Connected Car Trend Creates Modularity Challenges

Article #3 of our Connected Transport Series. Successful connected car designs require secure, well-designed connectors that solve modularity challenges.

This is the third article in a 5-part series exploring the connectivity solutions for the future of transportation. The series will detail various connectivity challenges engineers face and describe the technology that will provide the solutions to enhance transportation and driving experience.

The articles were originally published in an e-magazine, and have been substantially edited by Wevolver to update them and make them available on the Wevolver platform. This series is sponsored by Mouser Electronics, an online distributor of electronic components. Through their sponsorship, Mouser Electronics supports engineers in building a highly connected transport future in addition to knowledge sharing on related topics of electric vehicles, 5G, and autonomous transport.

Everything is connected. Doctors know this. Automakers realize it, too.

The body's nervous system is made up of parts that coordinate to trigger a reaction. Touching a hot stove sends a signal through your peripheral nervous system to your brain, which results in the sensation of pain and causes you to move your hand. The peripheral nervous system, neurons, dendrites, and axons all work together to deliver information to the central nervous system so the brain can process it and determine an appropriate reaction. Today, vehicles work in much the same way.

New functions being implemented in transportation designs, such as safety and infotainment capabilities, need to efficiently and reliably receive and transmit data to activate the appropriate responses. For example, when safety sensors detect an obstacle in the road, data is transmitted via cabling or antennas to processors that trigger a reaction. When a finger activates a capacitive switch in the dashboard, the resulting signal ultimately causes a response from the GPS or infotainment device. In other words, each of these functions relies on circuitry, an essential part of a vehicle's nervous system. As transportation engineers develop more and more functionality, the resulting increase in connectivity drives the industry's most significant modularity trend.

What Do We Mean by Modularity?

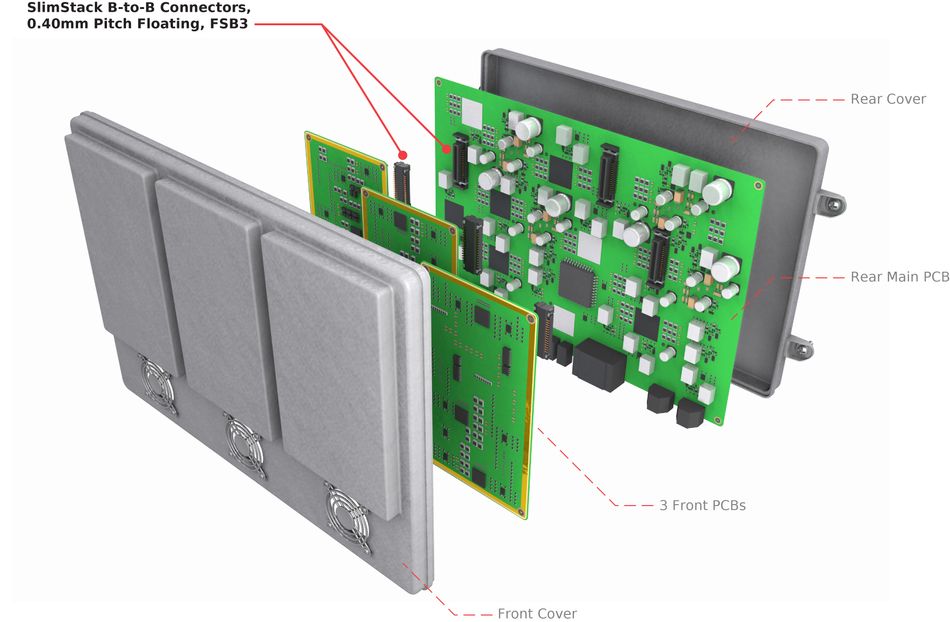

As smart capabilities become ubiquitous in our world, consumers are looking for similar functions in their vehicles. This requires systems that process information to do a task, and each of these systems involves complex electronics. The result is modularization, assemblies with active components, drivers, memory modules, and more. A functional module typically includes at least one - but often more - printed circuit board (PCB) along with connectors, flex assemblies, and other components.

Modularity impacts every part of transportation, such as cars and trucks, forklifts and tractors, and ATVs, and other recreational vehicles. Modular functions exist throughout - the drivetrain, power management systems, infotainment devices, autonomous driver assistance systems (ADAS), and more. These modularized electronics transmit data within the modules themselves, with other modules, and with other systems throughout the vehicle.

Modularity's Impact on the Driving Experience

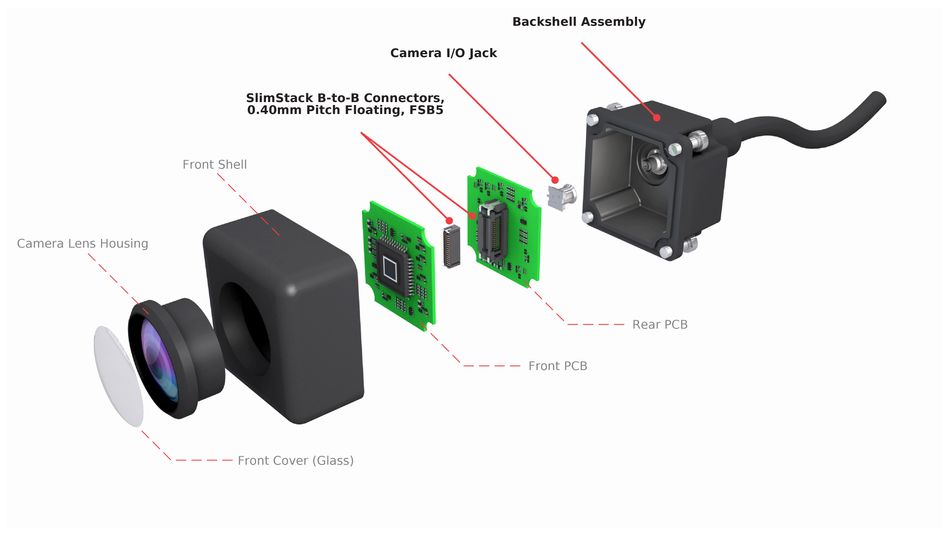

Innovative safety capabilities are one of the market's latest developments, and serve as a good illustration of this trend - the sensors involved need to be integrated with systems throughout the vehicle, creating a need for interconnectivity.

We have already pointed out the similarities between the human nervous system and the connected modularity within vehicles. However, there is a profound difference between the two - human reaction times can be far more fallible. The U.S. National Highway Traffic Safety Administration (NHTSA) states that 94 percent of vehicle crashes are because of human error. New technology, along with the electronics that enable it, can potentially save lives.

For example, let's say you're driving down a highway when you see a deer crossing in front of you. According to neuroscientists at the Massachusetts Institute of Technology, it would take you - at best - 13 milliseconds to process the image of the deer. Then - again, at best - it would take you an additional 500 milliseconds to respond by hitting the brakes. This means, if you are driving at 86kph (55mph), your car will travel 12.5m (40.5') between the time you see the deer and the time you brake. That distance increases to 17m (55.5') if you drive at 120kph (75mph). Again, this is a best-case scenario, if you have a top-notch reaction time.

As a result of this delay in human reaction, the milliseconds it takes to perceive a deer in the road and then apply the brakes could easily cause a severe accident. By avoiding human error and enhancing reaction time, the NHTSA estimates that automated vehicles and driver-assisted technologies - the kinds of technologies helping to drive the trend toward modularity - can significantly reduce the occurrence of traffic accidents. But for cameras and sensors to transmit vital information to activate the proper reaction, reliable, high-performing connectivity is crucial.

The Challenges of Modularity in Transportation Applications

High-Performance Requirements in Harsh Environments: Systems connected with complex electronics exist throughout the vehicle, and drivers and passengers expect these electronics to offer the same level of function and capability as the most sophisticated smart devices or security systems in their homes and offices, even though they operate under far more challenging conditions.

Space Constraints: At the same time that connectors are expected to perform at high levels, the transportation applications' inside profile becomes more space-constrained. Increased modularity limits the space between the connector and other components, so design engineers must rely on micro connectors that offer more profile and mating orientation options to address space, location, and connector entry point challenges.

Connectivity for the Proliferation of HMI

Human Machine Interfaces (HMI) are taking over car interiors, with automakers and Tier 1 manufacturers implementing smart interfaces and advanced technology platforms. The transformation from mechanical to electronic HMI controls promises to revolutionize the driving experience.

Take the Byton M-Byte for example. The key feature of its interior - and arguably its unique selling point - is a 48-inch hi-res display that runs almost the full width of the car's dashboard. Physical buttons are reduced to a minimum and instead replaced by a mixture of voice controls, gestures, and facial recognition. The car as the world's largest mobile device takes a step closer when this SUV is launched in 2021.

Byton's distinctive dash display. Image credit: Byton.

Byton's distinctive dash display. Image credit: Byton.As a result, more applications are implementing user interfaces, which have flex-to-board (F-to-B) connection points requiring a flexible PCB or board-to-board (B-to-B) connector. Besides, the demand for sensors, microphones, speakers, and cameras in the vehicle cabin further drives modularity that requires more, and better, flexible printed circuits (FPCs), flexible flat cables (FFCs), and B-to-B and wire-to-board (W-to-B) signal connections.

Modularity Connectivity Solutions

With a broad range of Easy-On FFC (Flexible Flat Cable)/FPC(Flexible Printed Circuit) V-Flip Connectors, Molex addresses the need for small pitches from 0.20mm to 2.00mm, with high reliability to deliver design flexibility for HMI and infotainment applications. And the Easy-On V-Flip Connectors provide a locking system and a wide variety of actuator options, including a zero-insertion-force (ZIF) design and flip-lock, establishing a secure connection between the FFC/FPC connectors and terminals while also enabling easy assembly.

The SlimStack Board-to-Board FSB5 Series Connectors support up to 6Gbps, provide great floating ranges and flexible mating heights, and deliver extraordinary compactness. They offer space-saving features while delivering reliability under conditions of heat and vibration.

A Successful Design Relies on the Right Connector

Vehicle electronics require ever-increasing speed and signal integrity to transfer data streams with higher bit rates. A high-speed solution is crucial to success in today's transportation marketplace, a solution that also supports the signal integrity margins needed for sensors, cameras, HMI, and system communications. By making sure all the separate systems work together as designed, the right connector answers the modularity challenges.

This article was originally published by Mouser and Molex in an e-magazine and substantially edited by the Wevolver team. It's the third article of a 5-part series exploring connectivity solutions for the future of transportation.

The first article examined how the 5G network will deliver Connected Cars.

The second article discussed connected transport and automotive ethernet.

The fourth article stressed the importance of regulations and infrastructure changes in order for connected cars to realize their potential.

The fifth article looked at connectivity requirements for ADAS.

About the sponsor: Mouser

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,100 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.

Sources:

U.S. National Highway Traffic Safety Administration Automated Vehicles for Safety: https://www.nhtsa.gov/technology-innovation/automated-vehicles-safety

Massachusetts Institute of Technology Rapid Identification study: https://news.mit.edu/2014/in-the-blink-of-an-eye-0116

Byton M-Byte: https://www.byton.com/m-byte