue operation in disaster areas.

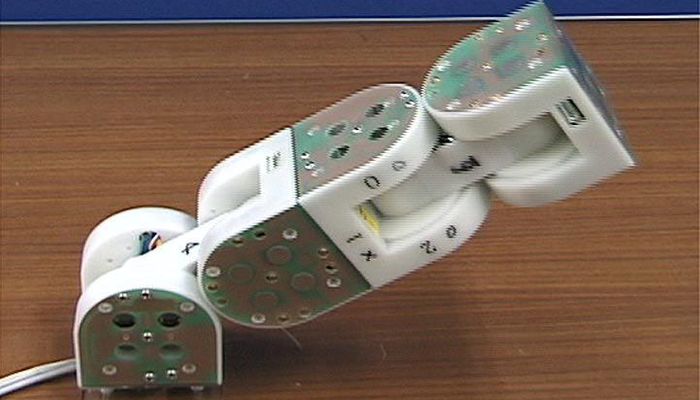

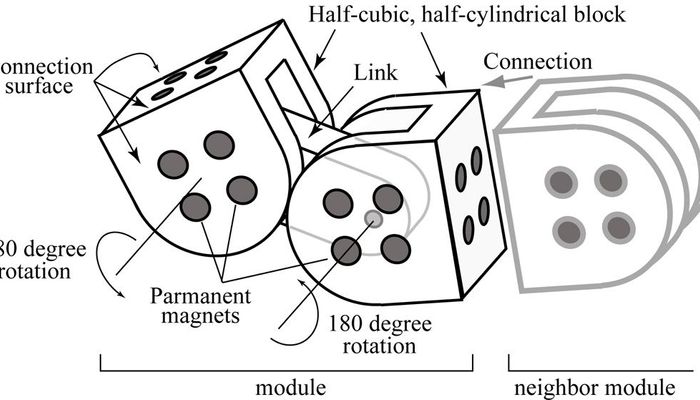

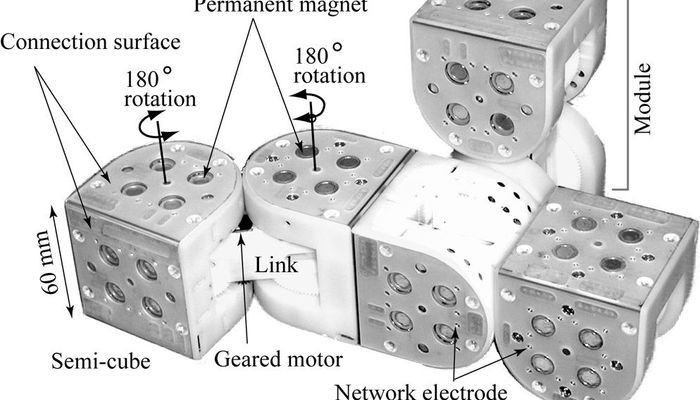

An M-TRAN module is made of two semi-cylindrical parts connected by a link. Each semi-cylindrical part can rotate about its axis by 180 degrees with a servomotor embedded in the link. Each semi-cylindrical part has three connecting surfaces with four permanent magnets and can connect to other modules’ surfaces that have the opposite polarity of the magnets. The two semi-cylindrical parts have surfaces of different polarity.

Mechanical and Electrical Design

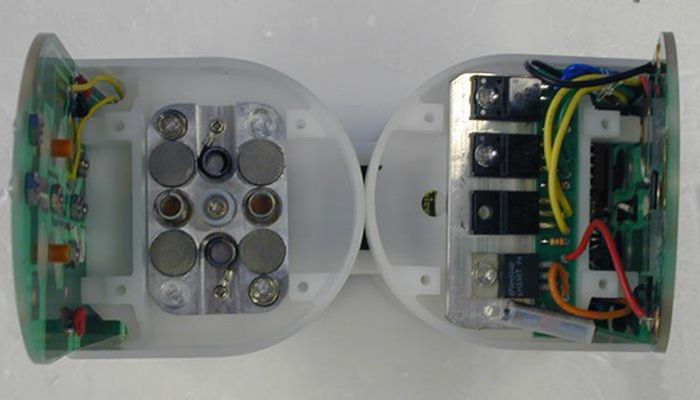

The link part includes two sets of geared motors and servo circuits. The maximum torque of each servo is enough to lift up one module. On all the connection surfaces, there are electrodes for power supply and serial communication. There are two parts, called active and passive part. Inside the active part, there is a connection mechanism that is made of non-linear springs, SMA (Shape Memory Alloy) coils and four permanent magnets, which are fixed on the connecting plate. This mechanism is based on the technique of IBMU (Internally Balanced Magnet Unit)

The connecting plate moves automatically to connect to the other modules’ surface by attractive force of magnets. It is detached by heating SMA coils by electric current. When detaching, the springs help SMA coils. Inside the passive part, there are control circuits including an onboard micro-computer. This controls motor rotation and heating of SMA coils. Control commands corresponding to these operations are issued by the host computer through the serial communication.

Each M-TRAN module has its own controller and intelligence, and all the controllers work cooperatively forming a Distributed Autonomous System as a whole.

References

Outlines the hardware and control system of MTRAN and demonstrates experiments of many-unit motions. Describes a motion generation method to enable a class of MTRAN clusters to move along a desired trajectory in a series of reconfiguration. The motion generator consists of a planner and a scheduler

Describes principles and the current M-TRAN hardware. An operation scenario is presented, followed by past research results of self-reconfiguration and whole body locomotion. Presents a detailed evaluation of the feasibility of the scenario using several examples of walker generation by M-TRANS.

Basic design and hardware development are described. Geometric self-reconfiguration sequence, especially flow-like motions, are presented. Simulators, description languages and controllers are outlined, with the result of a basic experiment.

Describes the development of M-TRAN III, especially that of its hardware, communication between modules and experiments of distributed self-reconfiguration. Future research into autonomous self-reconfiguration and remaining problems are also discussed. The basic design and hardware are described.

A feasibility study was made for self-assembly and self-reproduction using anM-TRAN modular robotic system.