MCC Buckets: Engineering Marvels Revolutionizing Material Handling

A deep dive into the basics of MCC buckets, architecture, applications, and challenges associated with the implementation of MCC buckets in varying industrial infrastructures.

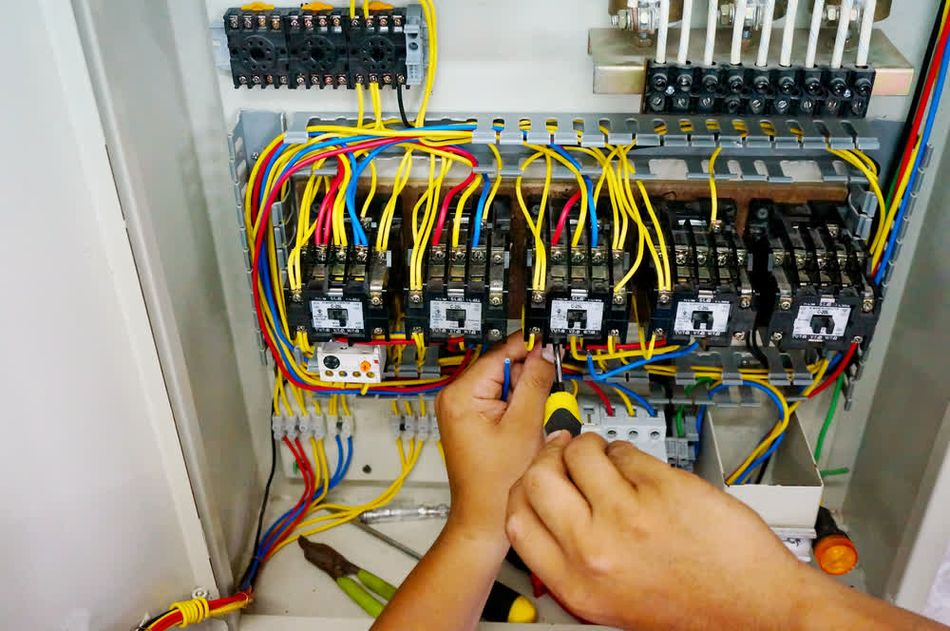

A low-voltage motor control centre with fixed shelves

Introduction

Motor Control Center (MCC) buckets are essential components in modern industrial automation systems, serving as modular units that house and organize motor controls and power distribution equipment. They are standardized compact enclosures, critical for efficient management of electrical systems across various industrial settings.

MCC buckets offer significant advantages, including

Enhanced modularity for easy reconfiguration

Improved safety through compartmentalization

Simplified maintenance due to their plug-in design.

Their versatility and reliability make them indispensable in manufacturing, oil and gas, water treatment, and power generation. By centralizing motor control functions and power distribution, MCC buckets enable streamlined operations, reduce downtime, and optimize space utilization in industrial facilities. As automation continues to advance, MCC buckets remain at the forefront of efficient and safe electrical system management.

Core Components of MCC BucketsPower Distribution Architecture

Motor Control Center (MCC) buckets feature a sophisticated power distribution architecture designed for efficient and safe electrical management. At the heart of this system lies the main bus, a horizontal copper or aluminum bar that runs through the entire MCC lineup, carrying the main power supply. Connected to the main bus are vertical bus systems, which distribute power to individual MCC buckets stacked vertically within each section.

- Circuit breakers play a crucial role by providing overcurrent protection and serving as disconnecting means for each bucket. They are typically mounted at the front of the bucket for easy access and operation.

Contactors are electromagnetic switches that control the power flow to the motor loads. They are positioned downstream of the circuit breakers and are responsible for remotely starting and stopping motors based on control signals.

This architecture ensures power is distributed efficiently from the main supply to individual motor loads while maintaining proper protection and control at each level. The modular nature of MCC buckets allows for easy maintenance, replacement, or reconfiguration of individual units without disrupting the entire system.

Control and Protection Mechanisms

MCC buckets incorporate sophisticated control and protection mechanisms to ensure the safe and efficient operation of motor loads. These mechanisms are designed to provide precise control over motor starting, stopping, and speed regulation while safeguarding against electrical faults and overloads.

Motor Starters

Motor starters are key control devices found in MCC buckets. They come in various types, including full-voltage (across-the-line) starters, reduced-voltage starters, and soft starters. Full-voltage starters provide simple on-off control, while reduced-voltage and soft starters offer more gradual motor acceleration, reducing mechanical stress and inrush current.

Overload Relays

Overload relays are crucial protection devices that monitor motor current and trip the circuit when excessive current is detected. Modern electronic overload relays offer advanced features such as phase loss protection, ground fault detection, and communication capabilities for remote monitoring.

Short Circuit Protection

Short circuit protection is typically provided by circuit breakers or fuses within the MCC bucket. These devices rapidly interrupt the circuit in case of a short circuit, preventing damage to equipment and potential arc flash incidents. Ground fault protection is often integrated into the same devices, detecting current leakage to ground and tripping the circuit to prevent electrical shock hazards.

Here is a summary of the essential control components and their functions in MCC buckets

Component | Function |

Starter | Control motor starting, stopping, and sometimes speed |

Overload Relay | Protect motors from overheating due to prolonged overcurrent conditions |

Circuit Breaker | Provide short circuit protection and serve as disconnecting means |

Contactor | Electromagnetic switches that make or break the main power circuit |

Control Transformer | Step down voltage for control circuits |

Pilot Device | Pushbuttons, selector switches, and indicator lights for local control and status indication |

Timer | Control time-based operations in motor circuits |

Current Transformer | Measure motor current for metering and protection purposes |

Power Factor Correction Capacitor | Improve power factor in motor circuits |

Variable Frequency Drive | Provide advanced motor speed and torque control |

Communication and Networking Capabilities

Modern Motor Control Center (MCC) buckets have evolved to incorporate advanced communication and networking capabilities, enabling seamless integration with broader industrial automation systems. These capabilities allow for real-time monitoring, remote control, and data acquisition, enhancing overall system efficiency and facilitating predictive maintenance strategies.

These modules are integrated into MCC buckets through dedicated slots or as part of intelligent motor control devices. They act as gateways, translating the MCC's internal data into standardized industrial protocols. This integration allows MCC buckets to communicate with programmable logic controllers (PLCs), human-machine interfaces (HMIs), and supervisory control and data acquisition (SCADA) systems.

Suggested Reading: What is a PLC (Programmable Logic Controllers): A Comprehensive Guide

Several industrial communication protocols are commonly used in MCC systems:

Modbus: A simple, robust protocol that has been a standard in industrial communication for decades. It supports both serial (Modbus RTU) and Ethernet (Modbus TCP) connections, making it versatile for various applications.

Profibus: Developed by Siemens, Profibus is widely used in process automation and manufacturing. It offers high-speed communication and is particularly strong in deterministic, real-time applications.

Ethernet/IP: Based on standard Ethernet technology, Ethernet/IP (Industrial Protocol) provides a flexible, scalable solution for industrial networking. It supports both cyclic and acyclic data exchange, making it suitable for a wide range of industrial applications.

The following table compares these communication protocols:

Protocol | Speed | Topology | Max Nodes | Determinism | Advantages |

Modbus | Up to 115.2 kbps (RTU), 10/100 Mbps (TCP) | Bus, Star | 247 (RTU), Unlimited (TCP) | Low | Simple, widely supported, cost-effective |

Profibus | Up to 12 Mbps | Bus, Tree, Star | 126 | High | Fast, deterministic, and robust in noisy environments |

Ethernet/IP | 10/100/1000 Mbps | Star, Ring | Unlimited | Medium | Flexible, scalable, uses standard Ethernet hardware |

The choice of protocol depends on factors such as the existing plant infrastructure, required communication speed, and the level of determinism needed for the application.

Cutting-Edge Innovations in MCC Bucket Design

Advanced Arc Flash Mitigation Techniques

Arc flash incidents in Motor Control Centers (MCCs) pose significant safety risks to personnel and can cause severe equipment damage. Modern MCC bucket designs incorporate cutting-edge technologies to mitigate these risks effectively. Advanced arc-resistant MCC designs utilize pressure relief systems, insulation barriers, and arc-quenching materials to contain and redirect arc flash energy away from personnel.

Detection Systems

One of the most significant innovations is the implementation of active arc flash detection systems. These systems use light sensors and current monitoring devices to detect arc flash events within milliseconds. Upon detection, they rapidly trigger upstream circuit breakers or specialized arc quenching devices to limit arc flash energy and duration.

Remote Capabilities

Remote operation capabilities have greatly enhanced safety in MCC environments. Modern MCC buckets can be equipped with motorized operators and communication modules, allowing for remote racking, switching, and monitoring. This technology enables operators to perform potentially hazardous operations from a safe distance, significantly reducing exposure to arc flash risks.

Key arc flash safety features in modern MCC buckets include:

Arc-resistant enclosures with reinforced structures and pressure relief systems

Optical arc flash detection sensors for ultra-fast fault recognition

High-speed communication networks for rapid fault clearing

Remote racking mechanisms for inserting and removing buckets without direct exposure

Insulation and isolation enhancements to prevent arc propagation between compartments

Arc-quenching materials that rapidly extinguish arcs upon detection

Zone-selective interlocking for improved coordination and reduced clearing times

Remote monitoring and diagnostics capabilities for proactive maintenance

Personal protective equipment (PPE) reduction through design improvements

Automatic shutters that cover exposed conductors when buckets are removed

These advanced features work in concert to create a multi-layered approach to arc flash protection, significantly enhancing the safety of MCC operations and maintenance activities.

Smart Diagnostics and Predictive Maintenance

Motor Control Center (MCC) buckets are increasingly incorporating Internet of Things (IoT) technologies to enable real-time monitoring and smart diagnostics. These systems use sensors to continuously collect data on various parameters such as temperature, vibration, current, voltage, and power factor. The data is transmitted via secure networks to cloud-based platforms or local servers for analysis and visualization.

IoT Integration

IoT integration allows for the creation of digital twins of MCC buckets, providing a virtual representation of the physical assets. This enables operators to monitor performance, track trends, and identify potential issues in real time.

Advanced monitoring systems can detect anomalies such as partial discharge, insulation degradation, or unusual temperature patterns, alerting maintenance teams before failures occur.

Artificial Intelligence

Artificial Intelligence (AI) and Machine Learning (ML) algorithms are being applied to the vast amounts of data collected from MCC buckets to enable predictive maintenance. These algorithms analyze historical data, identify patterns, and learn to recognize early indicators of potential failures. For example, AI models can predict motor bearing failures by analyzing vibration patterns or detect impending insulation breakdowns by monitoring partial discharge trends.

Data Analytics

Data analytics plays a crucial role in optimizing MCC bucket performance. Some examples include:

Power Quality Analysis: Advanced analytics tools analyze harmonic distortion, voltage sags, and power factor fluctuations to identify potential issues and optimize power distribution.

Thermal Profiling: Data analytics are used to create thermal profiles of MCC buckets, identifying hotspots and potential areas of concern before they lead to failures.

Load Balancing: Analytics tools analyze load patterns across different MCC buckets and suggest optimal load distribution to improve overall system efficiency and reduce wear on individual components.

Energy Efficiency Optimization: By analyzing energy consumption patterns, data analytics tools can recommend operational changes to reduce energy waste and improve overall efficiency.

Fault Prediction: Advanced algorithms analyze combinations of parameters to predict potential faults with high accuracy, allowing for proactive maintenance interventions.

These smart diagnostic and predictive maintenance capabilities significantly enhance the reliability, efficiency, and lifespan of MCC buckets while reducing operational costs and downtime.

.Suggested Reading: 6 Industrial Automation Trends For 2022

Energy Efficiency Enhancements

Motor Control Center (MCC) buckets have undergone significant improvements in energy efficiency, driven by the need to reduce operational costs and meet stringent environmental regulations. One key area of innovation is power factor correction. Modern MCC buckets incorporate advanced capacitor banks with intelligent switching systems that dynamically adjust the power factor. These systems use real-time monitoring of reactive power demand and automatically switch capacitor stages to maintain an optimal power factor, typically above 0.95.

Variable Frequency Drives (VFDs) have become integral components in energy-efficient MCC systems. VFDs are integrated directly into MCC buckets, allowing for precise control of motor speed and torque. By adjusting the motor speed to match the actual load demand, VFDs can reduce energy consumption by up to 50% in some applications. Moreover, the integration of VFDs into MCC buckets simplifies installation, reduces wiring complexity, and improves overall system reliability.

The following table compares traditional MCC buckets with energy-efficient models:

Feature | Traditional MCC Buckets | Energy-Efficient MCC Buckets |

Power Factor Correction | Fixed capacitor banks | Dynamic, intelligent PF correction |

Motor Control | Fixed speed starters | Integrated VFDs for variable speed control |

Efficiency at Partial Load | Low to moderate | High due to VFD speed adjustment |

Harmonic Distortion | Higher | Lower with built-in harmonic filters |

Soft Starting Capability | Limited | Advanced with VFD ramping features |

Energy Monitoring | Basic or none | Advanced with real-time monitoring |

Heat Generation | Higher | Lower due to improved efficiency |

Space Utilization | Less compact | More compact with integrated components |

Initial Cost | Lower | Higher |

Operational Cost | Higher | Lower due to energy savings |

Maintenance Requirements | More frequent | Less frequent with predictive capabilities |

Applications Across Industries: MCC Buckets in Action

Oil and Gas: Powering Offshore Platforms

Motor Control Center (MCC) buckets play a critical role in powering offshore oil and gas platforms, where they must operate reliably under extreme conditions. The offshore environment presents unique challenges, including constant exposure to salt spray, high humidity, and potentially explosive atmospheres. MCC buckets designed for offshore use must meet stringent requirements to ensure safe and continuous operation.

Specific requirements for offshore MCC buckets include:

Marine-grade materials and coatings to withstand saltwater corrosion

Sealed enclosures to prevent ingress of moisture and contaminants

Enhanced vibration resistance to withstand platform movement

Compact design to optimize limited space on offshore platforms

Compliance with maritime and offshore industry standards (e.g., ABS, DNV-GL)

Manufacturing: Streamlining Production Lines

Motor Control Center (MCC) buckets play a crucial role in enhancing the efficiency of automated production lines in manufacturing environments. These modular units centralize motor control and power distribution, significantly reducing wiring complexity and installation time. MCC buckets contribute to production line efficiency by providing:

Centralized control and monitoring of multiple motors

Rapid fault isolation and system recovery

Easy maintenance and replacement of individual motor control units

Compact design that optimizes floor space in manufacturing facilities

Scalability to accommodate changes in production line requirements

The integration of MCC buckets with Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems forms the backbone of modern automated manufacturing processes. This integration enables:

Real-time monitoring and control of motor operations

Automated sequencing of production line processes

Data collection for performance analysis and predictive maintenance

Remote operation and troubleshooting capabilities

Enhanced energy management through intelligent motor control

MCC buckets interface with PLCs through communication modules, allowing for bidirectional data exchange. The PLC sends control commands to the MCC buckets, which in turn provide status updates and performance data back to the PLC. This data is then aggregated by the SCADA system, providing operators with a comprehensive view of the entire production line.

The following illustrates the role of MCC buckets in a typical manufacturing process:

Production Equipment: Represents the various machines and devices on the production line.

MCC Buckets: Centralize motor control for the production equipment.

Control Systems: Act as an intermediary between MCC buckets and higher-level control.

Control System (PLC/SCADA): Provides overall process control and monitoring.

Suggested Reading: PLC and SCADA: Understanding the Differences in Industrial Automation Systems

This integrated approach allows for seamless coordination between different parts of the production line, enhancing overall efficiency, reducing downtime, and improving product quality through precise control of manufacturing processes.

Overcoming Design Hurdles in MCC Buckets

Thermal Management Challenges

Thermal management is a critical aspect of Motor Control Center (MCC) bucket design, particularly in high-density installations where heat generation can significantly impact performance and longevity. As MCC buckets become more compact and powerful, innovative cooling solutions are essential to maintain optimal operating temperatures and ensure reliability.

Phase Change Materials (PCM) can absorb excessive heat, so they have become an innovative cooling solution for MCC buckets.

Micro-channel liquid cooling systems feature a coolant that circulates throughout the MCC structure to reduce heat build-up.

Ambient temperature plays a crucial role in MCC bucket performance. Higher ambient temperatures reduce the efficiency of air-based cooling systems and can lead to increased component stress. For every 10°C rise in ambient temperature above the rated value, the life expectancy of electronic components can be reduced by up to 50%. To mitigate this, some modern MCC designs incorporate adaptive cooling systems that adjust their operation based on real-time temperature monitoring, ensuring optimal performance across a wide range of ambient conditions.

The following table compares different cooling methods and their effectiveness in MCC bucket applications:

Cooling Method | Effectiveness | Pros | Cons |

Natural Convection | Low | Simple, low cost | Limited cooling capacity, sensitive to ambient temperature |

Forced Air Cooling | Medium | Improved heat dissipation, cost-effective | Noise, potential for dust accumulation |

Liquid Cooling | High | Excellent heat transfer, compact | Complex installation, risk of leaks |

Phase Change Materials | Medium-High | Passive operation, temperature stabilization | Limited heat capacity, potential for long-term degradation |

Thermoelectric Cooling | Medium | Precise temperature control, no moving parts | High power consumption, limited cooling capacity |

Heat Pipe Technology | High | Efficient heat transfer, no moving parts | Orientation sensitive, limited distance for heat removal |

Space Optimization Strategies

In industrial environments where floor space is at a premium, optimizing the layout of Motor Control Center (MCC) buckets is crucial. Compact design techniques have evolved to maximize power density while minimizing footprint. One key strategy is the use of high-density components, such as miniature circuit breakers and compact contactors, which allow for more control units within a single bucket.

Vertical stacking is a primary method for space optimization in MCC installations. Modern MCC designs can accommodate up to 12 buckets in a single vertical section, compared to traditional designs that typically housed 6-8 buckets. This vertical expansion is made possible through:

Improved thermal management techniques that allow for closer component spacing

Advanced insulation materials that reduce clearance requirements

Innovative bus bar designs that minimize vertical space requirements

Modular configurations further enhance space efficiency. These designs allow for:

Easy addition or removal of buckets without disrupting adjacent units

Customizable layouts to fit specific room configurations

Standardized bucket sizes for interchangeability and simplified inventory management

A typical space-efficient MCC bucket layout might include:

A main vertical section measuring 2000mm (height) x 600mm (width) x 600mm (depth)

Within this section, 10 modular buckets, each measuring 200mm in height

A horizontal bus bar system at the rear, occupying 100mm of depth

Front-accessible buckets with withdrawable units for easy maintenance

For ultra-compact installations, back-to-back configurations can be employed. This arrangement involves:

Two rows of MCC sections placed back-to-back

A shared central bus bar system, reducing the overall depth to approximately 1000mm

Access aisles on both sides, typically 900mm wide for maintenance

In applications requiring even greater space optimization, wall-mounted MCC configurations can be utilized. These designs feature:

Shallow depth units (typically 400mm or less) mounted directly to walls

Vertical stacking of up to 6 buckets in a single column

Front-only access, eliminating the need for rear maintenance space

These space optimization strategies not only reduce the physical footprint of MCC installations but also contribute to improved cooling efficiency, reduced cable lengths, and easier maintenance access, ultimately enhancing the overall performance and reliability of the motor control system.

Suggested Reading: What is Distributed Control System (DCS)?

Electromagnetic Compatibility (EMC) Solutions

Electromagnetic Compatibility (EMC) is crucial in Motor Control Center (MCC) bucket design to ensure reliable operation in industrial environments with high electromagnetic interference (EMI). Proper EMC design prevents MCC buckets from both emitting excessive electromagnetic radiation and being susceptible to external EMI sources, which can cause malfunctions, data corruption, or equipment damage.

Shielding techniques are fundamental to EMC solutions in MCC buckets. These include:

Metallic enclosures that act as Faraday cages, containing internal EMI and blocking external interference.

Conductive gaskets and seals to maintain shield integrity at joints and openings.

Cable shielding using braided or foil shields to prevent both radiated and conducted EMI.

Recommended Reading: EMI Shielding: Protecting Electronic Devices in a Noisy World

Grounding practices play a vital role in EMC performance. Effective grounding strategies involve:

Low-impedance ground connections to dissipate high-frequency noise.

Star-point grounding to prevent ground loops and minimize common-mode interference.

Dedicated ground planes in printed circuit boards for high-frequency signal return paths.

Conclusion

MCC buckets are essential for modern industry. They offer modular design, advanced control, and efficiency. They improve safety with arc flash mitigation and energy efficiency through cooling solutions and power factor correction. Smart features like diagnostics and predictive maintenance enable proactive management. MCC buckets are crucial for Industry 4.0, ensuring seamless integration with automation systems. Future advancements will continue to enhance their capabilities, shaping the future of industrial automation.

Frequently Asked Questions

What is the typical lifespan of an MCC bucket?

The average lifespan of an MCC bucket is typically 20-30 years, but this can vary significantly based on several factors:

Operating environment (temperature, humidity, contaminants)

Maintenance practices

Frequency and severity of use

Quality of initial installation

What are the best practices to extend the life of MCC Buckets?

To extend the life of MCC buckets:

- Implement regular preventive maintenance schedules

- Conduct thermal imaging to detect hotspots early

- Keep the environment clean and within specified temperature ranges

- Perform periodic tightening of connections to prevent loose contacts

- Update firmware and software for digital components regularly

3. How do MCC buckets compare to traditional switchgear?

Feature | MCC Buckets | Traditional Switchgear |

Size | Compact, modular | Larger, less flexible |

Maintenance | Easy access, removable units | Often requires full shutdown |

Scalability | Highly scalable | Limited expansion options |

Control Integration | Advanced integration capabilities | Limited control options |

Cost | Higher initial cost, lower long-term cost | Lower initial cost, higher long-term cost |

4. Can MCC buckets be retrofitted with new technologies?

Yes, MCC buckets can be retrofitted with new technologies. The process typically involves:

Assessing the existing MCC structure and available space

Designing the retrofit solution (e.g., adding smart devices, communication modules)

Planning the installation to minimize downtime

Implementing the upgrades, often during scheduled maintenance periods

Testing and commissioning the new components

5. What are some major limitations with MCC buckets?

Limitations and considerations include:

Physical space constraints within existing buckets

Compatibility with legacy systems

Potential need for additional cooling or power supply

Ensuring compliance with current standards after modifications

6. What are the latest safety standards applicable to MCC buckets?

Relevant standards include:

IEC 61439-1 and IEC 61439-2 for low-voltage switchgear and controlgear assemblies

NEMA ICS 18 for Motor Control Centers

IEEE 1683 for Motor Control Centers in the Petroleum and Chemical Industry

UL 845 for Motor Control Centers

References

Table of Contents

IntroductionCore Components of MCC BucketsPower Distribution ArchitectureControl and Protection MechanismsMotor StartersOverload RelaysShort Circuit ProtectionCommunication and Networking CapabilitiesCutting-Edge Innovations in MCC Bucket DesignAdvanced Arc Flash Mitigation TechniquesDetection SystemsRemote CapabilitiesSmart Diagnostics and Predictive MaintenanceArtificial IntelligenceData AnalyticsEnergy Efficiency EnhancementsApplications Across Industries: MCC Buckets in ActionOil and Gas: Powering Offshore PlatformsManufacturing: Streamlining Production LinesOvercoming Design Hurdles in MCC BucketsThermal Management ChallengesSpace Optimization StrategiesElectromagnetic Compatibility (EMC) SolutionsConclusionFrequently Asked Questions3. How do MCC buckets compare to traditional switchgear?5. What are some major limitations with MCC buckets?6. What are the latest safety standards applicable to MCC buckets?References