Rigid Flex PCB: Revolutionizing Modern Electronics Design

Understanding the need for Rigid Flex PCB technology, capturing its manufacturing process and applications, and the innovations it has brought in modern electronics design and industrial manufacturing.

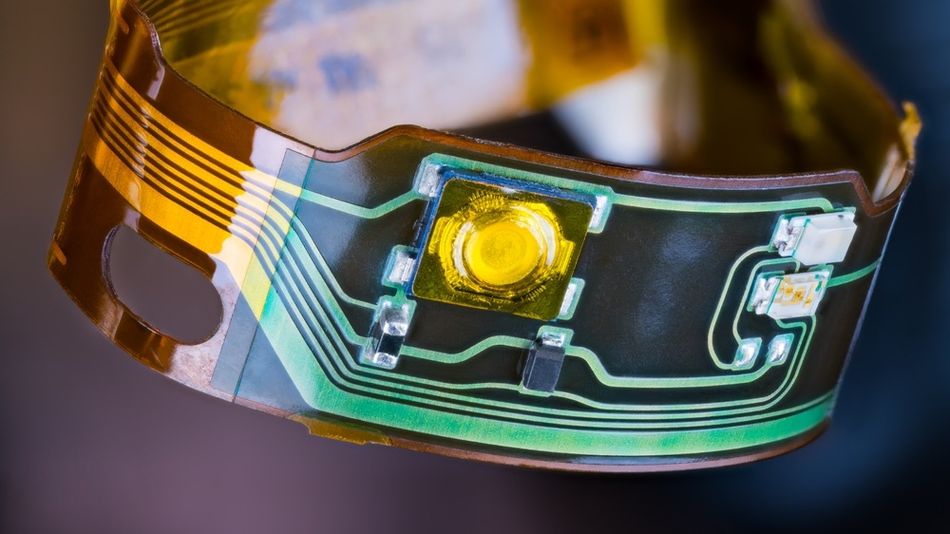

Close-up of a Rigid-Flex PCB featuring a microchip and miniature electronic components

Introduction

Rigid Flex PCB technology represents a transformative leap in electronic circuit design, combining the best attributes of rigid printed circuit boards (PCBs) and flexible circuits. This hybrid solution offers unparalleled flexibility, enabling designers to create more complex, reliable, compact electronic devices. Integrating rigid and flexible PCBs into a single component allows for a more streamlined design process, reducing the need for connectors and cables, which can be failure points in electronic systems.

Rigid-Flex PCBs are pivotal in modern electronics, particularly for space-constrained applications. The technology is widely used in high-end consumer electronics, medical devices, and aerospace applications, where the combination of lightweight, flexible design and robust performance is essential. Their ability to fold and flex can also contribute to the longevity of devices, as it minimizes stress on solder joints and traces that typically occur with rigid boards.

What are Rigid-Flex Printed Circuit Boards?

It’s quite intuitive to classify PCBs into two types, i.e., flexible and rigid.

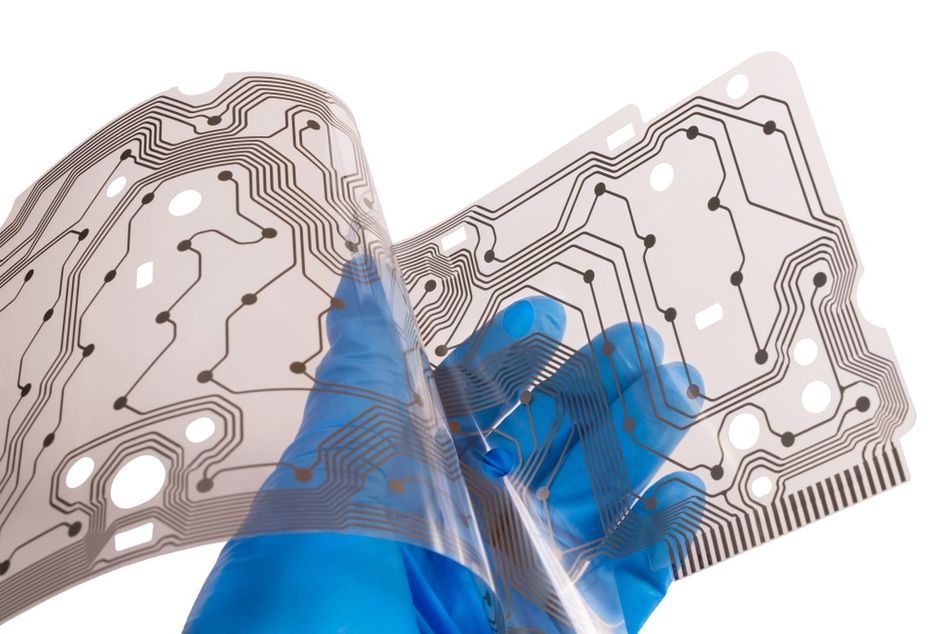

A Flex PCB, or Flex Circuit Board (FCB), can bend and curve to fit tight spaces, acquiring unique shapes and adjusting inside different housings. An ATM keypad is a classic example of a flex PCB.

On the other hand, rigid PCBs are more conventional types of PCBs with a rigid substrate that doesn’t bend. For instance, the motherboard of a CPU.

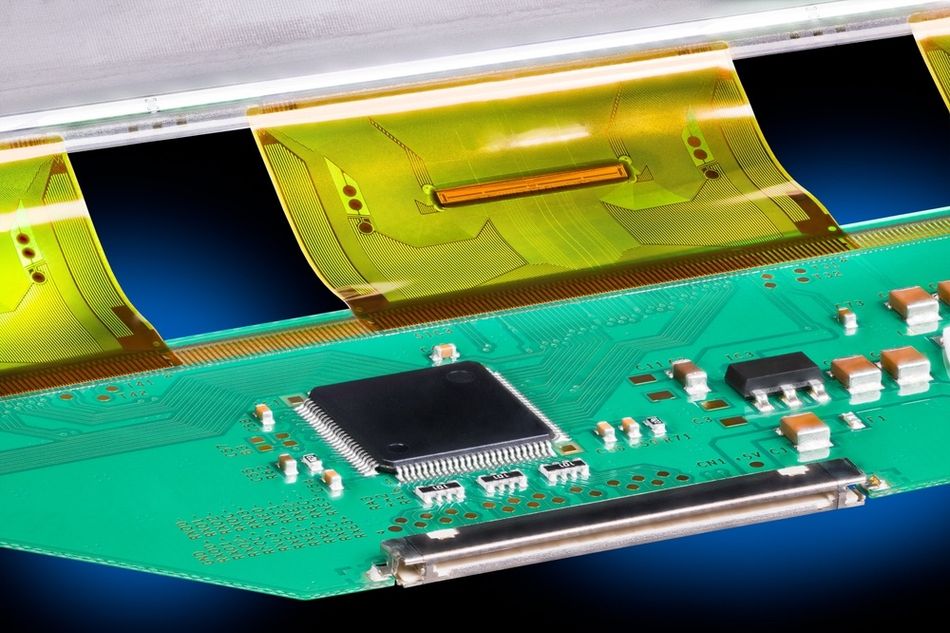

Fig 1: A flex-printed circuit featuring small electronic components and traces

Fig 1: A flex-printed circuit featuring small electronic components and traces

Rigid-flex PCBs offer a unique combination of rigid and flex PCBs. They are characterized by their layers of rigid and flexible laminated substrates.

- The flexible layers are typically made of polyimide or similar polymers, which provide flexibility.

- The rigid layers are made of fibreglass, like FR4, which offers structural stability.

Conductive copper circuits are etched onto these substrates, creating a board that can be designed to fit into tight or unconventional spaces within electronic devices.

This technology supports the miniaturization trend and opens up new possibilities in electronic design, allowing engineers to rethink how they approach the layout and construction of circuits. As devices continue to shrink in size while growing in complexity, the demand for innovative solutions like Rigid-Flex PCBs is expected to rise.

Recommended Reading: PCBA Design Trends to Watch in 2023

Understanding Rigid-Flex PCB Technology

As a combination of rigid and flex PCBs, a rigid-flex PCB further elaborates the role of these types. Typically, flex boards may be used as entire circuits or connectors between two or more rigid boards. It adds more board flexibility and negates space constraints.

The core advantage of Rigid Flex PCBs is that they can maintain the precision of a rigid PCB layout while being equally adaptable like a flexible PCB. This adaptability is not just physical; it extends to the design process, where Rigid-Flex PCBs can be folded or twisted to fit into unconventional geometries, a significant boon for compact and custom-shaped electronic devices.

The technology also reduces the need for multiple interconnects, simplifying the assembly process and enhancing reliability by reducing the number of solder joints and connectors, which are common points of failure.

From a technical perspective, Rigid Flex PCBs are complex constructs. They require careful planning and design to ensure that the flex portions of the board do not compromise the integrity of the rigid sections. Therefore, it involves a deep understanding of the mechanical stresses involved in flexing and the electrical requirements of the circuit. So designers must consider mechanical aspects such as

- Bend radius of the flex areas

- Material fatigue

- Fractures

Composition of Rigid-Flex PCBs

The composition of Rigid-Flex PCBs is a delicate balance between flexibility and rigidity, achieved through various materials and layering techniques.

- Flexible Layers: Made from high-temperature resistant thermoplastic materials to provide the necessary flexibility and heat resistance, and offer excellent electrical properties.

- Rigid Layers: Usually composed of materials used in traditional rigid PCBs, to provide structural stability, support components, and maintain the board's shape.

- Conductive Copper layers: Etched onto rigid and flexible substrates to form the circuitry Rigid-flex PCB construction. The copper thickness varies from 9 to 35 micrometres, depending on the current-carrying requirements of the circuit.

- Lamination Layers: Features a thin layer of adhesive material to laminate the rigid and flexible substrates together.

- Coverlays: Flexible, protective layers made of polyimide with an adhesive backing used to insulate and protect the external circuitry on the loose sections of the board.

- Stiffeners: Usually made from materials like FR4 or aluminum are added to specific areas of the flexible layers to support mounting components or require extra rigidity.

Design Considerations for Rigid-Flex PCBs

Designing Rigid-Flex PCBs requires understanding the mechanical and electrical aspects of the board's function. The unique blend of rigid and flexible elements in a single PCB introduces several critical considerations that must be meticulously managed to ensure the board's performance and reliability.

Bend Radius

The bend radius is the minimum radius at which a flex section can be bent without causing damage to the board or affecting its performance. It’s a primary mechanical consideration in rigid-flex PCB design.

A general rule of thumb is that the bend radius should be at least ten times the thickness of the flexible layer. This parameter is called the Bend ratio and is calculated as follows:

Bend ratio = r/h

where ‘r’ is the bend radius and ‘h’ represents PCB thickness.

It’s highly critical because bending the flex section too sharply can lead to uninvited issues in PCBs such as:

- Stress concentrations in PCB material

- Cracks in conductive traces

- Delamination of the layers.

Ultimately, it can lead to mechanical failures and signal integrity issues. On the other hand, if the bend radius is too large, it potentially causes stress on the PCB, leading to failure over time.

Recommended Reading: Understanding PCB Thickness: A Comprehensive Guide

Layer Count

Rigid Flex PCB design hinges on layer count and stack-up configuration. Balancing layers in rigid and flexible sections is crucial to meet electrical needs, manufacturing feasibility, and cost constraints.

Much like a multilayer PCB, the flexible part of a rigid flexible PCB can have multiple layers that are adequately insulated to avoid signals from intermixing. The stack-up sequence must ensure proper impedance control, especially in high-speed circuits. Moreover, special care is required for transitions to prevent impedance disruptions and signal integrity issues.

Flexibility

Flexibility is a mechanical attribute and a design philosophy that focuses on how the board will be flexed during assembly and operation. Designers must consider the number of flex cycles (the number of times the board can be bent without failure) the application requires for accurate design of the flex sections. The design must prioritise durability and fatigue resistance for dynamic applications, especially for frequent flexing. So, designers generally focus on

- Using more flexible materials

- Adjusting layout to distribute stress evenly

- Adding strain-relief features at flex-to-rigid transitions.

How Rigid-Flex PCBs are Manufactured

The manufacturing process of Rigid Flex PCBs combines elements of both rigid and flexible PCB fabrication techniques, tailored to produce boards that incorporate the benefits of both.

Material Selection

The manufacturing process starts with the material preparation. The flexible parts of the PCB are typically made from polyimide or similar polymers, known for their flexibility and heat resistance. In contrast, the rigid sections are made from materials like FR4, a glass-reinforced epoxy laminate material. It’s a standard material in rigid PCB manufacturing.

Circuit Pattern Creation

Pattern creation is usually achieved through photolithography. A photoresist is applied to the material, exposed to ultraviolet light through a mask that outlines the circuit pattern, and then developed to remove the unexposed photoresist. Following this, the exposed material undergoes an etching process to remove the unwanted copper, leaving behind the desired circuit pattern.

Lamination

Lamination is a critical step that binds together multiple layers of rigid and flexible materials. It uses heat and pressure, with adhesive layers in between, and combines the different materials into a single board. This ensures the integrity of the electrical connections between layers.

The choice of adhesive is crucial, as it must withstand the thermal stresses of the manufacturing process and the operational environment of the PCB. A protective thin film ranging from 0.0005 to 0.002 inches is commonly used for flexible circuits.

Drilling and Plating

Drilling and plating are subsequent steps where holes are created in the PCB for mounting components and establishing vias between different board layers. In Rigid-Flex circuit boards, special attention must be paid to the transition zones between rigid and flexible sections to avoid damaging the flex material. After drilling, the holes are plated with copper to create conductive pathways.

Solder Mask and Silkscreen

The application of solder mask and silkscreen layers marks the final stages of the manufacturing process. The solder mask protects the copper circuits and prevents accidental solder bridging during component soldering, while the silkscreen layer adds labels and identifiers to the board.

Finally, the manufacturing process concludes with tests and inspections to ensure the PCB meets all specifications and quality standards.

Prototyping and Small Batch Production

Prototyping Rigid Flex PCBs, allows designers and engineers to test and refine their designs before moving to mass production. Prototyping involves manufacturing small number of boards to:

- Evaluate performance

- Identify design flaws and make necessary adjustments.

This phase ensures that the final product meets all functional and quality requirements.

The transition from prototyping to small batch production is a significant step. A limited number of boards are manufactured for market testing or as part of a pilot run before full-scale production. This phase allows manufacturers to:

- Fine-tune the production process

- Identify and resolve any scalability issues

- Ensure that the manufacturing process can be efficiently scaled up.

Cost Considerations in Prototyping

Due to the complex nature of Rigid-Flex boards, the initial costs can be higher than those for standard rigid or flexible PCBs. However, these costs can be optimized by:

- Reducing failure costs by collaborating with expert designers.

- Optimizing circuit design to reduce components, layers, and substrate thickness

- Integrating flex cables with the rigid PCB requires careful design and material selection.

The goal is to balance cost, performance, and manufacturability, ensuring that the final product meets the desired specifications while remaining economically viable.

Advantages of Rigid-Flex PCBs

Rigid-flex PCBs offer convenience to design engineers. They are compact, cost-effective, reliable, and provide better thermal and shock resistance. Here are some of the significant advantages of Rigid-Flex PCBs.

- They can eliminate the need for connectors from circuit boards. Alternatively, the flexible part of the PCB is connected to a ZIF socket, which is easier to remove.

- Their small footprint enables a more consolidated PCB design that is compatible with small devices.

- They are much lighter than rigid PCBs.

- Highly reliable circuits as there are fewer cross-sectional changes in the conductors.

- These boards offer high thermal resistance and can withstand aggressive environmental conditions.

- The flex sections of these boards can bend up to 360 degrees, stretch, compress, and twist without experiencing any circuit deformation.

- It allows easier PCB testing as it features printed subcircuits to automate the testing procedure. Moreover, they reduce electronic components so fewer connections can be tested on a PCB.

Further Reading: Why Should You Use Rigid-Flex PCB Assembly?

Applications of Rigid Flex PCBs in Engineering

Rigid Flex PCBs have found their place in various engineering applications, becoming a staple in industries where electronic devices must withstand harsh environments or fit into compact spaces.

Consumer Electronics

Rigid Flex PCBs are extensively used in smartphones, cameras, and wearable devices. These applications benefit from the PCB's ability to conform to the ergonomic requirements of wearable devices and the space constraints within smartphones. For instance, the Rigid Flex PCB can snake around other components in a smartphone, optimizing space utilization and reducing the device's overall thickness.

Aerospace Systems

Because of their lightweight and high reliability, rigid-flex PCBs are also critical in aerospace manufacturing. They are extensivley used in satellites and space probes, where every gram of weight counts and the conditions can be extreme., Rigid-Flex PCBs help minimize the payload while ensuring that the electronics can withstand the shocks, vibrations, exposure to radiations and temperature variations experienced during launch and operation at high altitudes and in space.

Medical Devices

Rigid flex PCBs can be sterilized, and their reliability make them ideal for medical implants and diagnostic equipment. In an implantable device, the Rigid Flex PCB can be designed to fit the contours of the device, ensuring that it occupies minimal space while providing the necessary electronic functions. These are extensively used insulin pumps, CPAP machines, and portable defibrillators. Moreover, a flex sensor is a specially designed electronic device that tracks the movement of fingers. These sensors are widely used in gesture recognition and tracking systems for disabled an

Automotive Manufacturing

The automotive industry also adopts Rigid Flex PCBs for applications such as dashboard electronics and control systems. The vibration resistance and the ability to form 3D shapes make Rigid Flex PCBs suitable for the automotive environment, where electronics are often subjected to mechanical stress and must fit into irregularly shaped spaces.

Innovations Enabled by Rigid Flex PCBs

Rigid Flex PCB technology has been a driving force behind several recent innovations in electronics, enabling devices to become more functional and user-friendly.

Wearable Technology

One of the most notable areas of innovation is in wearable technology. Rigid Flex PCBs are ideal for wearables due to their lightweight and ability to conform to the shape of the human body. For example, a fitness tracker uses a Rigid Flex PCB to wrap comfortably around a user's wrist while housing sensors and connectivity modules that track health metrics.

Internet of Things

The Internet of Things (IoT) is another domain significantly impacting Rigid Flex PCBs. IoT devices often require electronics to fit into small or irregularly shaped spaces, and Rigid Flex PCBs can be designed to meet these spatial constraints.

Smart home devices, such as smart thermostats and lighting systems, utilize Rigid Flex PCBs to integrate seamlessly into the home environment, often unnoticed by the user.

Recommended Reading: What is IoT Device Management

Smart Technology

In smart technology, Rigid Flex PCBs facilitate the development of devices with complex, multi-functional capabilities. Smartphones, for instance, continue to evolve with features like foldable or curved screens, which are made possible by using Rigid Flex PCBs that can bend and flex to support these innovative designs.

Challenges and Solutions in Rigid Flex PCB Design and Use

The integration of Rigid Flex PCB technology into electronic devices brings a set of challenges such as:

- Cost - It has a higher production cost than traditional rigid or flexible PCBs mainly due to the need for specialized materials for fabrication. Therefore, designers and manufacturers must focus on design optimization to mitigate production costs.

- Design Complexity - Rigid Flex PCBs require high-level design precision to ensure that the flexible areas can withstand bending and folding without damage while maintaining electrical performance across the flex-to-rigid transitions. So, there is a need for advanced design tools and techniques and close collaboration between the PCB designers and the manufacturing team.

- Durability - In repeated flexing applications, durability becomes a significant concern for rigid-flex PCBs. The materials and construction of the flex sections must be selected and designed to withstand the mechanical stresses of bending and flexing over the product's lifetime.

Environmental and Durability Considerations

The environmental impact of Rigid Flex PCB manufacturing and disposal concerns in the electronics industry due to hazardous materials and recycling challenges.

Efforts to address these challenges include greener manufacturing practices and enhancing durability.

Rigid-Flex PCBs aid in sustainable electronics design by enabling compact, efficient devices and longer product lifespans.

Conclusion

Rigid Flex PCBs blend flexibility and rigidity, offering unique design possibilities. It is one of the most common circuit board technologies in modern industrial manufacturing. This article explored the composition, manufacturing, applications, innovations, and challenges associated with rigid-flex PCBs, emphasizing versatility across various industries.

The evolving manufacturing of Rigid Flex PCBs promises accessibility and cost-effectiveness—collaboration and research fuel advancements, heralding a bright future for more compact and efficient electronics.

FAQs

What is the difference between a Rigid Flex PCB and a traditional PCB?

Rigid Flex PCBs combine the best features of rigid and flexible PCBs into a single board. Unlike traditional rigid PCBs, Rigid Flex PCBs can bend and flex, allowing them to be used in applications where space is limited, or the PCB needs to conform to a specific shape.

How do you design a Rigid Flex PCB for maximum durability?

Designing a Rigid Flex PCB for durability involves careful consideration of the bend radius, material selection, and the placement of components. Using materials with high fatigue resistance and designing strain relief features into the flex sections can enhance durability.

What are the cost considerations when opting for Rigid Flex PCBs?

Rigid Flex PCBs are generally more expensive than traditional rigid or flexible PCBs due to the complexity of their design and manufacturing process. However, the cost can be mitigated by optimizing the design for manufacturability and leveraging the benefits of Rigid Flex PCBs to reduce the overall part count and assembly costs.

How are Rigid Flex PCBs tested for quality and reliability?

Rigid Flex PCBs undergo tests to ensure their quality and reliability. These tests include electrical testing to verify circuit functionality, mechanical testing to assess the durability of the flex sections, and environmental testing to ensure performance under various conditions.

Can Rigid Flex PCB technology be considered environmentally friendly?

While the manufacturing process of Rigid Flex PCBs involves materials and methods that can impact the environment, efforts are being made to make them more sustainable. This includes using environmentally friendly materials, improving the recyclability of PCBs, and designing for durability to reduce waste.

References

What is Flex PCB? — An Overview of Flex and Rigid-Flex PCB - News - PCBway

The Importance of Bend Radius, Layer Count, and Material Flexibility in Flexible PCB - 86PCB

Rizwanullah, Ritula, (2017). “Flex Sensors Based Robotic ARM for Disabled Persons: A Review”, published in International Journal of Emerging Technologies in Engineering Research (IJETER) Vol-5-issue-9-M-01.pdf (everscience.org)

What is Rigid-flex PCB? - Design Guidelines and Fabrication - JHYPCB (pcbelec.com)

What is Flexible PCB? Definition, Material & Manufacturing - The Engineering Projects

PCB Design: 7 Essential Guidelines for Designing Aerospace PCBs (epowerjournal.com)

Rigid Flex Circuitry Applications in Medical and Medical Device Worlds - pcbsfactory.com

Table of Contents

IntroductionWhat are Rigid-Flex Printed Circuit Boards?Fig 1: A flex-printed circuit featuring small electronic components and tracesUnderstanding Rigid-Flex PCB TechnologyComposition of Rigid-Flex PCBsDesign Considerations for Rigid-Flex PCBsBend RadiusLayer CountFlexibilityHow Rigid-Flex PCBs are ManufacturedMaterial SelectionCircuit Pattern CreationLaminationDrilling and PlatingSolder Mask and SilkscreenPrototyping and Small Batch ProductionCost Considerations in PrototypingAdvantages of Rigid-Flex PCBsApplications of Rigid Flex PCBs in EngineeringConsumer ElectronicsAerospace SystemsMedical DevicesAutomotive ManufacturingInnovations Enabled by Rigid Flex PCBsWearable TechnologyInternet of ThingsSmart TechnologyChallenges and Solutions in Rigid Flex PCB Design and UseEnvironmental and Durability ConsiderationsConclusionFAQsReferences