How to hide supercapacitors in electric vehicles

Wire-shaped capacitors offer the opportunity to boost power storage and improve power quality without sacrificing range or cargo space.

Affordable, high-range, efficient electric vehicles are one of the most anticipated technologies of the century. Power storage is arguably the most critical component of an electric vehicle and holds the biggest potential to make electric vehicles supersede internal combustion engine cars. Most limitations of single-source electric vehicles (one without a secondary source of propulsion) are caused by issues with power storage. To cover flaws caused by the main power source, an ancillary source is added to turn the vehicle into a dual- or multi-source system, or systems to make them more independent and reliable.

Adding supercapacitors, also often referred to as ultracapacitors, is the solution most frequently explored to overcome battery storage issues. In this article, we’ll explore the role of supercapacitors in battery electric vehicles and look at how a flexible supercapacitor can enhance the performance and design of electric vehicles.

The problem with storage

There are three main components of an electric vehicle: an electric motor, a power storage system, and a controller. The electric motor is the actuator that moves the vehicle by supplying forces to move the wheels and as generators for regenerative braking. While the controller manages how much power is needed to accelerate and decelerate the vehicle and communicates with both the motor and the power storage system. However, the factor that deeply influences the performance and price of an electric vehicle is its power storage units. Most battery electric vehicles, available on the market, use lithium-ion batteries which have great properties such as low self-discharge rate, no memory effect, and a slow loss of charge when not in use. Despite their dominance, there are still some issues to solve for this technology to reach a balance of efficiency, economy, and reliability.

For one, li-ion batteries are easily affected by high temperature, causing loss of range and efficiency. The batteries also decrease in performance over time, caused by a multitude of factors, such as peak usage, overcharging, and properties of the current electroactive materials. The style of driving also affects the lifetime of the battery life in your electric vehicle, as the acceleration and deceleration of your vehicle, as well as unexpected driving conditions can wear the battery.

Power storage support

To protect batteries from power fluctuations and other weaknesses, electric vehicles need additional power storage systems. The most frequently explored addition to an EV’s power storage system is a supercapacitor. Supercapacitors are power storage devices that leverage both the electrostatic and electrochemical principles used by batteries and capacitors to store energy. They can charge and discharge energy very quickly and are becoming increasingly important to meet the battery storage challenges presented by electric vehicles.

Supercapacitors have a much higher capacitance than conventional capacitors and come in a variety of sizes from 0.1F to over 1000F. Their low internal resistance and high power density, enable them to be able to charge and discharge as well as have a nearly instantaneous ability to absorb and deliver power. But a supercapacitor’s role in an electric vehicle can go beyond a backup power supply. Unlike batteries, the energy in supercapacitors is partially stored as a static charge, leading to a high power density that batteries lack. While batteries are perfect for a slow discharge over time, rapid bursts of power easily damage the chemical elements and reduce their performance. The high power density of a supercapacitor allows it to rapidly charge or discharge a high amount of power without damaging its ability to store energy. This makes supercapacitors favorable in facilitating scenarios where you need to supply or capture a lot of power in a short time, such as acceleration and regenerative braking, where supercapacitors capture the kinetic energy from deceleration that is usually dissipated into heat. For this reason, supercapacitors are often used on hybrid vehicles, such as the Lamborghini Sian and Toyota FCHV.

On the other hand, supercapacitors have a lower energy density than batteries, so most can’t support pure electric vehicles on their own. They also have a higher self-discharge rate than batteries, making them unsuitable for long-term storage.

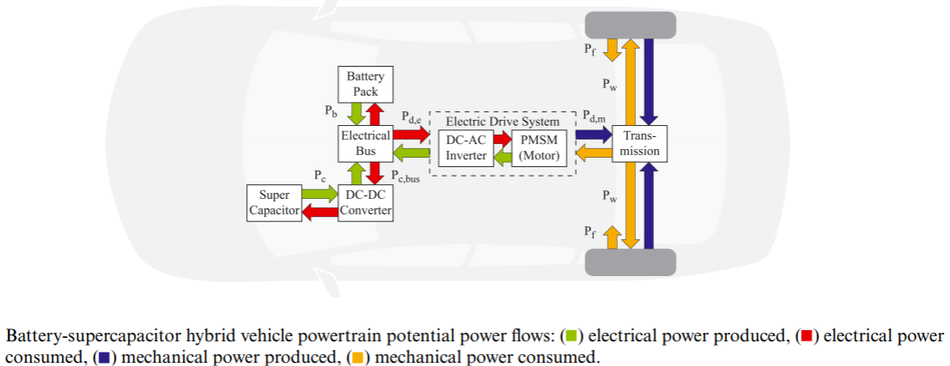

Rather than solely using batteries or supercapacitors, the combination of supercapacitors and batteries is being increasingly explored by researchers to improve the driving range and battery lifetime of battery electric vehicles. The combination of two energy storage options, in this case, battery and supercapacitor, is referred to as a hybrid energy storage system (HESS). The coupling between battery and supercapacitors makes the system more robust as they cover each other’s weaknesses. Supercapacitors protect batteries from power fluctuations and lead to a longer lifespan while the batteries can provide long-term storage for the energy needed by EVs.

An innovative approach to supercapacitors

Over the years, supercapacitor design has improved dramatically. The improvements come from include trying on different materials and shapes for both the surface of the conductor plate and the electrolyte used to improve the power density. However, these improvements don't solve the problem in EVs, where designers still have to sacrifice the functionalities and performance of their EVs to fit in a supercapacitor. There is a need to balance the right amount of battery packs and supercapacitors to attain the most efficient power usage.

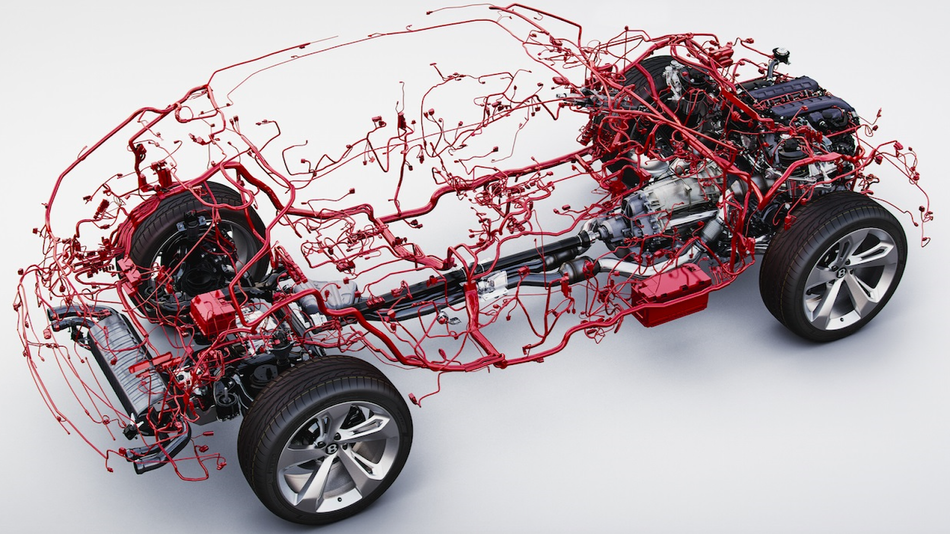

Capacitech Energy, an Orlando-based company, has developed a wire-shaped supercapacitor, known as a cable-based capacitor (CBC) which endeavors to solve many of the space and design problems associated with traditional supercapacitors. CBC’s are wire-shaped power storage devices with supercapacitor performances that can be integrated into wiring infrastructure, freeing supercapacitors from circuit boards. This flexible supercapacitor offers the opportunity to sneak supercapacitors into the wiring harnesses, which are aplenty in electric vehicles, for the creation of agile and efficient HESS systems.

Conclusion

Power storage is one of the most important and costly components of an electric vehicle. Coupling batteries with supercapacitors, often referred to as hybrid energy storage system (HESS), may provide some of the solutions to the challenges facing Lithium-ion batteries. Flexible supercapacitors could be the ingredient missing in these systems.

Complete information on Capacitech product specs, as well as ordering and delivery, can be found on the Capacitech site.

References and Further Reading

Horn, Michael, et al. “Supercapacitors: A New Source of Power for Electric Cars?” Economic Analysis and Policy, vol. 61, 2019, pp. 93–103., doi:10.1016/j.eap.2018.08.003.

Meyer, Richard T., et al. “Hybrid Model Predictive Power Management of a Battery-Supercapacitor Electric Vehicle.” Asian Journal of Control, vol. 18, no. 1, 2015, pp. 150–165., doi:10.1002/asjc.1259.

Poonam, et al. “Review of Supercapacitors: Materials and Devices.” Journal of Energy Storage, vol. 21, 2019, pp. 801–825., doi:10.1016/j.est.2019.01.010.

Simon, P., et al. “Where Do Batteries End and Supercapacitors Begin?” Science, vol. 343, no. 6176, 2014, pp. 1210–1211., doi:10.1126/science.1249625.