SPI Protocol: Revolutionizing Data Communication in Embedded Systems

The Serial Peripheral Interface (SPI) protocol is a critical communication standard for high-speed data exchange in embedded systems. This article discusses its architecture, advancements, and practical applications in engineering to help engineers optimize and overcome design challenges.

Introduction

The Serial Peripheral Interface (SPI) protocol is a synchronous serial communication interface specification used for short-distance communication, primarily in embedded systems. It is an easy-to-use interface and relatively faster than other communication interfaces. SPI is crucial for efficient communication between microcontrollers and peripheral devices, thanks to its high-speed data transfer capabilities. Its full-duplex communication model allows simultaneous data transmission and reception between slave and master devices, enhancing overall system performance.

SPI's versatility and efficiency make it indispensable in various engineering fields, including robotics, IoT, and consumer electronics, where it facilitates seamless integration and reliable data exchange. This widespread applicability underscores SPI's critical role in advancing modern technology.

Understanding SPI Protocol Architecture

What is SPI Protocol?

The Serial Peripheral Interface (SPI) protocol, developed by Motorola in the mid-1980s, has become a cornerstone in embedded systems for short-distance communication. Designed to facilitate efficient and reliable data transfer, SPI connects microcontrollers to various peripheral devices, making it indispensable in modern electronics.

At its core, SPI operates through a set of four key signal lines, each with a specific function that ensures synchronized communication between devices:

Master: The controller of the communication process, typically a microcontroller, initiates and manages data exchanges.

Slave: One or more devices that respond to the master’s commands.

MOSI (Master Out Slave In): This line transmits data from the master to the slave, typically operating at a voltage level of 3.3V or 5V.

MISO (Master In Slave Out): This line transmits data from the slave to the master, matching the voltage level used by the MOSI line.

SCLK (Serial Clock): Generated by the master, this clock signal synchronizes data transmission. It specifies the clock frequency and polarity, and when the data bits will be transferred. SCLK is configurable to meet the requirements of the slave device.

SS/CS (Slave Select/Chip Select): This control line selects the active slave device. It is usually active low, meaning the selected slave is enabled when the line is driven low.

SPI’s full-duplex mode allows for simultaneous data transmission and reception, significantly boosting communication efficiency. Unlike I2C, which uses addressing schemes and can be slower due to its complexity, SPI’s simplicity and speed are key advantages, particularly in applications requiring rapid data transfer.

For example, in a digital camera, SPI facilitates fast communication between the microcontroller and the image sensor, ensuring quick and efficient image processing. This efficiency and speed are why SPI is widely used in consumer electronics, industrial systems, and IoT devices.

SPI Communication: How It Works

Developed in the 1980s by Motorola, the Serial Peripheral Interface (SPI) protocol quickly became a staple in embedded systems due to its efficient full-duplex communication capabilities. This protocol allows simultaneous data transmission and reception, enhancing communication speed and efficiency. The master device, usually a microcontroller, orchestrates the data exchange over four dedicated lines:

MOSI

MISO

SCLK

SS/CS (Slave Select/Chip Select)

In SPI communication, data is sent and received simultaneously over the MOSI and MISO lines. For instance, in a digital audio system, the microcontroller sends audio data to a digital-to-analog converter (DAC) while receiving status information from the DAC concurrently, minimizing delay and maximizing throughput which is crucial in real-time for applications.

Clock Polarity in SPI

Central to SPI’s operation is the clock polarity (CPOL) and clock phase (CPHA) settings, which define the timing relationship between the clock signal (SCLK) and the data lines. These settings ensure data integrity and synchronization:

Clock Polarity (CPOL): Indicates the idle state of the clock signal.

CPOL = 0 means the clock is low when idle

CPOL = 1 means the clock is high when idle

Clock Phase (CPHA): Determines which clock edge data is sampled.

CPHA = 0 sample data on the leading edge

CPHA = 1 sample data on the trailing edge.

These configurations create four distinct SPI modes:

Mode 0: CPOL = 0, CPHA = 0

Mode 1: CPOL = 0, CPHA = 1

Mode 2: CPOL = 1, CPHA = 0

Mode 3: CPOL = 1, CPHA = 1

These modes are critical for SPI device configuration to ensure proper data exchange.

For example, in a temperature monitoring system, selecting the correct SPI mode aligns the microcontroller with the sensor's communication requirements, ensuring accurate temperature readings.

How SPI Compares with Other Communication Protocols

The following table highlights the unique advantages of SPI, particularly its speed and simplicity, against I2C and UART:

Feature | SPI | I2C | UART |

Communication | Full-duplex | Half-duplex | Full-duplex |

Speed | Higher, typically up to 50 MHz | Slower, typically up to 3.4 MHz | Variable, common rates up to 115.2 kbps |

Complexity | Simple, no addressing | Complex, requires addressing | Simple, point-to-point |

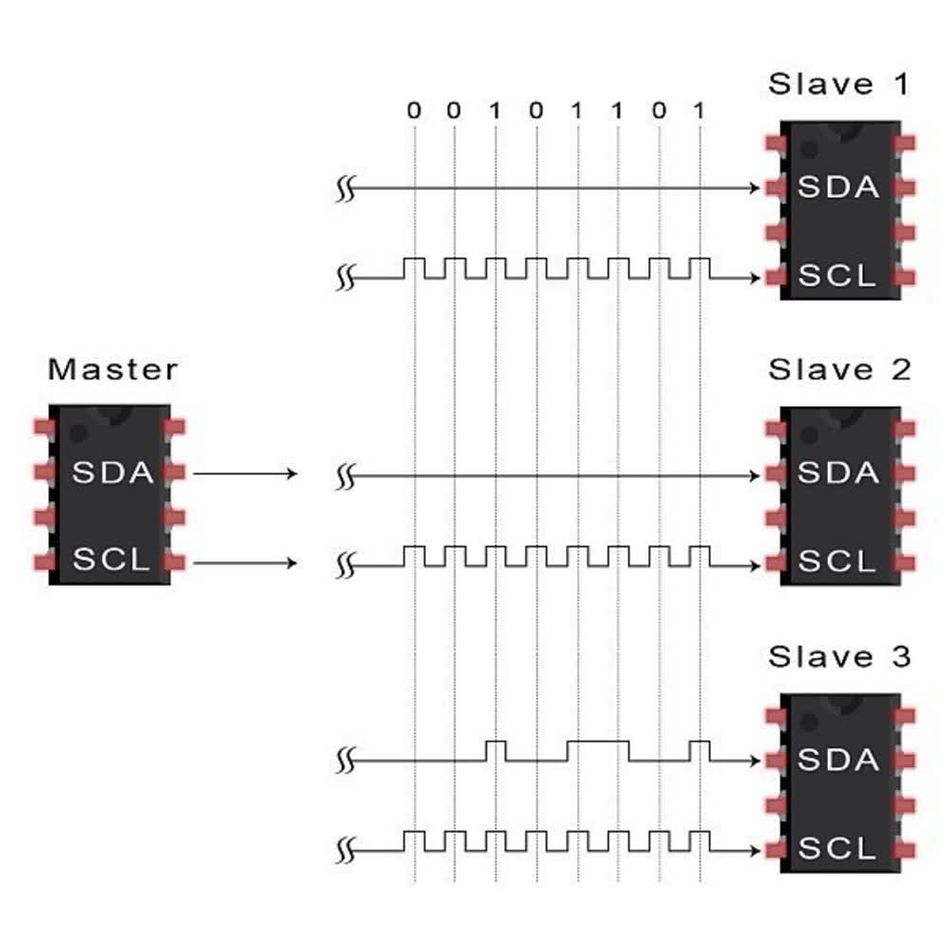

Signal Lines | 4 (MOSI, MISO, SCLK, SS/CS) | 2 (SDA, SCL) | 2 (TX, RX) |

Mode of Operation | Master-slave | Multi-master/multi-slave | Peer-to-peer |

Further Reading: UART vs I2C (vs SPI): Understanding the Differences

SPI’s straightforward implementation and high-speed capability make it a preferred choice for applications where rapid data transfer and minimal complexity are paramount, such as in flash memory devices, sensors, and display controllers.

Benefits of Using SPI Protocol

SPI design prioritizes ease of implementation and high-speed data transfer, which has led to its widespread adoption in various applications. Some of its key advantages include

Simplified Design

SPI's has a straightforward architecture, involving only four primary signal lines. It simplifies both hardware and software design. This simplicity contrasts with more complex protocols like I2C, which requires addressing and more intricate handshaking.

For instance, in a basic sensor interface setup, a microcontroller can easily communicate with a temperature sensor using SPI without needing additional communication overhead.

High-Speed Data Transfer

One of SPI's standout features is its high-speed data transfer capability. It’s almost twice as fast as I2C, with data rates reaching up to 50 MHz or higher. So, it’s well-suited for data acquisition systems and real-time sensors.

Flexible Architecture

The master-slave architecture of SPI enables flexible communication configurations. Multiple slave devices can be connected to a single master, each selected individually via the SS/CS line. This flexibility is particularly useful in complex systems like industrial control units, where a single controller needs to manage various peripherals such as actuators, sensors, and memory devices.

The technical benefits of SPI include:

Precise Timing Control: SPI allows for precise control over the timing of data transmission, which is crucial for applications requiring accurate timing and synchronization.

Low Latency: The full-duplex communication and lack of overhead in SPI minimize latency, making it ideal for real-time applications. In robotics, where immediate feedback from sensors can dictate movement, SPI's low latency ensures that the system responds swiftly to inputs.

Minimal Overhead: SPI's communication involves minimal protocol overhead, maximizing the effective data transfer rate. This efficiency is advantageous in systems with limited processing power and memory, such as portable medical devices, where conserving resources is critical.

Cutting-Edge Developments in SPI Protocol

Enhancements in Speed and Efficiency

The Serial Peripheral Interface (SPI) protocol has undergone significant advancements to meet the growing demands for higher speed and efficiency in data communication.

Exceptional Clock Speeds - Modern SPI implementations can now achieve clock speeds up to 100 MHz, substantially increasing from the traditional 50 MHz limit. This boost in speed is crucial for high-resolution displays and real-time data acquisition systems.

Fabrication Techniques - One of the key drivers behind these improvements is the advancement in semiconductor fabrication techniques. The integration of three-dimensional FinFET technology in SPI transceivers has played a significant role in achieving higher clock rates while maintaining low power consumption.

Signal Integrity - Signal integrity has also been a focus of recent developments. Improved PCB (Printed Circuit Board) layout practices and the adoption of differential signaling techniques have minimized noise and electromagnetic interference, which help maintain data integrity at higher clock speeds, particularly in electrically noisy environments.

Software Optimization - Additionally, software optimizations have enhanced SPI efficiency. Advanced SPI drivers now incorporate DMA (Direct Memory Access) support, which reduces CPU overhead and allows for faster, more efficient data transfers. This is particularly beneficial in embedded systems, where processing power is often limited. For example, in automotive systems, DMA support enables seamless communication between sensors and control units, improving overall vehicle performance.

Security Upgrades in SPI Communication

As the use of SPI (Serial Peripheral Interface) in critical applications grows, the need for robust security measures to prevent data breaches has become increasingly important.

Data Encryption - One of the primary security upgrades in SPI is the implementation of encryption to protect data integrity and confidentiality. Advanced Encryption Standard (AES) is commonly used in SPI communications, which is a strong encryption mechanism that ensures data transmitted between master and slave devices is unreadable to unauthorized parties. This is particularly crucial in applications such as financial transactions and secure communications where sensitive information must be protected.

Diffie Hellman Key Exchange - Another significant enhancement is the use of secure key exchange protocols. Diffie-Hellman key exchange is one such protocol that enables secure sharing of cryptographic keys over an unsecured communication channel. By integrating this into SPI communication, devices can establish a shared secret key, which is then used to encrypt and decrypt the transmitted data.

Authentication Mechanisms - These mechanisms have been incorporated into SPI to verify the identities of communicating devices. For instance, the use of HMAC (Hash-based Message Authentication Code) ensures that the data has not been altered during transmission and verifies the sender's authenticity. This is especially important in applications like medical devices and industrial control systems, where data integrity and authenticity are paramount.

Some security-intensive real-world applications of SPI protocol include:

Medical Devices: In medical environments, devices such as insulin pumps and pacemakers use SPI for communication. Ensuring the security of these communications prevents malicious attacks that could potentially harm patients.

Industrial Control Systems: In industries, SPI is used in various control systems and sensors. Securing these communications prevents industrial espionage and sabotage, protecting sensitive operational data.

Smart Grid Systems: For energy management, SPI is used in smart meters and grid infrastructure. Secure SPI communication ensures the reliability and confidentiality of energy consumption data, preventing unauthorized access and manipulation.

Compatibility and Integration with Modern Systems

The Serial Peripheral Interface (SPI) protocol has evolved to maintain compatibility with a wide range of modern microcontrollers and peripheral devices.

Modern microcontrollers from leading manufacturers like ARM, Microchip, and Texas Instruments come with built-in SPI modules that support advanced features such as higher clock speeds, multiple slave select lines, and DMA (Direct Memory Access) support.

Detailed compatibility matrices highlight the range of devices that support SPI:

Microcontroller Series | Supported SPI Features | Max Clock Speed | Number of SPI Channels |

ARM Cortex-M | Standard and advanced SPI modes, DMA support | 100 MHz | Up to 6 |

Microchip PIC32 | Enhanced buffer management, multiple slave select lines | 80 MHz | Up to 4 |

Texas Instruments MSP430 | Low-power SPI operation, multiple clock options | 50 MHz | Up to 3 |

NXP LPC | High-speed SPI, flexible pin configuration | 80 MHz | Up to 5 |

STMicroelectronics STM32 | Full-duplex and half-duplex modes, DMA support | 100 MHz | Up to 6 |

Integration examples demonstrate how these features are utilized in real-world applications:

Consumer Electronics: The ARM Cortex-M series, with its advanced SPI capabilities, is widely used in smartwatches and fitness trackers.

Industrial Automation: Texas Instruments' MSP430 microcontrollers, known for their low-power operation, are often employed in industrial sensor networks.

Automotive Systems: STMicroelectronics' STM32 microcontrollers, with their full-duplex SPI modes and DMA support, are integral to automotive infotainment systems.

Popular devices that support advanced SPI features include:

Microchip PIC32 which is frequently used in embedded systems requires efficient buffer management and multiple slave device integration.

NXP's LPC series microcontrollers offer flexible pin configurations, making them ideal for custom hardware designs that require tailored SPI communication setups.

Real-World Applications of SPI in Engineering

SPI in Consumer Electronics

SPI (Serial Peripheral Interface) is integral to the functionality of many consumer electronics, including smartphones, smartwatches, and gaming consoles. Its ability to facilitate high-speed, reliable communication between microcontrollers and peripheral devices makes it an essential component in these devices.

Smartphones - SPI is commonly used to connect the main processor with various peripherals such as touchscreens, fingerprint sensors, and memory modules. For example, the Qualcomm Snapdragon series of processors, widely used in high-end smartphones, utilize SPI to manage communication with touchscreen controllers and fingerprint sensors.

Smartwatches - Tracking devices and Smartwatches rely heavily on SPI for efficient communication between the microcontroller and sensors, display drivers, and memory. The Apple S-series chipsets, used in Apple Watches, employ SPI to interface with the OLED display and various sensors, including accelerometers and heart rate monitors.

Gaming Consoles - PlayStation, Xbox, and similar gaming consoles also benefit from SPI's high-speed data transfer capabilities. The custom AMD APUs (Accelerated Processing Units) in these consoles use SPI to communicate with memory and peripheral controllers, ensuring smooth gameplay and quick load times. For instance, the PlayStation 5's DualSense controller utilizes SPI to relay data from the controller to the console, enabling responsive haptic feedback and adaptive trigger functionalities.

Implementation in Industrial Automation

The Serial Peripheral Interface (SPI) protocol is critical in industrial automation systems, where efficient control and data acquisition are paramount.

Programmable Logic Controllers - Programmable Logic Controllers rely on SPI to communicate with various sensors, actuators, and other modules. For instance, temperature sensors, pressure transducers, and motor controllers frequently interface with PLCs via SPI, allowing for real-time monitoring and control of industrial processes. The high-speed data transfer enables immediate response to changing conditions.

Data Acquisition - SPI also contributes to efficient data acquisition in industrial environments. Data acquisition systems (DAQs) utilize SPI to gather information from multiple sensors and convert it into a format that can be analyzed and acted upon. In a typical DAQ setup, an array of sensors sends data to a microcontroller via SPI. The microcontroller processes the data and transmits it to a central system for further analysis. This setup is used in various applications, including process control, environmental monitoring, and quality assurance.

Industrial Communication Protocols - SPI is integral to several industrial communication protocols and standards.

Modbus protocol - widely used in industrial automation for serial communication, can be implemented over SPI. for seamless communication between different devices and systems within an industrial network.

HART - SPI is also used in implementing HART (Highway Addressable Remote Transducer) protocol, which facilitates communication between field devices and control systems, enhancing the efficiency and reliability of industrial operations.

Recommended Reading: Modbus TCP: A Comprehensive Guide to the Protocol and Its Applications

Role in Internet of Things (IoT)

SPI (Serial Peripheral Interface) is critical in the Internet of Things (IoT) landscape, where seamless communication between sensors, actuators, and microcontrollers is essential. Its high-speed, full-duplex data transfer capability makes SPI ideal for IoT applications requiring real-time data exchange and low latency.

Sensor Connectivity

SPI is commonly used to interface with various IoT sensors and actuators. For instance, environmental monitoring systems deploy numerous sensors to measure parameters like temperature, humidity, and air quality.

These sensors use SPI to communicate with a central microcontroller, ensuring rapid data collection and transmission. The quick and reliable data transfer facilitated by SPI allows these systems to provide timely and accurate environmental readings.

Datalogging Applications

Several IoT projects and devices rely heavily on SPI for efficient data transfer. The Arduino platform, a popular choice for IoT development, uses SPI to connect microcontrollers with sensors, displays, and memory devices.

The Arduino Uno, for example, leverages SPI to interface with SD card modules for data logging purposes. This setup is crucial in applications such as weather stations and remote data collection systems, where large volumes of sensor data need to be stored and processed efficiently.

Smart Home Devices

Smart home devices also benefit from SPI's robust communication capabilities. Smart thermostats, security cameras, and home automation hubs often use SPI to facilitate communication between the central processor and various peripheral components. This ensures that commands are executed swiftly and that sensor data is transmitted without delay, enhancing the responsiveness and reliability of smart home systems.

Specific IoT platforms have developed comprehensive SPI communication stacks to support their ecosystems. For example, the Raspberry Pi platform includes extensive SPI support, allowing developers to easily integrate a wide range of SPI-compatible peripherals. The Raspberry Pi's SPI interface is used in projects ranging from home automation to industrial control systems, demonstrating its versatility and effectiveness in IoT applications.

Suggested Reading: The Rise Of Raspberry Pi In Industrial Settings

ESP Devices with Built-in Wi-Fi Applications

Another notable example is the Espressif ESP8266 and ESP32 series, which are widely used in IoT projects for their built-in Wi-Fi capabilities and SPI support. These microcontrollers use SPI to connect to external sensors and actuators, enabling complex IoT applications like remote monitoring and control systems.

The SPI interface in ESP8266/ESP32 ensures that data from sensors is promptly transmitted to the cloud for processing, enabling real-time analytics and decision-making.

Addressing SPI Protocol Challenges

Overcoming Signal Integrity Issues

Signal integrity is critical for SPI (Serial Peripheral Interface) communication, especially as systems operate at higher speeds and in electrically noisy environments.

Crosstalk occurs when the signal from one line induces unwanted signals in adjacent lines. This can be particularly problematic in high-speed SPI communication where the close proximity of MOSI, MISO, and SCLK lines can result in interference.

Electromagnetic interference (EMI) is another significant issue, especially in industrial environments with high levels of electrical noise. EMI can distort SPI signals, leading to incorrect data transmission.

Signal reflections happen when signals reflect back from impedance mismatches along the transmission line, causing interference and potential data errors.

To mitigate these issues, several best practices and solutions can be employed:

Shielding: Encasing SPI signal lines in a grounded conductive shield can significantly reduce EMI. Shielded cables or PCB traces with ground planes can help isolate SPI signals from external noise sources. This practice is essential in environments with high electrical noise, such as industrial automation systems.

Suggested Reading: EMI Shielding: Protecting Electronic Devices in a Noisy World

Differential Signaling: Although SPI traditionally uses single-ended signaling, adopting differential signaling for SPI lines can improve noise immunity. Differential pairs, such as those used in LVDS (Low-Voltage Differential Signaling), offer better resistance to EMI and crosstalk. While not standard for SPI, implementing differential signaling in custom SPI designs can enhance signal integrity.

PCB Layout Techniques: A careful PCB layout is crucial for maintaining signal integrity in SPI communication. Key techniques include:

Controlled Impedance Traces: Designing PCB traces with controlled impedance minimizes signal reflections and ensures consistent signal quality. Using tools to calculate and match the impedance of SPI traces is critical.

Ground Planes: Placing a continuous ground plane beneath SPI signal traces provides a return path for signals and reduces EMI. Ground planes also help in maintaining consistent impedance and reducing crosstalk.

Trace Separation: Increasing the physical separation between SPI signal traces can reduce crosstalk. Ensuring adequate spacing between MOSI, MISO, and SCLK traces helps prevent interference.

Bypass Capacitors: Placing bypass capacitors close to the power supply pins of SPI devices can filter out high-frequency noise, improving overall signal integrity.

Managing Data Transfer Rates and Latency

Efficient management of data transfer rates and latency is crucial in SPI (Serial Peripheral Interface) communication, especially as applications demand higher speeds and lower latency. However, achieving optimal performance in SPI can be challenging due to various factors that affect data transfer rates and introduce latency.

Challenges in Data Transfer Rates and Latency

Clock Speed Limitations: The maximum clock speed of SPI is constrained by the hardware capabilities of the master and slave devices. As the clock speed increases, maintaining signal integrity becomes more difficult, potentially leading to data errors.

Bus Contention: When multiple slave devices share the same SPI bus, contention can occur, leading to delays as the master switches control between different slaves.

Processing Overhead: The CPU overhead involved in managing SPI communication, especially without DMA (Direct Memory Access) support, can introduce significant latency, affecting real-time performance.

Strategies for Optimizing Data Transfer and Reducing Latency

Increase Clock Speed: One of the most straightforward methods to improve data transfer rates is to increase the SPI clock speed. However, this must be done cautiously, ensuring that the signal integrity is maintained and the slave devices can operate reliably at a higher speed.

Utilize DMA: Implementing DMA can significantly reduce CPU overhead by allowing data transfers to occur directly between memory and SPI peripherals without CPU intervention. This frees up the CPU to perform other tasks while the SPI communication proceeds in the background.

Efficient Bus Management: Minimizing bus contention is crucial for reducing latency. Techniques such as time-division multiplexing can be used to allocate specific time slots to each slave device, ensuring that the SPI bus is used efficiently.

Optimize SPI Configuration: Fine-tuning the SPI configuration settings, such as clock polarity (CPOL) and clock phase (CPHA), can optimize the timing of data transfers, reducing the likelihood of setup and hold time violations.

Integration Complexities and Solutions

Integrating the Serial Peripheral Interface (SPI) protocol into various systems can present several complexities due to differences in hardware configurations, communication requirements, and environmental conditions.

Complexities in Integrating SPI

Hardware Compatibility: Different devices may have varying voltage levels, clock speeds, and timing requirements. Ensuring that all connected devices are compatible with the SPI master’s specifications is critical.

Signal Integrity: High-speed SPI communication can suffer from signal integrity issues such as crosstalk, electromagnetic interference (EMI), and signal reflections, especially in electrically noisy environments.

Timing and Synchronization: Accurate timing and synchronization between the SPI master and slave devices are crucial for reliable data transfer. Misalignment in timing parameters can lead to data corruption.

Bus Contention: In systems with multiple slave devices, managing bus contention and ensuring proper slave selection can be challenging.

Practical Tips and Solutions for Smooth Integration

Ensure Hardware Compatibility:

Voltage Level Shifting: Use level shifters to match the voltage levels of the master and slave devices. This ensures that signals are correctly interpreted without damaging any components.

Clock Speed Adjustment: Configure the SPI clock speed to match the capabilities of the slowest device on the bus, preventing timing issues.

Enhance Signal Integrity:

Shielded Cables and Ground Planes: Use shielded cables and ground planes to reduce EMI. Ensuring a solid grounding system helps minimize noise and signal reflections.

Controlled Impedance Traces: Design PCB traces with controlled impedance to maintain signal integrity. Use tools to calculate and match the impedance of SPI traces.

Optimize Timing and Synchronization:

Clock Polarity and Phase Configuration: Set the correct clock polarity (CPOL) and phase (CPHA) to ensure proper timing. Test different configurations to find the optimal settings for your specific devices.

Precise Timing Analysis: Perform timing analysis to ensure that setup and hold times are met. Adjust trace lengths and add delay elements if necessary to align timing.

Real-World Integration Challenges and Solutions

Challenge: Integrating SPI in a Multi-Device Industrial Control System

In an industrial control system, integrating SPI with multiple sensors and actuators presented challenges in ensuring signal integrity and managing bus contention. The environment’s electrical noise interfered with the SPI signals, leading to data corruption.

Solution:

Shielded Enclosures: Placing SPI components in shielded enclosures reduced EMI and improved signal integrity.

Optimized PCB Layout: Redesigning the PCB with controlled impedance traces and solid ground planes minimized signal reflections.

Dedicated Chip Select Lines: Allocating individual chip select lines for each sensor and actuator prevented bus contention, ensuring reliable communication.

Challenge: High-Speed Data Acquisition System

A high-speed data acquisition system required integrating SPI with multiple high-speed ADCs (Analog-to-Digital Converters). Ensuring accurate timing and high data transfer rates was crucial.

Solution:

Clock Synchronization: Using a common clock source for the master and ADCs ensured precise synchronization.

DMA Implementation: Implementing DMA reduced CPU overhead and enabled efficient data transfers, meeting the high-speed requirements.

Conclusion

The Serial Peripheral Interface (SPI) protocol has proven to be an indispensable communication standard in modern embedded systems. This article has explored the foundational concepts of SPI, technological advancements, real-world applications, and the challenges associated with its implementation.

SPI's simplicity, speed, and flexibility make it ideal for a wide range of applications, from consumer electronics to industrial automation and IoT devices. As technology continues to evolve, the SPI protocol is expected to see further enhancements in speed, efficiency, and security, ensuring its continued relevance and utility in future engineering projects.

Frequently Asked Questions (FAQs)

What is the primary purpose of the SPI protocol?

The primary purpose of the SPI protocol is to facilitate high-speed, full-duplex communication between a master device and one or more slave devices in embedded systems. It is commonly used to connect microcontrollers to peripherals such as sensors, displays, and memory devices, enabling efficient data transfer and control.

What are common issues faced with SPI communication?

Common issues in SPI communication include:

Signal Integrity: Crosstalk and electromagnetic interference can distort signals, especially at high speeds.

Bus Contention: In systems with multiple slaves, improper management can lead to conflicts.

Timing Mismatches: Incorrect clock polarity (CPOL) and phase (CPHA) settings can lead to data corruption.

Can SPI be used for long-distance communication?

SPI is generally not suitable for long-distance communication due to its reliance on short, direct connections for high-speed data transfer. Over long distances, signal degradation and timing issues become significant. Alternatives for long-distance communication include:

RS-485: Suitable for long-distance and multi-drop communication.

Ethernet: Provides robust networking capabilities over long distances.

CAN Bus: Commonly used in automotive and industrial applications for reliable long-distance communication.

References

Serial Peripheral Interface - an overview | ScienceDirect Topics

What is SPI? Serial Peripheral Interface Explained | Arrow.com

Basics of the SPI Communication Protocol (circuitbasics.com)

https://articles.saleae.com/logic-analyzers/spi-vs-i2c-protocol-differences-and-things-to-consider

https://www.usnews.com/360-reviews/privacy/what-is-advanced-encryption-standard

Basics of Serial Peripheral Interface (SPI) - ElectronicsHub USA

SPI Tutorial – Serial Peripheral Interface Bus Protocol Basics (corelis.com)

Table of Contents

IntroductionUnderstanding SPI Protocol ArchitectureWhat is SPI Protocol?SPI Communication: How It WorksClock Polarity in SPIHow SPI Compares with Other Communication ProtocolsBenefits of Using SPI ProtocolSimplified Design High-Speed Data TransferFlexible ArchitectureCutting-Edge Developments in SPI ProtocolEnhancements in Speed and EfficiencySecurity Upgrades in SPI CommunicationCompatibility and Integration with Modern SystemsReal-World Applications of SPI in EngineeringSPI in Consumer ElectronicsImplementation in Industrial AutomationRole in Internet of Things (IoT)Sensor Connectivity Datalogging Applications Smart Home DevicesESP Devices with Built-in Wi-Fi Applications Addressing SPI Protocol ChallengesOvercoming Signal Integrity IssuesManaging Data Transfer Rates and LatencyChallenges in Data Transfer Rates and LatencyStrategies for Optimizing Data Transfer and Reducing LatencyIntegration Complexities and SolutionsComplexities in Integrating SPIPractical Tips and Solutions for Smooth IntegrationReal-World Integration Challenges and SolutionsConclusionFrequently Asked Questions (FAQs)References