Higher Reliability and Longer Lifetimes with Advanced Battery Management in Healthcare Energy Storage Systems

Article 1 of our Energy Storage Solutions series: State-of-the-art battery monitoring systems can exploit the benefits of new lithium battery chemistries.

This is the first article in a 5-part series exploring Energy Storage Systems (ESS). The series will provide insight into emerging technologies, covering topics including battery manufacturing, testing, and application.

The articles were originally published in an e-magazine, and have been substantially edited by Wevolver to update them and make them available on the Wevolver platform. This series is sponsored by Mouser, an online distributor of electronic components. Through their sponsorship, Mouser Electronics supports the growth of a sustainable future fuelled by renewable and distributed energy generation technologies.

Introduction

Batteries play a vital role in many applications, from going the extra mile in electric vehicles to storing renewable energy for the smart grid. Medical devices use the same, and similar battery technologies for increased safety of operation and freedom to move instruments around in hospitals. All these applications run on batteries that need accurate and efficient semiconductors to monitor, balance, protect, and communicate. This article explains how a state-of-the-art battery monitoring system, including cell balancing and isolated communication networks, can exploit the benefits of new lithium battery chemistries. Using innovative integrated circuits permits higher reliability and a 30 percent longer battery lifetime, especially for large-scale energy storage systems.

Energy Storage Systems in Medical Applications

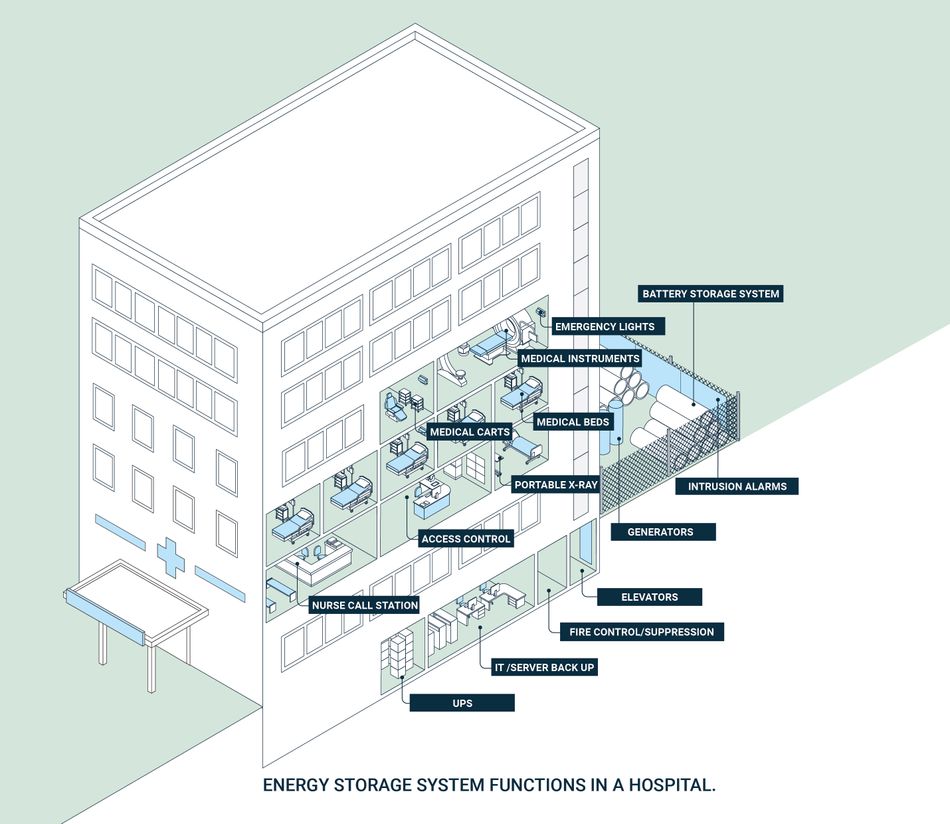

Batteries used in medical applications need to meet very high standards for reliability, efficiency, and safety in all applications. Typical applications include patients’ portable systems such as chest compression systems, hospital emergency room equipment, powered medical carts and beds, portable ultrasound machines, remote monitoring, and the newcomer in the market, energy storage systems (ESS).

Energy storage systems are not linked to patients, nor are they operated by doctors. They are the next step forward for uninterruptible power supplies (UPS). UPS have traditionally been used as backup power for the most critical applications (for example, emergency room devices, IT network critical infrastructure). Energy storage systems for hospitals are covering more and more functions, enabled by the new lithium-based batteries. They are becoming fully integrated with the hospital power grid, bringing advantages such as:

- Complete backup power for entire facilities, rather than just a small, critical subset of facilities, as well as protection from blackouts, poor power/voltage quality from the grid, and reduced usage of emergency diesel generators. With megawatt-hour (MWh) scale ESS, hospitals can operate even during prolonged blackouts, and they can participate in grid stabilization.

- Economic benefits. With ESS, hospitals can directly control the usage profiles of electricity and reduce high-power peak demands, which results in lower utility bills.

Hospitals generally have sizable roof estate, which is suitable for installing photovoltaic (PV) systems to generate electricity. PV systems combined with ESS allow for the storage and self-use of generated electricity while also providing economic benefits and a reduced carbon footprint.

Figure 1. Example uninterrupted power supply system in a hospital setting.

Figure 1. Example uninterrupted power supply system in a hospital setting. Lithuim batteries

Lithium-based chemistries are now state of the art for the batteries used in various markets, from automotive to industrial to healthcare. Different types of lithium batteries have different benefits to suit the varying power requirements of applications and product designs. As an example, LiCoO2 (lithium cobalt oxide) has very high specific energy, and this makes it suitable for portable products; LiMn2O4 (lithium manganese oxide), with its very low internal resistance, enables fast charging and high current discharging, which means that it’s a good choice for peak shaving energy storage applications. Lithium iron phosphate (LiFePO4) is more tolerant to full charge conditions and can sustain being kept at high voltage for a prolonged time. This results in it being the best candidate for big energy storage systems that need to work during a power outage. The drawback is a higher self-discharge rate, but this is not relevant in the above-mentioned storage implementations.

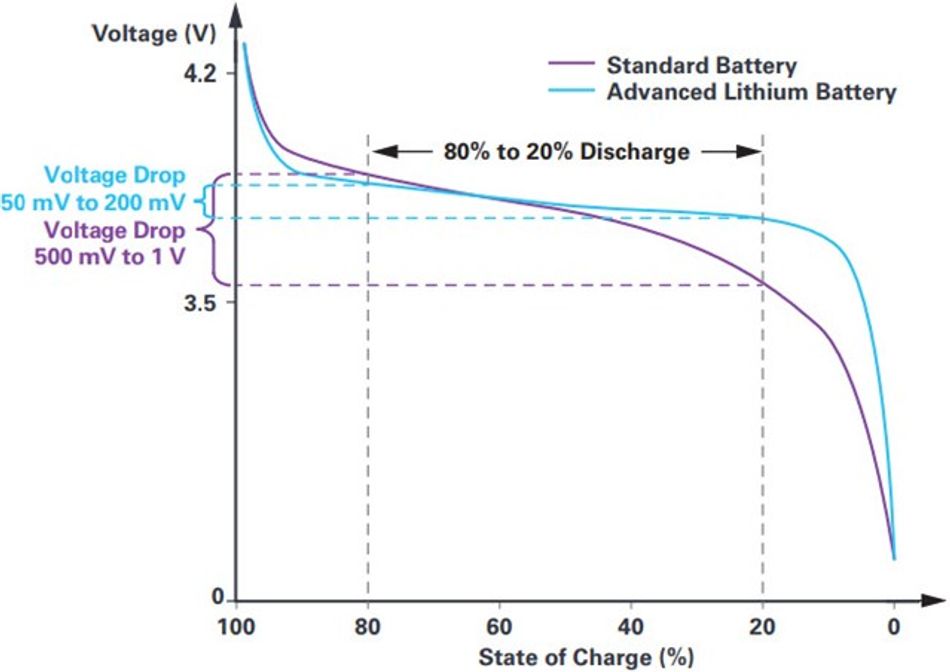

The differing needs of applications require a variety of battery types. For example, automotive applications need high reliability and a good charging and discharging speed, while healthcare applications necessitate high peak current sustainability for efficiency and a long lifetime. However, the commonality among all these solutions is that the various lithium chemistries all have a very flat discharge curve at a nominal voltage range.

While in standard batteries we see a voltage drop in the range of 500mV to 1V, in advanced lithium batteries, such as lithium iron phosphate (LiFePO4) or lithium cobalt oxide (LiCoO2), the discharge curve shows a plateau with a voltage drop in the range of 50mV to 200mV.

Figure 2. Lithium battery discharge profile.

Figure 2. Lithium battery discharge profile.Understanding the curve

The flatness of the voltage curve has tremendous benefits in the power management chain of ICs linked to the battery voltage rail: The DC-to-DC converters can be designed to operate at a maximum efficiency point in a small input voltage range. Converting from a known VIN to a very close VOUT, the power chain of the system can be designed to have an ideal duty cycle of the buck and boost converters to achieve >99 percent efficiency throughout all operating conditions. Moreover, the battery charger can accurately target the charging voltage and the loads are dimensioned according to a stable operating voltage to increase the precision of the final applications, such as remote monitoring or patient in-body electronics. In case of old chemistries or non-flat discharge curves, the DC-to-DC conversion operated from the battery will work with lower efficiency, which results in a shorter battery duration (–20 percent), or, when linked to portable medical devices, the need to charge them more often because of the extra power dissipation.

The main drawback of a flat discharge curve is that the state of charge (SOC) and state of health (SOH) ratings of the battery are much harder to determine. SOC must be calculated with high precision to ensure that the battery is properly charged and discharged. Overcharging can introduce safety issues and generate chemistry degradation and short circuits that lead to fire and gas hazards. Over-discharging can damage the battery and shorten the battery lifetime by more than 50%. SOH gives information about the battery status to help prevent replacing good batteries and monitor the state of bad batteries before an issue appears. The main microcontroller analyzes the SOC and SOH data in real-time, adapts the charging algorithms, informs the user about the potential of the battery (for example, if the battery is ready for a high current deep discharge in case of power break), and makes sure that, in big energy storage systems, the balance between batteries in bad condition and batteries in good condition is optimal to increase the total battery life.

By imaging a very old battery with a steep discharge curve, it is easier to calculate the state of charge of that battery by measuring the delta of the voltage drop in a small amount of time and knowing the absolute value of the battery voltage. For a new lithium-based battery, the accuracy required to make this measurement is orders of magnitude higher, since the voltage drop is much smaller in a given time frame.

Precise SOH extend battery life

For the SOH, old batteries discharge faster and more predictably. Their voltage discharge curve becomes even steeper and the target charging voltage cannot be reached. New lithium batteries will keep the same good behavior longer, but eventually can degrade with more exceptional behavior and rapidly change their impedance and discharge curve just when they are close to end of life or if they are damaged. Extra care must be taken for temperature measurements, ideally at every single cell, to integrate the SOC and SOH algorithms with this information to make them more accurate.

Precise and reliable SOC and SOH calculations help extend battery lifetimes from 10 years to 20 years in the best case and generally result in a 30 percent lifetime improvement, which reduces the total cost of ownership of the energy storage system by greater than 30 percent after including maintenance costs. This, together with the higher accuracy of the SOC information, avoids overcharging or discharging conditions that can quickly drain a battery; minimizes the chance of short circuits, fire, and other risky situations; helps use all the energy in a battery; and enables charging batteries in the best, most efficient way possible.

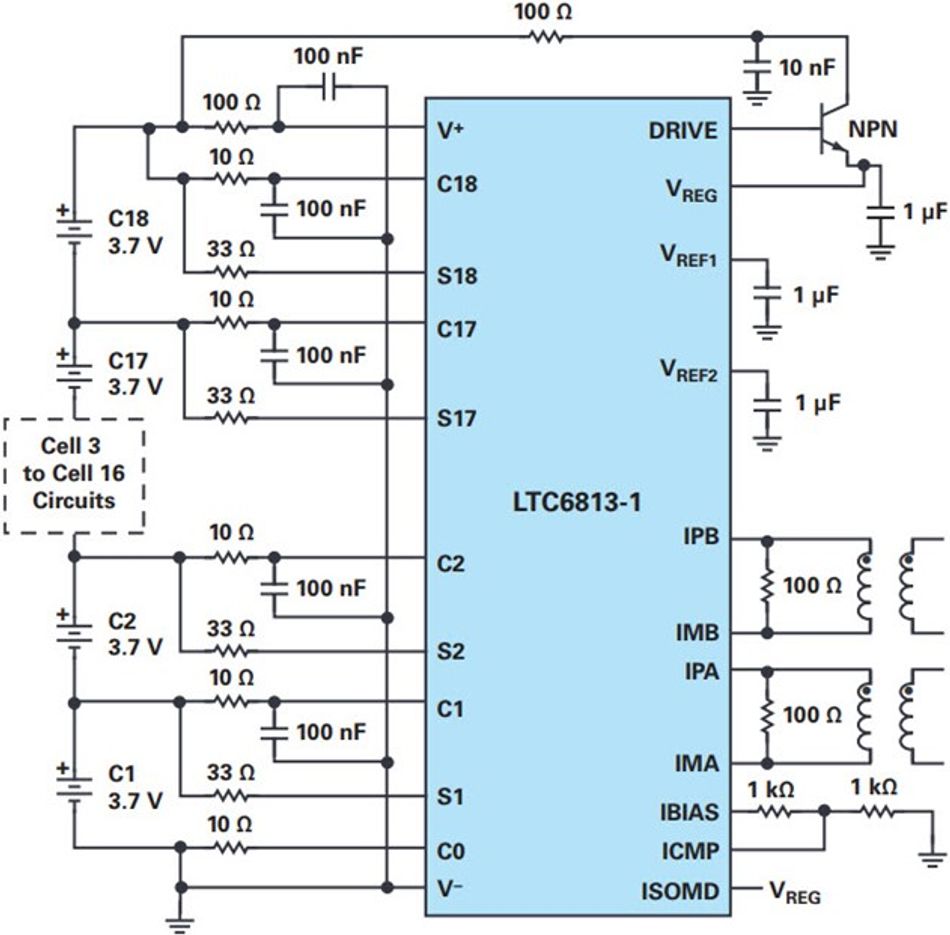

The LTC6813 battery management solution (BMS) proposed in this article can be used in healthcare devices such as portable ultrasound machines and in large scale (megawatt/hours) energy storage systems (for hospitals, factories, grid stabilization, electric vehicle charging infrastructure, and residential units), as well as in industrial robots and vehicles. The portability of ADI technology brings terrific advantages in reliability and safety, as it’s designed to work in different, harsh environments and is compliant to various functional safety standards, from the Automotive ASIL to Industrial SIL (for example, VDE AR 2510-2/-50, IEC EN 61508, and others).

Figure 3. LTC6813 application schematic.

Figure 3. LTC6813 application schematic.Efficient and reliable battery monitoring

One new and unique solution for having the most efficient and reliable battery monitoring system involves the combination of an 18-cell monitor and balance IC with a microcontroller to SPI slave isolated interface. A multicell battery stack monitor measures up to 18 series-connected battery cells with a total measurement error of less than 2.2mV. The cell measurement range of 0V to 5V makes it suitable for most battery chemistries. All 18 cells can be measured in 290μs, and lower data acquisition rates can be selected for high noise reduction. Multiple stack monitor devices can be connected in series, permitting simultaneous cell monitoring of long, high-voltage battery strings. Each stack monitor has an isoSPI™ interface for high speed, RF immune, long-distance communications. Multiple devices are connected in a daisy chain with one host processor connection for all devices. This daisy chain can be operated bidirectionally, ensuring communication integrity, even in the event of a fault along the communication path. The IC can be powered directly from the battery stack or from an isolated supply. The IC includes passive balancing for each cell, with individual PWM duty cycle control for each cell. Other features include an onboard 5V regulator, nine general-purpose I/O lines, and a sleep mode where current consumption is reduced to 6μA.

Due to the short- and long-term accuracy demands of the BMS application, it uses a buried Zener conversion reference rather than a band gap reference. This provides a stable, low drift (20ppm/√kHr), low-temperature coefficient (3ppm/°C), low hysteresis (20ppm) primary voltage reference along with excellent long-term stability. This accuracy and stability is critical since it is the basis for all subsequent battery cell measurements, and these errors have a cumulative impact on acquired data credibility, algorithm consistency, and system performance.

Although a high accuracy reference is a necessary feature to ensure superior performance that alone is not enough. The analog-to-digital converter architecture and its operation must meet specifications in an electrically noisy environment, which is the result of the pulse-width modulated (PWM) transients of the system’s high current/voltage inverter. Accurate assessment of the state of charge and health of the batteries also requires correlated voltage, current, and temperature measurements.

To mitigate the system noise before it can affect the BMS performance, the stack monitor converter uses a Σ-Δ topology that is aided by six user selectable filter options to address noisy environments. The Σ-Δ approach reduces the effect of electromagnetic interference (EMI) and other transient noise, by its very nature of using many samples per conversion, with an averaging filtering function.

Balancing essential over time

The need for cell balancing is an unavoidable consequence in any system that uses large battery packs arranged as groups of cells or modules, such as the big energy storage units used to supply hospital microgrids and subgrids. Although most lithium cells are well-matched when first acquired, they lose capacity as they age. The aging process can differ from cell to cell based on several factors, such as gradients in pack temperature. Exacerbating the whole process, a cell that can operate beyond its SOC limits will prematurely age and lose additional capacity. These differences in capacity, combined with small differences in self-discharge and load currents, lead to cell imbalance.

To remedy the cell imbalance issue, the stack monitor IC directly supports passive balancing (with a user-settable timer). Passive balancing is a low-cost, simple method to normalize the SOC for all cells during the battery charge cycle. By removing charge from the lower capacity cells, passive balancing ensures these lower capacity cells are not overcharged. The IC can also be used to control active balancing, a more complicated balancing technique that transfers charge between cells through the charge or discharge cycle.

Whether done using active or passive approaches, cell balancing relies on high measurement accuracy. As measurement error increases, the operating guard band that the system establishes must also be increased, and therefore the effectiveness of the balancing performance will be limited. Further, as the SOC range is restricted, the sensitivity to these errors also increases. A total measurement error of less than 1.2mV is well within system-level requirements for battery monitoring systems.

In energy storage systems, a communication loop is mandatory to connect all battery cells. This loop transmits data from the system’s battery to a cloud-based energy management algorithm that tracks charging and discharging events to determine the best way to maximize battery use or to keep the highest capacity battery fully charged in case of a power outage. ADI, (also know as Analog Devices) LTC681x and LTC680x families battery stack monitors. The 18-channel version is called LTC6813.

The battery stack monitor device needs to communicate with the master unit where a microcontroller or processor calculates the SOC and SOH values and regulates the charging and discharging profiles. Various forms of interconnection are possible, where the isolated communication channel is preferred for high voltage applications, such as energy storage systems (400V to 1500V) and portable devices with high capacity batteries (40V to 200V).

The isoSPI feature built into the LTC6813 battery stack monitor, when combined with an LTC6820 isoSPI communications interface, enables safe and robust information transfer across a high voltage barrier. isoSPI is particularly useful in energy storage systems that produce hundreds of volts via series-connected cells, which require full dielectric isolation to minimize hazards to personnel.

In these storage systems, where more than 18 cells are used, multiple LTC6813 BMS boards will need to be interfaced together. Here a robust interconnection of multiple identical PCBs, each containing one LTC6813, is configured for operation in a daisy chain. The microprocessor is located on a separate PCB. To achieve 2-wire isolation between the microprocessor PCB and the first LTC6813 PCB, the LTC6820 support IC is used. When only one LTC6813-1 is needed, it can be used as a single (non-daisy-chained) device if the second isoSPI port (Port B) is properly biased and terminated.

The main design challenge for battery stack monitors with balancing and communication functions is to create a noise-free PCB layout design, with critical trace routes far from the noise sources—such as switching power supplies—giving clear signals to the stack monitor. The stack monitor’s accuracy and precision can help optimize already good designs. The batteries will then be efficiently used, have a 30% longer lifetime, and operate with maximum safety.

This article was originally written by Stefano Gallinaro for Mouser and substantially edited by the Wevolver team. It's the first article of a 5-part series exploring Energy Storage Systems (ESS). Future articles will explore communication solutions for solar PV and energy storage, electric vehicle production futures, and battery monitoring systems for lithium-ion solutions.

Article two explained communication systems for energy storage.

Article three gave an overview of battery stack monitoring systems for li-on batteries.

Article four provided a deep analysis of the critical design considerations in estimating the state of lithium-ion batteries.

Article five looked at solutions for scaling electric vehicle production.

About the sponsor: Mouser

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 800 industry-leading manufacturers. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.