High Voltage Protection in DC Fast Charging

The risks associated with high-voltage DC fast charging are reduced by essential high-quality components, ensuring that electric vehicles are not only a cleaner option but also a safe and reliable choice.

Introduction

Electric Vehicles have become a crucial part of the global movement towards a sustainable future. According to Cox Automotive, approximately 1.3 million Electric Vehicles were sold in the United States in 2024. With more people switching to EVs, the need for safe, reliable, and efficient charging infrastructure has also increased.

DC Fast Chargers provide a practical solution for quickly charging EVs, helping to meet the growing demand for fast and convenient recharging. However, to provide rapid power, these chargers operate at much higher voltages than standard chargers, which brings both advantages and risks.

In this paper, we will explore the risks associated with high-voltage DC fast charging and look at the components that are essential to reduce these dangers to ensure Electric Vehicles are not just a cleaner option but also a safe and reliable one.

The Basics of DC Fast Charging

What is DC Fast Charging?

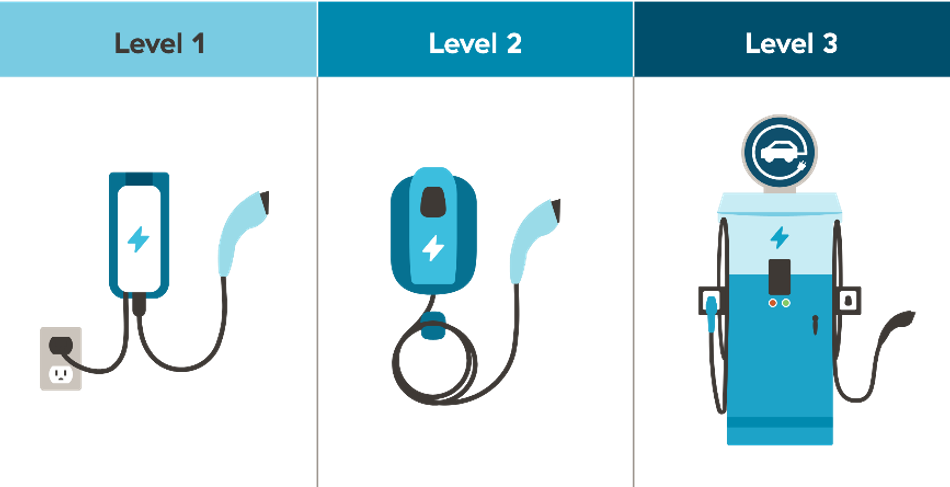

DC Fast charging, also known as Level 3 EV Charging, is a method of charging electric vehicles that delivers direct current (DC) power straight to the battery at high speeds. Unlike Level 1 and Level 2 chargers, which use alternating current (AC) and require the vehicle to convert it to DC, DC chargers bypass this conversion and provide much faster and more efficient charging.

Feature | Level 1 Charging | Level 2 Charging | Level 3 (DC Fast Charging) |

Power Source | 120V AC (Standard home outlet) | 240V AC (Dedicated circuit) | 400V - 800V DC |

Charging Speed | Slow (3-5 miles of range per hour) | Moderate (15-30 miles of range per hour) | Fast (80% charge in ~30 minutes) |

Current | 12-16 amps | 16-80 amps | 100A - 500A or more |

Typical Use | Home use, overnight charging | Home, public, workplace charging | Public stations, highway rest stops |

Charging Time | 12+ hours for full charge | 4-8 hours for full charge | 30 minutes for an 80% charge |

Connector Type | Standard 3-prong plug (NEMA 5-15) | SAE J1772 connector | CHAdeMO, CCS, or Tesla Supercharger |

Cost | Low (no installation required) | Moderate (requires Level 2 installation) | High (requires specialized infrastructure) |

Level 1, Level 2, and Level 3 or Rapid charging

Technical Specifications of DC Fast Chargers

DC Fast chargers typically deliver power ranging from 50kW to over 350kW, depending on the charger's design and capability. The voltage supplied by DC fast chargers usually spans from 400V to 800V. (though some ultra-fast option offers voltages even higher than 800V) The higher the voltages, the more power can be delivered to an EV in a shorter amount of time, making rapid charging a reality.

DC fast chargers also carry higher currents, typically ranging from 100A to 500A, which also affects the speed and efficiency of the charging process.

Risks and Challenges Associated with High Voltages in DC Fast Charging

Electrical Hazards

One of the biggest concerns associated with DC fast charging is the risk of electrocution. The deadly combination of high voltage and current increases the possibility of electric hazards if safety protocols are not followed. In case of faulty wiring, improper handling, and equipment malfunction, users and technicians can be exposed to high levels of current.

Proper grounding, insulation, and specialized equipment are needed to avoid accidental contact with live components, along with insulation monitoring devices to check for system faults.

Overvoltage

Another critical challenge of high-voltage charging systems is overvoltage. When the vehicle receives voltage beyond its battery rating, it can lead to overcharging, which damages the battery cells and may result in thermal runaway. Apart from damaging battery cells, overvoltage also affects other components of the charging infrastructure, such as cables, connectors, and power electronics, leading them to overheat and premature failure.

To address these concerns, modern DC fast chargers come with voltage regulation systems, but these systems can also malfunction, especially in less advanced models.

Component Damage and System Failures

The intense voltage levels in DC fast charging stations cause damage and degradation of components over time. Power electronics and connectors, along with cables, experience wear and tear from voltage spikes, which can cause operational failure and decreased efficiency.

Continuous monitoring, surge protection, and regular maintenance practices are required to maintain the durable performance of DC fast charging stations. Neglecting these issues will increase repair frequency and cause system outages, thus harming user satisfaction and increasing operational expenses.

Key Protection Components in DC Fast Charging Systems

Overcurrent Protection

Overcurrent protection is one of the most important aspects of high voltage protection in DC fast charging systems. It makes sure that the system remains within safe current limits.

Let’s discuss components used for overcurrent protection in DC fast chargers.

Fuses

Fuses are one of the simplest and most effective overcurrent protection devices used in high-voltage applications like DC fast chargers.

A fuse consists of a thin wire or metal element inside a casing. This element is designed to carry the normal operating current of the circuit. When the current exceeds the fuse's rated value, the element heats up due to the increased current flow. If the current remains excessive for a prolonged period, the element will melt or "blow," effectively opening the circuit and stopping the flow of electricity.

Standard thermal fuses are designed to protect against sustained overcurrent, but their response time is often too slow to react to the transient overcurrent conditions common in DC fast charging. Additionally, in some scenarios, the current may be too low to trigger the fuse yet still exceed the contactor's ability to interrupt the flow safely. This delay in fuse activation creates a "grey zone" where the system remains unprotected, exposing sensitive components to potential damage or failure.

To address these challenges, Sensata Technologies has designed the world’s first hermetically sealed, bi-directional electromechanical fuse, the GigaFuse, specifically for high-current, high-voltage applications like DC fast charging. The GigaFuse offers faster, more reliable protection by using advanced materials and design features, ensuring rapid response to overcurrent conditions.

Circuit Breakers

Circuit breakers are more advanced overcurrent protection devices that can be reset after they trip. These devices use a mechanical switch to disconnect the circuit when an overcurrent condition is detected. They operate through thermal or electromagnetic mechanisms. When the current exceeds a set limit, the breaker is triggered to open the circuit and stop the flow of electricity.

The major advantage of circuit breakers over fuses is that they can be reused without needing replacement, making it a cost-effective option. However, like fuses, circuit breakers require careful calibration to ensure they trip at the appropriate current levels.

Surge Protection

Power grid fluctuations and lightning strikes can lead to surges, which can damage sensitive components of DC fast charging systems. To address this issue, Surge Protection Devices (SPDs) are placed at different points to protect the EV battery by clamping the voltage to a manageable level in case of transient voltages.

Some commonly employed SPDs are:

Metal Oxide Varistors (MOVs)

Metal Oxide Varistors (MOVs) are one of the most common components used for surge protection in DC fast chargers. It is a voltage-dependent resistor that changes its resistance in response to changes in voltage. When a voltage surge occurs, the MOV rapidly absorbs excess energy by dropping its resistance and conducting a large current to the ground.

The major advantage MOVs offer is their ability to absorb spikes quickly. However, MOVs can degrade over time due to repeated voltage surges, so they must be monitored or replaced to ensure the protection of the charging infrastructure.

Gas Discharge Tubes (GDTs)

Gas Discharge tubes (GDTs) are another component used in high-voltage DC fast chargers for protecting against transient voltages. These are sealed tubes filled with gas, which ionizes in case of a voltage spike, allowing excess energy to pass through the tube to the ground.

GDTs are highly effective in handling high-voltage surges such as lightning strikes, but their slower response time makes them less useful for systems where fast reaction times are required.

Transient Voltage Suppression (TVS) Diodes

Transient Voltage Suppression (TVS) diodes protect electronic systems from transient overvoltage events. Unlike Zener diodes, which provide a continuous breakdown voltage, TVS diodes provide fast, transient protection by clamping voltage spikes to a safe level.

TVS diodes are particularly well-suited for protection against the short-duration voltage transients in DC fast charging systems.

Overvoltage Protection

Before diving into the details of components and circuits used for overvoltage protection, let's quickly revise the difference between voltage surges and overvoltage.

Surges and overvoltage are both conditions that can pose high risks to DC fast charging systems, but the difference lies in their nature and duration.

Surges are short-duration, high-energy voltage spikes that typically last for milliseconds or microseconds and are usually caused by external factors such as switching operations in the grid and lightning strikes. In contrast, overvoltage refers to a condition where the system experiences prolonged periods of overvoltage that surpass its normal operating range and lasts for several seconds or even minutes.

Now that the difference between surges and overvoltage is clear let's have a look at the key components used to protect DC fast charging systems from the harmful effects of sustained overvoltage.

Zener Diodes

Zener diodes are commonly used for overvoltage protection in DC fast charging systems due to their ability to maintain a specific voltage across their terminals. When the input voltage exceeds the diode's breakdown voltage, the Zener diode starts to conduct in reverse, limiting the voltage and protecting the rest of the system.

Zener diodes are cost-effective and work well for controlling moderate overvoltage conditions. However, they are generally used with other protection measures to provide full coverage against high-voltage spikes.

Crowbar Circuit

A crowbar circuit protects the system against overvoltage by “shorting” the voltage across the load when a surge is detected. This results in a rapid voltage drop and protects the components from excessive voltage levels.

Crowbar circuits are especially effective in high-voltage systems where rapid voltage regulation is necessary. However, they can cause a temporary disruption in service, which may result in downtime while the protection system resets.

Thermal Protection

In high-voltage systems, heat is generated as a natural byproduct of the charging process. Effective thermal management is required to prevent the degradation of the charging infrastructure and can be accomplished through various key components. Let’s discuss each one individually.

NTC Thermistors

Negative Temperature Coefficient (NTC) thermistors are temperature-sensitive resistors whose resistance decreases as temperature increases. These thermistors are often placed in series with charging circuits to monitor the temperature and prevent overheating. When the temperature exceeds a safe threshold, the resistance of the NTC thermistor decreases, triggering the protection circuit to cut off the power.

NTC thermistors are particularly effective in situations where gradual heating needs to be monitored and controlled.

PTC Resistors

Positive Temperature Coefficient (PTC) resistors work oppositely to NTC thermistors, increasing their resistance as temperature rises. When the temperature exceeds a preset value, the PTC resistor becomes highly resistive, reducing the current and preventing further heating.

PTC resistors are self-resetting and provide continuous thermal protection without manual intervention or replacement.

Temperature Sensors

Temperature sensors, including thermocouples and RTDs, are used to continuously monitor the temperature of key components, such as cables, connectors, and power electronics.

When the temperature exceeds a predefined value, the temperature sensors send a signal to the control system, which can take action to prevent overheating.

Fault Isolation and Detection

Fault detection and isolation are designed to identify any irregularities or faults in the system and take action to isolate the affected component or circuit to prevent further damage or hazards.

Here are the key components used for fault detection and isolation:

Solid State Relays (SSR)

Solid-state relays are electronic switches that use semiconductor devices to detect faults and disconnect the circuit when necessary. SSRs are faster and more reliable than mechanical relays, offering improved performance in high-voltage environments.

Contactor Relay

A contactor relay is one of the key components for electrical isolation and serves as an automated switch to control the flow of electrical power between the charging station and the EV. Its primary function is to open or close the circuit depending on the system’s operational status or fault conditions.

However, one of the key challenges when using contactors in high-voltage DC circuits is the arc generated when the contactor opens to interrupt current flow. In DC circuits, the current is continuous, meaning it does not naturally pass through zero as in AC circuits. This makes arc quenching significantly more difficult and important for ensuring safe and reliable operation.

Normal contactors, which are typically designed for lower-voltage AC applications, often fail to effectively quench arcs in high-voltage DC environments. They lack the necessary features to deal with the persistent arc in DC circuits.

To address this, specialized contactors with built-in arc quenching technologies and features like arc chambers, magnetic blow-out systems, and sealed contact systems should be incorporated in DC fast charging stations to suppress and extinguish the arc rapidly.

Isolation Transformers

Isolation transformers play a critical role in preventing faults from spreading between different sections of the charging system. These transformers electrically separate the primary power source from the secondary circuit, thus preventing faults from one part of the system from affecting the rest of the system.

Moreover, isolation transformers are essential in preventing ground loops. Ground loops occur when there is more than one path to the ground, which can create dangerous conditions in electrical systems. The isolation transformer eliminates this risk by ensuring that the charging station and the EV remain at a safe, isolated potential relative to the ground.

Conclusion

In conclusion, high voltage protection is crucial for the safe and efficient operation of DC fast charging systems. As electric vehicles become more common, the demand for fast, reliable charging continues to rise. While DC fast chargers can charge vehicles quickly, they also come with risks like electrical shocks, overheating, and damage to equipment. To address these risks, various protection systems, such as overcurrent protection, surge protection, and thermal management, are used. Components like fuses, contactors, circuit breakers, diodes, sensors, and isolation transformers help keep the system safe and ensure smooth operation.

As the technology behind electric vehicles and charging stations evolves, these protection methods will continue to play a key role in making sure that DC fast charging remains a safe, efficient, and long-lasting option for users.

To learn more about high-end protection components, visit Sensata Technologies from TTI, Inc.