Allegro ACS37041: Integrated Hall-effect Current Sensor

Allegro MicroSystem’s ACS37041 is a compact, integrated Hall-effect current sensor.

Technical Specifications

| Product | Integrated Hall-effect Current Sensor |

| Package | 3 x 3 mm SOT23-W 5-pin package |

| Isolation | Functional isolation up to 100 V |

| Bandwidth | 125 kHz |

| Supply Voltage | 5 V and 3.3 V variants |

| Sensing Capability | Bidirectional with ±10 A and ±30 A variants |

| Internal Conductor Resistance | >1 mΩ |

| Applications | Motor Control, Power Supplies, Battery Management Systems, Solar Inverters, and Building Automation Systems |

Overview

Allegro ACS37041 is a compact, integrated Hall-effect current sensor that provides precise current measurements in low voltage and low current settings while minimizing power dissipation. Designed to replace traditional shunt-resistor based current measurement circuits, the ACS37041 offers a more reliable and compact alternative. It eliminates the need for external components such as shunt resistors, operational amplifiers and passive filtering components that are typically used in conventional current sensing technologies. This integration simplifies the overall design and boosts system reliability and performance, which makes the ACS37041 ideal for a wide range of applications across fields such as clean energy, automotive and industrial, while also extending to other technological areas.

Integrated Hall-effect Current Sensor: ACS37041 Features

Current and Voltage Ratings

Allegro's ACS37041 is capable of bidirectional current sensing, and is offered in variants that can handle up to ±30 A, thereby making it suitable for low to moderate power applications. Robustly designed with a working voltage for functional isolation up to 100 Vrms, the product enhances its suitability for environments with higher voltage spikes. The sensor features a bandwidth of 125 kHz that allows it to quickly track changes in current.

Compact Design

The ACS37041 allows current measurement through its internal conductor without external resistors, operational amplifiers, filter components, or the additional circuitry typically required for current shunt amplifiers. With its compact 3 x 3 mm SOT23-W package, the ACS37041 occupies substantially less space than traditional circuits by using 1 mΩ shunt resistors, which are typically housed in larger 6.4 x 3.2 mm 2512 packages. These resistors alone are larger than ACS37041 in the SOT23-W.

Traditional setups require additional components, which collectively can expand the board space used to approximately 15 x 8 mm. In contrast, the ACS37041 integrates all necessary functions within its much smaller package, which significantly reduces the overall footprint required on the PCB. This integration results in a space saving of over 90% compared to traditional component setups and dramatically enhances the efficiency of board layout design.

This optimized design reduces the overall bill of materials (BOM) and allows for the use of smaller PCB enclosures. As a result, it delivers significant improvements by making products using the ACS37041 more compact. These features make the ACS37041 an excellent choice for applications that demand cost efficiency and optimal use of space.

Thermal Management

Effective heat dissipation is essential for sensors operating in high-current environments to ensure accuracy and prevent thermal damage. Despite its compact size, the ACS37041 is engineered to manage heat efficiently. Its low internal resistance of 1 mΩ significantly minimizes thermal load to ensure that the sensor maintains safe operating temperatures under all conditions.

Isolation and Reliability

The ACS37041 comes with functional isolation rated up to 100 V that ensures the sensor can operate reliably in electrically noisy environments by preventing ground loops and electrical noise from affecting the accuracy of the measurements. Additionally, ACS37041's inherent galvanic isolation increases common mode transient immunity (CMTI) over traditional shunt amplifier circuits.

The sensor is designed to perform reliably across a temperature range from -40°C to 125°C, with a total output error of less than ±5%. This ensures accurate current measurement even under harsh and varying environmental conditions.

A response time of just 4 µs allows the sensor to react quickly to changing conditions, which is crucial for protecting systems against overcurrent events and enhancing overall safety.

Applications

The ACS37041 is ideally suited for a variety of applications, ranging from industrial motor control and power supplies to battery management systems, solar inverters and building automation systems. In motor control systems, its ability to measure current accurately helps monitor the motor current and protect against overcurrent conditions. For power supplies, current measurement is required for reliable power output. In battery management systems, the sensor monitors and controls the charge and discharge processes to ensure battery efficiency and longevity.

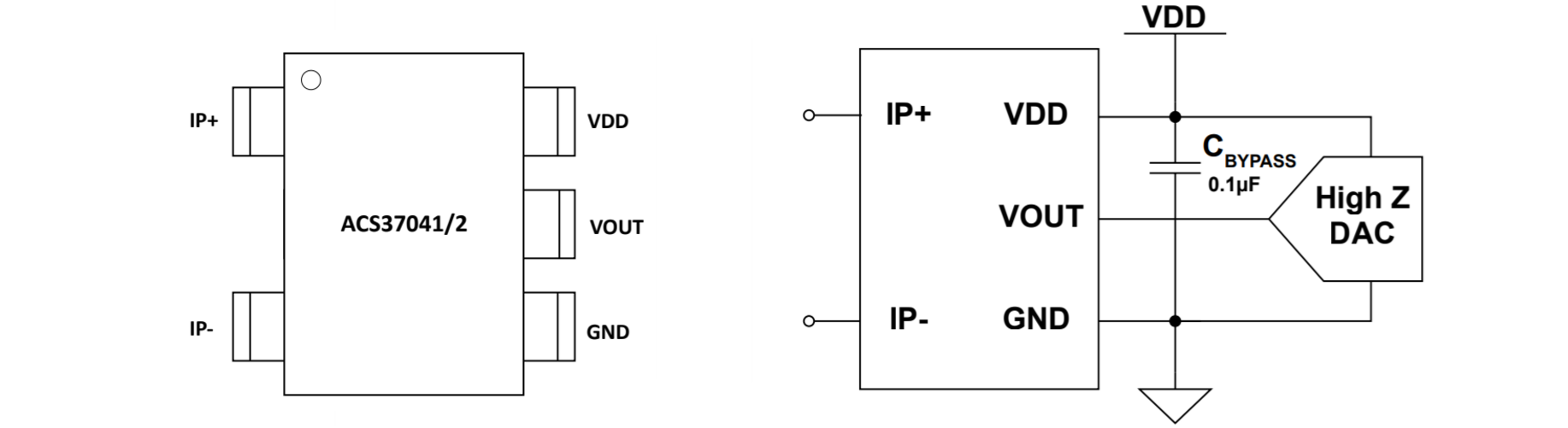

Pinout (left) and typical application circuit (right) of Allegro’s ACS37041 Magnetic Current Sensor

Summary

Allegro ACS37041 integrated Hall-effect current sensor sets a new standard in current sensing technology by offering a blend of performance and reliability in a compact package. Its ability to measure current accurately and reliably, even in challenging environmental conditions, makes it a perfect choice for designers and engineers. By reducing component count and simplifying design, the ACS37041 not only lowers the overall system cost but also enhances the reliability and efficiency of electronic systems. It is a critical component in advancing modern electronic design and should be included in your next project.

Discover Allegro’s Magnetic Current Sensors to Make Your Design Better!

References

Recommended Specs

Continue Reading

Optimizing Battery Performance: Advanced Management Systems for Enhanced Safety, Efficiency, and Utilization

Several technologies have suddenly come into the spotlight in measures against global warming. Typical examples of these technologies include solar and wind power generation, electric vehicles (EVs), power semiconductors, and fuel cells.