Using contact mechanics analysis to solve the toughest problems in engineering

Article #3 Simulation Education Series. How simulation software assisted the engineers designing rugged, all-terrain mobility solutions.

Isaac Shannon in the AdvenChair. Image credit AdvenChair/Ansys.

This is the final article of a 3-part series looking at engineering fundamentals and exploring how they are applied in innovative engineering case studies. We further demonstrate how free online courses can elevate your knowledge – no matter your engineering experience. The AdvenChair case study described in this article is based on the article on this story available on Ansys.com.

Contact mechanics is an area of engineering which is crucial to the understanding of how two surfaces in contact interact. For mechanical systems found in engines, machinery, vehicles, and structures, contact is a reality that must be accounted for in the safety and stability of the products designed and built for the public. But the field of study remains quite challenging to predict and simulate.

In this article, we will take a close look at the field of contact mechanics. We will define what it is, the types of contact that exist, and how engineers formulate and simulation contact mechanics. In addition, we’ll discuss the design of a rugged, off-road wheelchair that required simulation to assess the structural integrity and contact mechanics inherent in the design. Finally, we’ll outline how to improve your own understanding of contact mechanics by highlighting a free course from Ansys.

What is contact mechanics?

Contact mechanics is the study of the interaction of structures at their surfaces. Understanding and predicting how surfaces deform due to contact is an essential piece of designing common systems, such as disc brakes, gears, and even tires.

At their point of contact, the two surfaces of any material exert forces on one another. Depending on the materials' characteristics and the surfaces' shape, they may deform under the forces applied. Contact mechanics is concerned with capturing the stress distribution over the surfaces that are in contact. Stress is a measure of force applied over a given area. Engineers can use the known strength of materials to determine if the stresses seen on a surface will cause any deformation that could lead to failure, like cracking or shattering.

There are three different types of contact:

- Bonded contact

- Frictionless contact

- Frictional contact

Engineers determine the type of contact by examining how the force of each body is exerted on the other. The force vector is broken down into its normal and tangential components at the point of contact. If the force is only in the normal direction (and the tangential component is zero), then it is frictionless contact. If the surfaces cannot be pulled apart and both the normal and tangential forces are very high (i.e., tend to infinity) then it is bonded contact. Both of these contact types are rare. The last type, frictional contact, is when the tangential force, Fμ, is not zero or infinity, but it is directly related to the normal force, FN, at the surface by Coulomb’s Law: Fμ = μ x FN. This is the most common type of contact.

Looking at the example of disc brakes, we can examine what features of contact mechanics are at play. When the brakes are disengaged, the wheels of the vehicle spin freely, and there is no contact between the spinning brake disc of the and the brake caliper. When the brakes are applied, the brake caliper’s pistons shoot out, forcing the brake pad into contact with the spinning brake disc. Because the disc can still move, it is not bonded contact. The wheel begins to slow as the brake pad continues to apply forces to the surface of the brake, using frictional contact.

Both normal and tangential forces are applied to the surface of the brake disc and pad. Over time, both parts will experience deformation and degradation, resulting in the need to replace pads and discs (commonly called rotors). But in designing the braking system engineers need to understand the deformation at the surfaces each time the brakes are applied and then predict the lifetime of the parts to ensure they are replaced well before any failure.

Why contact mechanics remains a difficult phenomenon to model/predict

The problem with contact mechanics modeling is that the phenomenon is nonlinear at its root. And when looking at the surfaces of solids in contact at a microscopic level, they are naturally uneven; no surface is completely flat. Capturing that level of detail in a model, calculation, or even simulation remains a very difficult task. While we have tables of empirical values for the coefficient of friction of various surfaces on one another, they are averages of a much more complex problem: frictional contact.

In current contact formulations, there are three assumptions made to analyze contact possible:

- No penetration between bodies

- Applied and contact forces must balance in the case of a static problem

- Conservation of momentum in the case of a dynamic problem

There are two types of formulation that meet the above requirements:

- Penalty formulation

- Lagrange formulation

Penalty formulation models the resistance between the two bodies in contact as a spring, only allowing for a very small amount of penetration. This formulation uses the properties of the materials, the geometry of the surfaces, and their kinematics to determine the contact stiffness. This formulation is used to calculate both contact pressure and frictional stresses. While it may be more accurate to allow for that little bit of penetration, the solution to these formulations produce are not always as accurate as the alternative method.

Lagrange formulation, on the other hand, allows for additional degrees of freedom, and though it does not require a contact stiffness, it forces contact penetration to be zero. The normal and tangential contact forces are unknowns solved in a matrix equation. In addition, contact gaps and sliding distances are solved as for other degrees of freedom. With all this added detail, the solutions from this formulation tend to be more accurate. However, the constraint of zero penetration can result in spuriously high forces at the contact, which may imbalance the forces.

While there are methods to predict contact forces, each has drawbacks and requires the keen eye of the engineer who created the simulations to understand the limitations. Currently, simulation tools are used to develop a system or component and improve its design, with physical testing of the true operating conditions occurring to validate the simulation results. As simulation solutions are developed for the complexities of contact mechanics, engineers can rely more and more on cost-effective and relatively quick simulations instead of expensive, time-intensive physical tests.

How engineers used contact mechanics analysis to design a rugged mobility solution

AdvenChair is a company founded by an avid outdoor adventurer to enable people with mobility challenges to visit wild and wondrous places. The founder, Geoff Babb, was inspired to create a wheelchair that could take him back to the places he used to frequent outdoors when hiking, biking, and skiing before he had a stroke that changed his mobility.

The company’s founder and employees began by looking at traditional wheelchairs in the marketplace to see if they could modify them to account for the more rugged conditions seen while on a hiking trail. But the stresses and strains their testing generated were too great for the regular wheelchair design, and the forces transmitted to the rider were too jarring to make the journey enjoyable. After a few prototypes, Jack Arnold, a seasoned engineer with experience in product development and mechanical design/assembly, joined the team and spearheaded a completely new design for the AdvenChair.

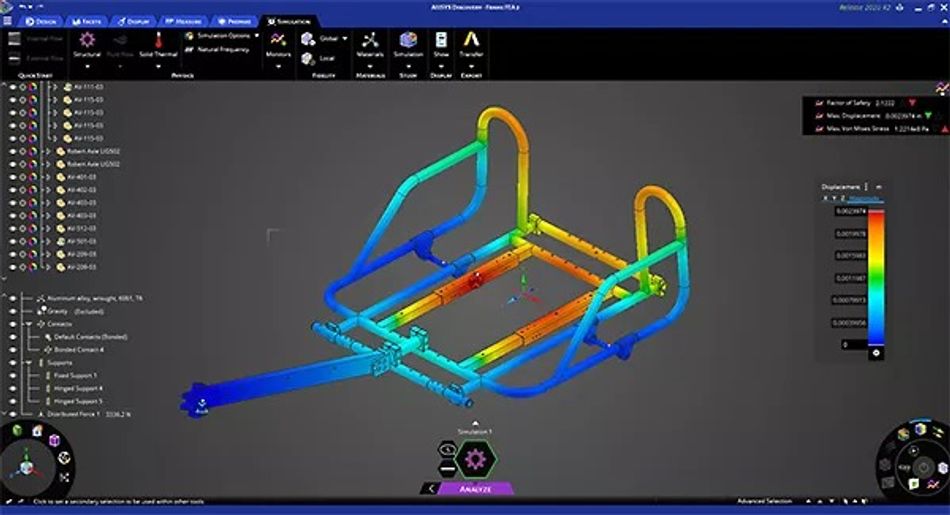

As an engineer with product development and simulation experience, Jack understood the software's limitations and benefits. He decided to also simulate the contact mechanics of the AdvenChair by adding predicted load cases that the wheels would experience on a rugged trail. Using contact mechanics, the simulation software could predict how those loads translated into stresses and strains throughout the suspension and chair and how the contact regions were stressed. This allows him to see if improvements could be made to the strength, materials, or design of the wheels, brakes, and suspension.

How the Ansys Startup Program helped solve a contact mechanics engineering problem

While Jack had experience with simulation in his previous engineering roles, being part of a startup meant a limited budget for software, no matter how essential it was to the process. The Ansys Startup Program ended up being the best solution for the AdvenChair team. It offered discounted simulation software for the startup and contained support hours that helped to quickly get those on the team unfamiliar with the interface up to speed.

For Jack and the AdvenChair team, it provided access to simulations both for the strength of the chair’s frame and suspension components, but it also helped to optimize the design when considering the contact mechanics at play. With a much more advanced wheelchair design, there were now additional considerations to account for, like rougher impact mechanics, additional contacts, and optimizing the structure for the manufacture. The company also used the included generative design features to refine their AdvenChair for the required strength, but without all the additional mass.

The Ansys suite of software available to them was key to optimizing all parts of the design prior to its initial manufacturing effort.

Learn more about contact mechanics from Ansys

The free Ansys Innovation Courses provide a method for gaining a strong foundational knowledge of various engineering topics and explaining how simulation tools can be used to analyze more complex systems. To learn more about contact mechanics and how to get started with simulation tools, check out the free Contact Mechanics course online.

The course also takes a deeper dive into frictional contacts, such as the brake disc example discussed earlier in this article, and provides real-world examples of contact mechanics analysis, including a seat belt buckle and gears within industrial-grade machinery.

You can download a copy of Ansys Discovery Student from their website, allowing you to begin exploring contact mechanics simulation. The Contact Mechanics course provides Ansys files to help you get started with your analyses in the form of different projects. You can investigate the contact mechanics of a bowling ball striking pins and the effect of frictional contact on a pile of logs.

If you require additional help with getting used to the software interface and learning how to create efficient workflows in the Ansys software, you can also check out their Getting Started courses on the website.

This is the final article in a three-part series.

Article one examined heat transfer simulation.

Article two provided an overview of mechanical analysis.

Article three looked at contact mechanics.

About the sponsor: Ansys

Ansys provides engineering simulation software used to predict how product designs will behave in real-world environments. Founded in 1970, Ansys employs more than 4,400 professionals, many of whom are expert M.S. and Ph.D.-level engineers in finite element analysis, computational fluid dynamics, electronics, semiconductors, embedded software, and design optimization.