FR4: Understanding the Material and Its Applications in PCB Design

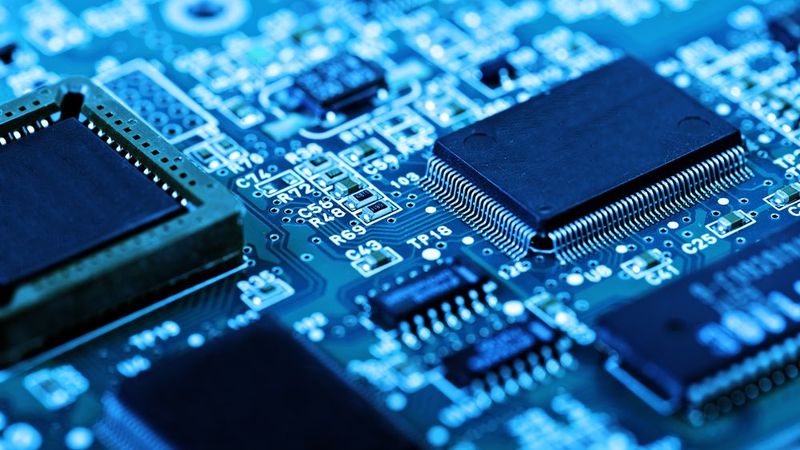

FR4, often called "fiberglass," quietly underpins our daily lives. Think about your electronics, from smartphones to car and appliance circuit boards. FR4 is the unsung hero behind the scenes, making them work smoothly and power our modern world.

FR4 in PCB

Introduction

In our increasingly interconnected world, electronic devices play a pivotal role in our daily lives. Imagine your smartphone, for instance, powering up seamlessly, connecting you with the world, and remaining cool to the touch even during prolonged use. This level of performance and safety is made possible by a remarkable material: FR4. FR4 is more than just a substrate; a flame-resistant shield that ensures your device’s safety even when things get hot.

Understanding the properties and applications of FR4 is crucial for engineers and designers working with PCBs, as it can greatly impact the performance, reliability, and cost of electronic devices. This article will delve into the composition, properties, and applications of FR4, as well as discuss its limitations and alternatives, providing valuable insights for those working with PCBs.

What is FR4?

The term "FR4" stands for "Flame Retardant 4," and it indicates that the material is designed to be flame-resistant and self-extinguishing when exposed to heat or an open flame.

FR4 is a class of printed circuit board base, a widely used material in the electronics industry, particularly for printed circuit boards (PCBs). It is widely used in the electronics industry because of its excellent electrical insulating properties, mechanical strength, and resistance to heat. PCBs made from FR4 are known for their durability and reliability, making them suitable for a wide range of electronic devices, from consumer electronics to industrial equipment.

FR4 materials often adhere to NEMA (National Electrical Manufacturers Association) standards, ensuring they meet industry-recognized quality and performance criteria. This compliance enhances the reliability and safety of electronic components and devices utilizing FR4 substrates.

Composition

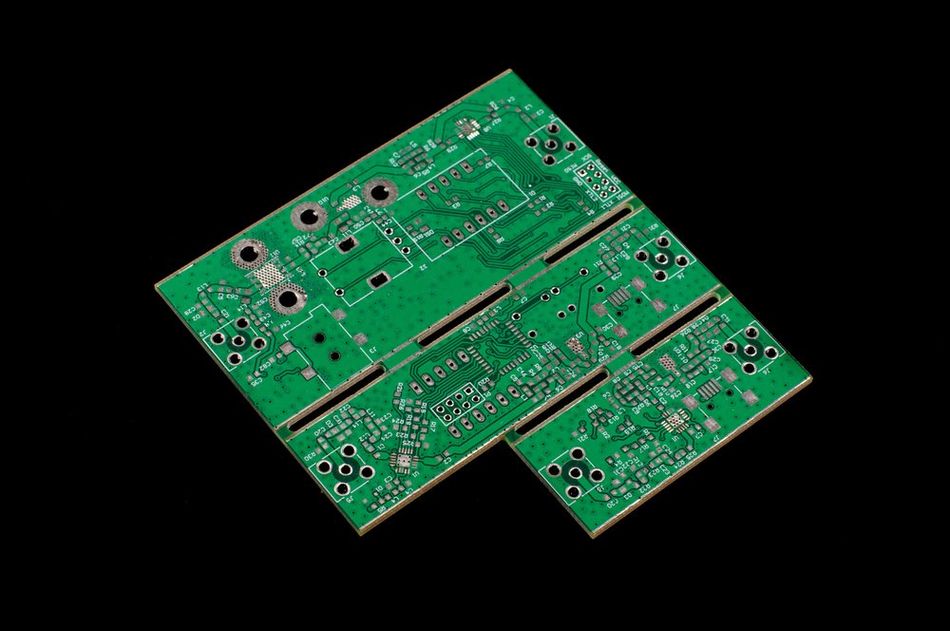

FR4 (check FR4 image), also referred to as glass-reinforced epoxy, is a composite material consisting of two primary components: woven fiberglass cloth and epoxy resin. A standard FR4 PCB has a FR4 layer sandwiched between two layers of copper plate.

The fiberglass cloth provides mechanical strength and dimensional stability, while the epoxy resin binds the fibers together to impart electrical insulation and thermal resistance. The ratio of fiberglass to epoxy resin can vary depending on the specific grade of FR4, but typically, the material contains approximately 60% fiberglass and 40% epoxy resin by weight.

The fiberglass cloth used in FR4 is made from E-glass fibers, which are known for their high tensile strength, low electrical conductivity, and excellent resistance to heat and chemicals.

The epoxy resin is a thermosetting polymer that cures when heated, forming a strong, rigid, and chemically resistant matrix that encapsulates the fiberglass fibers. The cured epoxy resin also exhibits good electrical insulation properties, making it an ideal material for use in PCBs where electrical isolation between conductive traces is crucial.

Properties of FR4

FR4's unique combination of mechanical, electrical, and thermal properties makes it a popular choice as PCB base material . These properties contribute to the material's performance, reliability, and suitability for various applications. In this section, we will explore the key properties of FR4 and their implications for PCB design and manufacturing.

Flame Retardant

Fire-resistant chemicals applied to materials are commonly referred to as FR, which stands for "flame retardant." This designation signifies that the material complies with the UL94V-0 standard for the inflammability of plastic materials. You can find the 94V-0 code on all FR-4 PCBs, and it guarantees that the material does not support the spread of fire and quickly extinguishes when exposed to flames.

To enhance their fire resistance, FR4 materials are blended with flame retardants. These treatments can be categorized as either organic or inorganic. Inorganic treatments incorporate substances like aluminum trihydrate (ATH), while organic treatments involve halogen compounds such as bromine, iodine, and chlorine. Below are the few benefits of FR4’s flame retardant properties:

- Self-extinguishing: When FR4 is exposed to an open flame or heat source, it does not sustain combustion. Instead, it stops burning as soon as the flame is removed. This characteristic is vital for safety, as it prevents fires from spreading within electronic devices or systems.

- Compliance with Safety Standards: FR4 materials used in the electronics industry often adhere to strict safety and fire resistance standards and regulations. These standards ensure that electronic devices incorporating FR4 components meet rigorous safety criteria.

- Material Integrity: Even when subjected to heat or flames, FR4 maintains its structural integrity. It does not disintegrate or emit toxic fumes that could endanger nearby individuals or equipment during a fire event. This resilience contributes significantly to the safety and reliability of FR4-based electronic devices.

Mechanical Properties

The mechanical properties of FR4 play a crucial role in determining the durability and reliability of PCBs. Two important mechanical properties of FR4 are tensile strength and flexural strength.

- Tensile strength refers to the maximum stress that a material can withstand while being stretched or pulled before breaking. FR4 has a high tensile strength, typically ranging from 300 to 500 MPa, depending on the specific grade and composition. This high tensile strength ensures that the PCB can withstand the stresses encountered during manufacturing, assembly, and operation without breaking or deforming.

- Flexural strength, also known as bending strength, is the ability of a material to resist deformation under bending loads. FR4 exhibits good flexural strength, typically in the range of 350 to 600 MPa. This property is particularly important for PCBs that may be subjected to bending or flexing during installation or use, such as in flexible electronics or devices with moving parts.

The mechanical properties of FR4 are also influenced by temperature. As the temperature increases, the material's strength and stiffness decrease, which can affect the performance and reliability of the PCB. It is essential to consider the operating temperature range of the intended application when selecting an FR4 grade and designing a PCB to ensure that the material's mechanical properties remain within acceptable limits.

Electrical Properties

The electrical properties of PCB materials play a crucial role in ensuring signal integrity and impedance control. These properties determine the speed of electrical signal propagation through the material and its ability to store electrical charge within a given volume.

When working with FR4 material, it's essential to consider several key electrical properties, including the dielectric constant, dissipation factor, surface resistivity, and volume resistivity.

Dielectric Constant (Dk) and dissipation factor (Df) are two key electrical properties of FR4.

- Dielectric constant (Dk): Also known as relative permittivity, is a measure of a material's ability to store electrical energy in an electric field. The dielectric constant of FR4 typically ranges from 3.8 to 4.8 depending on the specific grade and composition. A lower dielectric constant is generally preferred for high-frequency applications, as it can result in lower signal attenuation and reduced crosstalk between adjacent conductive traces. The dielectric constant of FR4 is also known to vary with frequency, which can affect the signal integrity and performance of high-speed digital and radio frequency (RF) circuits.

FR4's dielectric constant (Dk) property offers several key benefits in the context of printed circuit boards (PCBs) and other electronic applications:

- Controlled Signal Propagation: FR4's known and stable Dk value allows designers to precisely control the speed at which electrical signals propagate through the PCB. This control is crucial for maintaining signal timing integrity, reducing signal skew, and preventing timing errors in high-speed digital circuits.

- Reduced Signal Distortion: FR4's moderate Dk value contributes to minimizing signal distortion, especially in high-speed digital designs. Signal distortion, such as dispersion and attenuation, is reduced, resulting in cleaner and more reliable signal transmission. This is particularly important for data communication and high-frequency analog applications.

- Dissipation Factor (Df): Also known as loss tangent, is a measure of a material's tendency to dissipate electrical energy as heat. A lower dissipation factor indicates lower energy loss and is desirable for high-frequency applications where signal integrity is critical. The dissipation factor of FR4 typically ranges from 0.015 to 0.025, depending on the specific grade and composition. It is important to consider the dissipation factor when designing PCBs for high-frequency applications, as excessive energy loss can lead to signal degradation and reduced performance.

FR4's low dissipation factor (Df) offers several significant benefits in the context of printed circuit boards (PCBs) and electronic applications:

- Signal Integrity: A low Df means that FR4 dissipates minimal electrical energy as heat when AC signals pass through it. This property is crucial for maintaining the integrity of high-frequency and high-speed signals in PCBs. With low signal loss, signal quality and accuracy are preserved, reducing the risk of data errors.

- Controlled Impedance: Df is a crucial factor in controlling the characteristic impedance of transmission lines on a PCB accurately. Low Df values allow engineers to achieve controlled impedance, which is essential for minimizing signal reflections and ensuring efficient power transfer.

- High-Frequency Applications: FR4's low Df makes it well-suited for high-frequency applications, such as RF (radio frequency) and microwave circuits. In these applications, even small losses of signal strength can have a significant impact, so minimizing Df is essential to maintain signal quality.

The electrical properties of FR4 play a crucial role in determining the performance and reliability of PCBs, particularly in high-frequency applications. Designers must carefully consider these properties when selecting an FR4 grade and designing PCBs to ensure optimal signal integrity and performance.

Thermal Properties

The thermal properties of FR4 are important factors in determining its suitability for various PCB applications, particularly those with high power dissipation or elevated operating temperatures. Two key thermal properties of FR4 are thermal conductivity and glass transition temperature (Tg).

- Thermal conductivity: It is a measure of a material's ability to conduct heat. FR4 has a relatively low thermal conductivity, typically in the range of 0.3 to 0.5 W/m·K. This low thermal conductivity can result in localized hotspots on the PCB, which can negatively impact the performance and reliability of electronic components. In applications with high power dissipation or elevated operating temperatures, it may be necessary to consider alternative materials with higher thermal conductivity or employ additional thermal management techniques, such as heat sinks or thermal vias, to effectively dissipate heat. This property can also be advantageous in PCBs because it helps insulate heat-producing components from one another, reducing the risk of thermal interference or overheating.

- Glass transition temperature (Tg): It is the temperature at which a material transitions from a rigid, glassy state to a more flexible, rubbery state. The Tg of FR4 typically ranges from 130°C to 180°C, depending on the specific grade and composition. Tg is the temperature at which the material transitions from a rigid, glassy state to a softer, rubbery state. As the temperature approaches the Tg, the material's mechanical and electrical properties can degrade, potentially leading to PCB failure. It is crucial to select an FR4 grade with a suitable Tg for the intended application to ensure that the PCB can withstand the operating temperature range without significant degradation of its properties.

Also, FR4's heat resistance and dimensional stability make it an ideal substrate for soldering components onto circuit boards. It can withstand the high temperatures involved in the soldering process without deforming.

Understanding the thermal properties of FR4 is essential for designing PCBs that can effectively manage heat and maintain their performance and reliability under various operating conditions. Designers must carefully consider these properties when selecting an FR4 grade and designing PCBs for applications with demanding thermal requirements.

Low Moisture Absorption

FR4 material possesses exceptional resistance to moisture absorption, maintaining its shape and size even when subjected to high humidity levels. This characteristic renders it well-suited for applications where exposure to moisture is a common occurrence, including electronic devices and various electrical components.

Furthermore, FR4's hygroscopicity, which gauges its ability to resist water absorption, is notably impressive. Under controlled conditions, FR4 exhibits minimal moisture absorption, with a mere 0.10% increase in weight after a 24-hour immersion in water.

These attributes make FR4 an ideal choice for demanding environments, such as the engine rooms of marine applications. Despite direct exposure to water in nautical settings, FR4 remains unfazed, proving its suitability for critical marine components. Its resistance to moisture, stable dimensions in varying temperatures, and excellent dielectric properties collectively establish FR4 as a versatile and dependable material in numerous electrical and electronic applications.

FR4 Material Benefits

Considering the numerous properties of FR4, let’s conclude with the numerous benefits it offers for PCB and electronics applications, making it a popular choice among engineers and designers. Here are some key advantages:

- Low Cost: FR4 is a cost-effective alternative to many other similar materials, offering high performance without a significant price premium.

- Excellent Mechanical and Electrical Properties: FR4 is known for its exceptional combination of mechanical strength and electrical performance, providing a reliable substrate for electronic components.

- Lightweight with High Strength-to-Weight Ratio: FR4 is lightweight, making it suitable for portable electronic devices, while still maintaining a high strength-to-weight ratio.

- Wide Range of Thickness Options: FR4 is available in a range of thicknesses, typically from 0.2 to 3.2 mm, providing versatility for various PCB designs.

- High Dielectric Strength: FR4's high dielectric strength ensures effective electrical insulation, reducing the risk of short circuits and electrical interference in PCBs

- Thermal Stability: FR4 materials maintain their structural integrity and electrical properties across a wide operating temperature range, from 50℃ to 115℃. This thermal stability is essential for reliable performance in varying environmental conditions.

- High Tg Value: FR4 materials have a higher glass transition temperature (Tg) of approximately 180℃, indicating their ability to withstand elevated temperatures without losing structural integrity.

- Moisture and Water Resistance: FR4 exhibits resistance to moisture, making it suitable for applications where exposure to humidity or occasional moisture is expected.

- Chemical and Solvent Resistance: FR4 is resistant to many chemicals and solvents, enhancing its durability in challenging environments.

- Ideal for Various Environments: FR4's combination of properties makes it suitable for a wide variety of environments and applications, from consumer electronics to industrial and automotive systems.

Importance of FR4 in PCB Design and Its Impact

FR4 is at the core of modern PCB design, influencing the performance, reliability, and cost-effectiveness of electronic devices. Its versatile properties, including electrical insulation, mechanical strength, and flame resistance, make it the preferred base material for a wide range of applications. This section explores how FR4 impacts material selection, stackup design, and signal integrity considerations in PCB design.

Material Selection

Choosing the right FR4 material is crucial, as it affects the PCB’s thermal performance, frequency handling, and overall cost. Each FR4 grade has unique electrical properties and mechanical characteristics suited for different applications, from consumer electronics to industrial systems. Here's what to consider:

- Operating Temperature Range:

For devices exposed to high temperatures or significant power dissipation, high Tg (glass transition temperature) FR4 grades are recommended. These materials maintain their mechanical and electrical properties even under thermal stress, ensuring reliability and longevity. - Frequency Performance:

High-speed digital circuits and RF applications require materials with a lower dissipation factor to minimize signal loss. In such cases, high-frequency FR4 grades are ideal, as they offer stable dielectric constants and reduce signal attenuation. This is critical for maintaining signal integrity in communication devices and high-performance computing systems. - Cost Considerations:

Cost is always a critical factor in material selection. Standard FR4 boards are low-cost and sufficient for most general-purpose applications. However, specialized FR4 grades with enhanced electrical properties come at a premium. Designers must balance performance needs with budget constraints to optimize cost-effectiveness. - Compliance and Certifications:

To ensure safety and reliability, designers should also consider industry standards like IPC and UL certifications. For example, selecting flame-resistant FR4 materials rated UL94V-0 is crucial for applications requiring high safety standards, such as automotive and industrial electronics.

Stackup Design

The stackup design, or the arrangement of layers within a PCB, significantly influences performance, manufacturability, and signal integrity. An optimal stackup design involves a strategic combination of conductive copper layers, insulating dielectric layers, and ground planes. Here's how FR4 impacts stackup design:

- Dielectric Constant and Impedance Control:

The dielectric constant of FR4 directly affects the impedance of copper traces. Proper impedance control is essential for high-speed digital circuits to minimize signal reflections and crosstalk. Designers must carefully calculate trace widths, spacing, and layer distances to achieve the desired impedance values, ensuring consistent signal transmission. - Thermal Conductivity:

FR4’s thermal conductivity impacts its ability to dissipate heat generated by electronic components. In high-power applications, incorporating thermal management solutions, such as thermal vias or heat sinks, is essential to prevent overheating and ensure device reliability. - Mechanical Properties:

The mechanical strength of FR4, including its flexural strength and tensile strength, contributes to the PCB’s durability. It helps the PCB withstand stress during manufacturing, assembly, and operation. Proper stackup design ensures rigidity, preventing issues like warping, delamination, or mechanical failure.

Example Scenario:

In multi-layer boards used for high-density applications like smartphones and networking equipment, designers often utilize high Tg FR4 to enhance thermal performance while maintaining mechanical integrity. This allows for compact designs without compromising on signal integrity or durability.

Signal Integrity and Electromagnetic Compatibility (EMC)

FR4 plays a pivotal role in maintaining signal integrity and ensuring electromagnetic compatibility (EMC). Poor signal integrity can lead to data corruption, while inadequate EMC design can cause interference with other electronic devices. Here’s how to optimize these aspects:

- Signal Integrity:

Signal integrity depends on consistent impedance and minimal signal loss. The dielectric constant and dissipation factor of FR4 influence signal transmission quality. By carefully designing trace geometries and using differential pairs, designers can minimize crosstalk and signal attenuation, ensuring reliable data transmission. - Electromagnetic Compatibility (EMC):

FR4’s electrical insulation properties help in reducing electromagnetic interference (EMI). Incorporating continuous ground planes and designing proper return paths for signals are effective EMC strategies. Shielding layers or enclosures can also be added to minimize external EMI.

Best Practices for Optimal Performance:

- Impedance Control: Ensures minimal signal reflections and stable signal transmission.

- Ground Planes: Provide low-impedance return paths, reducing EMI and enhancing signal integrity.

- Differential Signaling: Improves noise immunity and minimizes EMI in high-speed circuits.

- Decoupling Capacitors: Help stabilize voltage levels and filter power supply noise.

Example Scenario:

In high-speed digital devices like routers and communication systems, maintaining signal integrity is crucial. Designers use high-frequency FR4 grades with lower dissipation factors to minimize signal loss and ensure precise impedance control, enhancing data transmission quality.

Suggested Reading: Tented Via: The Ultimate Guide to PCB Design and Manufacturing Techniques

Suggested Reading: What is a Multilayer PCB?

Suggested Reading: PWB vs PCB: Differences and Similarities

FR4 vs. High-Frequency (HF) Laminates: Making the Right Choice

When it comes to high-speed digital or RF circuits, choosing between FR4 and HF laminates can make all the difference. Here’s how they compare:

- Electrical Performance:

HF laminates outperform FR4 in high-frequency applications due to their lower dissipation factor and more consistent dielectric constant, reducing signal loss and maintaining signal integrity. FR4, however, is suitable for low to medium-frequency circuits where these factors are less critical. For applications demanding precise impedance control and minimal electrical noise, HF laminates provide superior electrical properties, making them the go-to choice for advanced communication systems and radar applications. - Cost and Availability:

FR4 is a low-cost, readily available solution, making it the go-to choice for budget-sensitive designs. In contrast, HF laminates are more expensive and may require specialized sourcing, impacting production costs. However, the performance benefits of HF laminates can justify the higher cost in critical applications where signal quality and speed are non-negotiable. This makes them an investment rather than just an expense in high-performance electronic systems. - Mechanical Properties:

Both materials offer excellent strength-to-weight ratio and flexural strength, but FR4 is easier to machine, making it more cost-effective for complex designs. Additionally, FR4 boards are more adaptable to standard PCB fabrication processes, whereas HF laminates may require specialized machining techniques. This difference in machining compatibility can influence production timelines and costs, making FR4 a more practical choice for prototypes and short-run manufacturing. - Flame Resistance and Safety:

Both FR4 and HF laminates are available with flame-resistant options, typically rated UL94V-0, ensuring safety and compliance. This makes them suitable for use in consumer electronics, industrial control systems, and automotive applications where flammability and safety standards are critical. - Application Suitability:

FR4 is ideal for general-purpose and low-frequency circuits, while HF laminates excel in high-speed digital, RF, and microwave applications. If the design involves complex signal routing or high-speed data transfer, HF laminates provide better signal integrity. Conversely, FR4 is a reliable choice for conventional applications like power supply units, audio devices, and other low-frequency electronics.

Example Comparison:

- In consumer electronics like smartphones, laptops, and home appliances, FR4 is the preferred choice due to its low cost and sufficient performance for moderate frequencies. Its flame-resistant properties also ensure safety and compliance in household environments.

- For high-speed communication equipment, satellite systems, and advanced networking devices, HF laminates are necessary to maintain signal integrity and minimize signal loss. Their superior electrical properties enhance data transmission speed and reduce interference, making them indispensable in high-frequency scenarios.

Cost-Performance Trade-Off:

For startups or budget-sensitive projects, FR4 provides a reliable and cost-effective solution with adequate performance for most applications. Established manufacturers aiming for high-performance, high-frequency applications should invest in HF laminates despite the higher cost. The decision ultimately depends on the required electrical properties, budget constraints, and the criticality of signal performance in the final product.

Choosing between FR4 and HF laminates depends on the application requirements, budget constraints, and performance expectations. Understanding their differences ensures an optimal choice, balancing cost, performance, and safety.

FR4 Grades and Specifications

FR4 is available in various grades, each with its own set of specifications tailored to different applications and requirements. These grades differ in terms of their mechanical, electrical, and thermal properties, as well as their manufacturing tolerances and quality standards. Understanding the different FR4 grades and their respective specifications is essential for selecting the appropriate material for a specific PCB application.

- Standard FR4: This is the foundational FR-4 type, extensively utilized in the electronics industry. It strikes a balance between mechanical, electrical, and thermal properties while remaining cost-effective. Standard FR4 typically features a glass transition temperature (Tg) of approximately 130°C to 140°C, making it well-suited for general-purpose applications with moderate thermal demands.

- High Tg FR4: Engineered for demanding environments, high Tg FR4 boasts an elevated glass transition temperature, typically ranging from 170°C to 180°C. This enhanced Tg equips it to excel in applications with higher operating temperatures or greater power dissipation, maintaining its mechanical and electrical properties under thermal stress. High Tg FR4 finds prominent use in power electronics, automotive systems, and other high-reliability applications.

- High-Frequency FR4: Designed for specialized high-frequency applications, such as radio frequency (RF) and microwave circuits, high-frequency FR4 features a lower dielectric constant and dissipation factor. These properties minimize signal attenuation and enhance signal integrity at high frequencies. This grade is widely deployed in telecommunications, aerospace, and radar systems.

- High CTI FR4: For scenarios demanding efficient heat dissipation, high CTI FR4 stands out. It possesses superior thermal conductivity compared to regular FR4 material and boasts a Comparative Tracking Index (CTI) exceeding 600 Volts, making it adept at dissipating heat effectively.

- FR4 without Copper Laminate: This non-conductive FR4 variant offers substantial mechanical strength and is tailored for insulating boards and board supports, ensuring dependable insulation without the presence of copper.

- FR4 G10: Representing a solid core material, FR-4 G10 shines with outstanding mechanical properties, high resistance to thermal shock, excellent dielectric characteristics, and strong electrical insulation capabilities.

In addition to these grades, there are also FR4 materials with enhanced properties, such as improved thermal conductivity, increased flame retardancy, or reduced moisture absorption. These specialized grades can be used in applications with specific requirements that cannot be met by standard FR4 materials.

When selecting an FR4 grade for a PCB application, it is important to consider the specific requirements of the device, such as its operating temperature range, power dissipation, and frequency performance. Additionally, industry standards and certifications, such as IPC and UL, should be taken into account to ensure that the chosen material meets the necessary quality and safety requirements.

Limitations of FR4 Circuit Board Materials

Thermal Management Limitations

FR4 has a lower thermal conductivity compared to ceramics or aluminum substrates, which can pose challenges in applications requiring efficient heat dissipation. With a typical thermal conductivity of approximately 0.3 W/mK, FR4 is significantly less effective at transferring heat than aluminum (around 200 W/mK) or ceramic-based materials (ranging from 20–200 W/mK). This limitation makes thermal management a key design consideration, especially in power electronics and high-frequency applications.

To mitigate these thermal constraints, engineers implement several design optimizations:

- Thermal Vias: Placing multiple plated-through vias in heat-generating areas allows better thermal distribution and heat dissipation through copper connections to internal or external heat sinks.

- Thicker Copper Layers: Increasing the copper thickness in PCB traces (e.g., from the standard 1 oz/ft² to 2 oz/ft² or more) enhances heat conduction across the board.

- Heat Sinks and Thermal Pads: Attaching external heat sinks or integrating thermal pads improves heat transfer from the PCB to external cooling systems.

- Metal Core or Hybrid Designs: In high-power applications, hybrid PCB designs that incorporate FR4 with metal-core substrates can provide better thermal efficiency while maintaining cost-effectiveness.

Environmental Compliance

Standard FR4 contains halogenated flame retardants, such as brominated epoxy resins, which help achieve fire resistance but raise environmental concerns due to their toxic byproducts. These halogens can release harmful substances during PCB disposal or incineration, contributing to environmental pollution and health hazards.

To address these concerns, regulatory frameworks like the Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives enforce restrictions on hazardous materials, encouraging the adoption of halogen-free alternatives. Halogen-free FR4 variants eliminate brominated flame retardants while maintaining comparable performance, making them a preferred choice for environmentally conscious applications such as medical devices and eco-friendly consumer electronics.

Cost vs. Performance Trade-offs

FR4 is widely chosen for its affordability and versatility, making it the standard substrate for general-purpose PCBs. However, in specialized applications such as high-frequency RF or microwave circuits, premium materials like Rogers laminates offer superior electrical performance but at a significantly higher cost.

| Material Type | Cost ($ per sq. inch) | Dielectric Constant (Dk) | Thermal Conductivity (W/mK) | Best For | |

| 1 | Standard FR4 | Low (0.05 - 0.15)Moderate (0.10 - 0.25) | 4.0 - 4.5 | ~0.3 | General electronics, consumer devices |

| 2 | High-Tg FR4 | Moderate (0.10 - 0.25) | 4.0 - 4.5 | ~0.4 | Automotive, industrial applications |

| 3 | Rogers Laminates | High (0.50 - 2.00) | 2.2 - 3.5 | 0.6 - 1.2 | RF/microwave, aerospace, high-speed data transmission |

Choosing the Right FR4

Not all FR4 boards are created equal. Selecting the right one depends on balancing performance needs, cost constraints, and safety standards. Here’s how to make the right choice:

- Performance Requirements: Identify the electrical and mechanical demands of your application. High-speed circuits require FR4 with low dissipation factor and stable dielectric constant to maintain signal integrity. In contrast, power electronics benefit from thicker copper foil for better current handling.

- Environmental Considerations: Evaluate the operating temperatures and humidity resistance required for your application. High-Tg FR4 is ideal for harsh environments, while standard FR4 suits general-purpose designs.

- Cost vs. Performance: FR4 is known for its low cost, but not every application needs the most advanced variant. Balance cost with required performance to optimize budget without compromising quality.

- Compliance and Safety: Ensure the FR4 material meets UL94V-0 flammability standards for safety and regulatory compliance. This is critical for consumer electronics and industrial machinery alike.

- Supplier and Quality Standards: Check if the FR4 material complies with NEMA standards to ensure consistent quality and reliability.

Example Scenario:

If designing a high-frequency communication device, prioritize electrical properties such as low dissipation factor and consistent dielectric constant. For industrial control systems, focus on mechanical durability and operating temperature resilience.

Selecting the right FR4 is about understanding the application requirements and matching them with the right properties, ensuring both performance and safety.

Alternatives to FR4

While FR4 is a popular choice for PCB substrates, there are certain applications where its limitations may necessitate the use of alternative materials. These limitations can include inadequate thermal conductivity, insufficient performance at high frequencies, or insufficient mechanical strength. In this section, we will discuss some alternative materials to FR4 and their respective advantages and disadvantages.

- Polyimide is a high-performance polymer material often used in flexible PCBs and high-temperature applications. It offers excellent mechanical strength, high thermal stability, and good electrical properties. Polyimide has a higher Tg than FR4, typically around 250°C, making it suitable for applications with elevated operating temperatures. However, polyimide is more expensive than FR4 and can be more challenging to process, which may limit its use in cost-sensitive applications.

- PTFE (Teflon) is a fluoropolymer material with a low dielectric constant and low dissipation factor, making it an attractive choice for high-frequency and RF applications. PTFE-based laminates, such as Rogers RO4000 series, offer superior performance at high frequencies compared to FR4. However, PTFE materials are more expensive than FR4 and can be more difficult to process, particularly when it comes to drilling and plating.

- Metal-core PCBs (MCPCBs), such as aluminum or copper-core PCBs, are used in applications where high thermal conductivity is required. MCPCBs consist of a metal core, typically aluminum or copper, with a dielectric layer and copper traces on top. The metal core provides excellent thermal conductivity, allowing for efficient heat dissipation and improved thermal management. MCPCBs are commonly used in high-power LED lighting, power electronics, and automotive systems. However, they can be more expensive than FR4-based PCBs and may have limitations in terms of layer count and complexity.

- Ceramic substrates, such as alumina or aluminum nitride, offer high thermal conductivity, excellent electrical properties, and good mechanical strength. They are often used in high-power, high-temperature, or high-frequency applications, such as power electronics, RF devices, and aerospace systems. Ceramic substrates can be more expensive than FR4 and may require specialized processing techniques, limiting their use in some applications.

When selecting an alternative material to FR4, it is essential to consider the specific requirements of the application, such as operating temperature, power dissipation, frequency performance, and cost. By carefully evaluating these factors and the properties of the available materials, designers can choose the most suitable material for their PCB application.

FR4 Applications

FR4, a flame-retardant glass-reinforced epoxy material, finds extensive use in a diverse range of applications due to its exceptional properties. Let's explore some of the common and popular applications where FR4 proves its worth.

Consumer Electronics

FR4 is widely used in consumer electronics due to its ability to balance cost, durability, and performance. Its mechanical stability and electrical insulation properties make it an ideal substrate for mass-produced devices, ensuring reliability and efficiency in modern electronic circuits. The material's manufacturability supports high-volume production while maintaining consistent quality, crucial for competitive consumer markets.

- Smartphones: FR4 is used in mobile device PCBs to provide lightweight, compact, and high-performance circuitry.

- Laptops and Tablets: Ensures durability and signal integrity for complex, multilayer motherboard designs.

- Wearable Devices: Supports miniaturized, flexible PCB designs in smartwatches and fitness trackers.

- Televisions and Monitors: Used in display driver circuits and power management units.

- Gaming Consoles and Accessories: Provides structural integrity and reliability for high-speed gaming hardware.

- Home Automation and IoT Devices: Ensures stable signal transmission in smart home applications, including sensors and controllers.

Automotive Systems

FR4 is widely used in automotive systems due to its ability to withstand harsh environments while maintaining electrical reliability. High-Tg FR4 is particularly crucial in automotive applications where elevated temperatures and thermal cycling occur.

- Advanced Driver-Assistance Systems (ADAS): FR4-based PCBs provide the structural integrity needed for radar, lidar, and vision-based safety systems, ensuring consistent performance under extreme conditions.

- Power Management Units: Automotive power distribution and battery management systems rely on FR4's electrical insulation and mechanical durability to manage high currents and prevent electrical failures.

- Thermal Management Techniques: High-Tg FR4 materials enhance thermal performance by resisting delamination and degradation under high temperatures. Additional design optimizations, such as thermal vias and copper plane layers, improve heat dissipation in automotive electronic modules.

Industrial Automation and Robotics

FR4 ensures long-term reliability in industrial automation and robotic applications by offering mechanical stability, electrical insulation, and resistance to environmental stressors.

- Reliability Under Mechanical Stress: FR4's fiberglass-reinforced epoxy composition provides resilience against vibrations, shocks, and mechanical stress common in industrial environments.

- Harsh Environment Suitability: Its low moisture absorption and high dielectric strength enable consistent operation in manufacturing plants, outdoor automation systems, and high-temperature industrial setups.

- Application Examples

- Robotic Controllers: Industrial robots use FR4-based PCBs to control motor functions, process sensor data, and ensure real-time decision-making under high-speed operations.

- Industrial Sensors: FR4 PCBs power temperature, pressure, and proximity sensors used in automated assembly lines and predictive maintenance systems.

In conclusion, FR4's versatility and reliability have made it an indispensable material in various industries. From powering the heart of electronic devices on PCBs to providing safety and stability in industrial and electrical applications, FR4 continues to shape modern technology and engineering solutions.

Conclusion

FR4 is a versatile and widely used material in the electronics industry, particularly for printed circuit boards. Its unique combination of mechanical, electrical, and thermal properties makes it suitable for a wide range of applications. However, there are certain limitations to FR4 that may necessitate the use of alternative materials in some cases. By understanding the properties and applications of FR4, as well as its limitations and alternatives, engineers and designers can make informed decisions when selecting materials and designing PCBs to ensure optimal performance, reliability, and cost-effectiveness.

Frequently Asked Questions (FAQs)

1. What is FR4 made of?

FR4 is a composite material made of woven fiberglass cloth and epoxy resin. The fiberglass cloth provides mechanical strength and dimensional stability, while the epoxy resin binds the fibers together and imparts electrical insulation and thermal resistance.

2. What are the key properties of FR4?

FR4 has a combination of mechanical, electrical, and thermal properties that make it suitable for use in PCBs. Key properties include tensile strength, flexural strength, dielectric constant, dissipation factor, thermal conductivity, and glass transition temperature (Tg).

3. What are the different grades of FR4?

FR4 is available in various grades, such as standard FR4, high Tg FR4, high-frequency FR4, and specialized grades with enhanced properties. Each grade offers a unique set of properties tailored to different applications and requirements.

4. What are some alternatives to FR4 for PCB substrates?

Some alternatives to FR4 include polyimide, PTFE (Teflon), metal-core PCBs (MCPCBs), and ceramic substrates. These materials offer specific advantages and disadvantages, depending on the application requirements, such as operating temperature, power dissipation, and frequency performance.

5. How does FR4 affect signal integrity and electromagnetic compatibility (EMC) in PCBs?

The properties of FR4, such as its dielectric constant and dissipation factor, can impact signal integrity and EMC in PCBs. Designers must carefully consider these properties when selecting an FR4 grade and designing PCBs to ensure optimal signal integrity and EMC performance.

References

[1] https://www.protoexpress.com/blog/why-fr4-material-in-pcb-fabrication/

[2] https://www.wellpcb.com/fr4-material.html

[3] https://custommaterials.com/what-is-fr4-material/#BN-6f00a13cc12bd1cf

[4] https://jhdpcb.com/fr4-materials-in-pcb-manufacturing/#Material%20Types

Table of Contents

IntroductionWhat is FR4?CompositionProperties of FR4Flame RetardantMechanical PropertiesElectrical PropertiesThermal PropertiesLow Moisture AbsorptionFR4 Material BenefitsImportance of FR4 in PCB Design and Its ImpactMaterial SelectionStackup DesignSignal Integrity and Electromagnetic Compatibility (EMC)FR4 vs. High-Frequency (HF) Laminates: Making the Right ChoiceFR4 Grades and SpecificationsLimitations of FR4 Circuit Board MaterialsThermal Management LimitationsEnvironmental ComplianceCost vs. Performance Trade-offsChoosing the Right FR4Alternatives to FR4FR4 ApplicationsConsumer ElectronicsAutomotive SystemsIndustrial Automation and RoboticsConclusionFrequently Asked Questions (FAQs)References