Understanding Remote I-O: An In-depth Exploration

This article provides a detailed overview of the principles, components, types, applications, and future trends of Remote I/O technology.

Signals Transmission and Reception via Satellite

Introduction

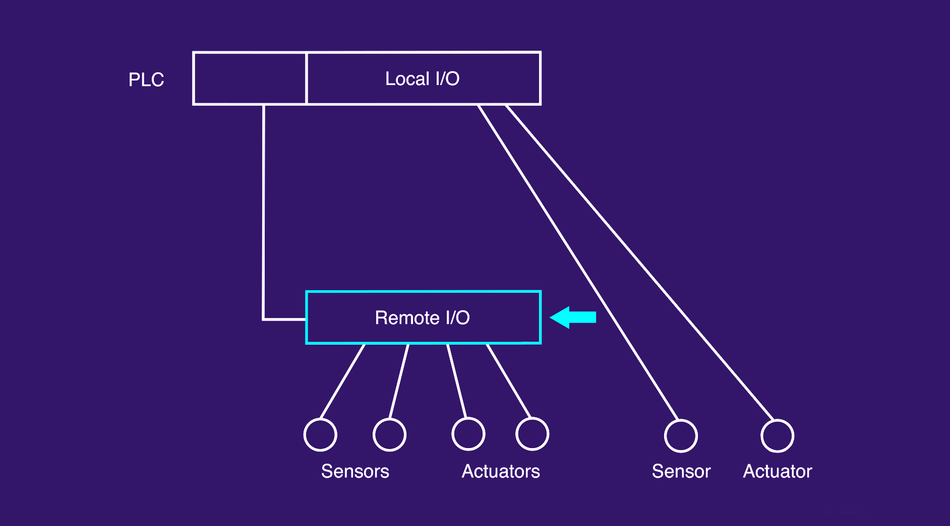

Remote I/O, or Remote Input/Output, plays a significant role in modern computing and industrial automation systems. This technology enables data communication between the central processing unit and remote devices within an extensive network. Remote I/O technology is pivotal as it aids in bridging the gap between data processing units and peripheral devices. It allows systems to be more flexible and scalable by enabling the placement of devices at a significant distance from the controller, thereby eliminating the need for extensive and costly wiring. Remote I/O enables the connection of devices, such as sensors, actuators, and other field devices, to a central control system or programmable logic controller (PLC) over a network.

The Basic Principles of Remote I/O

At its core, Remote I/O involves the data exchange between the computer’s central processing unit and its remote devices. This data exchange is facilitated through an I/O module that acts as an intermediary in the communication process. The central principle of Remote I/O is that it enables peripheral devices to communicate directly with the CPU, even from a remote distance.

The working mechanism of Remote I/O revolves around the I/O module, which essentially decodes the output signals from the CPU into a format that the peripheral devices can interpret and respond to. Similarly, it converts the input signals from the peripheral devices into a format that the CPU can understand. In this way, the CPU is able to delegate its I/O tasks to the Input and output module, thus freeing up its resources for other core functions.

It's also noteworthy that the data transmission on a Remote I/O device typically follows specific protocols, depending on the design of the system and adapter used. These protocols govern the identification of devices, the formatting and sequencing of data, and the detection and handling of communication errors. [1]

Why Remote I/O is Necessary

The necessity of Remote I/O stems from several challenges in traditional direct I/O systems. One of the main challenges is the limitation of the distance between the CPU and peripheral devices. In a direct I/O system, devices must be in close proximity to the central processing unit. This poses problems in large industrial applications where peripheral devices might be spread out over large areas.

Remote I/O allows devices to be decentralized and distributed throughout a facility or even across different geographical locations. Another challenge in direct I/O systems is the high load on the CPU due to the simultaneous management of multiple I/O tasks. In contrast, in a Remote I/O system, the CPU offloads its I/O tasks to the I/O module, resulting in more efficient use of its resources.

Lastly, Remote I/O systems are inherently more scalable than direct I/O systems. They allow for the easy addition or removal of devices without the need for significant reconfiguration, which is particularly beneficial in industries where system expansion or upgrades are frequent.

For example, in an oil refinery, numerous sensors and actuators are often spread across a vast area to monitor and control various processes. In such a scenario, using a Remote I/O system is beneficial as it allows the central controller to effectively communicate with these devices without the need for extensive wiring, thus reducing costs and improving efficiency.

Technavio has been monitoring the industrial I/O modules market, and it is expected to grow by USD 2,720.15 million during the five-year forecast period. As per the latest report, the market will progress at a CAGR of 6.66% from 2022 to 2027. [2]

Understanding Remote I/O Components

In a Remote I/O system, several components come together to ensure efficient communication between the central processing unit and peripheral devices. These components include remote I/O devices, the remote base, field devices, communication networks, and a CPU or programmable logic controller (PLC).

The I/O module is crucial, as it acts as the go-between for the CPU and the remote devices. It decodes output signals from the central processing unit into a format that the peripheral devices can interpret and vice versa.

The remote base is the housing unit for the I/O modules. This can often contain multiple modules and act as a node for communication between the CPU and remote devices. This base can be rack-based, where different input or output modules are slotted into a rack or distributed across multiple locations.

Field devices, like sensors and actuators, are the devices that provide input to or receive digital output from the I/O modules. Sensors are used to gather data from the environment, such as temperature or pressure, and this data is sent for processing. On the other hand, actuators perform an action based on commands received from the CPU, such as opening or closing a valve.

The communication network facilitates data exchange among all these components. Depending on the system's specific requirements, this could be wired or wireless, with different data transmission speeds and protocols.

Finally, the CPU, or PLC, is the brain of the system. It makes decisions based on the digital input received from the field devices through the input module or output module and sends commands to the actuators to perform specific actions.

The Role of the I/O Module

The I/O module serves as the core of a Remote I/O system. The chief function of a module is to act as an intermediary between the CPU and peripheral devices. It enables the exchange of digital or analog input signals between the CPU and field devices.

A typical I/O module is designed to handle both input and output operations. This modular device converts the digital signals from the CPU into electrical signals for the output devices and turns the electrical signals from the input module into digital signals for the central processing unit. These conversions are necessary because field devices such as sensors and actuators often deal with electrical signals, while the CPU communicates in digital signals.

The I/O module also helps in managing the data traffic in the communication network. The module buffers the data from multiple peripheral devices before sending it to the CPU. This buffering action can help manage the data flow and prevent data congestion in the system. [3]

The design and complexity of an I/O module can vary depending on the system's specific needs. Some modules might handle only digital signals, while others can deal with analog signals. Some modules might have built-in data processing capabilities to preprocess data before it reaches the CPU, while others simply pass the data through. The choice of the module depends on the specification of the field devices and the system’s requirements.

Importance of the Remote I/O Network

In a Remote I/O system, the I/O network is the backbone that supports the communication between the CPU and field devices. In essence, the network is the path that data travels along. The quality and type of network directly influence the efficiency and reliability of the system.

The I/O network ensures the safe and reliable transportation of data packets between the different components. The network should be robust enough to handle high traffic loads and adverse operating conditions. It must guarantee a low error rate and high reliability to prevent miscommunication and data loss.

The choice of network type has significant implications on the system's performance and efficiency. Networks for Remote I/O systems can be either wired or wireless. Wired networks, such as Ethernet or Fieldbus, provide reliable and fast data transmission but may require complex cabling and are less flexible in terms of installation and modification.

On the other hand, wireless networks, such as WirelessHART or Zigbee, offer more flexibility and are easier to install and modify. However, they may be more prone to interference and might not provide the same level of speed and reliability as wired networks. [4]

Another important aspect of the network is the protocol used for data transmission. Protocols define how data is packaged, addressed, transmitted, received, and unpacked. Common protocols used in Remote I/O systems include Modbus, Profinet, Profibus, EtherCAT, and others. The choice of protocol can affect the system's data transmission speed, determinism, and ability to handle network errors.

The Asia Pacific region is the largest market for remote I/O in manufacturing, followed by North America and Europe. In conclusion, the network is a key component of any Remote I/O system. It requires careful consideration and planning to ensure the overall efficiency and reliability of the system.

How Controllers Manage Remote I/O Systems

Controllers, in the context of Remote I/O systems, are devices that supervise and manage the operations of the entire system. They execute the control logic and make decisions based on the input data received from the field devices via the I/O modules.

At the core of a controller's role is the execution of control logic. This logic is essentially a set of instructions, or algorithms, written in a specific control language. It details how the controller should react to the data received from the field devices. For example, if a temperature sensor sends data indicating an excessively high temperature, the control logic might dictate that the controller send a command to a cooling system to reduce the temperature.

Controllers also manage the data flow within the Remote I/O system. They receive raw data from the I/O modules, process this data as per the control logic, and then transmit commands or information to other devices in the system. In this way, they serve as a central hub for data within the system, ensuring the right data gets to the right places at the right times.

A crucial aspect of a controller's job is communication management. Controllers are responsible for initiating and managing communication with the I/O modules and field devices. This communication is done via the I/O network, and controllers must effectively manage this to avoid network congestion and ensure timely data transmission. They also need to handle any communication errors or network faults that may occur.

Finally, controllers have a role in system diagnostics and fault detection. They continually monitor the state of the I/O modules and field devices, checking for any signs of malfunction or failure. HART (Highway Addressable Remote Transducer) is a communication protocol that is often used with remote I/O systems. HART allows users to communicate with field devices, such as sensors and actuators, over the same 4–20 mA current loop that is used for analog control.

Controllers are, therefore, a critical part of any Remote I/O system. They ensure the system's smooth operation, react to changes in field device data, manage data and communication within the system, and monitor for faults or failures.

Types of Remote I/O Systems

In the realm of industrial automation applications, there are two principal types of Remote I/O systems: wired and wireless. These differ mainly in the method of communication between the controller and the input or output modules.

Wired Remote I/O Systems

Wired Remote I/O systems are the traditional form of I/O systems, where physical cables are used to connect the I/O modules to the controller. These systems can use a variety of IEC 61131-9 remote I/O protocols, such as Ethernet/IP, Fieldbus, EtherCAT, Profibus, Profinet, or DeviceNet.

Reliability is a major advantage of wired Remote I/O systems. Physical connections tend to be less prone to interference and provide more stable data transmission, which is critical in many industrial applications where real-time control is necessary.

The data transmission speed is generally higher in wired systems. This is particularly important in applications that require high-speed data exchange. For instance, a manufacturing process involving rapid mechanical part movements may require quick data transmission to ensure accurate control and prevent collisions.

In terms of distance, wired systems are often more suitable for applications where the I/O modules and the controller are relatively close to each other. This is due to the fact that the effectiveness of wired communication diminishes as the distance increases.

One major drawback of wired systems is the infrastructure requirements. Installing and maintaining the network cables can be time-consuming and expensive, especially in large industrial plants. Additionally, the presence of physical cables can also restrict the flexibility of the system layout.

Despite these challenges, wired Remote I/O modules remain popular in many industrial control applications due to their reliability and high data transmission speeds. They are often preferred in environments that demand a high degree of control precision and where the potential for wireless interference is high.

Recommended Reading: The Future of Wired Communication Infrastructure: Single Pair Ethernet

Wireless Remote I/O Systems

Wireless Remote I/O systems, as the name suggests, use wireless technology for communication between the I/O modules and the controller. These systems offer unique advantages, especially in challenging environments where wiring is not feasible or cost-effective.

In wireless systems, communication protocols such as WirelessHART, ISA100.11a, or ZigBee can be used. These protocols were specifically designed for industrial environments and offer features like low energy consumption, robustness against interferences, and the ability to form mesh networks for higher reliability and coverage.

Flexibility is a distinct advantage of wireless systems. Without the need for physical wiring, the I/O modules can be installed or moved freely within the coverage area of the wireless network. This provides significant benefits in scenarios requiring frequent layout modifications or wiring that becomes challenging due to physical constraints.

Reduced infrastructure costs are another major benefit. The absence of network cables greatly simplifies installation and maintenance, resulting in substantial cost savings. This is particularly noticeable in large-scale industrial applications or in hazardous environments where the installation and maintenance of wired networks can be challenging and expensive. Backplanes eliminate the need for long cables between the remote I/O modules and the controller.

Scalability is also improved in wireless systems. New I/O modules can be easily added to the network without the need for additional cabling. This makes wireless systems particularly suitable for large industrial plants and applications that may require future expansion.

However, wireless systems do come with their challenges. Reliability and speed of data transmission can be affected by various factors, such as interference from other wireless devices or obstacles in the signal path. Thus, careful planning and design of the wireless network is essential to ensure effective communication.

Additionally, wireless systems can have limitations in terms of distance and bandwidth. The maximum communication distance is often limited by the wireless signal's power, which can be affected by obstacles and interference. Bandwidth, or the amount of data that can be transmitted per unit of time, can also be lower compared to wired systems.

Overall, wireless Remote I/O systems offer compelling benefits in terms of flexibility, reduced infrastructure costs, and scalability. However, these benefits must be weighed against the challenges in terms of reliability, speed, distance, and bandwidth. As with wired systems, the choice of wireless systems depends on the application's specific needs and the environment.

Recommended Reading: Future of Wireless communication: Wi-Fi 6E or 5G?

The Implementation of Remote I/O in Different Industries

Remote I/O in Manufacturing

The manufacturing industry has increasingly adopted Remote I/O systems to streamline and optimize its processes. The industry often involves intricate procedures that require precise control and monitoring, which is where the deployment of Remote I/O modules comes into play.

In the manufacturing industry, automation is key to increasing productivity, reducing errors, and maintaining consistency. Remote I/O systems play a central role in automation by allowing sensors and actuators to be placed at the precise point of need while being controlled from a centralized location. This reduces wiring complexity and improves the overall efficiency of the production process.

Another aspect where Remote I/O systems have significant benefits is fault detection and predictive maintenance. Human Machine Interface (HMI) can provide graphical displays of the I/O devices and their status. The data acquisition can make it easier to see what is happening in the system and to identify any problems. Incorporating remote I/O and HMI helps in minimizing downtime and prevent unexpected failures, thereby maximizing productivity.

For instance, in an automotive manufacturing plant, hundreds of sensors and actuators may be spread across a large area to monitor and control various aspects of vehicle assembly. In this context, employing a wired remote I/O system greatly simplifies the control system by utilizing a single communication cable to interface with multiple devices, reducing overall complexity. High voltage industrial digital I (DI) and digital output (DO) signals typically range in magnitude from 0 V to 24 Vdc. [5]

Consider a practical application involving a robotic arm used in assembling parts. A variety of sensors - including proximity sensors, pressure sensors, and Resistance Temperature Detectors (RTD) - might be installed on the arm. A local I/O module can aggregate data from these sensors and then send it back to the central controller using Remote I/O. This allows real-time monitoring and control of the robotic arm from a centralized location.

Another noteworthy example can be seen in food and beverage manufacturing. In such an environment, hygiene and cleanliness are paramount, and equipment often requires frequent washing. In such scenarios, wireless Remote I/O systems can be especially advantageous, eliminating the risk of water ingress associated with connectors and cables. Remote I/O is expanding Pepsi bottling operations and aims for a 100% increase in throughput. [6]

As such, Remote I/O systems and distributors provide manufacturing industries with a flexible, scalable, and efficient means to control and monitor a wide array of processes. This improves productivity, lowers maintenance costs, and ultimately enhances profitability.

Recommended Reading: Remote industrial monitoring provides critical data and insights

Remote I/O in Energy

In the energy sector, Remote I/O systems have become an essential element of operations, particularly in renewable energy technologies such as wind farms and solar power plants, as well as traditional setups like oil and gas refineries.

Remote I/O systems are employed in wind farms to connect and manage the sensors and actuators placed on each wind turbine. These systems collect real-time data on wind speed, wind direction, rotor speed, operating temperature, and torque. This allows operators to monitor turbine performance and control its operations from a centralized location, even in harsh environments. Specifically, in the case of a wind farm with 100 turbines, each fitted with 20 sensors; a Remote I/O system can simplify the architecture by handling data from 2000 sensors through a single network.

Similarly, in a solar power plant, Remote I/O systems are crucial for data acquisition and control tasks. For instance, they can be used to monitor and control the position of solar panels to ensure they are always optimally oriented toward the sun. Furthermore, they are vital in data collection tasks such as tracking environmental parameters and measuring the energy output of each solar panel.

In oil and gas industries, Remote I/O systems are applied in a variety of operations, including drilling, production, refining, and distribution. For example, during drilling operations, various parameters such as pressure, temperature, and flow rate need to be monitored in real-time to ensure safe and efficient extraction. By integrating these parameters into a Remote I/O system, engineers can monitor and control the drilling operation from a central control room. This helps minimize potential hazards and allows quicker response times in case of anomalies.

Notably, the employment of wireless Remote I/O systems has seen a considerable increase in the energy sector, particularly in remote or hard-to-reach locations. For instance, deploying wireless Remote I/O systems in offshore oil platforms can help reduce installation costs and operational risks associated with physical wiring. In such situations, wireless Remote I/O systems can collect data from various sensors distributed across the platform and transmit it back to a central controller.

Therefore, the adoption of Remote I/O systems in the energy sector has led to significant advancements in operational efficiency, safety, and the capability to make data-driven decisions, proving to be a fundamental component in these highly interconnected and data-intensive environments.

Remote I/O in Telecommunications

In the field of telecommunications, Remote I/O systems have gained significant traction due to their ability to manage a multitude of signals and data traffic across vast, geographically dispersed networks. Remote I/O systems provide an effective means to monitor and control network equipment, ensuring efficient and uninterrupted service to customers.

Network operations centers rely heavily on Remote I/O systems for real-time surveillance and control of network elements. These elements can range from base stations in mobile networks, routers, and switches in data centers to customer-premises equipment such as modems and set-top boxes.

For instance, in a mobile network, base stations are equipped with numerous sensors that monitor parameters such as signal strength, data throughput, and operational temperature. These parameters are channeled through a Remote I/O system back to the network operations center, where they are continuously analyzed to ensure optimal network performance. In the scenario of a network with 5000 base stations, each containing around 10 sensors, a Remote I/O system could potentially handle data from 50,000 sensors.

Moreover, in data centers, Remote I/O systems play a pivotal role in ensuring the continuity of services. Power usage, cooling efficiency, and network traffic are monitored across thousands of servers. In a medium-sized data center hosting around 5000 servers, a Remote I/O system can handle data related to power and cooling from 10,000 data points if we assume each server has two such sensors.

Remote I/O systems are also critical in managing telecommunications hardware distributed across customer premises. These systems can remotely monitor and control hardware such as modems, routers, and set-top boxes, allowing for remote diagnostics and troubleshooting. This helps in improving the overall customer experience.

In the telecommunications sector, where uptime and service quality are foremost, Remote I/O systems provide the critical ability to monitor, control, and react in real time to the status of the network. They enable service providers to maintain network health, anticipate issues before they impact customers, and make informed decisions based on data-driven insights. As such, Remote I/O systems are integral to modern telecommunications infrastructures.

Conclusion

A comprehensive understanding of Remote I/O systems is instrumental in various industries, particularly those that heavily rely on automation and remote monitoring. They serve as a bridge between the physical world and the digital, collecting, and interpreting sensor data, allowing for sophisticated control of devices and machinery. As the industrial landscape continues to evolve and integrate more advanced technology, the importance of Remote I/O systems is likely to grow in lockstep. They have already demonstrated their indispensable role in manufacturing, energy, and telecommunications. With the growth and evolution of these sectors, Remote I/O systems will keep booming to meet their ever-increasing demands.

Frequently Asked Questions (FAQs)

Q. What is the role of a Remote I/O system in automation applications?

A. In automation, a Remote I/O system serves as an interface between the field devices and the automation system. It collects data from sensors, a converter, converts the data into a format the automation system can understand, and sends commands from the automation system to the devices in the field.

Q. How does a Remote I/O system improve efficiency in manufacturing?

A. By collecting and interpreting data from multiple sources, a Remote I/O system allows for real-time monitoring and control of manufacturing processes. This ability to swiftly react to changes reduces downtime, increases production efficiency, and can significantly improve product quality.

Q. What is the difference between a wired and a wireless Remote I/O system?

A. A wired Remote I/O system connects to field devices via physical wires or cables. In contrast, a wireless Remote I/O system uses radio frequency, Wi-Fi, or another wireless communication protocol to connect with field devices. The choice between wired and wireless will depend on factors such as the physical environment, required data transfer speed, and the cost of installation and maintenance.

Q. Why are Remote I/O systems important in telecommunications?

A. Remote I/O systems are critical in telecommunications for real-time monitoring and control of network equipment. They ensure efficient and uninterrupted service by managing a multitude of signals and data traffic across vast, geographically dispersed networks.

Q. What future developments can we expect in Remote I/O technology?

A. As we move further into the era of the Industrial Internet of Things (IIoT), we can expect Remote I/O systems to become more integrated with cloud-based platforms and to handle more complex tasks. Advances in artificial intelligence could lead to more autonomous systems capable of making decisions based on the data they collect. Furthermore, we may see more use of wireless technologies, enabling even more flexibility in system design and deployment.

References

1. Realpars. What is Remote I/O?. [Cited 2023 June 25] Available at: Link

2. Cision. Industrial I/O Modules Market size [Cited 2023 June 25] Available at: Link

3. Hydac. The Major Functions of an I/O Module [Cited 2023 June 25] Available at: Link

4. Isaaccomputerscience. Wired and wireless networks [Cited 2023 June 25] Available at: Link

5. analog. Industrial I/O [Cited 2023 June 25] Available at: Link

6. controleng. Remote I/O expands Pepsi bottling operation [Cited 2023 June 25] Available at: Link

Table of Contents

IntroductionThe Basic Principles of Remote I/OWhy Remote I/O is NecessaryUnderstanding Remote I/O ComponentsThe Role of the I/O ModuleImportance of the Remote I/O NetworkHow Controllers Manage Remote I/O SystemsTypes of Remote I/O SystemsWired Remote I/O SystemsWireless Remote I/O SystemsThe Implementation of Remote I/O in Different IndustriesRemote I/O in ManufacturingRemote I/O in EnergyRemote I/O in TelecommunicationsConclusionFrequently Asked Questions (FAQs)References